Patents

Literature

46results about How to "Avoid roasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cuttage seedling method for honey suckles

InactiveCN102696373AImprove survival rateIncrease temperaturePlant protective coveringsFertilizer mixturesField cropPlastic mulch

The invention discloses a cuttage seedling method for honey suckles. The method mainly comprises the following steps: paving a black mulching film; performing rooting treatment on cuttage seedlings; after the cuttage seedlings treated by a rooting agent pass through the black mulching film, inserting the cuttage seedlings into soil; and covering a soil layer with the diameter of 50 to 60 cm and the thickness of 5 to 6 cm at the periphery of the cuttage seedlings. By the method, the survival rate of the cuttage seedlings of the honey suckles can be increased and can reach over 90 percent. According to the photosynthesis principle of crop growth, the black mulching film is paved, so growth of weeds can be inhibited and the weeding aim is fulfilled basically. Soil moisture can be maintained and the ground temperature can be increased, so that growth of the crops can be accelerated, the crops are ripe in advance and the economic benefit is increased. The mulching film is simple to pave; and the width of the mulching film is selected according to the distance between the field crops. After the mulching film is paved, soil covers the periphery of the cuttage seedlings, so that the cuttage seedlings are prevented from being burned due to overhigh reflecting temperature of the black film.

Owner:句容市白兔镇德明金银花专业合作社

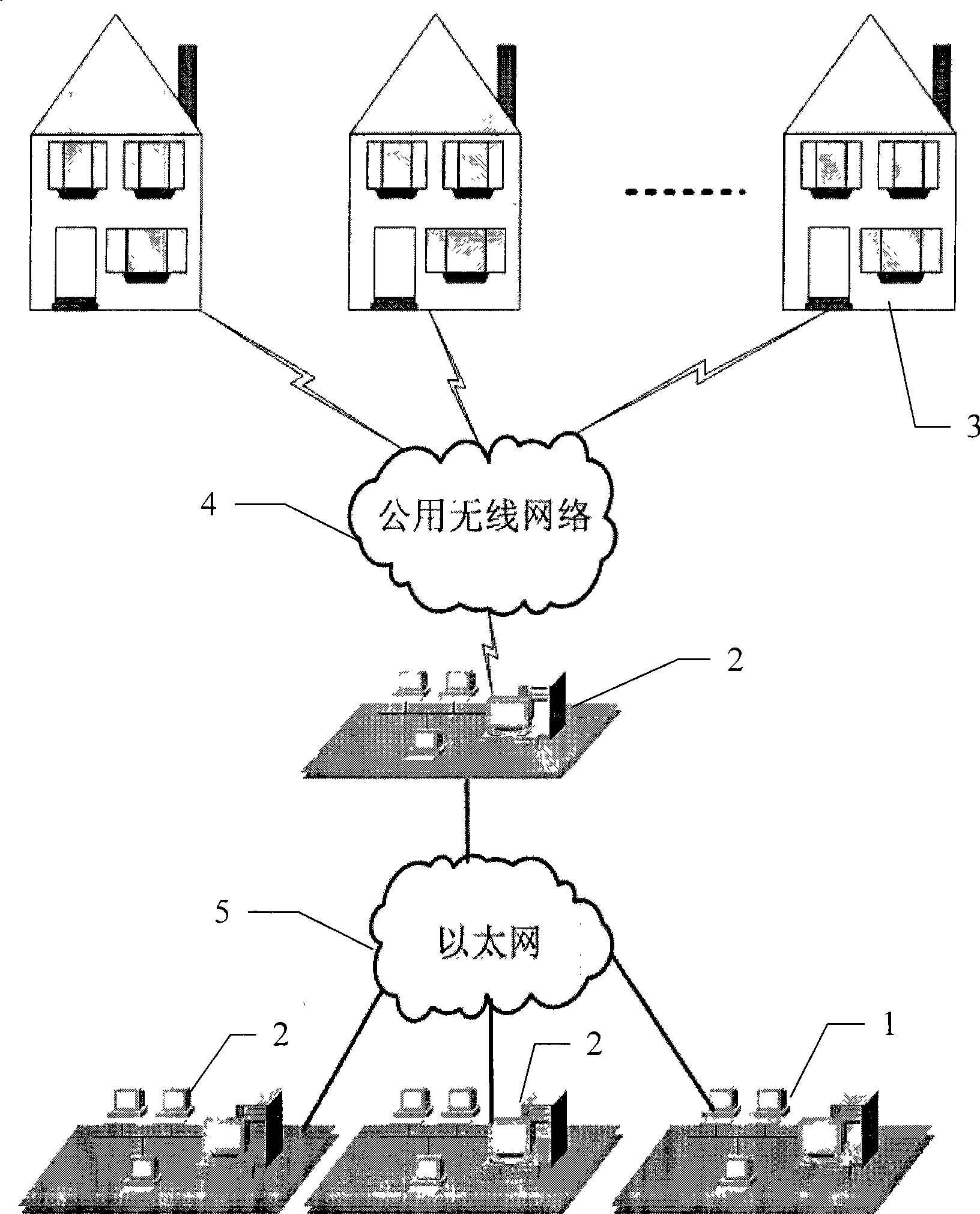

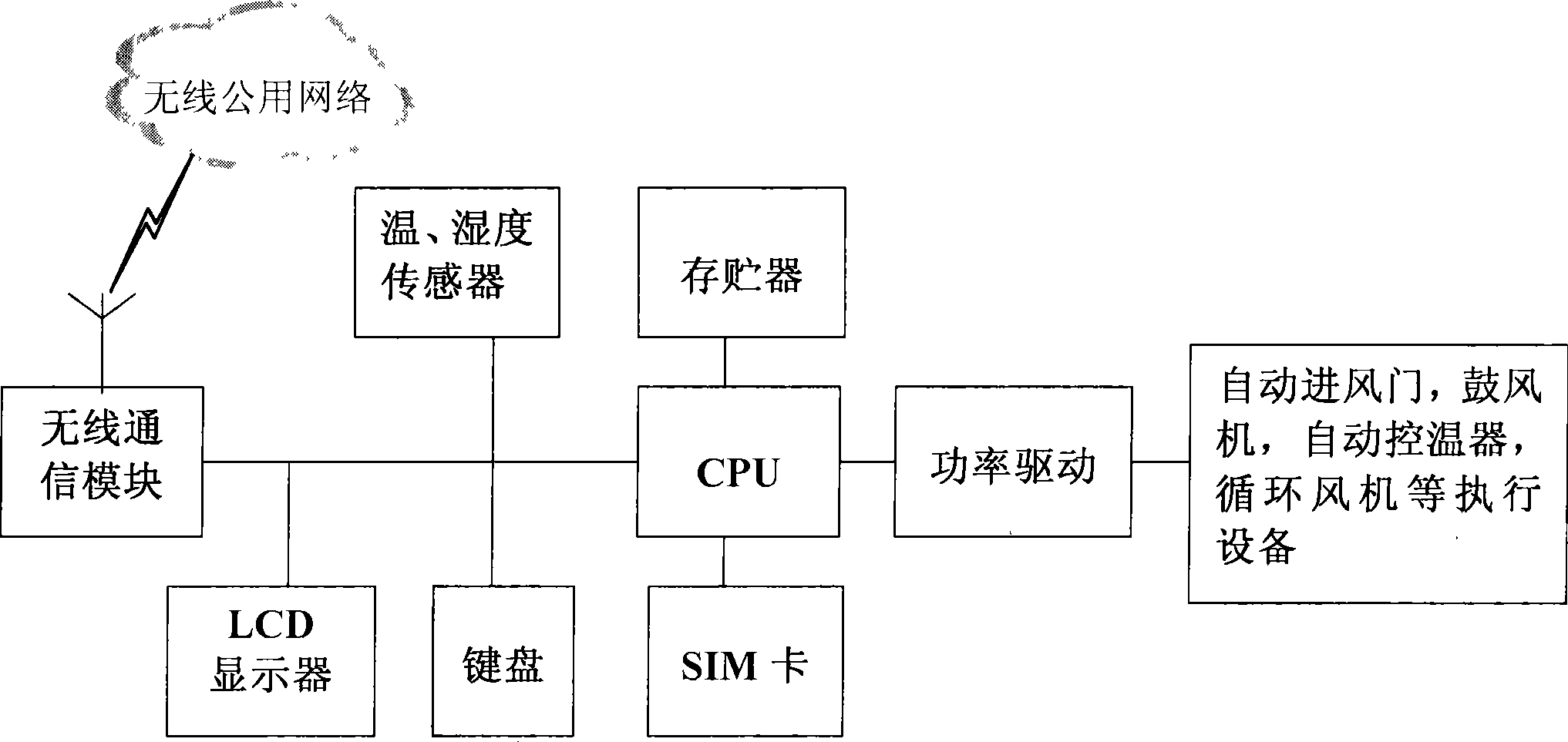

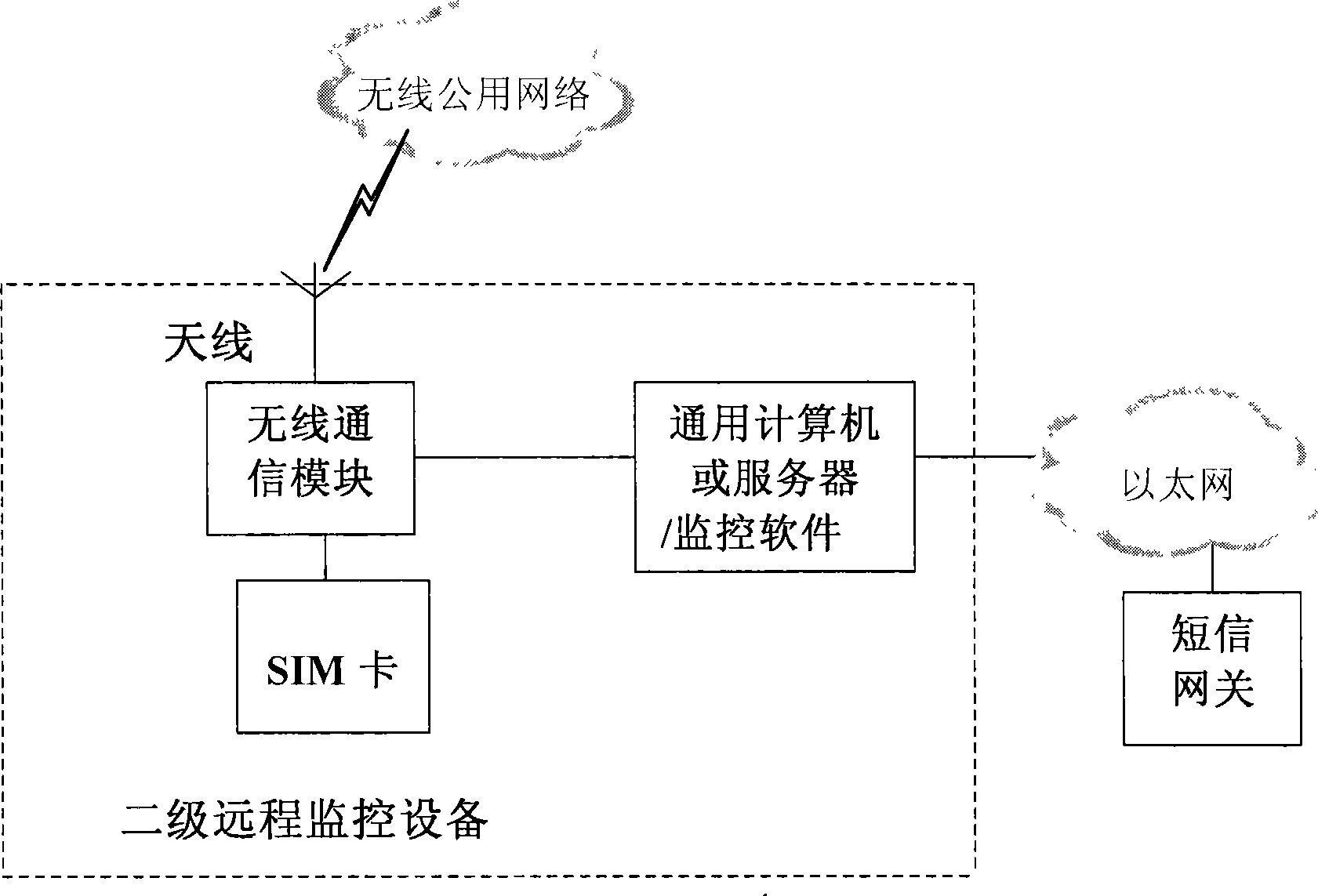

Remote centralized monitoring system and method for tobacco flue-curing house

InactiveCN101470425AReal-time online monitoring of working conditionsAvoid roastingComputer controlSimulator controlAutomatic controlThe Internet

Disclosed are a remote centralized monitoring system for flue-cured tobacco houses and a remote monitoring system thereof. The remote centralized monitoring system includes a primary remote monitoring device, a plurality of secondary remote monitoring devices, and automatic flue-cured tobacco house controllers disposed at each flue-cured tobacco house, wherein the primary remote monitoring device and the secondary remote monitoring devices are connected with the internet through the Ethernet, and each secondary remote monitoring device is communicated with the automatic flue-cured tobacco house controller at a corresponding area through the public wireless network. By combining the wireless communication technique and the flue-cured tobacco house automatic control equipment, remote centralized monitoring is realized for the scattered automatic flue-cured tobacco houses, monitoring technicians for the secondary remote monitoring devices can on-line monitor the working state of the flue-cured tobacco houses in their station in real time and can remotely assist tobacco growers in correctly setting the curing programs according to actual situations of curing, when the flue-cured tobacco houses work improperly, for example, temperature and humidity exceed standards, the system can alarm in real time, and further the monitoring technicians can input instructions to remotely control the state of the flue-cured tobacco houses or to inform the tobacco growers of emergency treatment, thereby avoiding bad flue-cured tobacco leaves.

Owner:深圳市中烟传媒有限公司

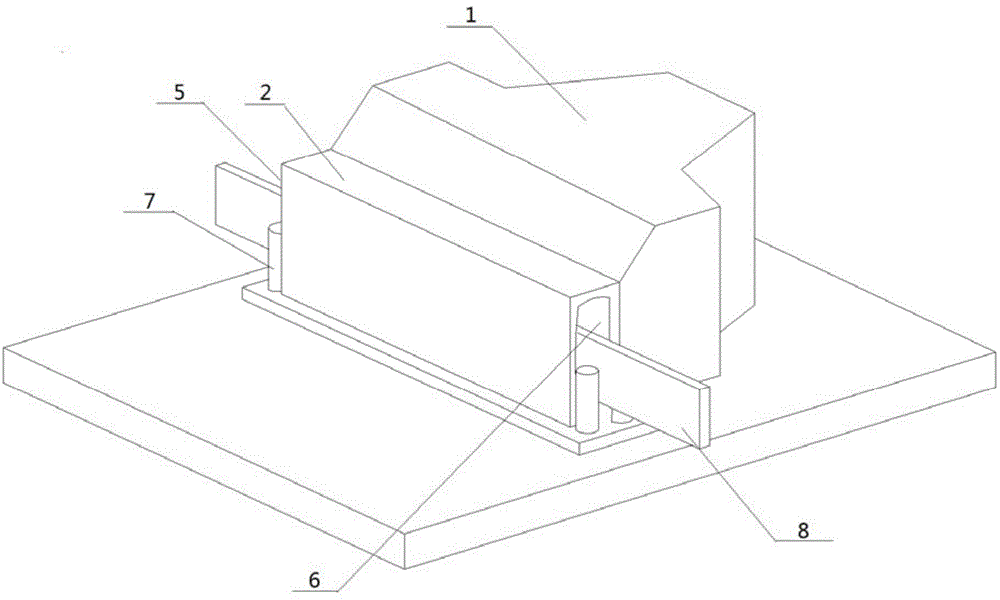

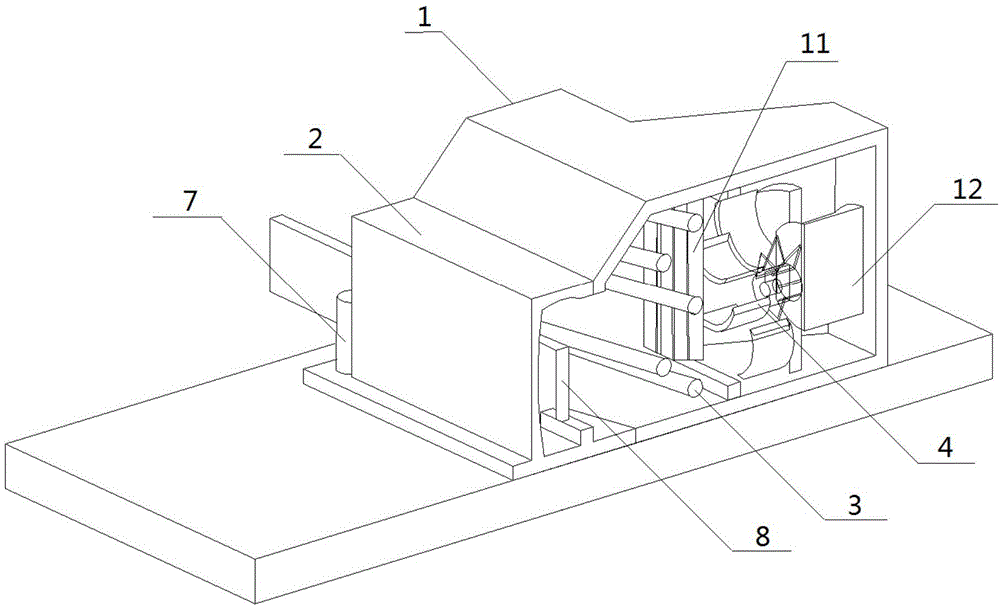

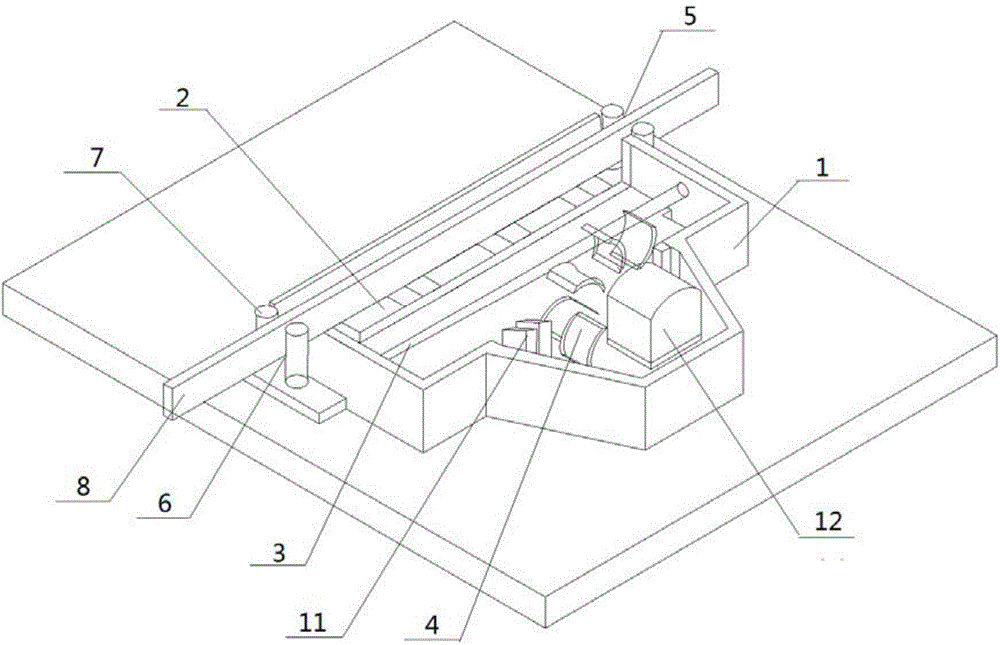

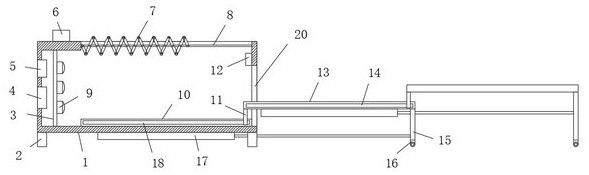

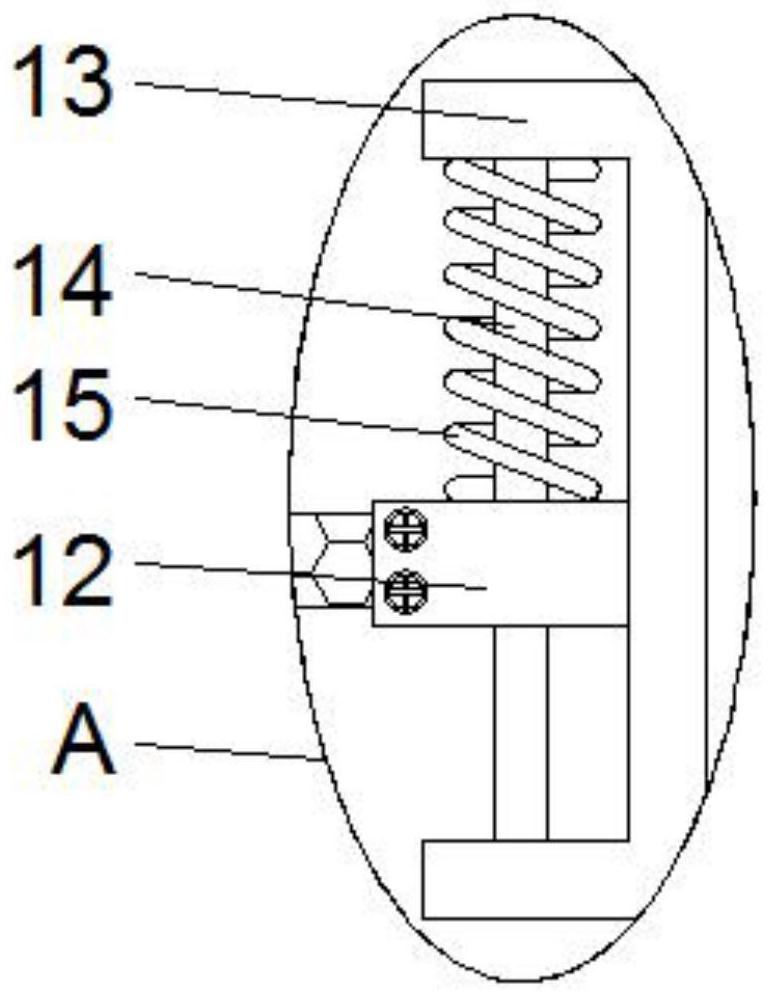

Preheating device for tape of edge bonding machine

InactiveCN104526834AHigh bonding strengthAdhesivelyWood working apparatusDomestic articlesBond qualityEngineering

The invention relates to the technical field of an edge bonding machine, and discloses a preheating device for a tape of an edge bonding machine. The preheating device comprises an edge bonding machine body in which an insulating cavity, a heating device and a blowing device are arranged, wherein the heating device is arranged between the blowing device and the insulating cavity, the insulating cavity is provided with a tape inlet and a tape outlet. The preheating device provided by the invention is simple in structure and convenient to use; furthermore, the tape can be preheated by combining the heating functions of a plate of an existing edge bonding machine, the bonding strength between the plate and the tape can be strengthened, the sealing tape can be glued firmly, and the edge bonding quality of products can be improved.

Owner:GUANGDONG SUNCOO TECH

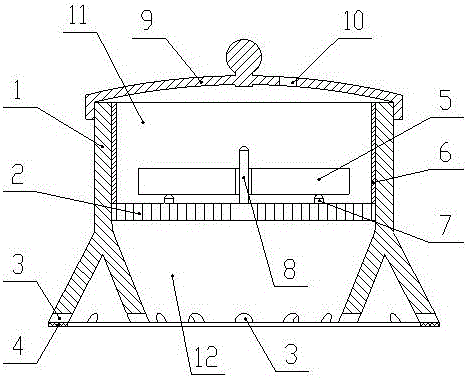

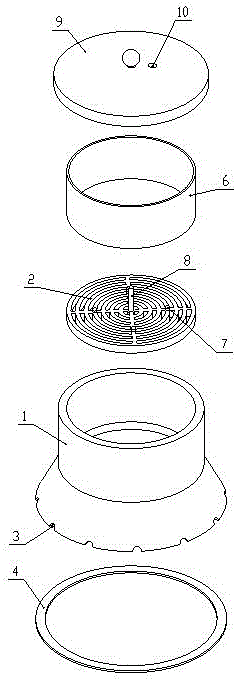

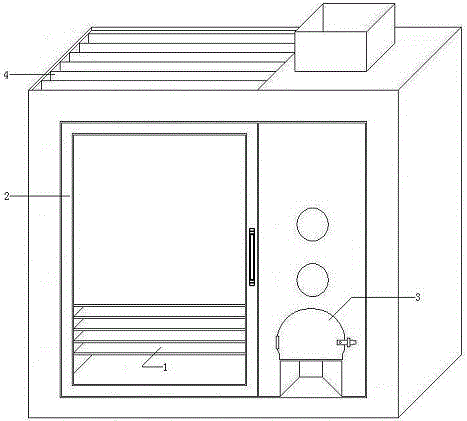

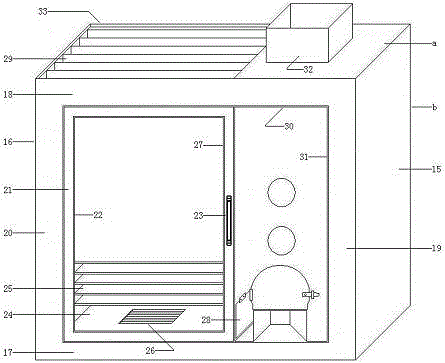

Moxa-moxibustion box

ActiveCN106109230ASimple structureLow costDevices for heating/cooling reflex pointsEngineeringReticular formation

The invention relates to a moxa-moxibustion box comprising a cylindrical housing and a holder arranged in the housing; the housing is at least divided into an upper cavity positioned in the most top of the housing and a lower cavity positioned in the most bottom of the housing; the holder is provided with through holes, or is a netted structure, or a hollow structure; the upper and lower cavities are mutually connected. The moxa-moxibustion box is simple in structure, low in cost, better in moxibustion effect, and stronger in practical value.

Owner:郭素英

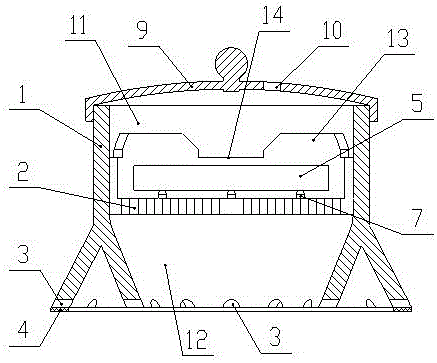

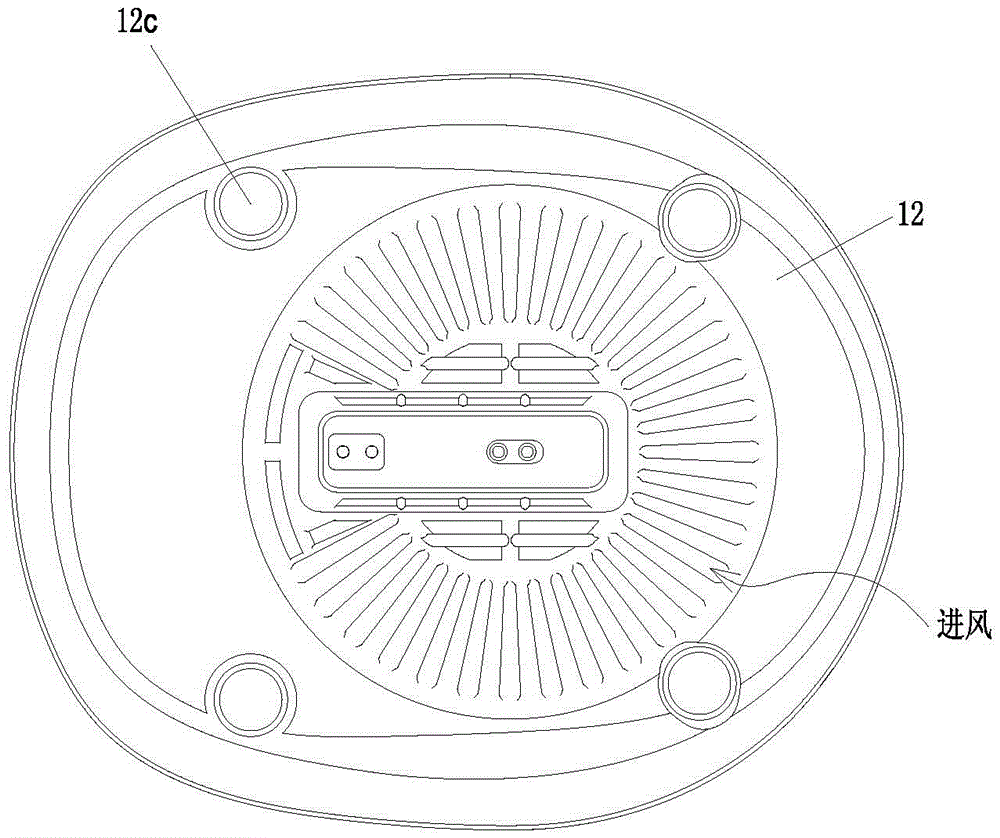

Digital and quantitative electric heating stove and implementation method thereof

InactiveCN104089312AReduce the temperatureImprove reliabilityDomestic stoves or rangesLighting and heating apparatusWhole bodyEngineering

The invention discloses a digital and quantitative electric heating stove, which comprises a stove core assembly and a shell assembly, wherein the whole body of the stove core assembly is cylindrical; the shell assembly is sleeved at the outer side and bottom of the stove core assembly; a weighing device is arranged between the center of the bottom of the stove core assembly and the chassis of the shell assembly; the weighing device is a long bar-shaped sensor with screw holes formed in both ends; one end of the sensor is connected with a boss at the bottom of the stove core assembly through a screw; the other end of the sensor is connected with a screw hole in the chassis through a screw; the sensor is electrically connected with a control circuit which is used for displaying the weight detected by the sensor; an air intake opening is formed in the chassis; an air channel and an air outlet are formed between the stove core assembly and the shell assembly. The invention further discloses an implementation method of the electric heating stove. According to the digital and quantitative electric heating stove, food can be accurately weighed; useful reference is provided for adjusting cooking scheme and cooking time; the cooking processing is greatly facilitated and the cooked food is delicious and nutritious.

Owner:深圳市康丽达实业有限公司

Honeysuckle flower cultivation method

InactiveCN105265121ASimple layingPromote growthPlant protective coveringsGround temperaturePlastic mulch

The invention discloses a honeysuckle flower cultivation method; the method mainly uses black mulch films to carry out rooting treatment for cuttings; the cuttings processed by a rooting agent penetrate the black mulch film, and insert the soil; a soil layer of 50-60 cm in diameter and 5-6 cm in thickness is arranged around the cuttings. The method can improve honeysuckle flower cutting seedlings survival rate to be above 90%; the black mulch film can use crop growth photosynthesis principle to prevent weed growth, thus basically realizing weeding purpose; soil moisture can be maintained, ground temperature can be improved so as to accelerate crop growth, so the corps can be mature in advance, thus improving economic benefits; the mulch film can be simply paved, and the mulch film width can be selected according to distance width along plants in the field; after the mulch film is paved, the surrounding of the cuttings must be covered by soil, so the mulch film reflection temperature cannot be overhigh, and thus burning the cuttings.

Owner:袁献武

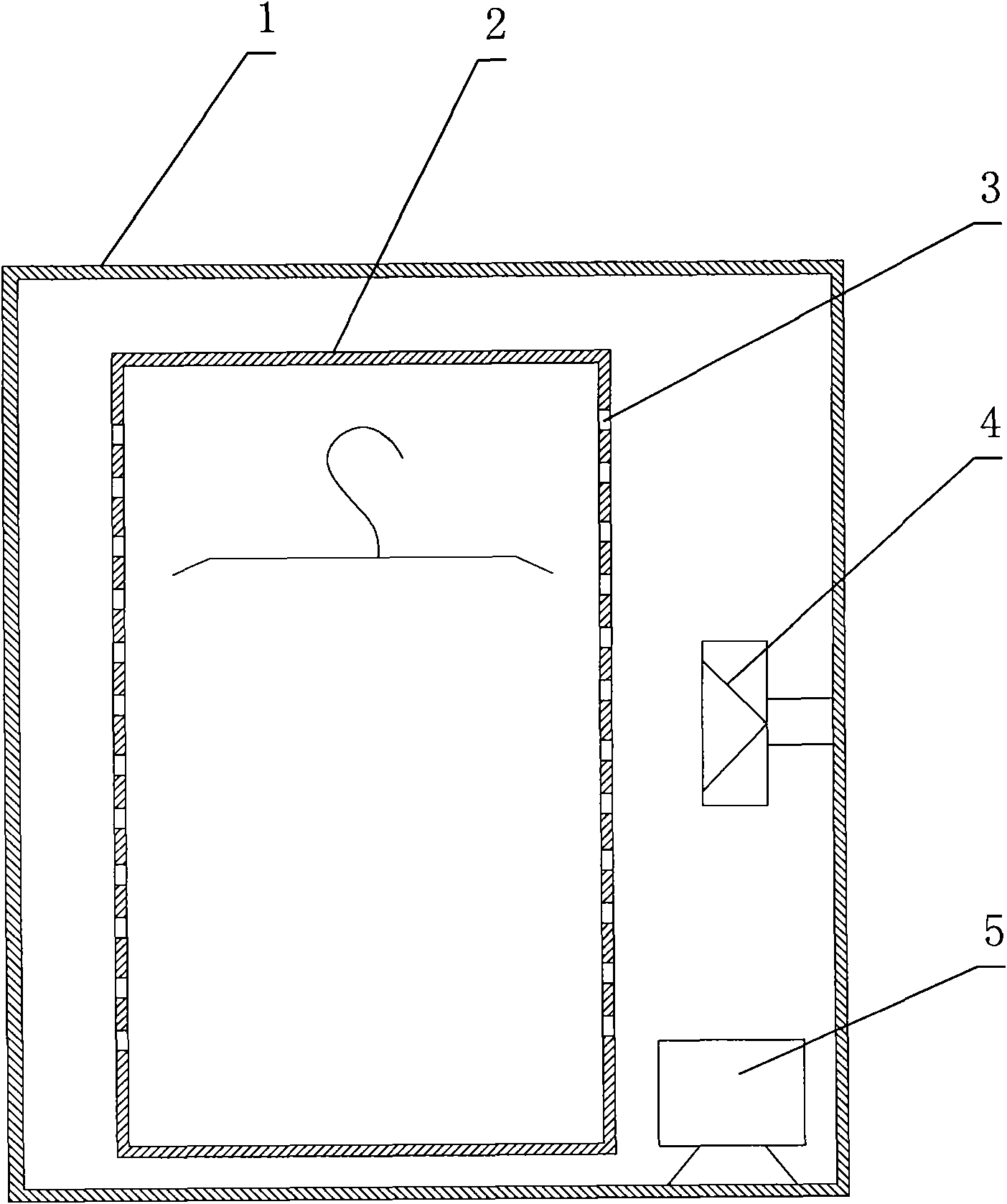

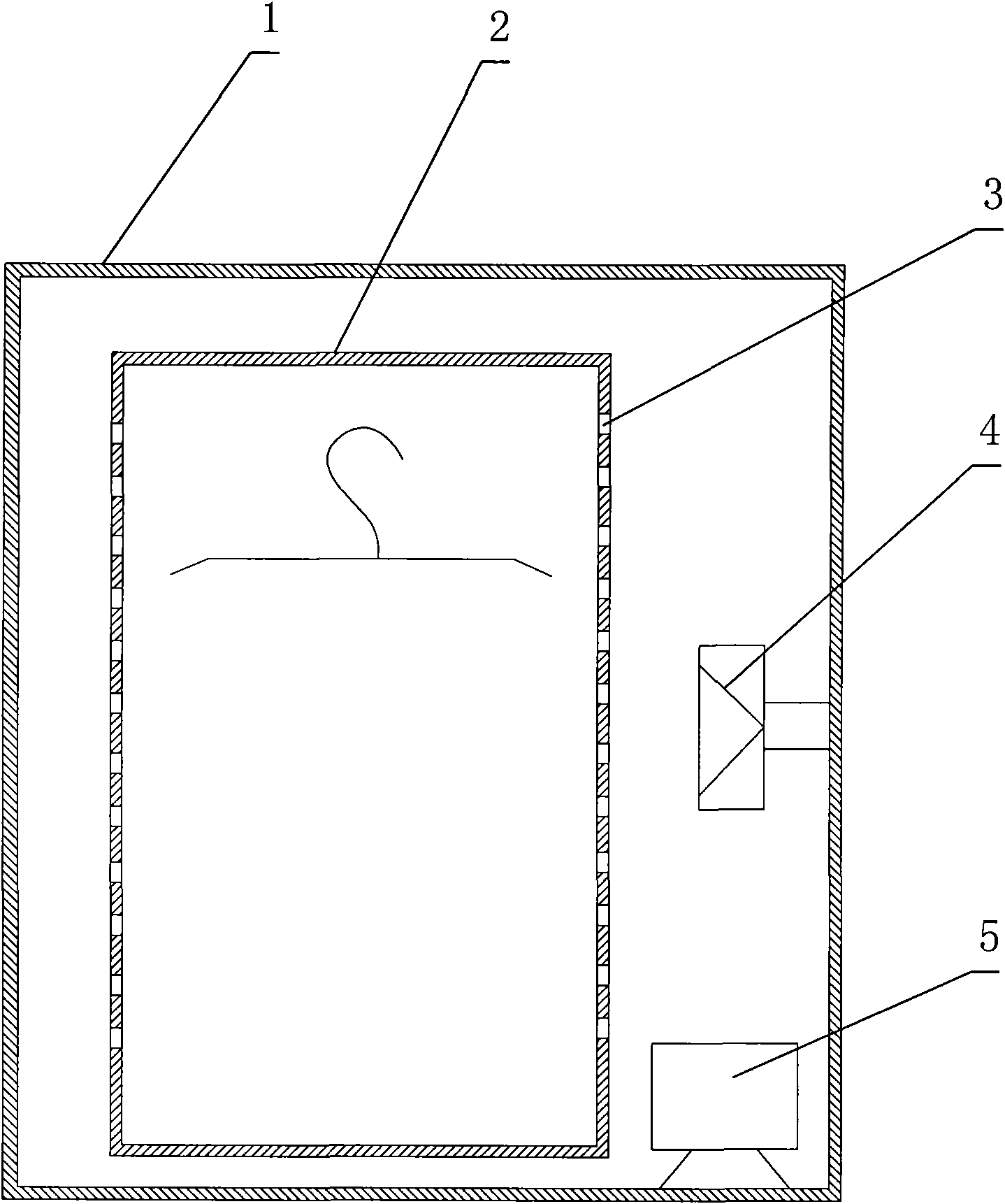

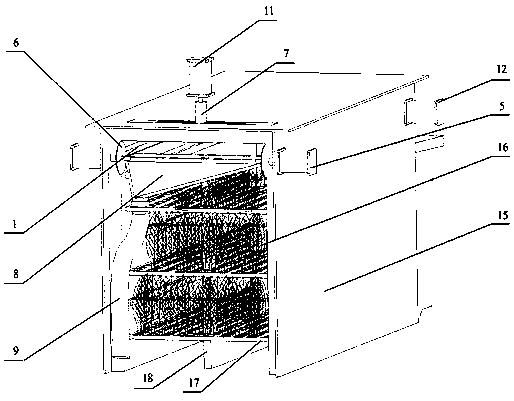

Clothes drying device

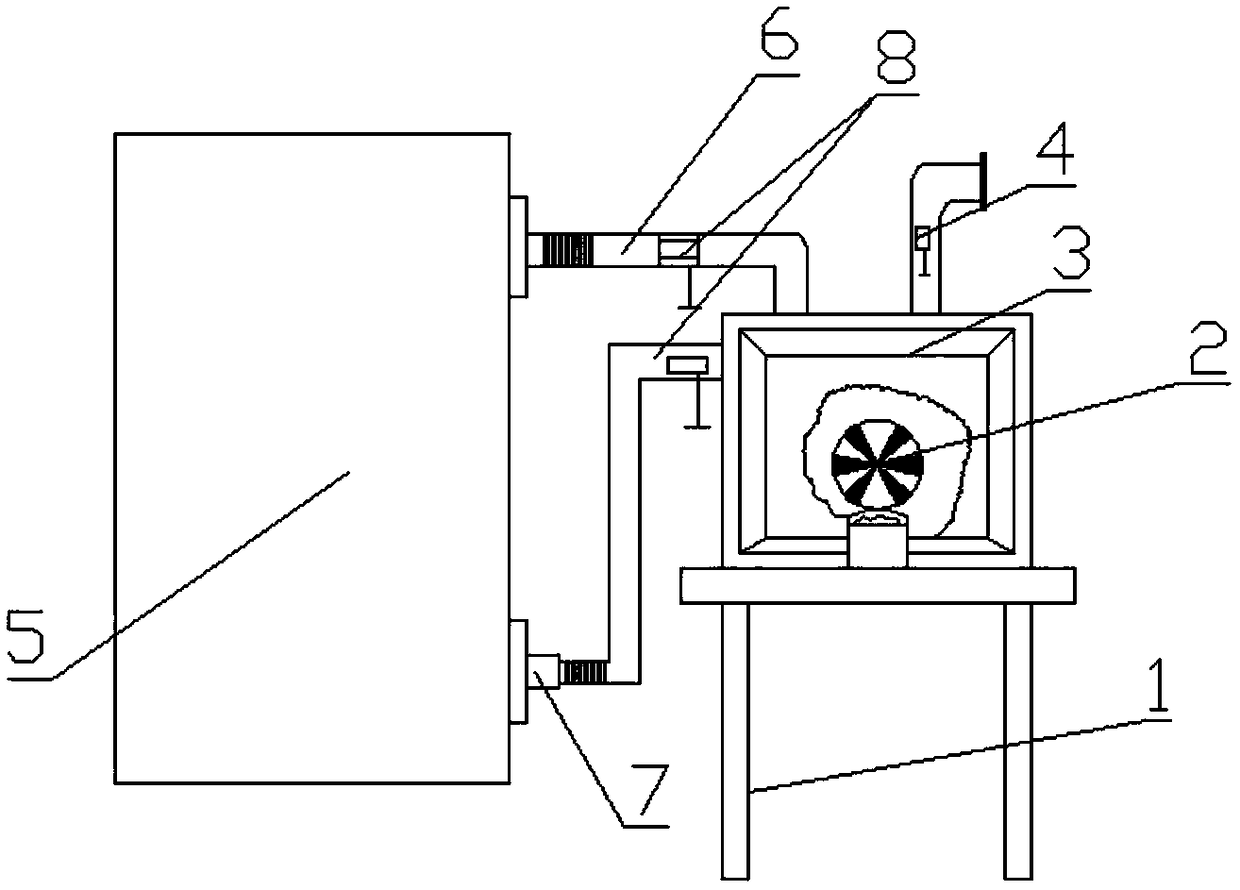

InactiveCN102418258ADry evenlyProtection securityTextiles and paperLaundry driersEngineeringBurning out

The invention discloses a clothes drying device. Aiming at the problems of unsmooth clothes and time and labor consuming of the conventional clothes drying, the invention provides the clothes drying device. The clothes drying device comprises an inner box and an outer box which are sleeved with each other, wherein a plurality of groups of through holes are formed in the box wall of the inner box; and a heater and a blower are arranged outside the inner box and inside the outer box. The blower is fixed to the box wall, at the intermediate height, of the outer box. In the clothes drying device, a clothes-drying rack is arranged in the inner box; and when in use, the heater in the outer box is started, and hot air is blown into the inner box from the through holes of the box wall of the inner box by the blower to dry clothes in the inner box. In the clothes drying device, the inner box plays a role in guaranteeing the safety of the clothes and preventing the clothes from being burnt out by the heater, and simultaneously the hot air can enter the inner box after being uniformly scattered by the through holes in the box wall of the inner box, so that the clothes is dried uniformly. The clothes drying device has a good drying effect and is favorable for popularization and application.

Owner:JIANGSU RYAN ELECTRIC LTD BY SHARE LTD

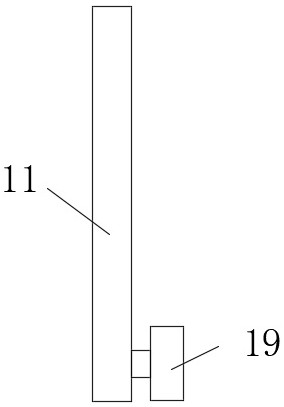

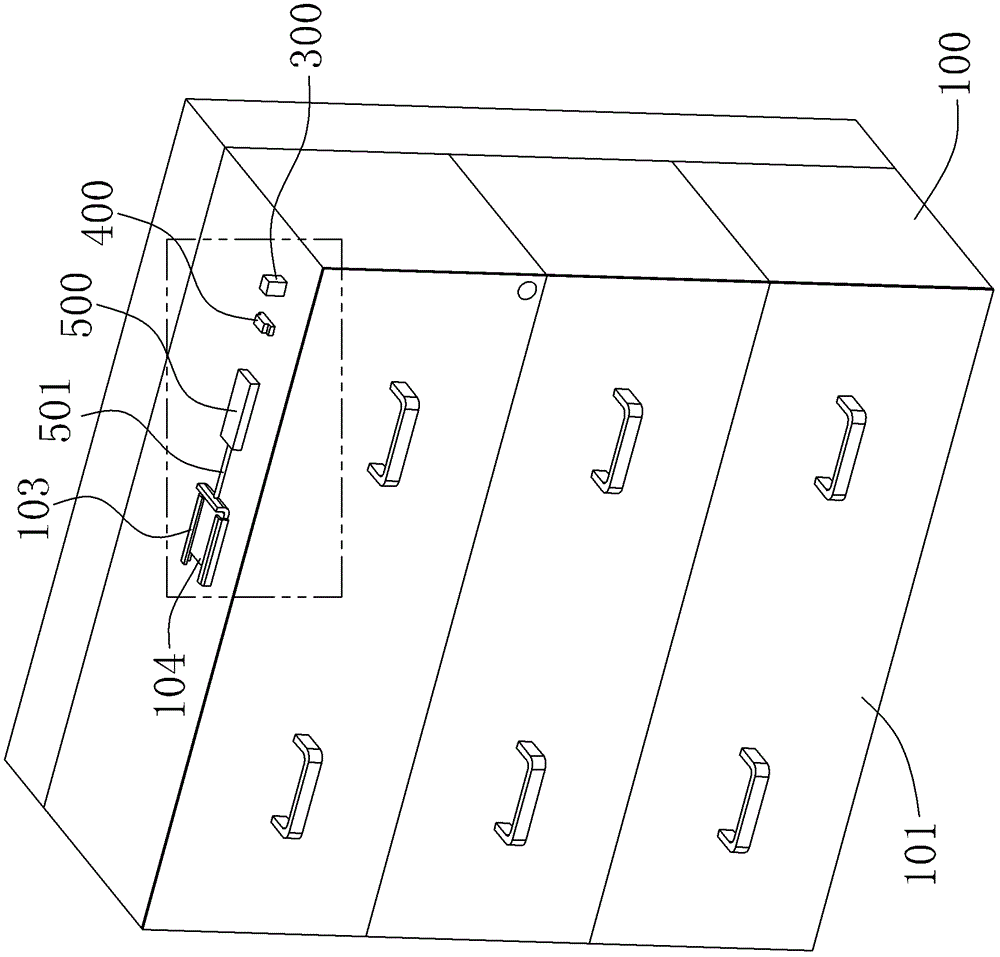

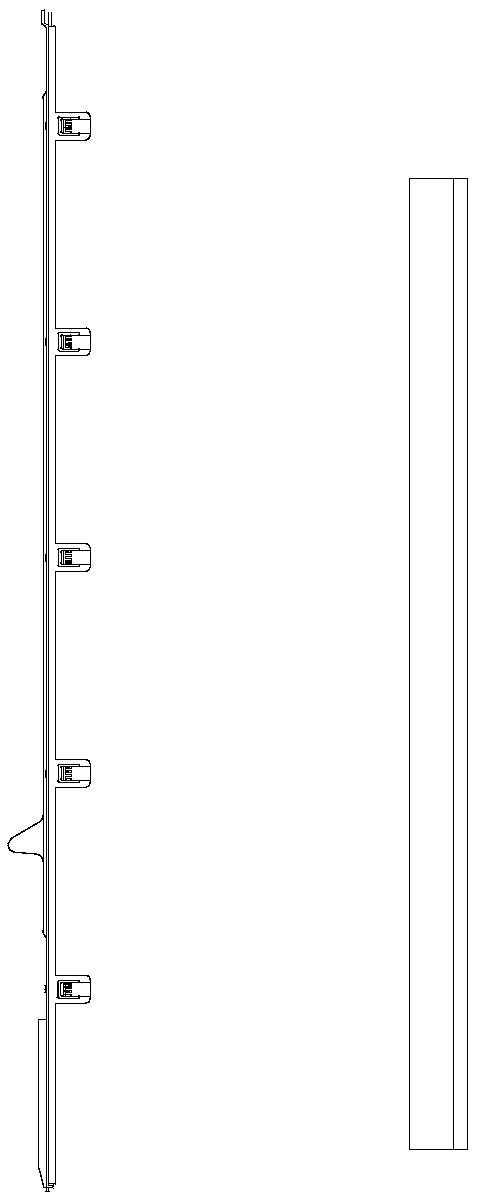

Constant temperature aging device

The invention discloses a constant temperature aging device, comprising an aging frame, a temperature controlled probe, a relay, an electromagnetic valve, a cylinder and a PTC (Positive Temperature Coefficient) heater, wherein one side of the aging frame is provided with a door; one face of the aging frame is provided with an opening; the opening is convexly provided with sliding slots at the two sides on the outer wall of the aging frame; plugboards are inserted into the sliding slots; the temperature controlled probe is arranged in the aging frame to detect the environmental temperature in the aging frame; the relay is connected with the temperature controlled probe so as to obtain the environmental temperature detected by the temperature controlled probe and compare the environmental temperature with a preset temperature; the electromagnetic valve is connected with the relay and controlled by the relay; the cylinder is connected with the electromagnetic valve and is controlled by the electromagnetic valve; the PTC heater is arranged at a place where the aging frame is closed to the bottom and connected with the relay; and when the environmental temperature in the aging frame is less than the preset temperature, the PTC heater is started to heat so as to provide an accurate testing environment. The articles to be tested are uniformly heated to avoid baking.

Owner:SHENXUN COMP KUNSHAN

Gas flow ascending type dense loose tobacco curing barn condensing water collecting device

PendingCN109757756AReduce dehumidification pressureAvoid drippingTobacco preparationWater dischargeEngineering

The invention discloses a gas flow ascending type dense loose tobacco curing barn condensing water collecting device. The gas flow ascending type dense loose tobacco curing barn condensing water collecting device comprises a curing barn; guide rails are arranged on the walls of the two sides of the curing barn; guide wheels are arranged in the guide rails; sponge brush machine frames are arrangedon the guide wheels; sponge is arranged on the sponge brush machine frames; a water brush process motor and a water brush return motor are arranged in the curing barn; output shafts of the water brushprocess motor and the water brush return motor are connected with rope wheels; water-collecting grooves are formed in the guide rails; water-removing extruding plates are arranged above the water-collecting grooves; the upper ends of the water-removing extruding plates are connected with water-removing extruding motors; and the lower ends of the water-collecting grooves are connected with water discharging pipes. The gas flow ascending type dense loose tobacco curing barn condensing water collecting device is suitable for the gas flow ascending type dense curing barn and is used for collecting condensing water formed on the top layer of the curing barn in the baking yellowing stage or in the color fixing early stage, so that the moisture discharging pressure is reduced and the baking energy consumption is reduced; on the other hand, the gas flow ascending type dense loose tobacco curing barn condensing water collecting device can prevent the condensing water on the top layer from gathering and dripping on the tobaccos of a top platform, avoids the problem that large area tobaccos in the curing barn are mildew and rot and indirectly improves the baking quality of the tobaccos.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +1

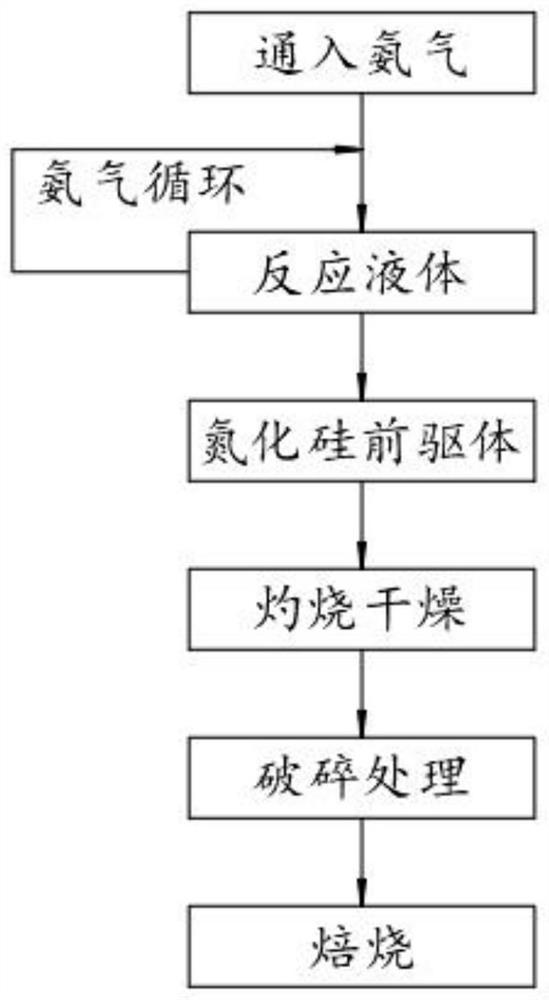

Method for preparing high-purity silicon nitride powder by ammonolysis method

ActiveCN113148966AIncrease productivityControl pressureNitrogen compoundsSilicon tetrachlorideMaterials science

The invention provides a method for preparing high-purity silicon nitride powder by an ammonolysis method, and relates to the field of silicon nitride preparation. The method for preparing the high-purity silicon nitride powder by the ammonolysis method comprises the following steps: adding a solvent and silicon tetrachloride into a reaction container, controlling the temperature and pressure in the container, fusing liquid ammonia into the solvent, and reducing the pressure in the container, so that the liquid ammonia is gasified and boiled so that the whole reaction system is disturbed, and a silicon nitride precursor is obtained; and burning, crushing and roasting the silicon precursor to obtain the silicon nitride. The reactants are in full contact, the generation efficiency of the silicon nitride precursor is high, the particle size of the silicon nitride precursor can be controlled through the solvent amount and the liquid ammonia introduction gasification speed, and control over the particle size of the final product silicon nitride is facilitated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for constructing green plant curtain wall

The invention discloses a method for constructing a green plant curtain wall, which comprises steps: wall connectors are arranged, a keel support frame is mounted, a galvanized mesh is mounted, an inverted trapezoidal plant module is mounted, an invisible weep pipe is mounted, a drainage channel is mounted, is arranged below the inverted trapezoidal plant module, is provided with a filter screen, and is connected with a drainage pipe, and the green plant curtain wall is checked, accepted and maintained. The green plant curtain wall which is formed through the method for constructing the green plant curtain wall is safe and also can improve survival rate of plants, and has the adjustment role for indoor temperature.

Owner:ZHEJIANG TONGYAN BUILDING PLANNING DESIGN CO LTD

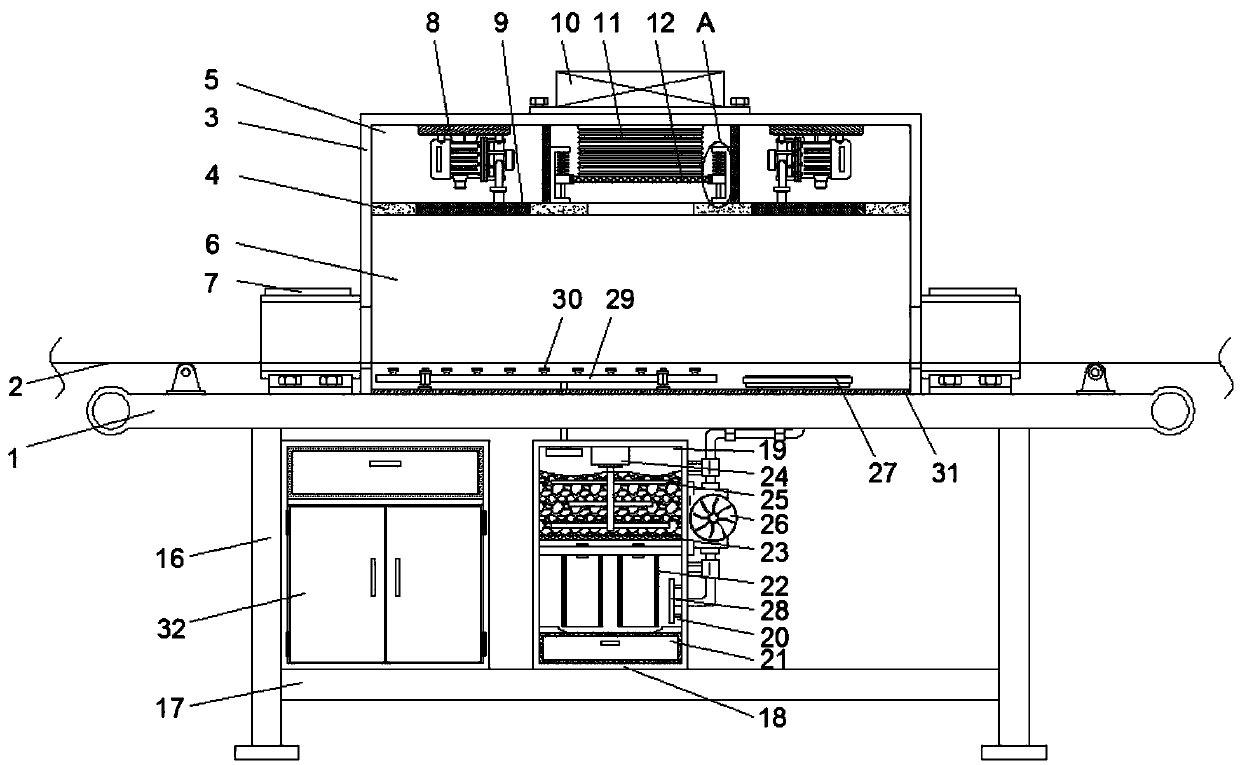

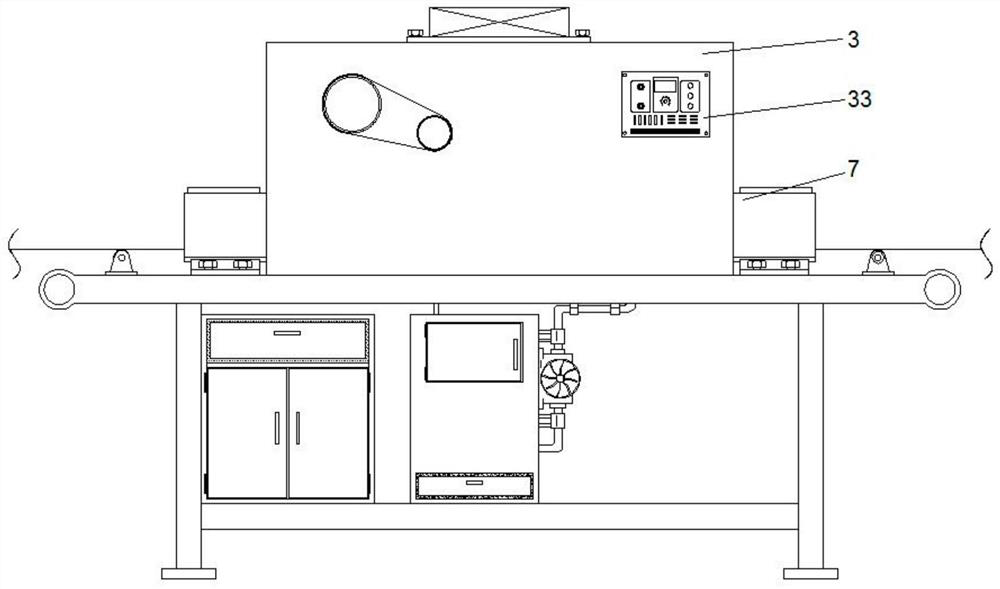

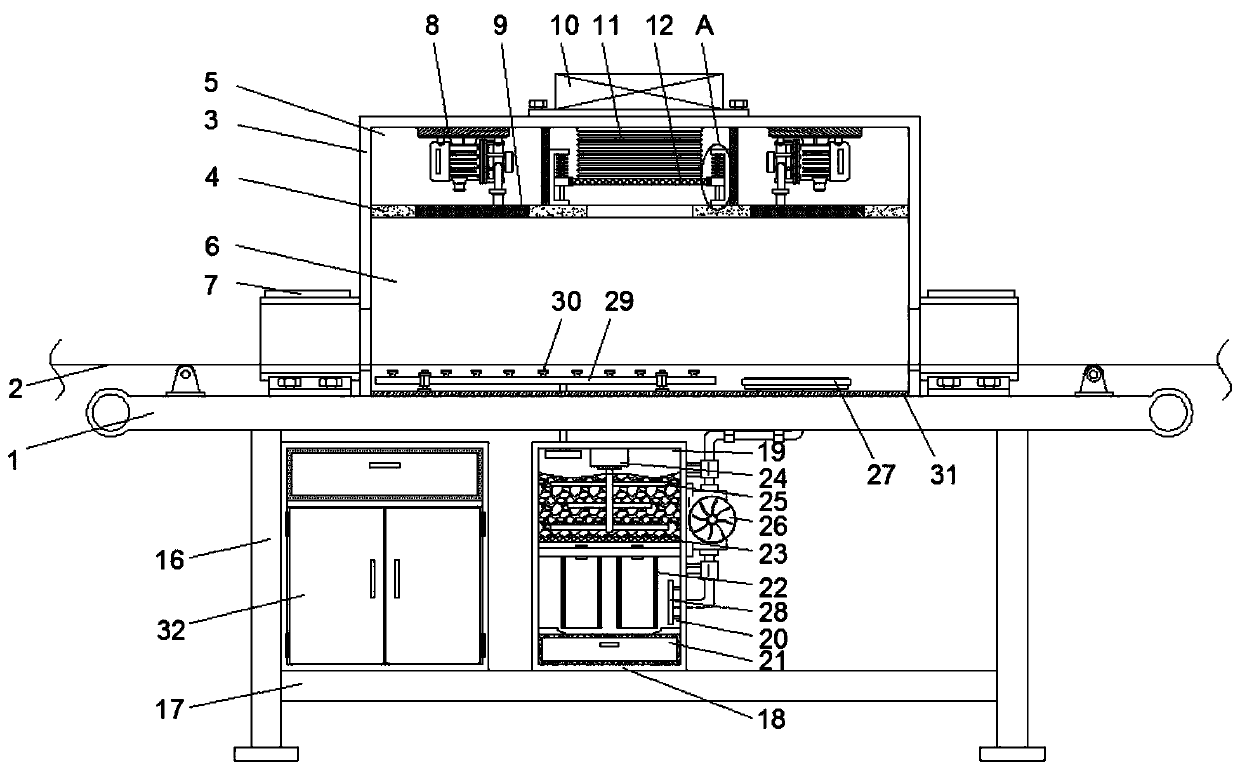

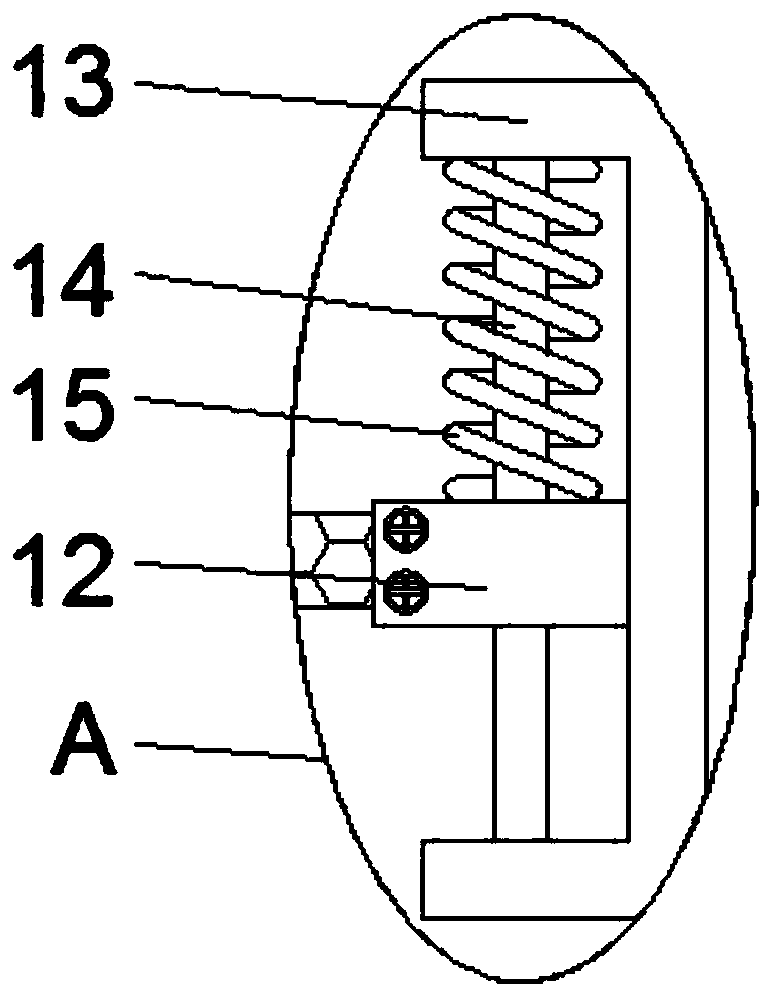

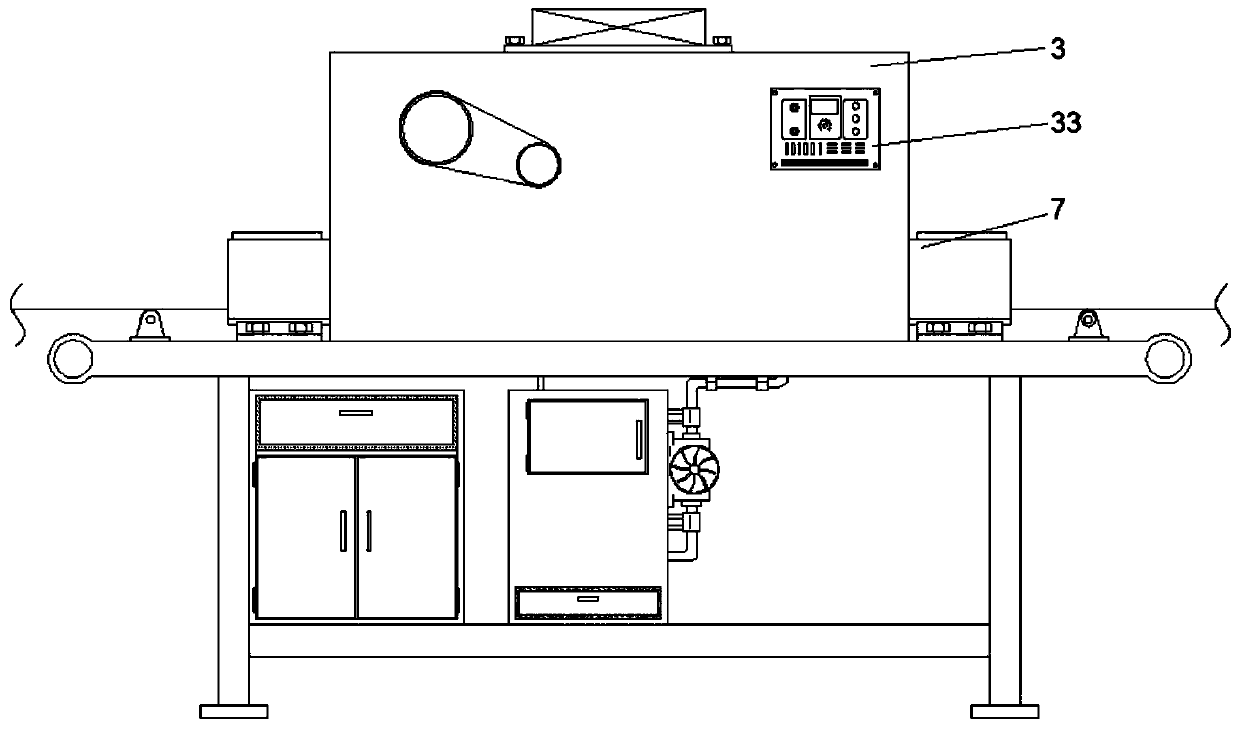

Drying heat exchange system for water-based ink printing

InactiveCN108688311AIncrease disturbanceEffective filteringDispersed particle filtrationPrinting press partsWater basedDry heat

The invention relates to a drying heat exchange system for water-based ink printing, and aims at providing a drying heat exchange system which is good in heat exchange effect and large in heat transfer temperature difference and achieves circulating backheating. The drying heat exchange system comprises a drying air box and a heat exchanger. A medium wave ultraviolet lamp tube is mounted in the drying air box, and mounted on a lamp tube rotator. A glass jalousie is arranged on the front portion of the drying air box, the downstream portion of the heat exchanger is connected with a heat exchange pump, and the heat exchanger and the heat exchange pump are connected through a heat circulating pipe. Two heat exchange areas are arranged in the drying heat exchange system, microwave heating is compounded with heat exchange tube heating, ripples are arranged in a heat exchange tube, heat and mass transfer disturbance is enlarged, heat and mass transfer is benefited, the heat exchange efficiency is improved, and fluid is subjected to circulating heating many times in the heat exchanger. Impurities in air are effectively filtered out, medium wave ultraviolet irradiation is used in the air box, and the situation that the heating temperature of heating materials is too high during shutdown, and consequently the printing materials are baked off is avoided.

Owner:广德美好包装科技股份有限公司

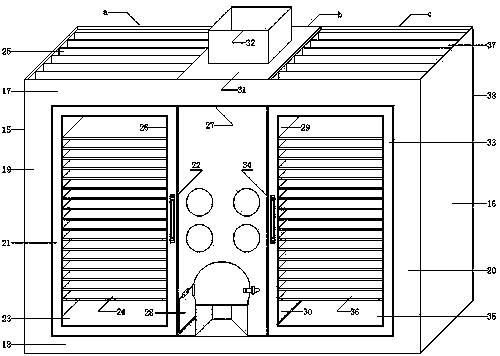

Manufacturing method of edible mushroom dry processing drying room

InactiveCN104305491AEffective placementAvoid softeningFood treatmentStructural engineeringEdible mushroom

The invention relates to a manufacturing method of an edible mushroom dry processing drying room. According to the manufacturing method, a drying room, a baking oven, a bamboo sieve, an exhaust fan, a heat supply passage and a pointer type temperature indicator are adopted. the manufacturing method is characterized in that a first long side plate is arranged at the right side of the drying room, a second long side plate is arranged at the left side of the drying room, a foot strip is arranged on the heat supply passage arranged at the bottom of the drying room, the upper part of the drying room is provided with a transverse cover plate, a first vertical cover plate is arranged at the right side of the drying room, a second vertical cover plate is arranged at the left side of the drying room, a door frame, a glass door plate and a pull handle are arranged on a sealing door arranged at the left side of the drying room, a bamboo sieve placing region, a bamboo sieve and a heat supply opening are arranged inside the sealing door, the upper part of the sealing door is provided with the pointer type temperature indicator, a first vertical separation plate is arranged on the baking oven arranged at the right side of the drying room, the lower part of the first vertical separation plate and the lower part of a second vertical separation plate are respectively provided with a skylight type heat supply opening and closing door, fan blades are arranged on the exhaust fan arranged at the top of the drying room, the baking oven, the second vertical separation plate and a top sealing plate are arranged at the right side of the drying room, and a back plate is arranged behind the drying room. The manufacturing method has the advantages of economy and applicability.

Owner:CHENGDU DRAGON WATER TREATMENT TECH RES INST

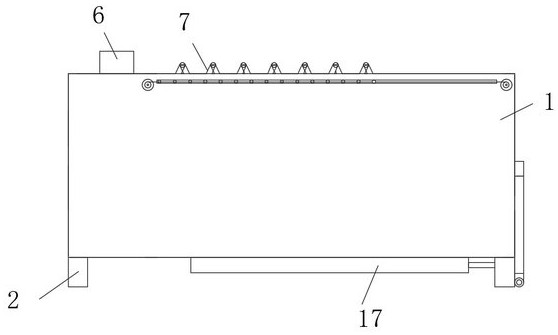

Plastic strip drying device for masterbatch processing

The invention discloses a plastic strip drying device for masterbatch processing. The plastic strip drying device for masterbatch processing includes a drying barrel; the side wall of the drying barrel is provided with a device box; the inner bottom of the device box is provided with a driving motor; the end of an output shaft of the driving motor is fixedly connected with a first connecting rod;a second connecting rod is rotationally connected to the end of the first connecting rod away from the driving motor; a fixed rod is arranged inside the device box; a movable rod is sleeved at the middle of the fixed rod; the second connecting rod is rotationally connected to the movable rod; a first straight tooth is arranged on one side of the movable rod; a rotating rod is rotationally connected to the inner side wall of the device box; and the side walls of the drying barrel and the device box are provided with two strip-type grooves of the same size and corresponding positions. The plastic strip drying device for masterbatch processing is reasonable in structure design and simple in operation, which is conducive to uniform heating of the plastic strip and improves the drying efficiency of the plastic strip.

Owner:安徽精卫医用材料科技有限公司

Seedling bed for blueberry planting

PendingCN111990119AEasy to breedEasy to storeCultivating equipmentsHorticulture methodsHydraulic cylinderEngineering

The invention discloses a seedling bed for blueberry planting. The seedling bed comprises a seedling box; a sun-blocking device is installed at the top of the seedling box; an illumination sensor is installed at the top of the seedling box; a first seedling plate is installed at the bottom in the seedling box; first sliding grooves are formed in two sides of the first seedling plate; a hydraulic cylinder is installed at the bottom of the seedling box; a second supporting rod is fixed to a piston rod of the hydraulic cylinder; second rolling wheels are installed at the bottom of the second supporting rod; a second seedling plate is fixed to the top of the second supporting rod; first supporting rods are fixed to the bottom of the second seedling plate; first rolling wheels are installed onthe side edges of the first supporting rods; and the first rolling wheels are installed in the first sliding grooves in a rolling mode. The seedling bed is convenient to unfold and fold, the seedlingarea is large, and good illumination protection can be conducted.

Owner:贵州艾威德生态农业发展有限公司

Drying method in corrugated paper production process

ActiveCN109577065AReduce shockPlay a role of buffer protectionCombination devicesGas treatmentAir volumeMicrowave

The invention discloses a drying method in corrugated paper production process, comprising the following steps: placing corrugated base paper on a conveyor belt of a conveying device, conveying the corrugated base paper into a protective casing by the conveying device, opening an air blower and filtering the introduced air by a filter screen plate, two ends of the filter screen plate slide along asliding rod under the impact of the air volume, a spring is stretched to cushion and protect the filter screen plate, and the two microwave generators cooperate with the air blower to dry the corrugated base paper entering a drying room. The drying method has the advantages that the temperature data acquisition can be quickly realized, the information security is effectively ensured by a front-end server, the temperature of the drying room can be monitored in real time, and the minimum output power that can meet the cooling requirements can be obtained by comparing with the preset temperature, thus avoiding the paper being baked by too high temperature.

Owner:恒达包装制品(龙南)有限公司

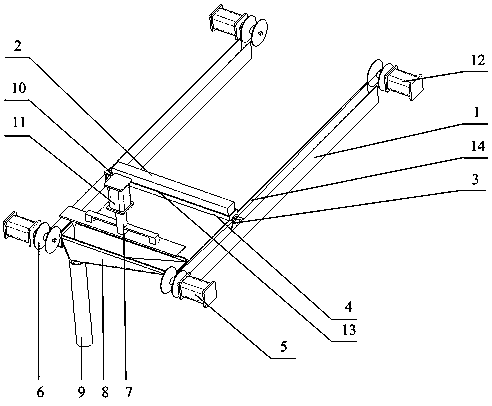

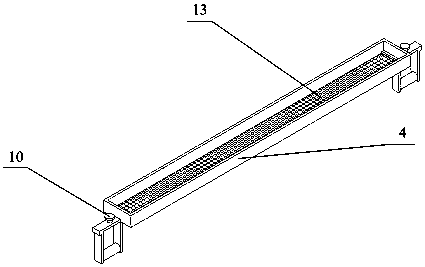

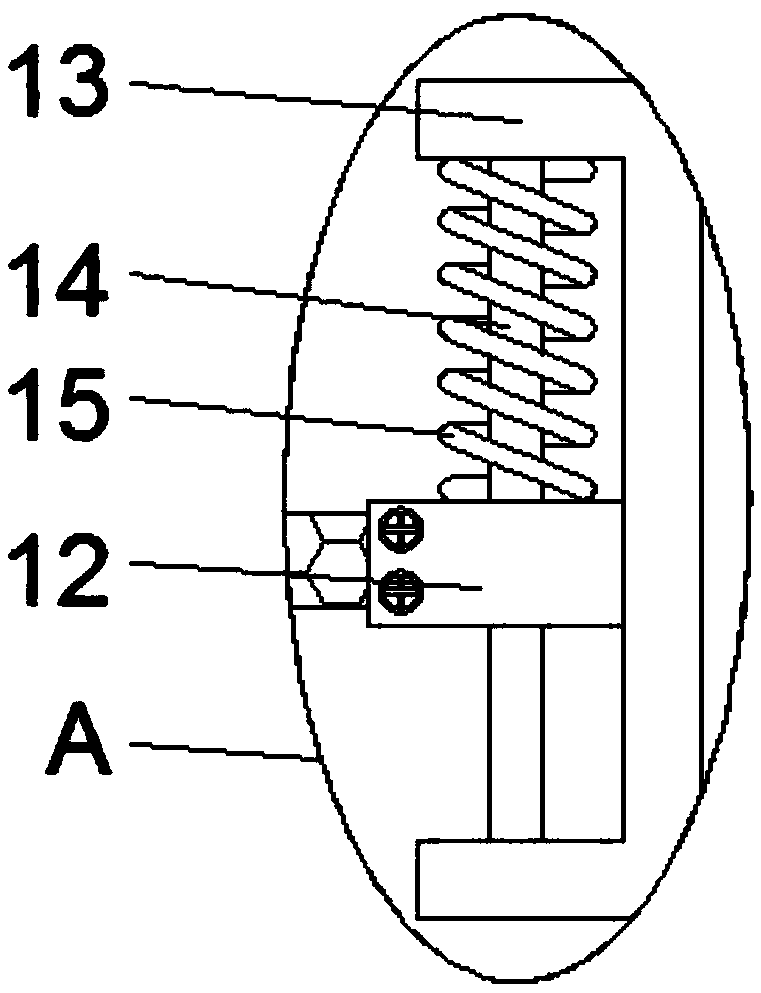

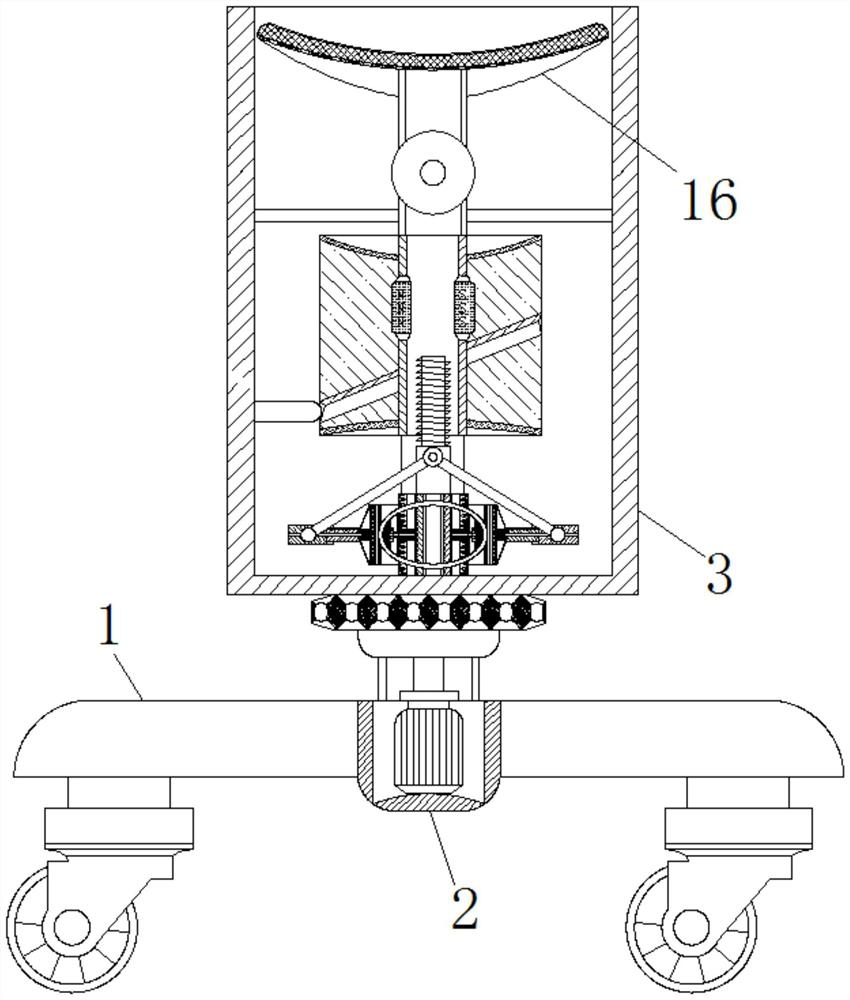

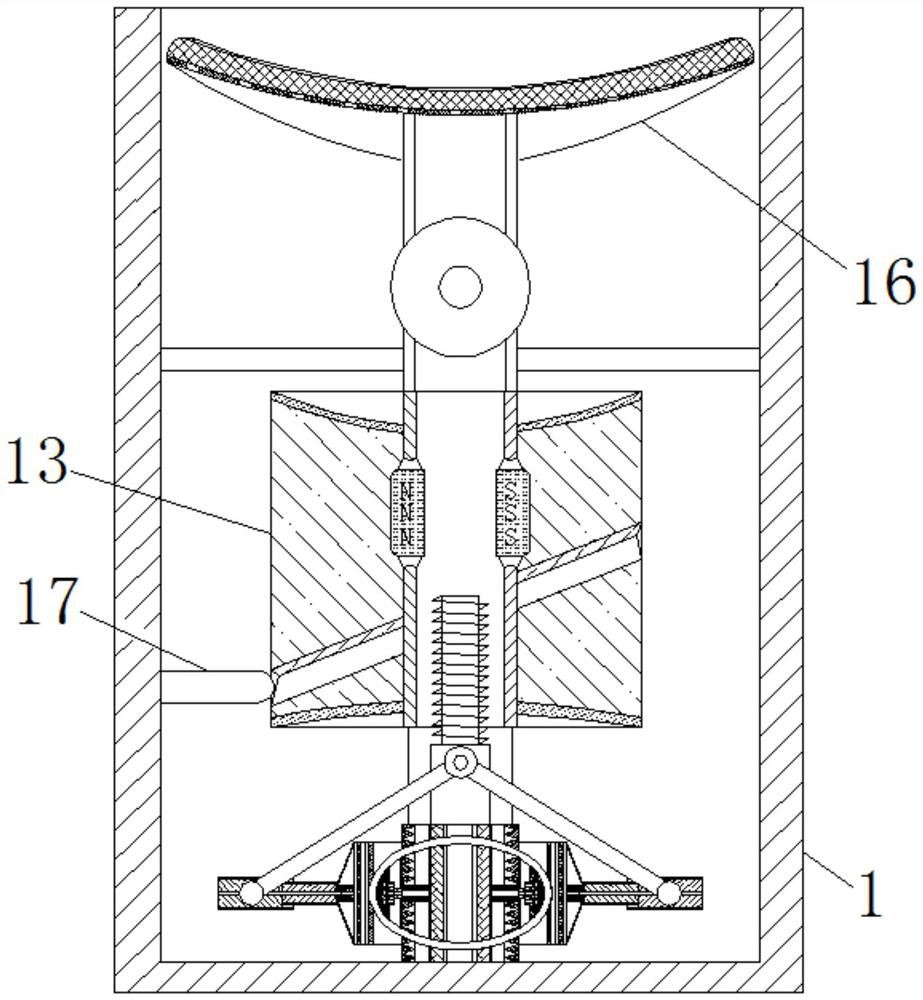

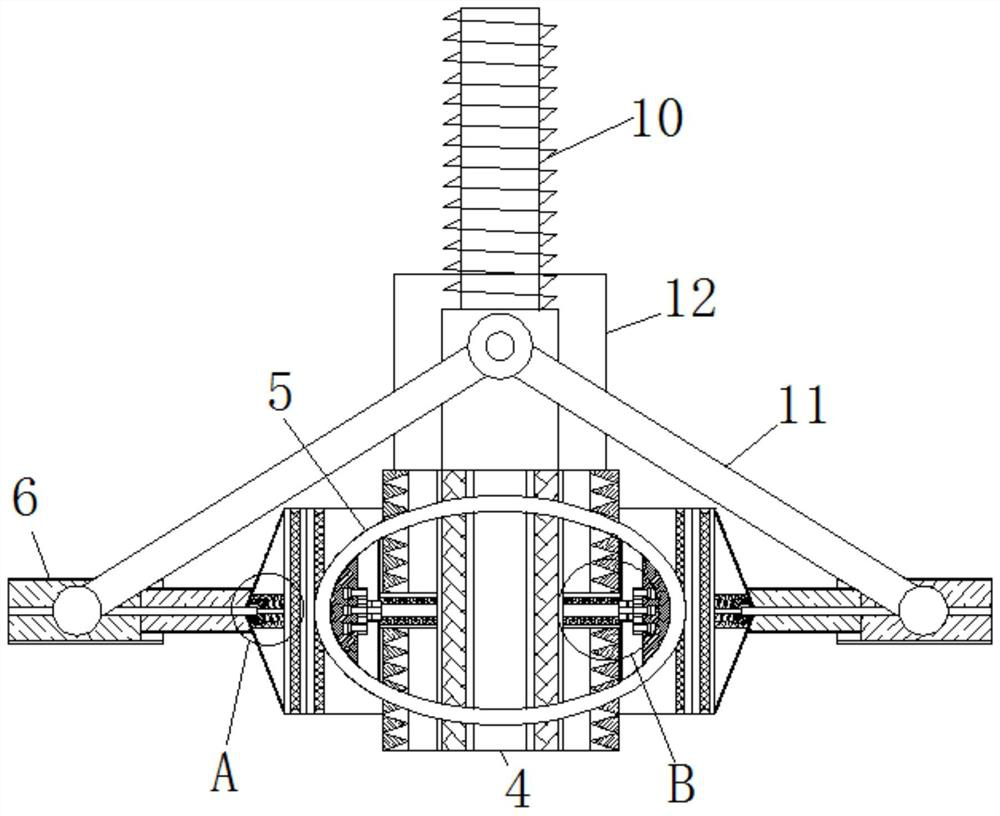

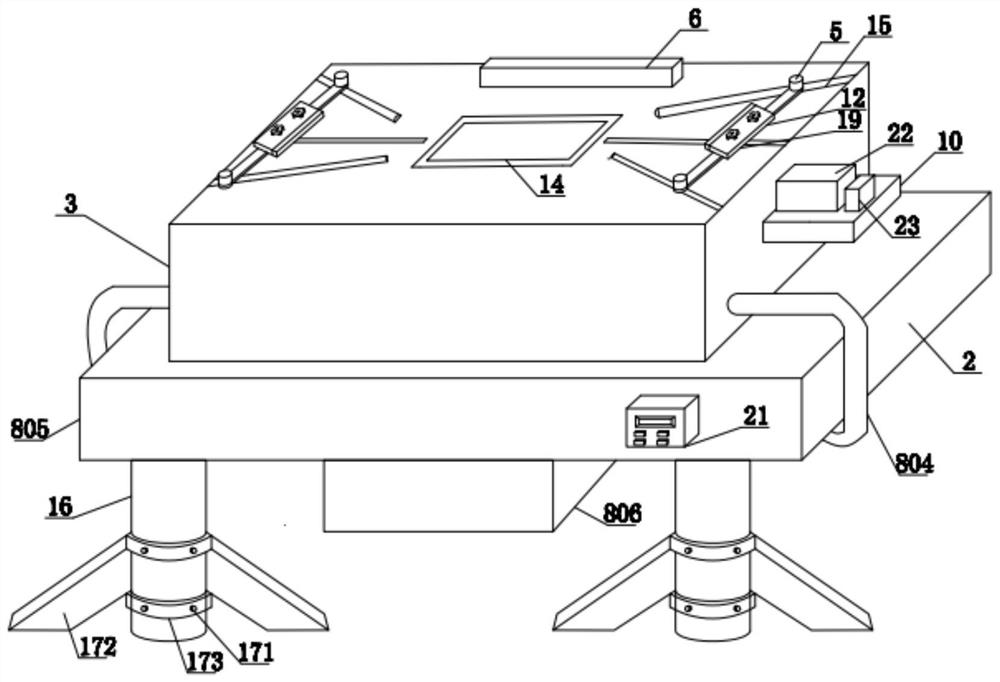

Chinese herbal medicine preparation device capable of adjusting drying temperature based on electromagnetic induction principle

InactiveCN112284082AAvoid roastingAvoid contactDrying chambers/containersDrying solid materialsEngineeringMechanical engineering

The invention relates to the technical field of Chinese herbal medicine preparation, and discloses a Chinese herbal medicine preparation device capable of adjusting drying temperature based on an electromagnetic induction principle. The Chinese herbal medicine preparation device comprises a bottom plate, wherein a driving device is fixedly mounted at the upper end of the bottom plate, and a protection cylinder is rotatably connected to the upper end of the driving device. According to the Chinese herbal medicine preparation device, in the downward moving process of a rotating cylinder in the protection cylinder, more and more parts of a fixed rod enter a magnetic field provided by permanent magnet blocks, and then an electrified wire wound on the fixed rod is used for performing magnetic induction line cutting movement in the magnetic field, so that a magnetic field signal is generated and transmitted to a heating device. The heating device can increase temperature, and is matched withthe rotating cylinder to downwards extrude a guide rod to drive a moving rod to extrude an air bag, and air in the air bag is extruded out, so that heat can be transmitted into a drying vessel, and the situation that Chinese herbal medicines are baked to be damaged due to direct contact between the heat and the drying vessel is avoided. Therefore, the effect that the medicine properties of the Chinese herbal medicines can be better exerted in the drying process, is achieved.

Owner:贵港赫迪信息科技有限公司

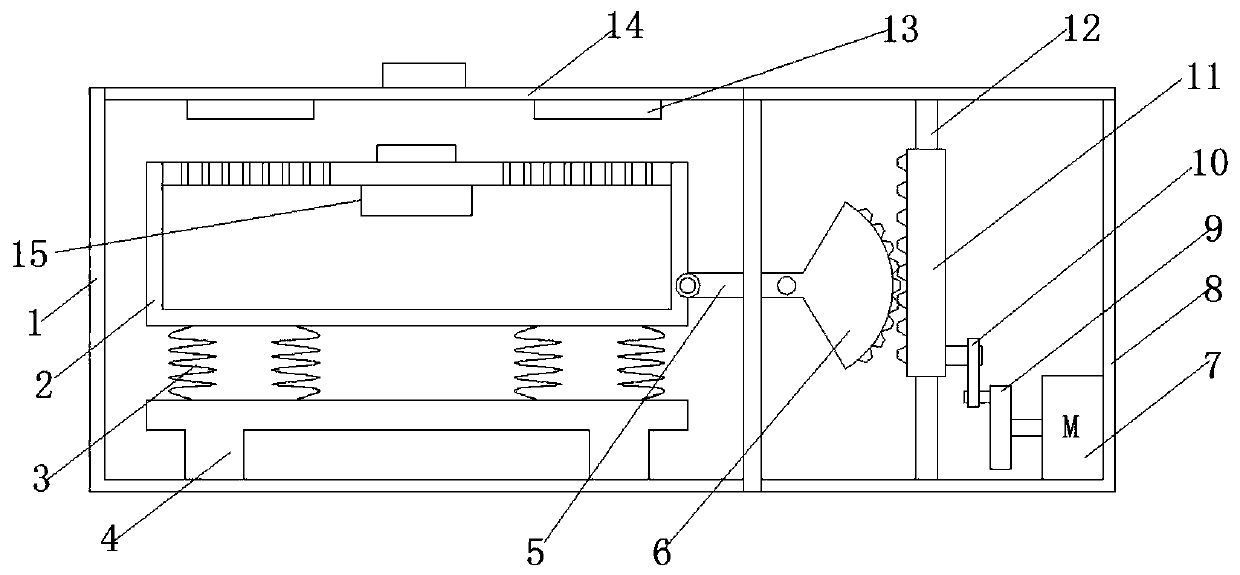

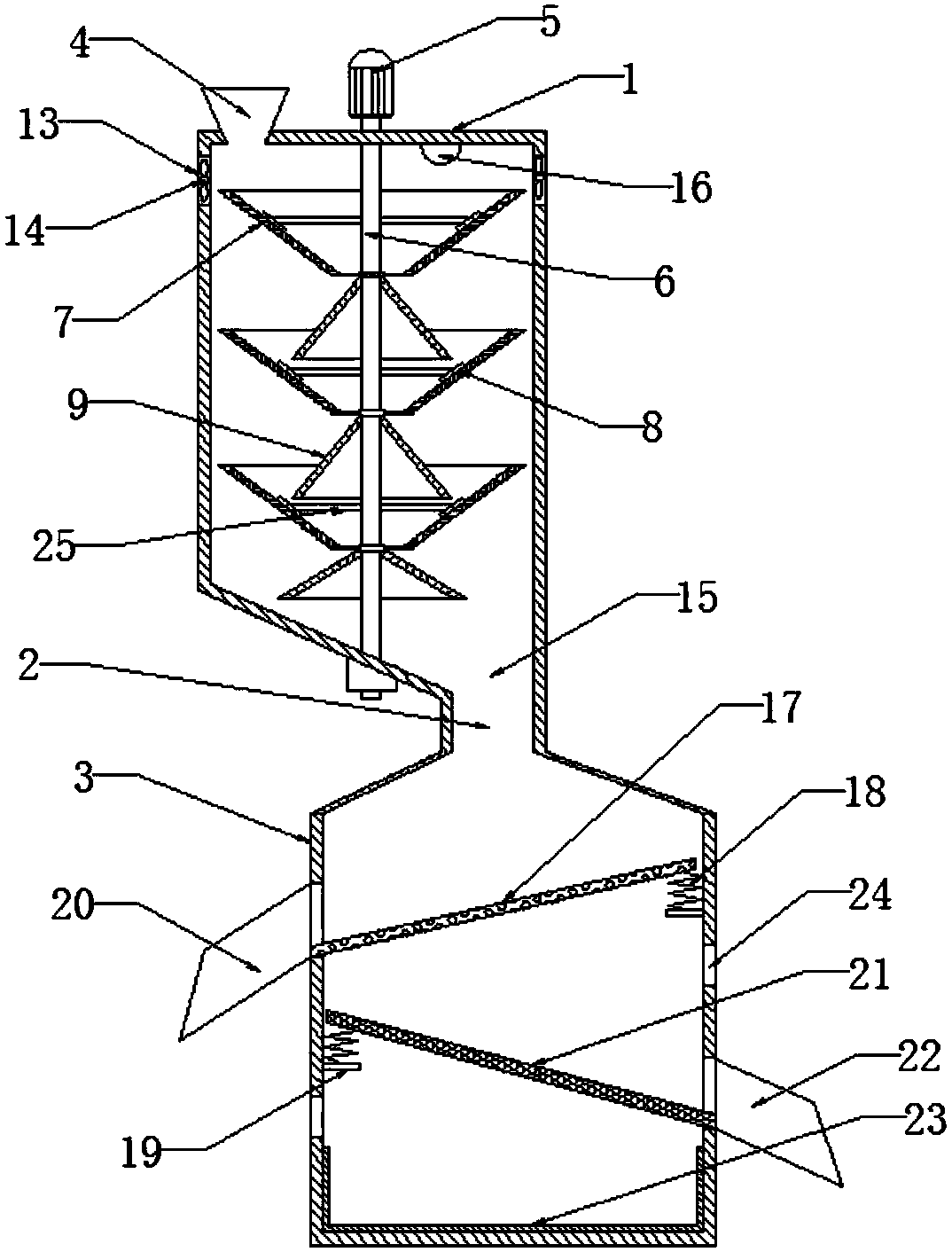

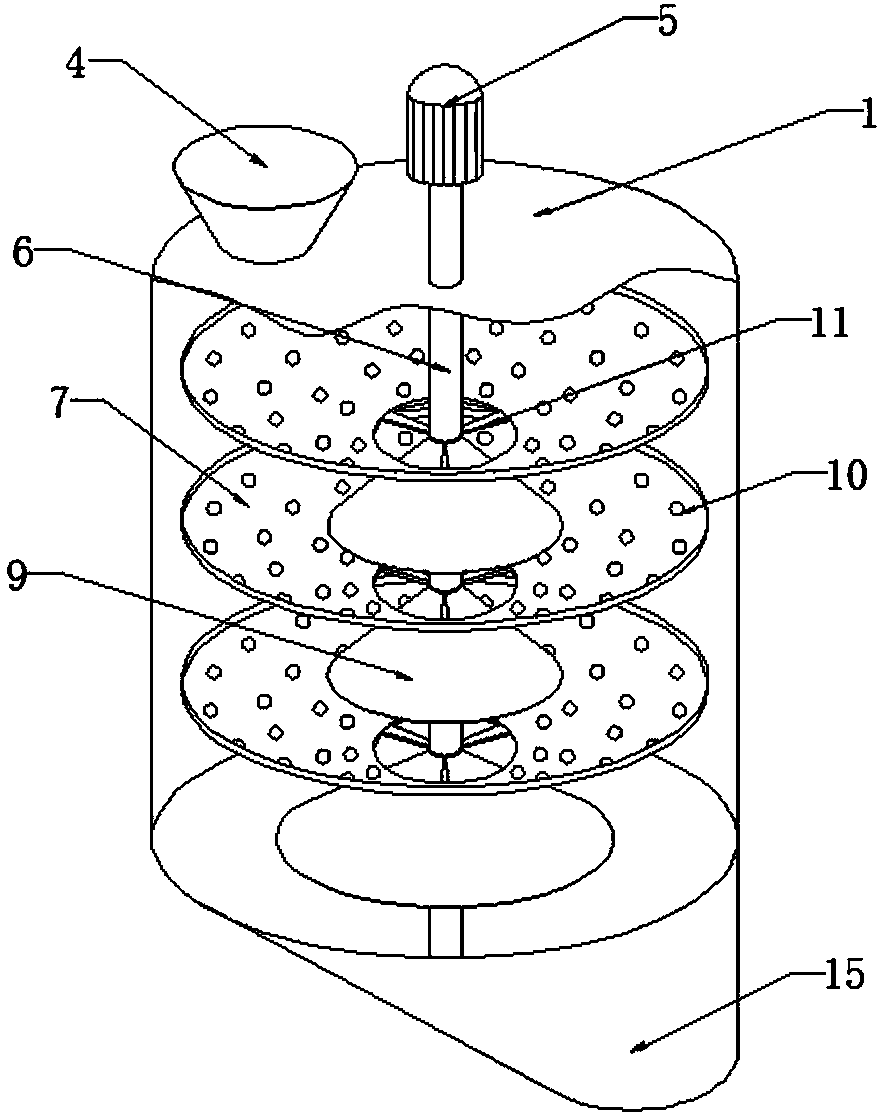

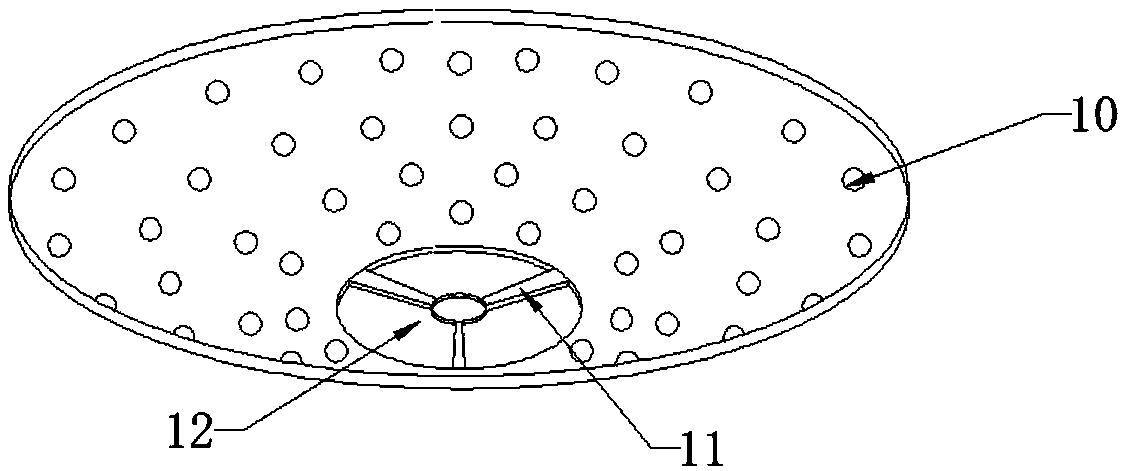

Novel screening device

InactiveCN109570007ADry evenlyQuality assuranceSievingScreeningAgricultural engineeringElectric motor

The invention discloses a novel screening device. The device comprises a drying box and a screening box, wherein the drying box is located above the screening box; a feeding opening is formed in the top of the drying box, a vertical rotating shaft is arranged in the drying box, and the rotating shaft is connected to a motor which is located outside the drying box; the rotating shaft is provided with two to five drying tanks, the tops of the drying tanks are open, material leaking openings are formed in the bottoms of the drying tanks, and electric heating wires are embedded in the side walls of the drying tanks; a discharging opening is formed in the bottom of the drying box, and a connecting channel is connected to the discharging opening; a screening plate which is inclined downwards relative to the horizontal plane is arranged in the screening box, a spring is arranged below the upward inclined end of the screening plate, a supporting plate is connected to the lower part of the spring, and the supporting plate is connected to the side wall of the screening box; and a discharging opening is formed in the side wall of the screening box corresponding to the downward inclined end ofthe screening plate. The novel screening device can be used for uniformly and thoroughly drying parts, and also has a screening function.

Owner:XINCHANG DINGSHI TECH CONSULTING SERVICE CO LTD

Construction method of greening curtain wall

The invention discloses a construction method of a green curtain wall. The construction method includes the following steps that wall connecting pieces are arranged; a keel supporting frame is mounted; a galvanized mesh is mounted; an inverted trapezoidal plant module is mounted; an invisible weep pipe is mounted; a drainage channel is mounted, specifically, the drainage channel is installed underthe inverted trapezoidal plant module, the drainage channel is provided with a filter screen, and a drain pipe is connected to the lower part of the drainage channel; and receiving inspection and maintenance are carried out. A curtain wall formed by the construction method of the green curtain wall is safe and can improve the survival rate of plants, and has the function of temperature regulationindoors.

Owner:ZHEJIANG TONGYAN BUILDING PLANNING DESIGN CO LTD

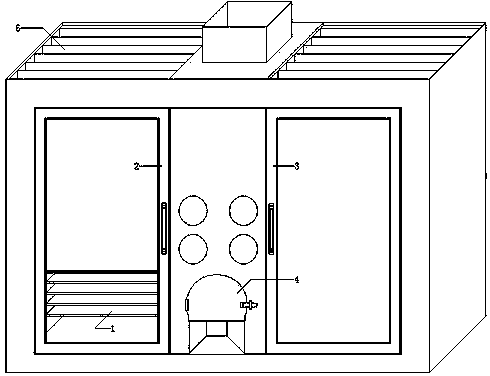

Edible mushroom baking room with gas exchange function and manufacture method

InactiveCN104351926AEffective placementEfficient dischargeFood treatmentCooking & bakingEdible mushroom

The invention provides an edible mushroom baking room with a gas exchange function and a manufacture method. A left side wall is arranged on the left of the baking room; a right side wall is arranged on the right side of the baking room; a cross beam is arranged at the upper part of the front of the baking room; a bottom beam is arranged at the lower part on the front of the baking room; a first vertical side wall is arranged on the left side of the baking room; a second vertical side wall is arranged on the right side of the baking room; a first sealing door, a first handle, a first bamboo sieve placing zone and a second bamboo sieve are arranged on the left baking room on the left side of the baking room; a first pointer type thermometer is arranged at the upper part of the first sealing door; first blades are arranged on an exhaust fan at the top of the left baking room; a first partition wall, a baking oven, a first air ventilation door, a second partition wall, a second air ventilation door, a top sealing plate and a chimney are arranged on the baking oven in the middle of the baking room sequentially; a second sealing door, a second handle, a second bamboo sieve placing zone and a second bamboo sieve are arranged on a right baking room on the right side of the baking room; a second pointer type thermometer is arranged at the upper part of the second sealing door; a main body wall is arranged behind the baking room. The edible mushroom baking room and the method are economic and practical.

Owner:CHENGDU DRAGON WATER TREATMENT TECH RES INST

Constant temperature aging device

The invention discloses a constant temperature aging device, comprising an aging frame, a temperature controlled probe, a relay, an electromagnetic valve, a cylinder and a PTC (Positive Temperature Coefficient) heater, wherein one side of the aging frame is provided with a door; one face of the aging frame is provided with an opening; the opening is convexly provided with sliding slots at the two sides on the outer wall of the aging frame; plugboards are inserted into the sliding slots; the temperature controlled probe is arranged in the aging frame to detect the environmental temperature in the aging frame; the relay is connected with the temperature controlled probe so as to obtain the environmental temperature detected by the temperature controlled probe and compare the environmental temperature with a preset temperature; the electromagnetic valve is connected with the relay and controlled by the relay; the cylinder is connected with the electromagnetic valve and is controlled by the electromagnetic valve; the PTC heater is arranged at a place where the aging frame is closed to the bottom and connected with the relay; and when the environmental temperature in the aging frame is less than the preset temperature, the PTC heater is started to heat so as to provide an accurate testing environment. The articles to be tested are uniformly heated to avoid baking.

Owner:SHENXUN COMP KUNSHAN

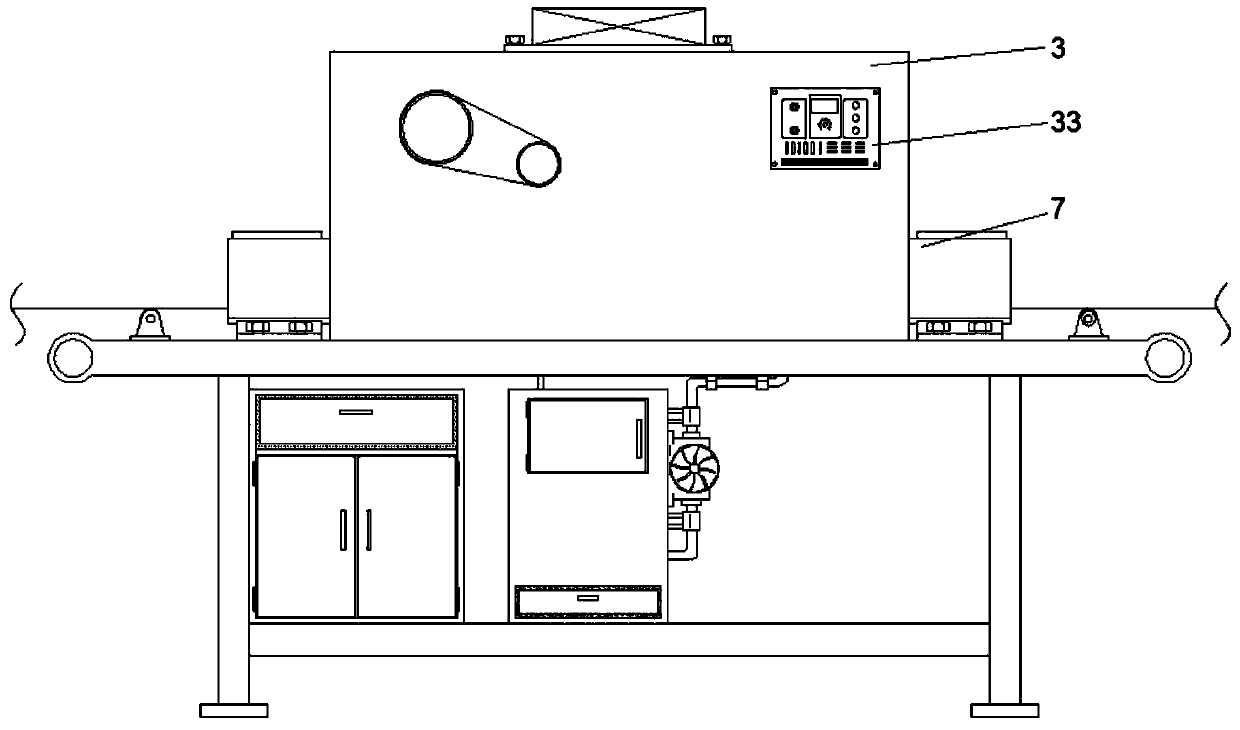

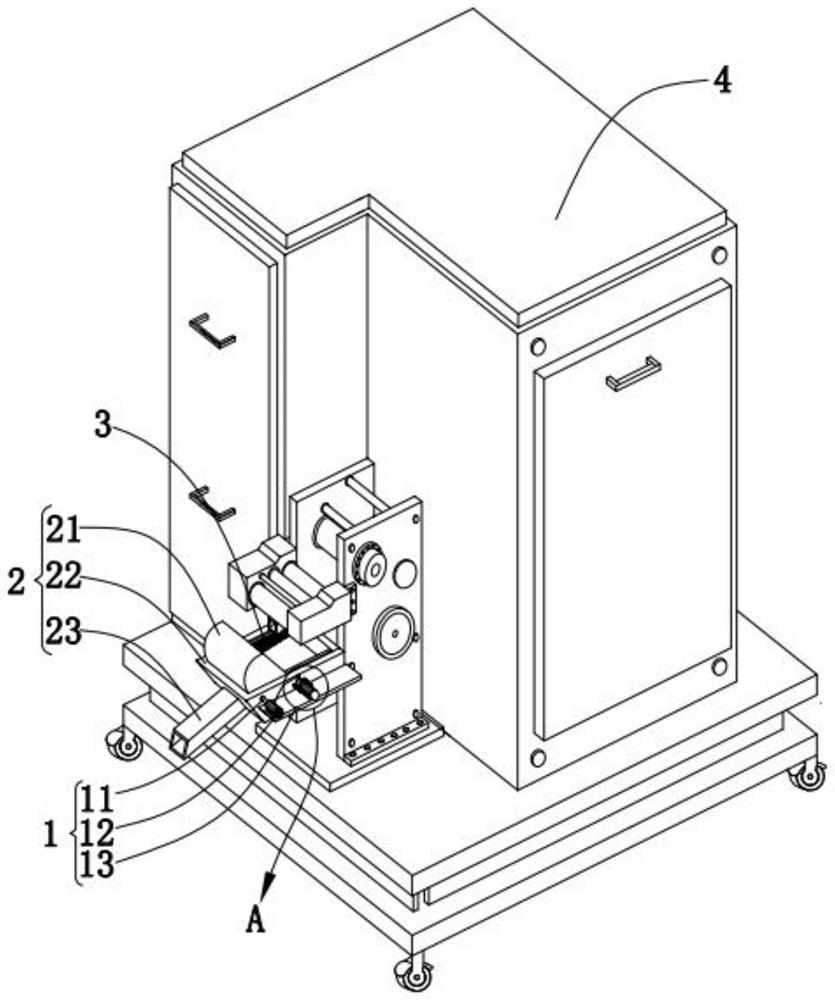

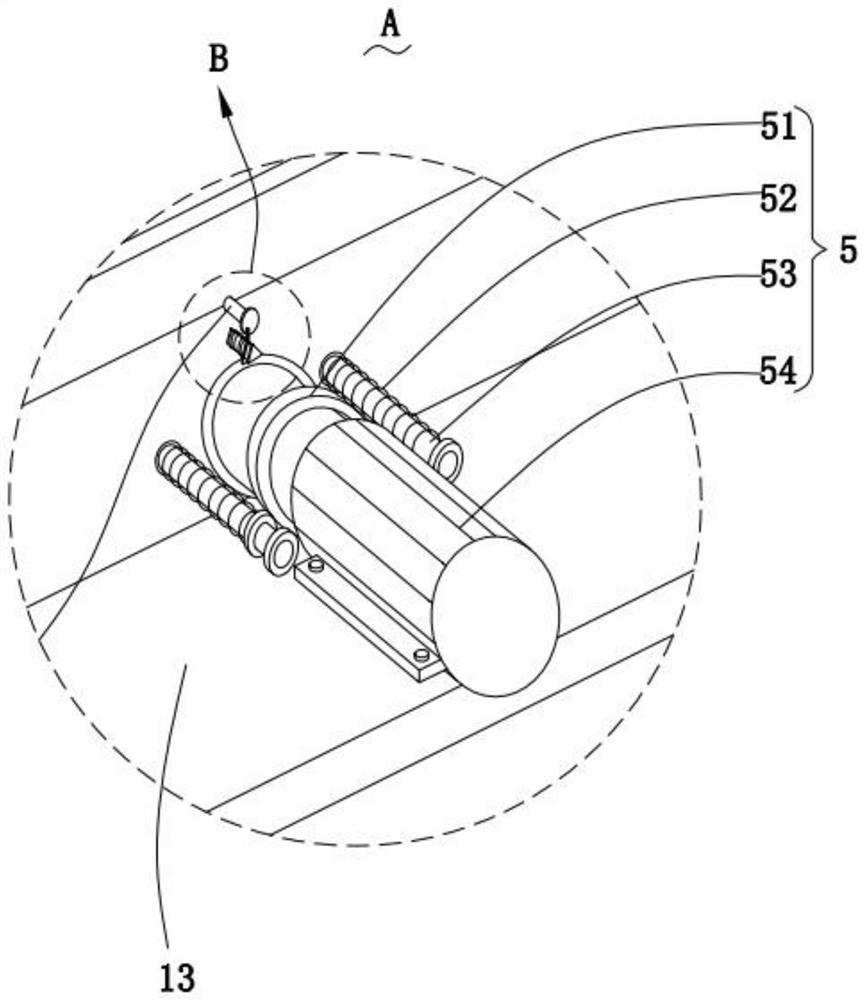

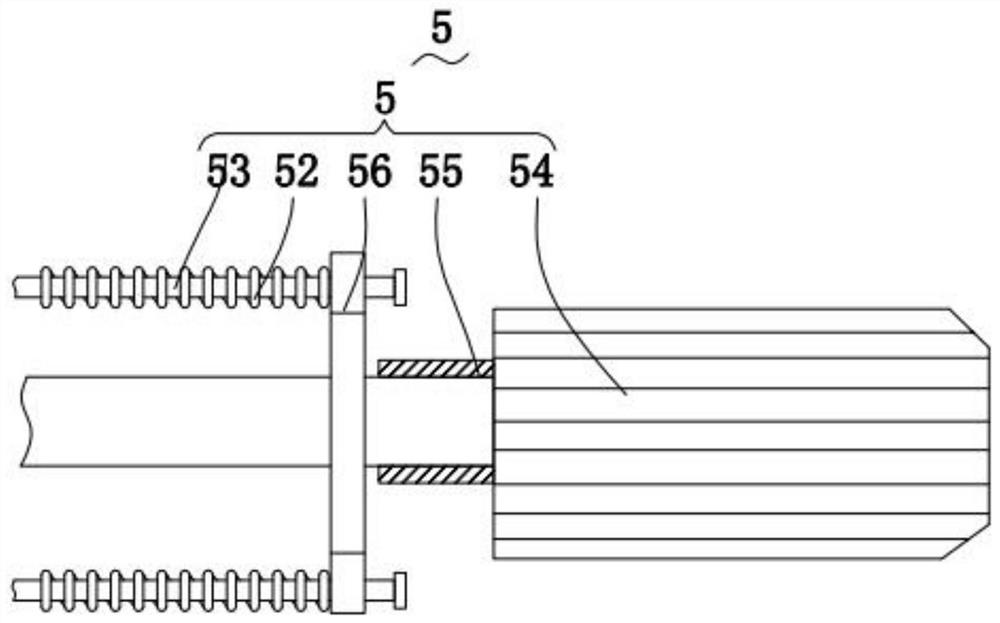

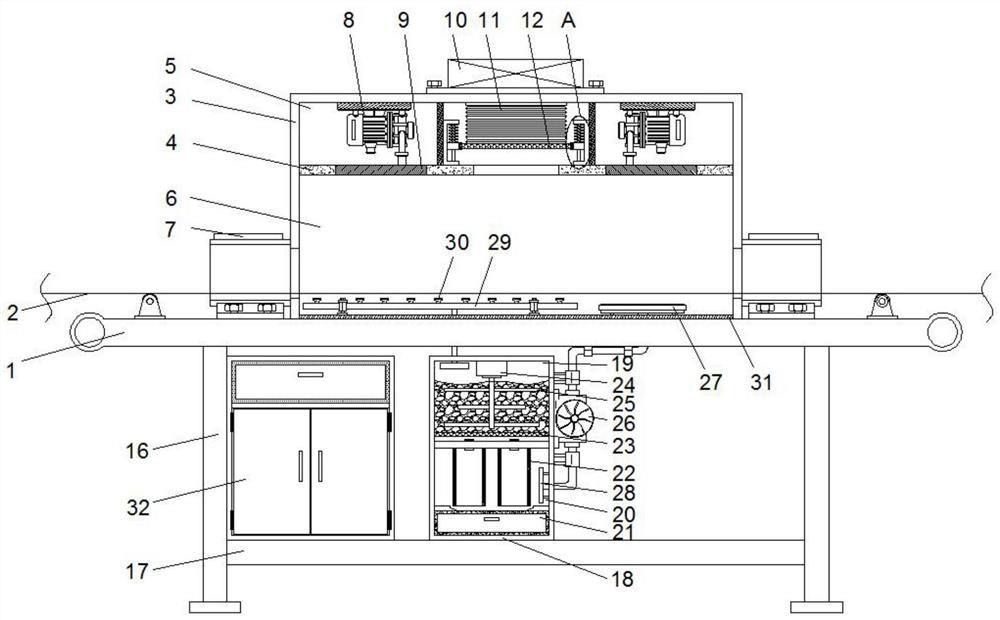

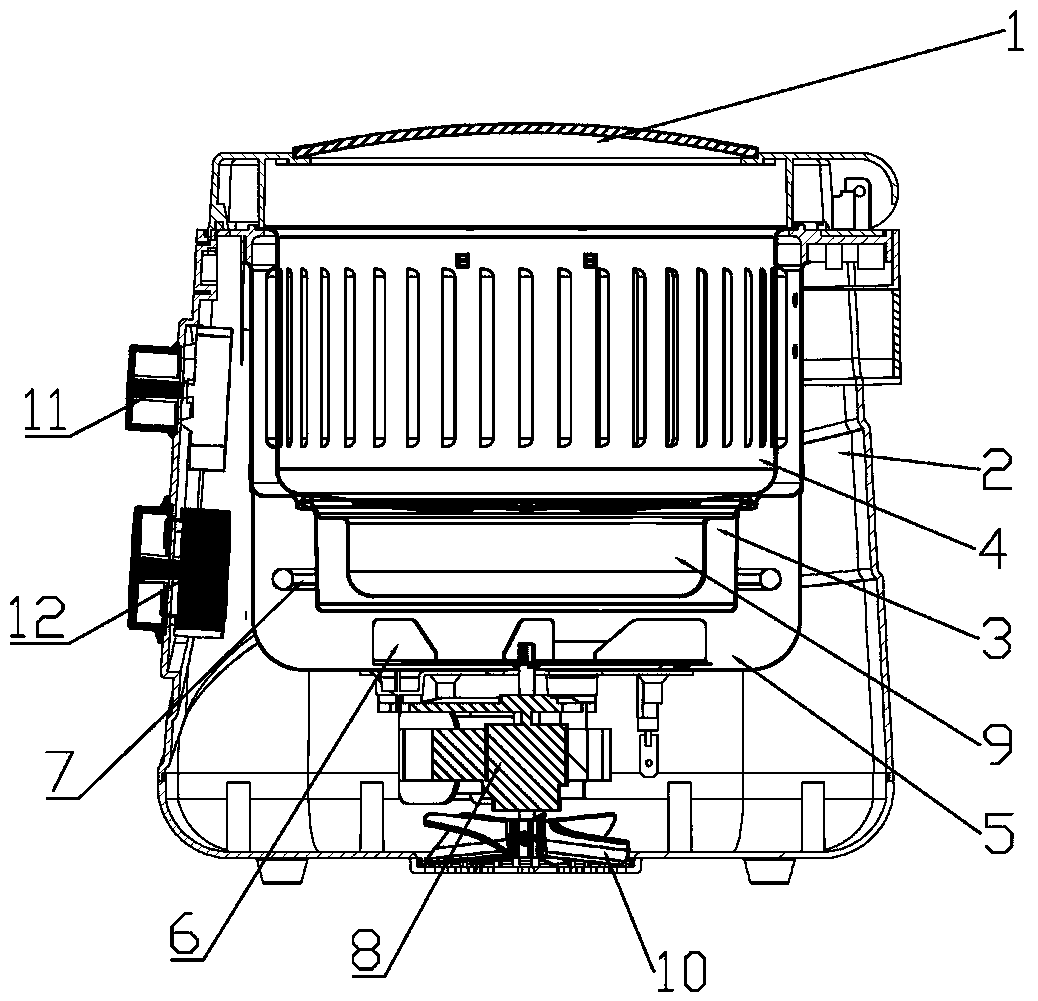

A special offset printing machine for bottle caps

ActiveCN109435433BAvoid scratchesHeating evenlyOther printing apparatusLithographyElectric machineEngineering

The invention relates to the field of offset presses, in particular to an offset press special for a bottle cap. The offset press special for the bottle cap comprises an overturning mechanism, a collecting mechanism, heating plates, a machine body, two driving mechanisms and a power supply communicating mechanism. The heating plates fixed to one end of an electric push rod are connected to the interior of a collecting hopper in a relatively sliding manner. By means of the electric push rod, uniform heating of the bottle cap inside the collecting hopper is realized, and scratches of handwritingand icons on the bottle cap are avoided. While the electric push rod moves, a pushing column makes contact with a butting ring, so that electrical connection between a copper sheet and a copper column can be realized, a motor is powered on to stir the bottle cap inside the collecting hopper, and the bottle cap is prevented from blocking a discharging pipe. A fan blade with an arc-shaped structureat one end can prevent the bottle cap from being scratched. Therefore, the bottle cap can be heated by the heating plates and be turned over. Through the contraction of the electric push rod, the copper sheet and the copper column can be powered off, and the heating plates can move oppositely to prevent the bottle cap from being over baked.

Owner:六安志成智能科技有限公司

A microwave hot air drying device for corrugated base paper for carton production

ActiveCN109631554BImprove cleanlinessAvoid contaminationDrying solid materials with heatDrying gas arrangementsThermodynamicsCarton

The invention discloses a microwave hot air drying device for corrugated base paper used in carton production, which comprises a workbench, a protective shell is fixedly installed on the workbench, and microwave suppression is installed on the feeding port and the discharging port of the protective shell. The interior of the protective shell is divided into an installation room and a drying room arranged up and down through a horizontal partition. The inner top wall of the installation room is fixedly installed with two symmetrically distributed microwave generators. The output of the microwave generator The end communicates with the drying chamber through a waveguide. The invention has the following beneficial effects: temperature data collection can be quickly realized, information security can be effectively guaranteed through the front-end server, the temperature of the drying chamber can be monitored in real time, and the minimum output power that can meet the cooling requirement can be obtained by comparing it with the preset temperature , avoiding the paper being damaged by excessive temperature.

Owner:宁波索思机械设计有限公司

Digital Quantitative Electric Heating Furnace and Its Realization Method

InactiveCN104089312BReduce the temperatureImprove reliabilityDomestic stoves or rangesLighting and heating apparatusControl circuitCooking process

Owner:深圳市康丽达实业有限公司

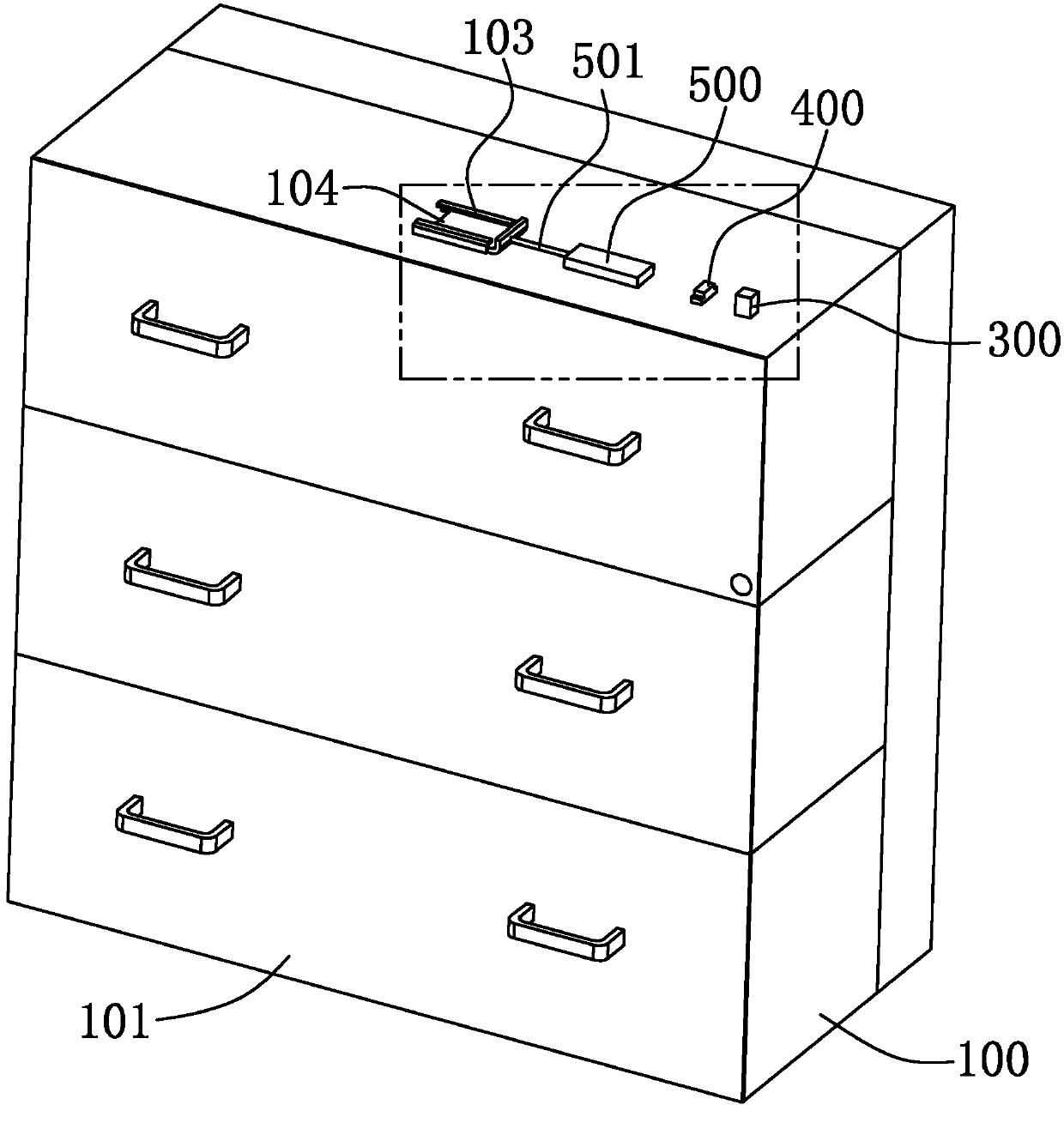

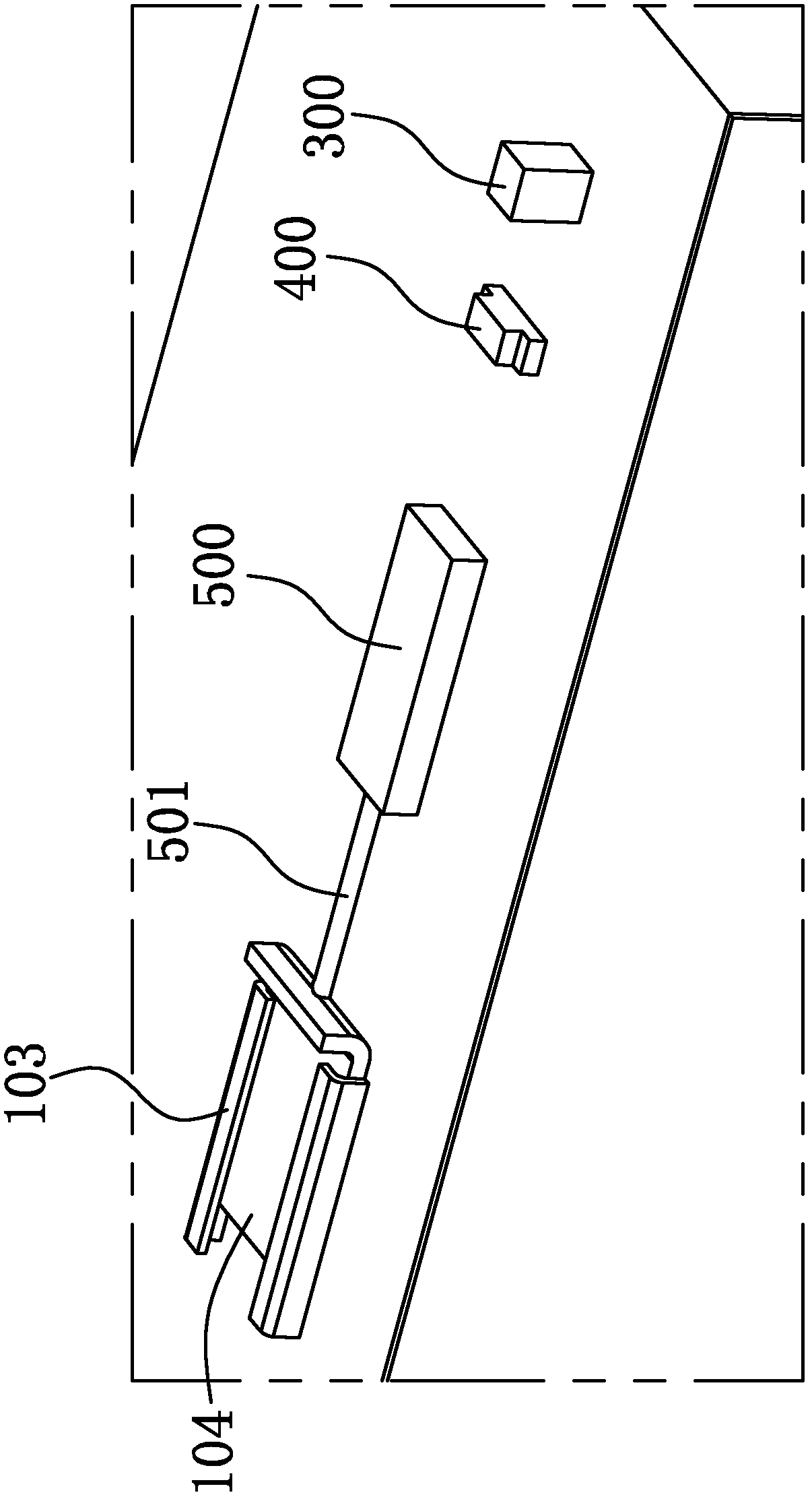

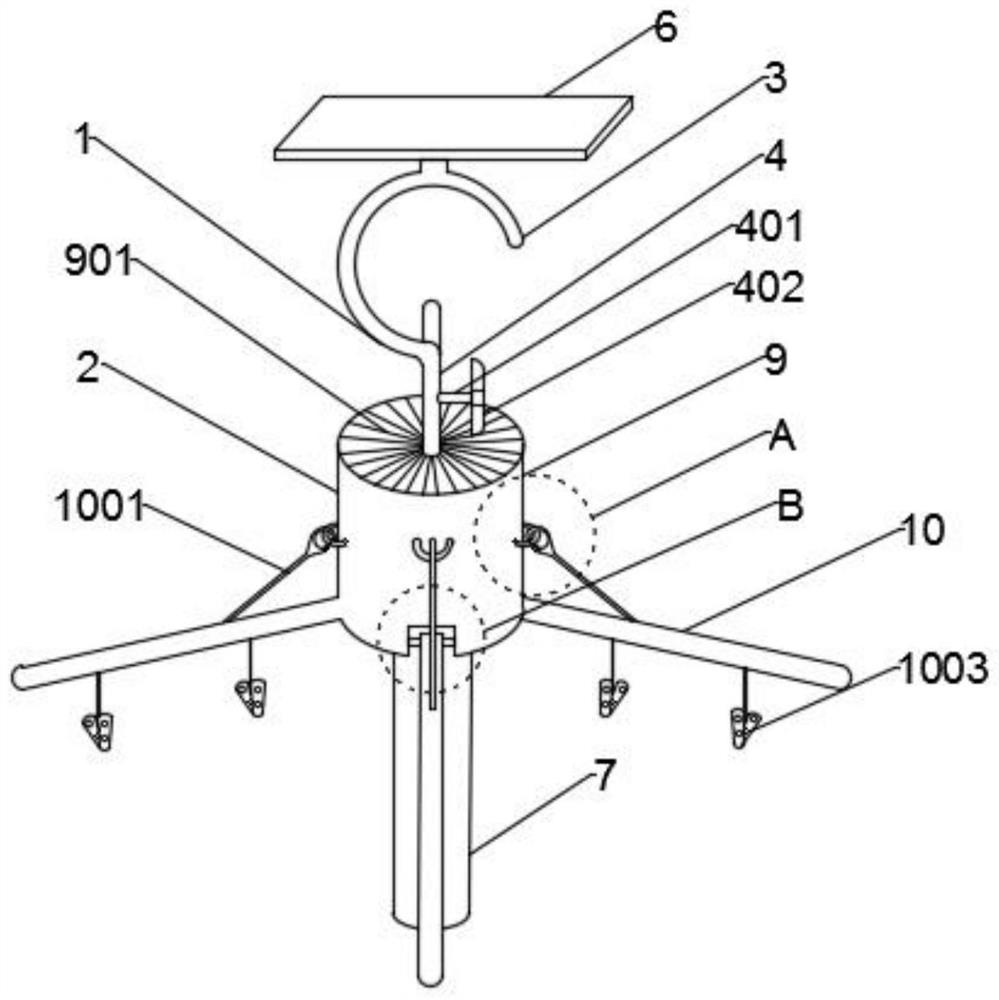

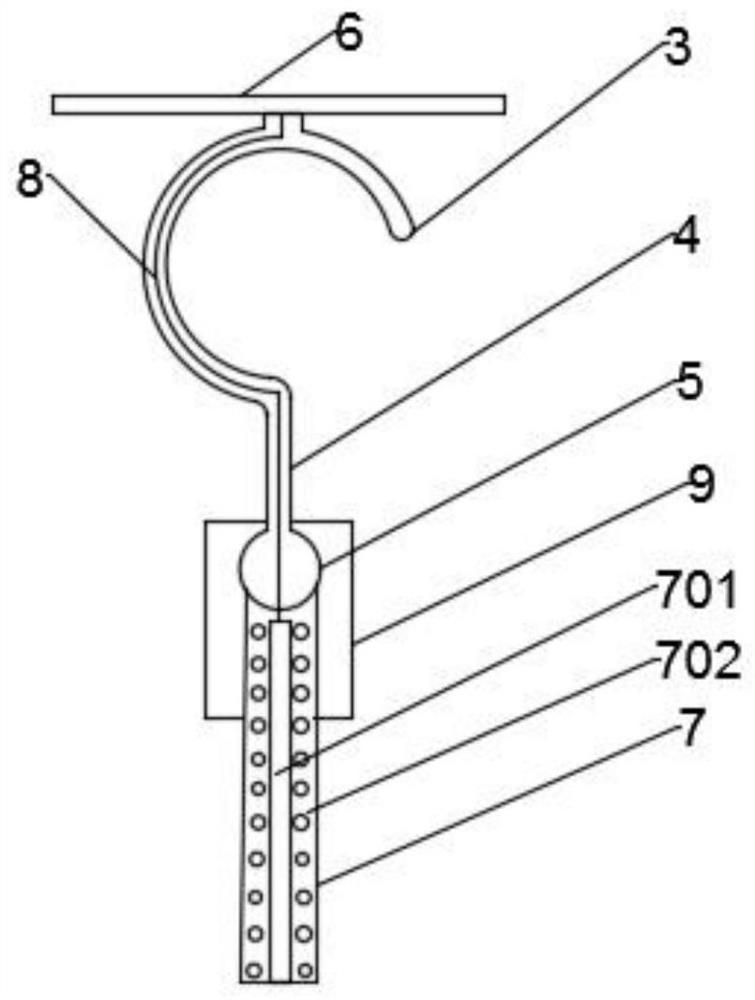

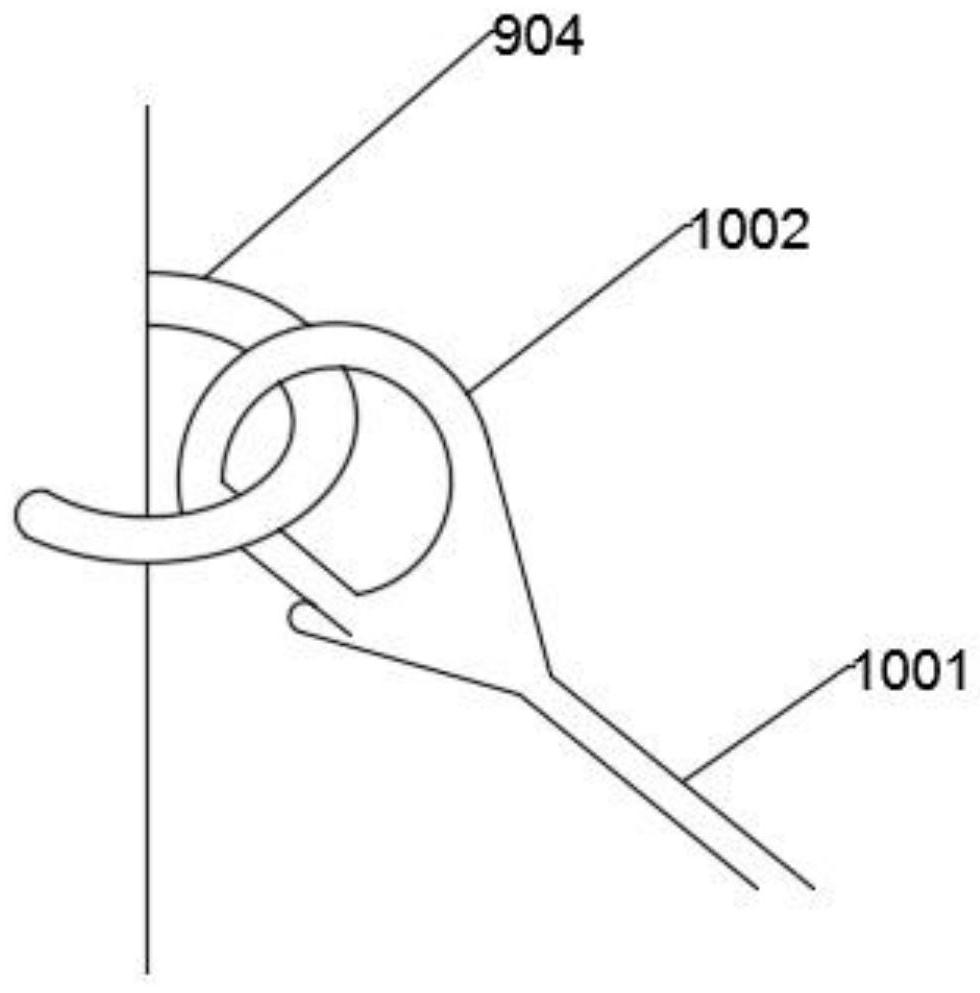

Drying device for metal material processing

PendingCN112902582ADry evenlyAvoid roastingBatteries circuit arrangementsDrying gas arrangementsElectric energyMetallic materials

The invention discloses a drying device for metal material processing. The drying device for metal material processing comprises a hook device and a suspension body, wherein the lower end of the hook device is rotatably connected with the suspension body, the upper end of the hook device is connected with a solar power storage device, a downward heating device is connected to the lower end of the hook device, a cavity is formed in the hook device, a power line is arranged in the cavity, the heating device is electrically connected with the solar power storage device through the power line, and the suspension body comprises a rotatable rotating shaft and supporting frames connected with the rotating shaft. By using the drying device for metal material processing, solar energy can be converted to electric energy to be stored through a solar storage battery during sun irradiation, the electric energy in the storage battery can be released to start the heating device in cloudy and rainy days, devices can be rapidly dried, and energy is saved.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD

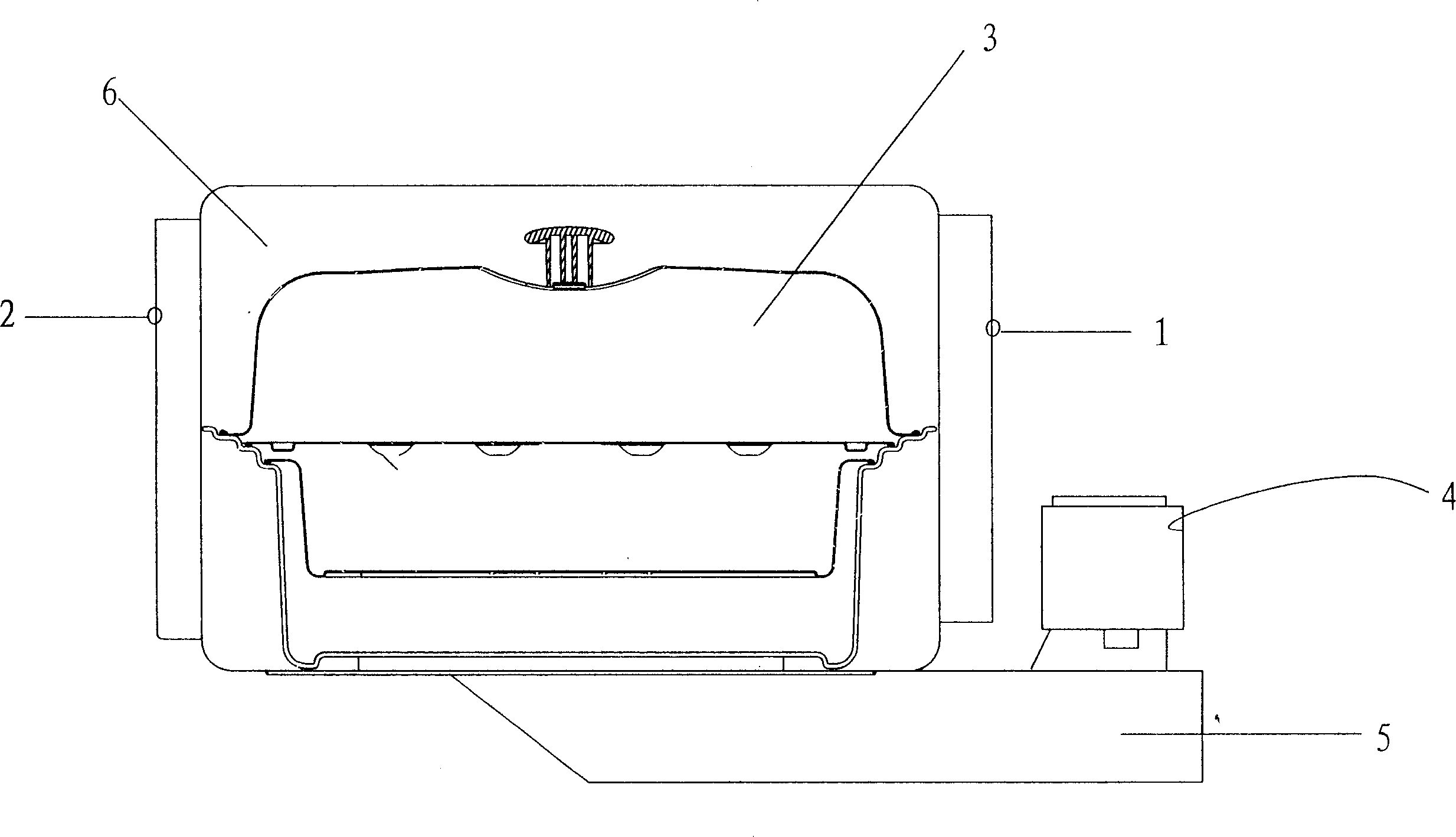

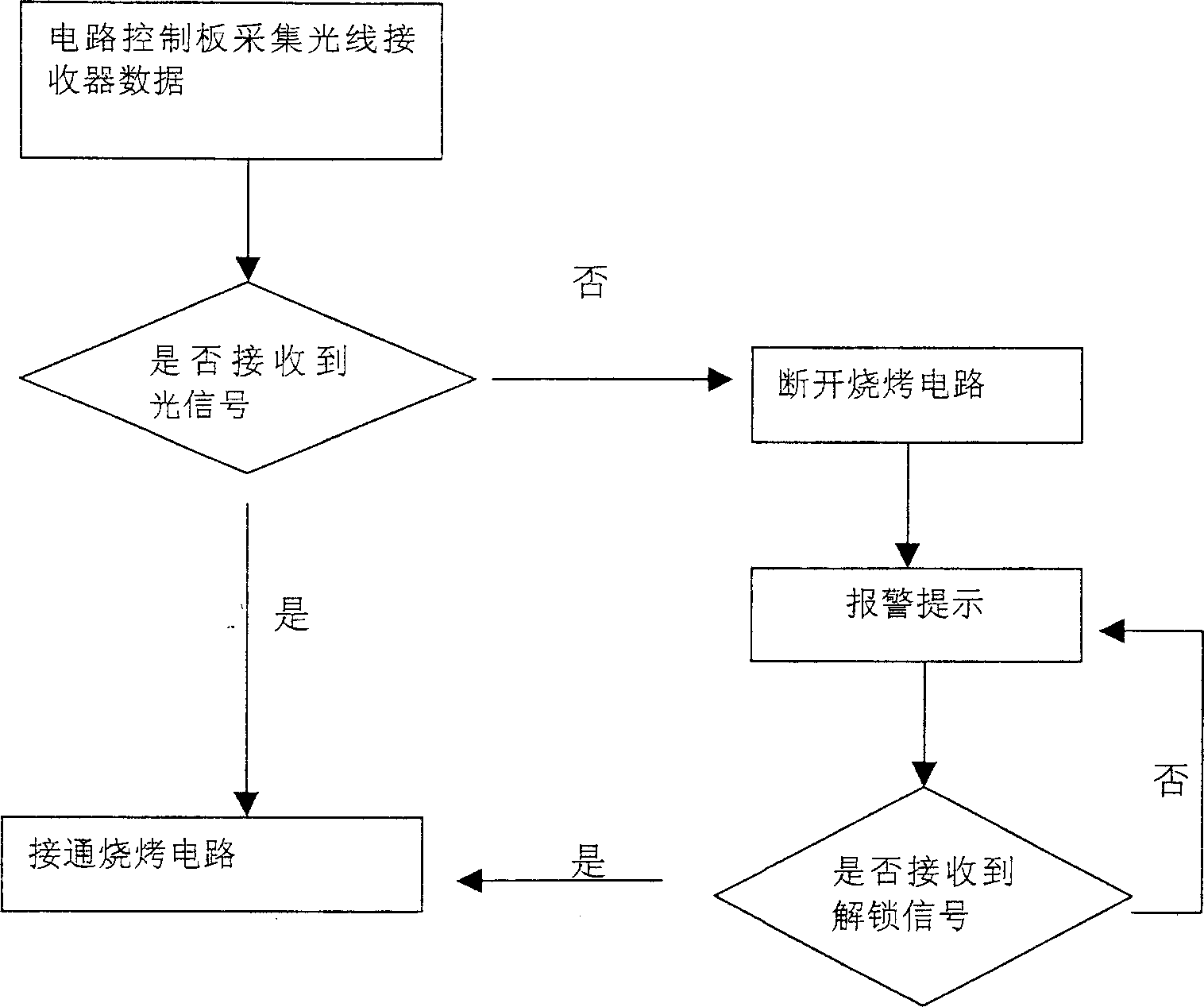

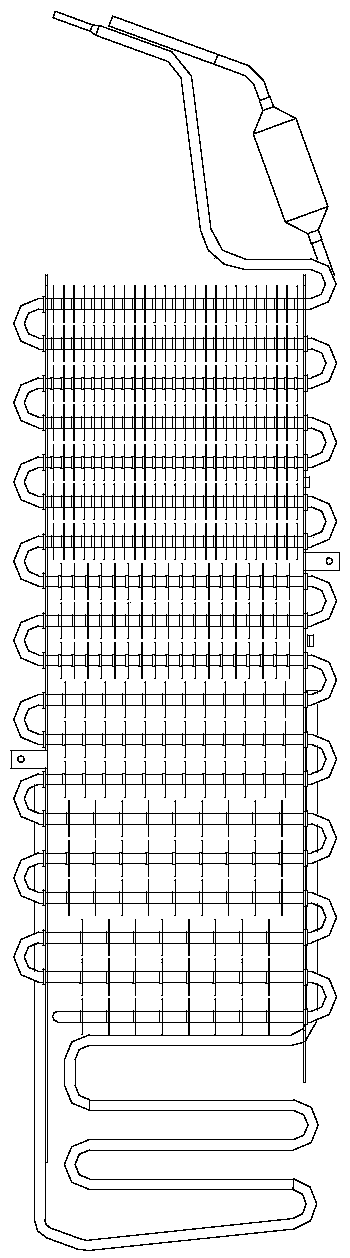

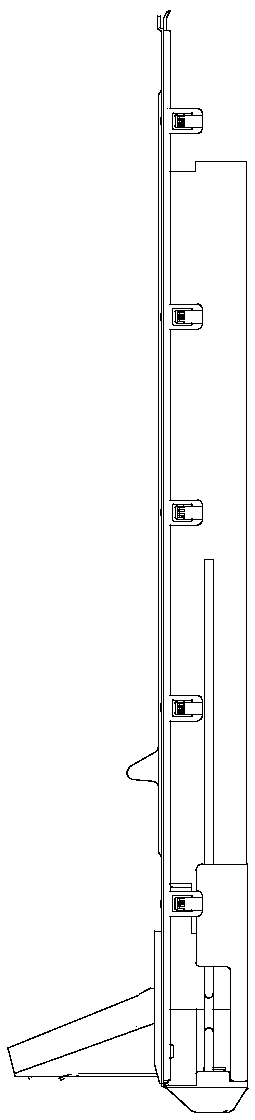

Microwave oven capable of preventing mistaken operation of roasting function

InactiveCN1884922AAvoid roastingDomestic stoves or rangesLighting and heating apparatusMicrowave ovenLight signal

The invention relates to a microwave oven which can avoid error operation of barbecue function, wherein one side wall of furnace chamber is arranged with one light generator; another side wall of furnace chamber has one light receiver for transmitting signal to the circuit control board; when the light receiver can receive the light of light generator, the circuit control board will connect the barbecue function circuit; when the boiling container is arranged inside the furnace chamber, the light is blocked, to make light receiver not receive light signal, to cutoff the barbecue function circuit; therefore, even the barbecue function key is pressed, the barbecue function will not be turned on.

Owner:HAIER GRP CORP +1

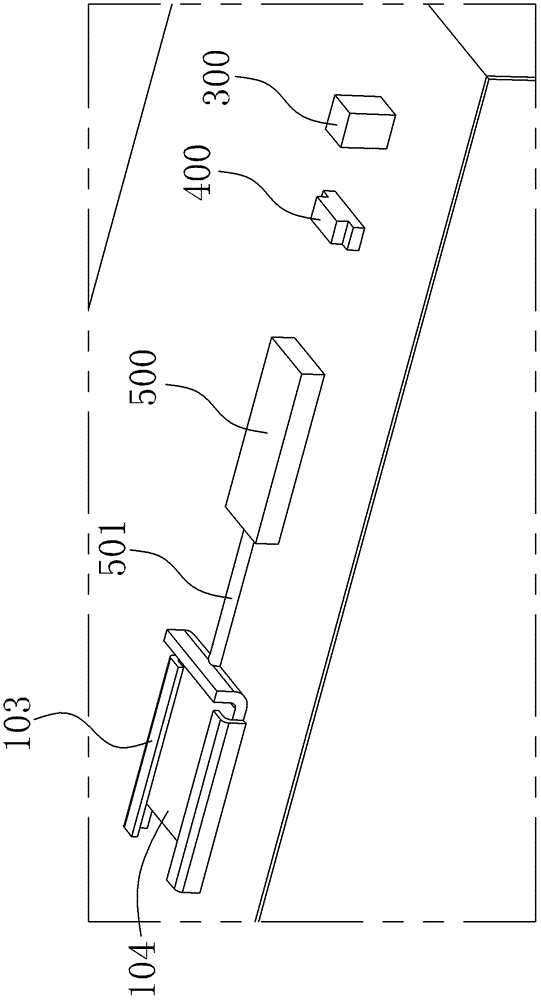

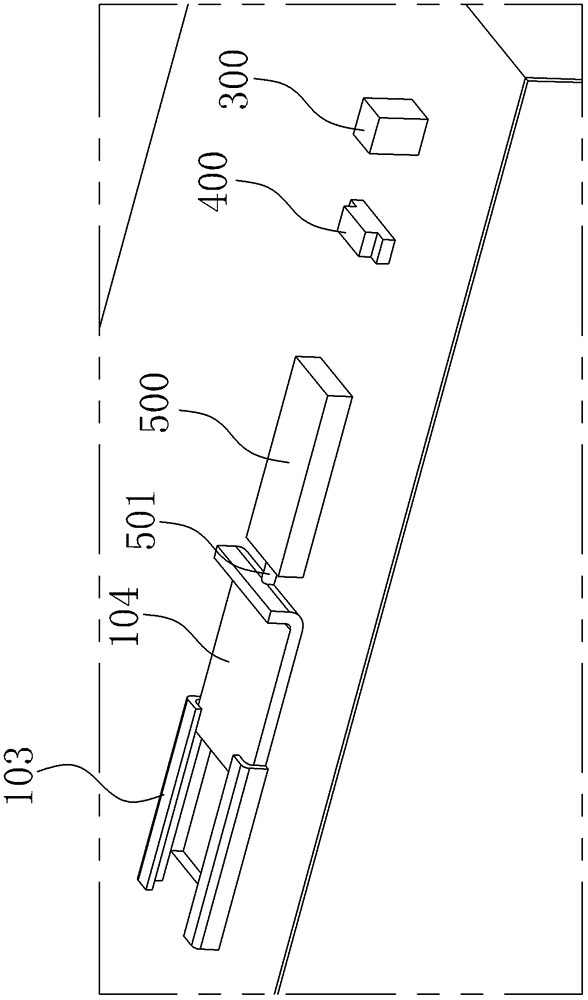

Air duct assembly and refrigerating device

InactiveCN108826803AIncrease temperatureReduce the temperatureLighting and heating apparatusInsulation for cooling apparatusThermal insulationEngineering

The invention provides an air duct assembly and a refrigerating device. The air duct assembly comprises an air duct, an evaporator, a heating part and a thermal insulation part. The evaporator is arranged in the air duct; the heating part is arranged in the air duct; the thermal insulation part comprises a compound thermal insulating layer which comprises a thermal insulating part and a radiationreflecting part, the thermal insulating part is attached to the inner wall face of the air duct, and the radiation reflecting part is arranged on the thermal insulating part and is located on the sideclose to the heating part. According to the air duct assembly provided by the invention, as the compound thermal insulating layer comprising the thermal insulating part and the radiation reflecting part is arranged on the inner wall face of the air duct to protect the air duct, the reflectivity to heat of an infrared part is improved effectively, and the temperature of the air duct is reduced effectively, so that the air duct is prevented from being roasted and melted and damaged.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

Efficient welding die for chip production

PendingCN112894226AAvoid damageRapid positioningWelding/cutting auxillary devicesAuxillary welding devicesElectrical and Electronics engineeringTouchscreen

The invention discloses an efficient welding die for chip production, which comprises a base table, columns are fixedly connected to the left side and the right side of the lower end of the base table, reinforcing mechanisms are arranged at the lower ends of the columns, a touch screen is fixedly connected to the front face of the base table, and a PLC is fixedly connected to the lower end of the base table; a die main body is fixedly connected to the upper end of the base table, a positioning plate is fixedly connected to the upper end of the die main body, mounting grooves are formed in the left side and the right side of the upper end of the die main body, transmission mechanisms are arranged on the inner sides of the mounting grooves, and telescopic mechanisms are fixedly connected to the upper ends of the transmission mechanisms; and sliding grooves are formed in the left side and the right side of the upper end of the die main body correspondingly, and the upper end of the die main body is slidably connected with linkage mechanisms through the sliding grooves. Water is fed through a water guide plate and a water inlet cavity, water is discharged through a sealing plate with a through holes in the filter box, and filtering is conducted through a screen, so that impurities generated in the cooling process can be reduced, and the situation that the heat dissipation effect of the die main body is affected due to pipeline blockage is avoided.

Owner:张斌

A drying method in corrugated paper production process

ActiveCN109577065BReduce shockPlay a role of buffer protectionCombination devicesGas treatmentMicrowaveAir volume

Owner:恒达包装制品(龙南)有限公司

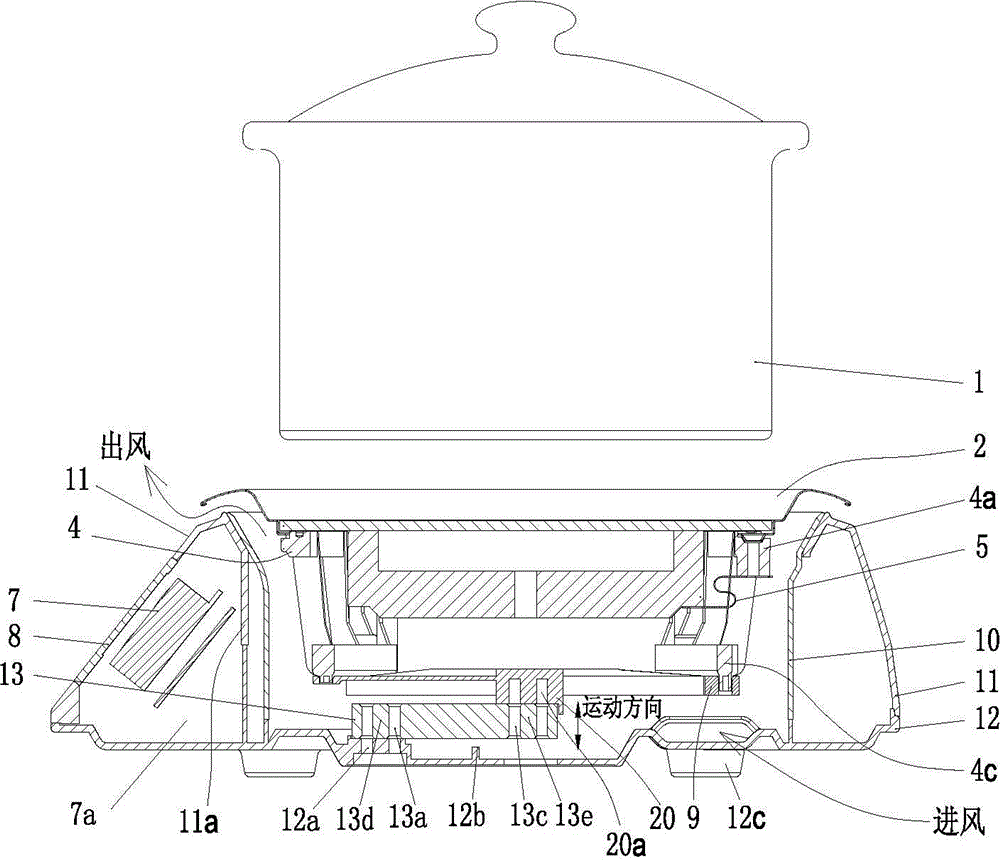

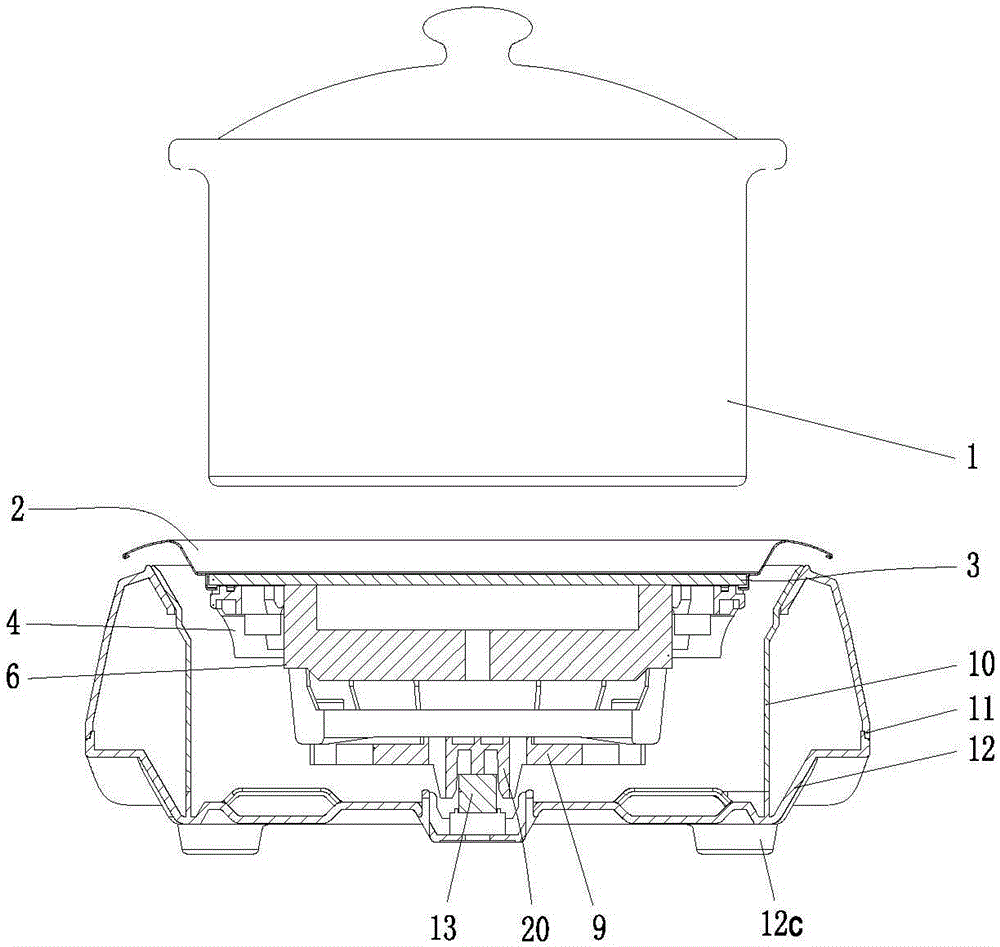

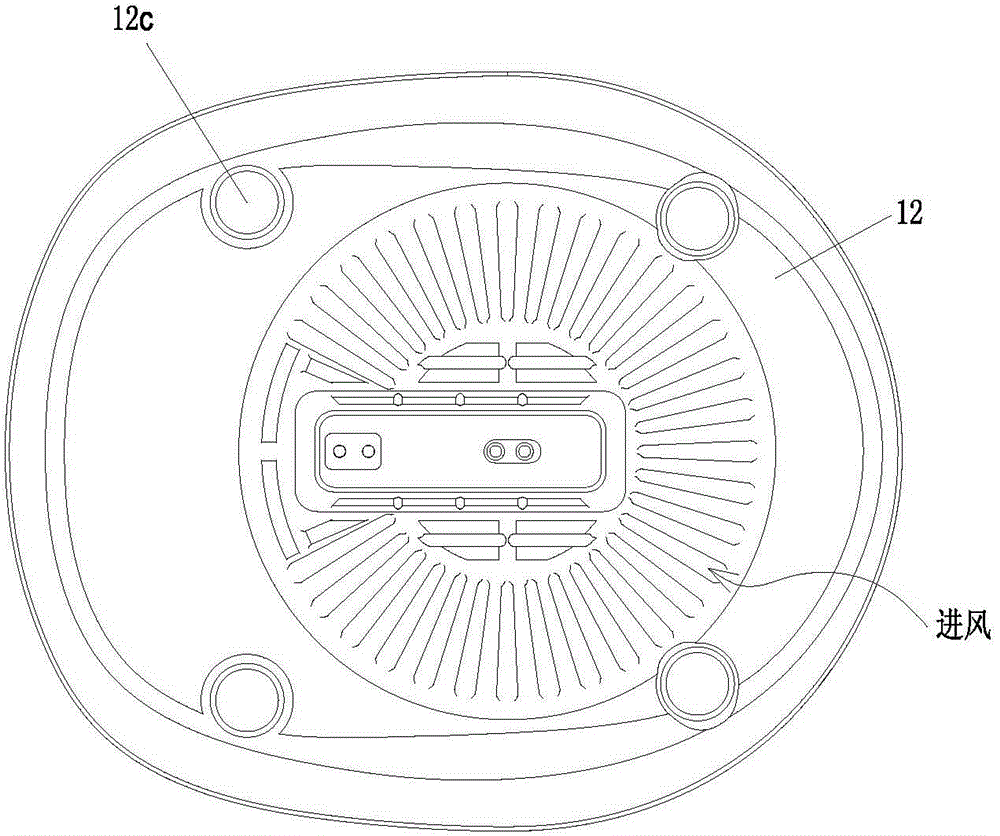

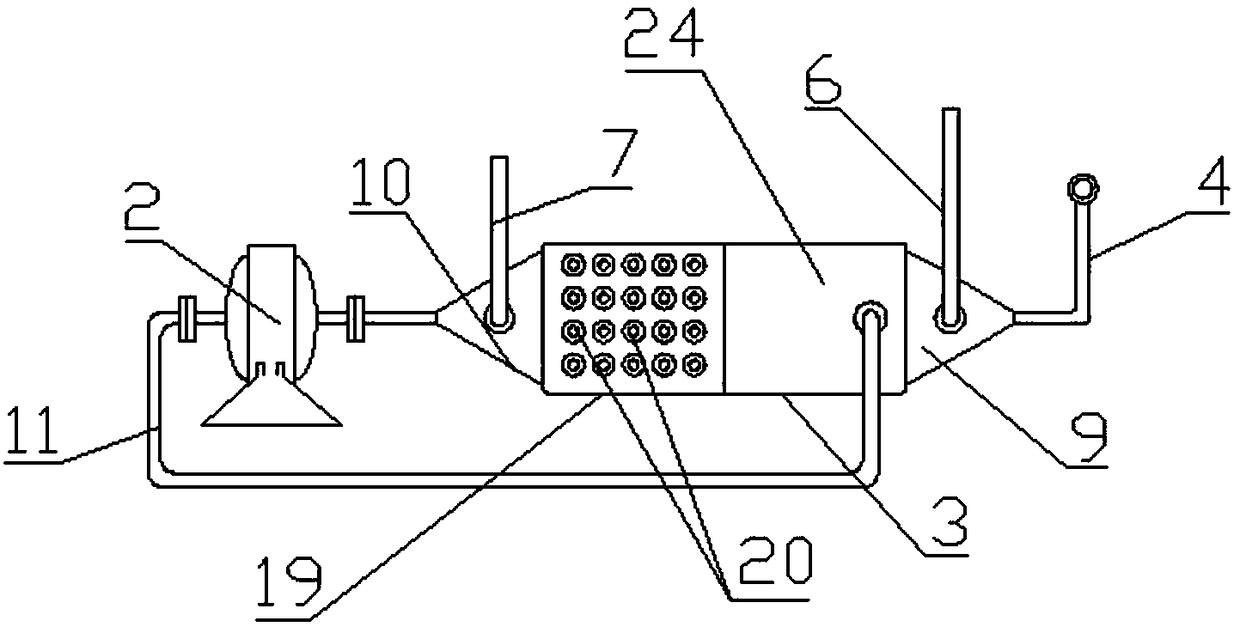

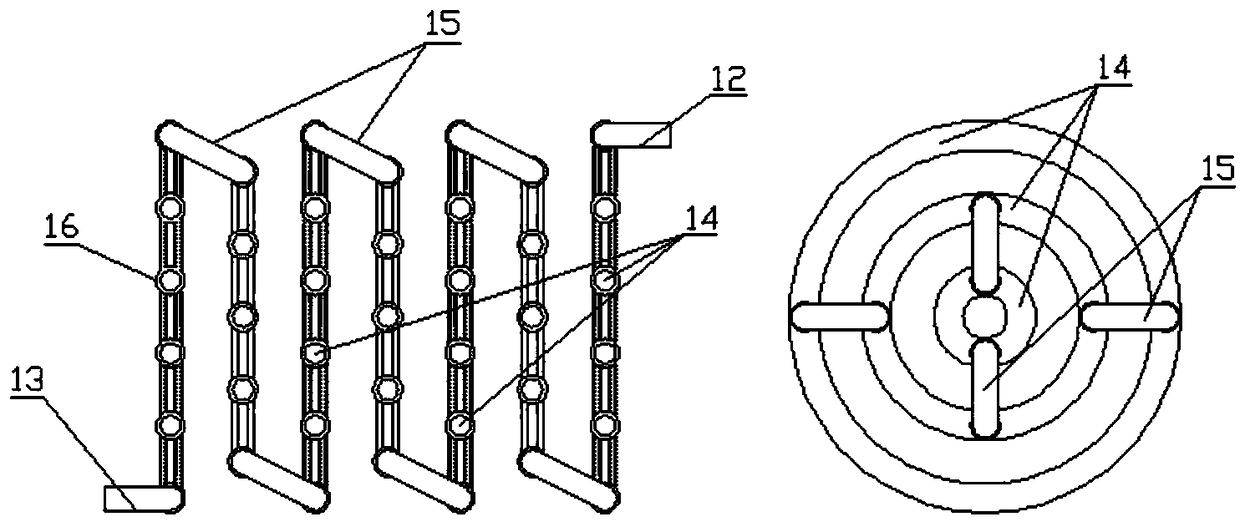

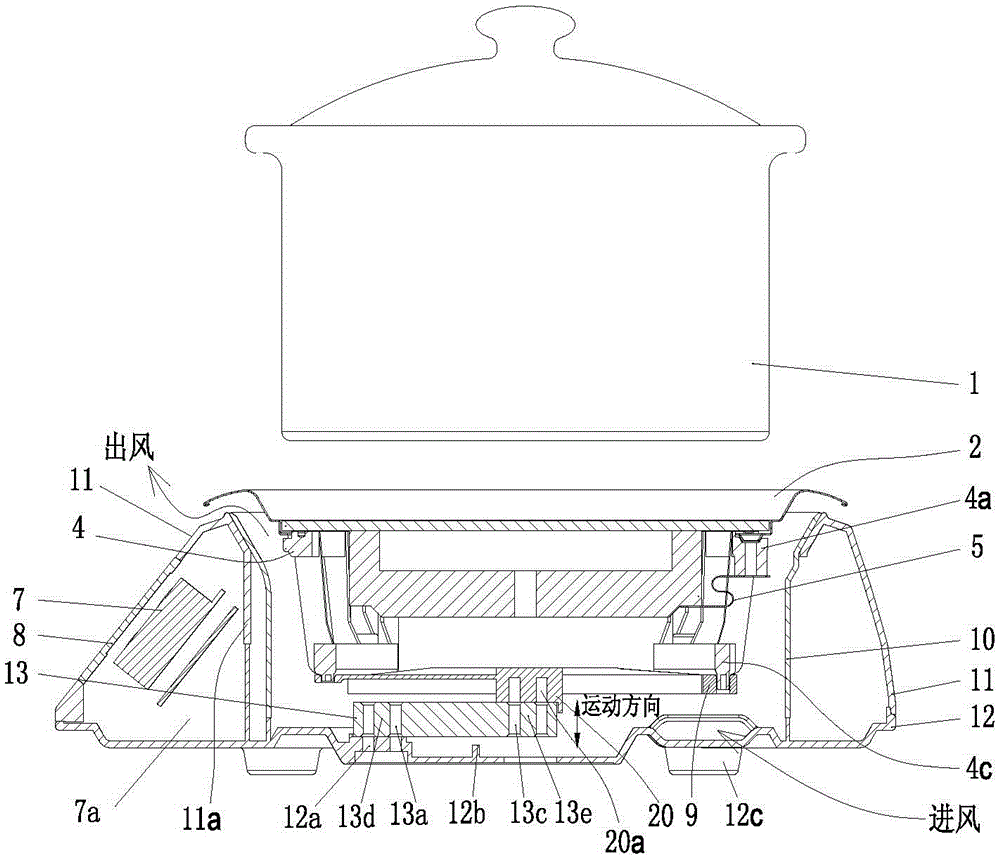

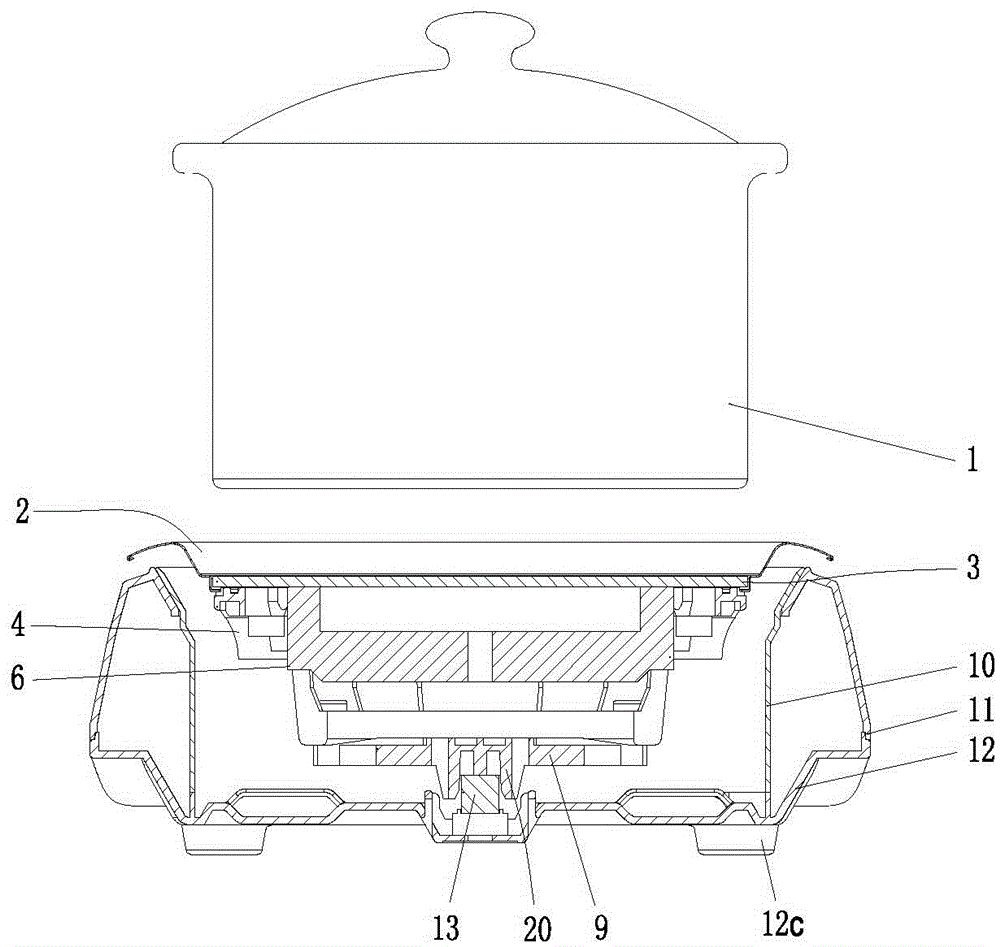

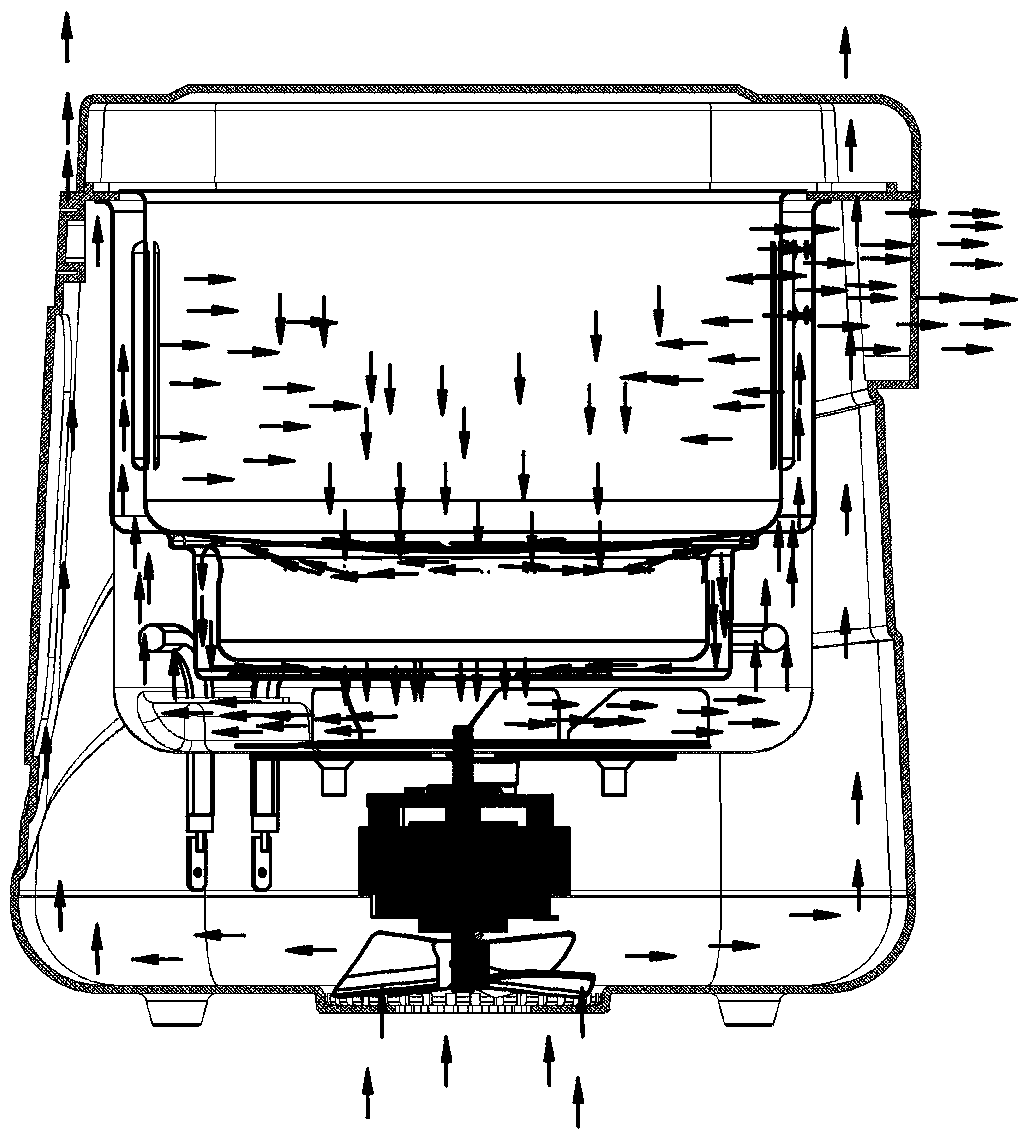

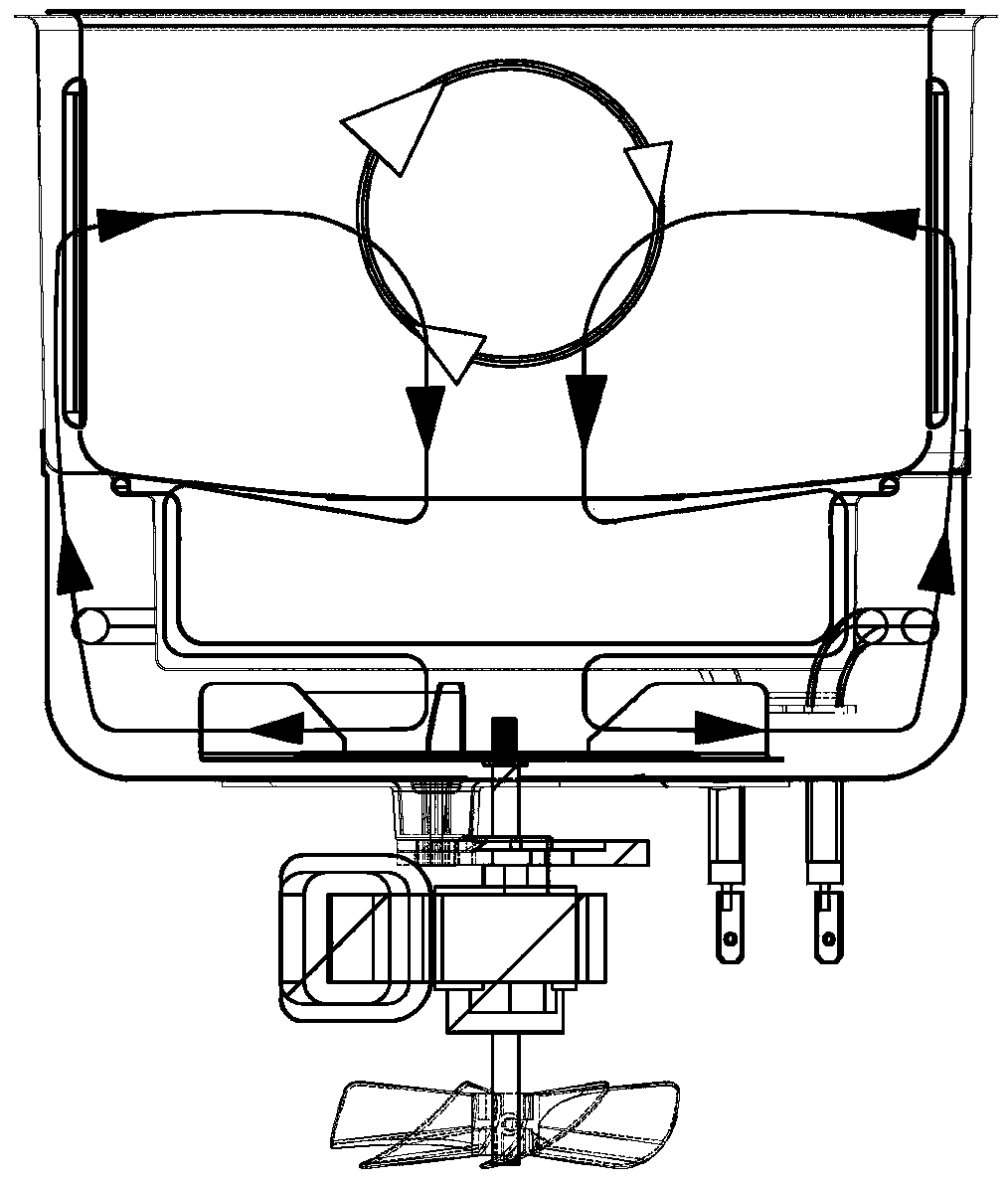

New air fryer

The invention provides a new air fryer which comprises a top cover, a body, and an outer pot, an inner pot and a heating tube cover in the body. The outer pot is arranged on the heating tube cover. Acentrifugal fan is arranged in the heating tube cover at the bottom of the outer pot. A heating tube surrounds the bottom of the outer pot and is arranged above the centrifugal fan. The centrifugal fan is connected to a motor shaft. An oil receiving box is arranged at the bottom of the inner pot. A gap is formed between the oil receiving box and the outer pot. An air outlet hole is formed at an upper part of the oil receiving box. An emission-shaped multi-ring-layer ventilating hole is arranged at the bottom of the outer pot. An air vent is arranged on an edge of the outer pot close to the bottom of the inner port. An exhaust hole is arranged at an upper part of the outer port. A wind window is arranged at a side wall of the inner pot. An emission-shaped multi-ring-layer ventilating hole is arranged at the bottom of the inner port. The ventilating hole at the bottom of the outer port and the air vent on the edge thereof, the wind window at the side wall of the inner port and the ventilating hole at the bottom thereof as well as the exhaust hole at the upper part of the oil receiving box form an inner circulation of heat in a furnace chamber. The new air fryer has the advantages ofreasonable structural design, smooth air circulation, high efficiency in cooking, good effect in heat dissipation, controllable temperature and timing, and convenient cleaning.

Owner:浙江浙南电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com