Remote centralized monitoring system and method for tobacco flue-curing house

A technology of remote monitoring and centralized monitoring, which is applied in the monitoring field of flue-cured rooms, which can solve the problems of not being able to understand the operation status of the curing rooms, the condition of tobacco leaf curing, management and monitoring, etc., and achieve the effects of scientific analysis, effective management and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

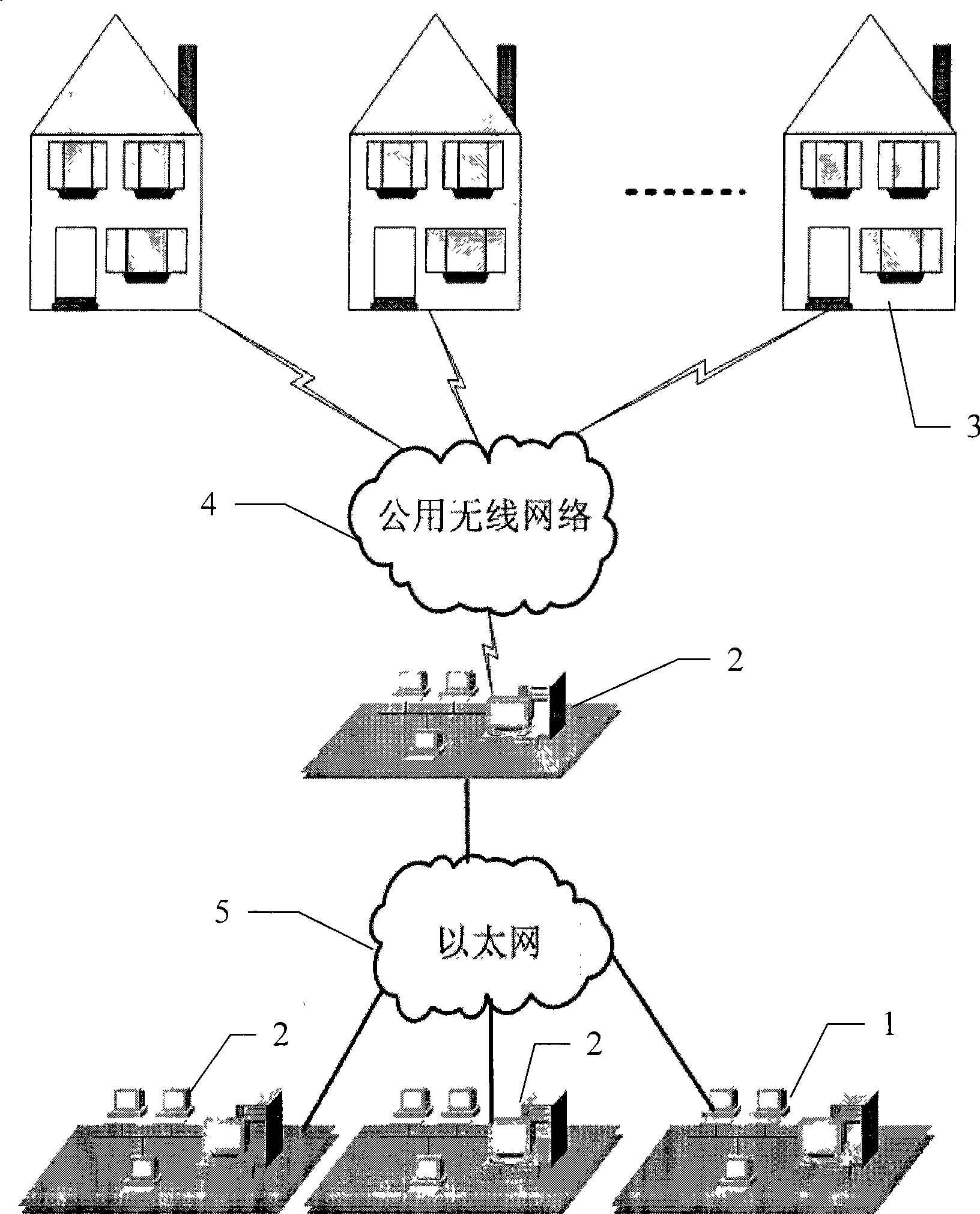

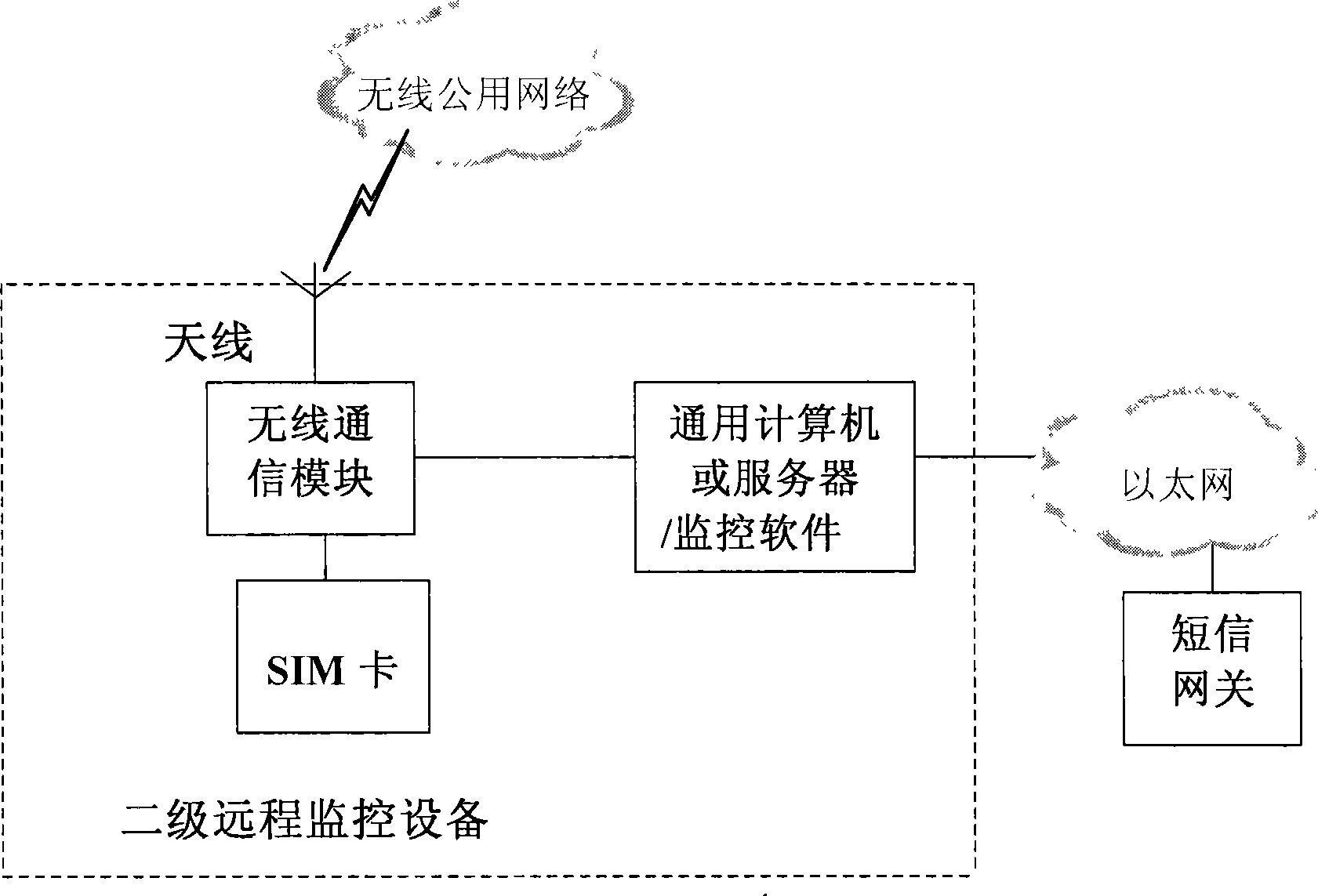

[0029] Such as figure 1 As shown, the remote centralized monitoring system of the flue-cured tobacco room includes a first-level remote monitoring equipment 1 (that is, a remote monitoring computer room installed in the national bureau), a number of secondary remote monitoring equipment 2 (that is, a remote monitoring computer room installed in each province, city or county) ) and the automatic flue-cured room controller 3 configured in each flue-cured room, the first-level remote monitoring device 1 and all the second-level remote monitoring devices 2 are networked through Ethernet 5, and each second-level remote monitoring device 2 and the automatic The tobacco curing room controller 3 communicates through a public wireless network 4 . Wherein, both the secondary remote monitoring equipment 2 and the automatic flue-cured room controller 3 are connected to the public wireless network 4 through the wireless communication module.

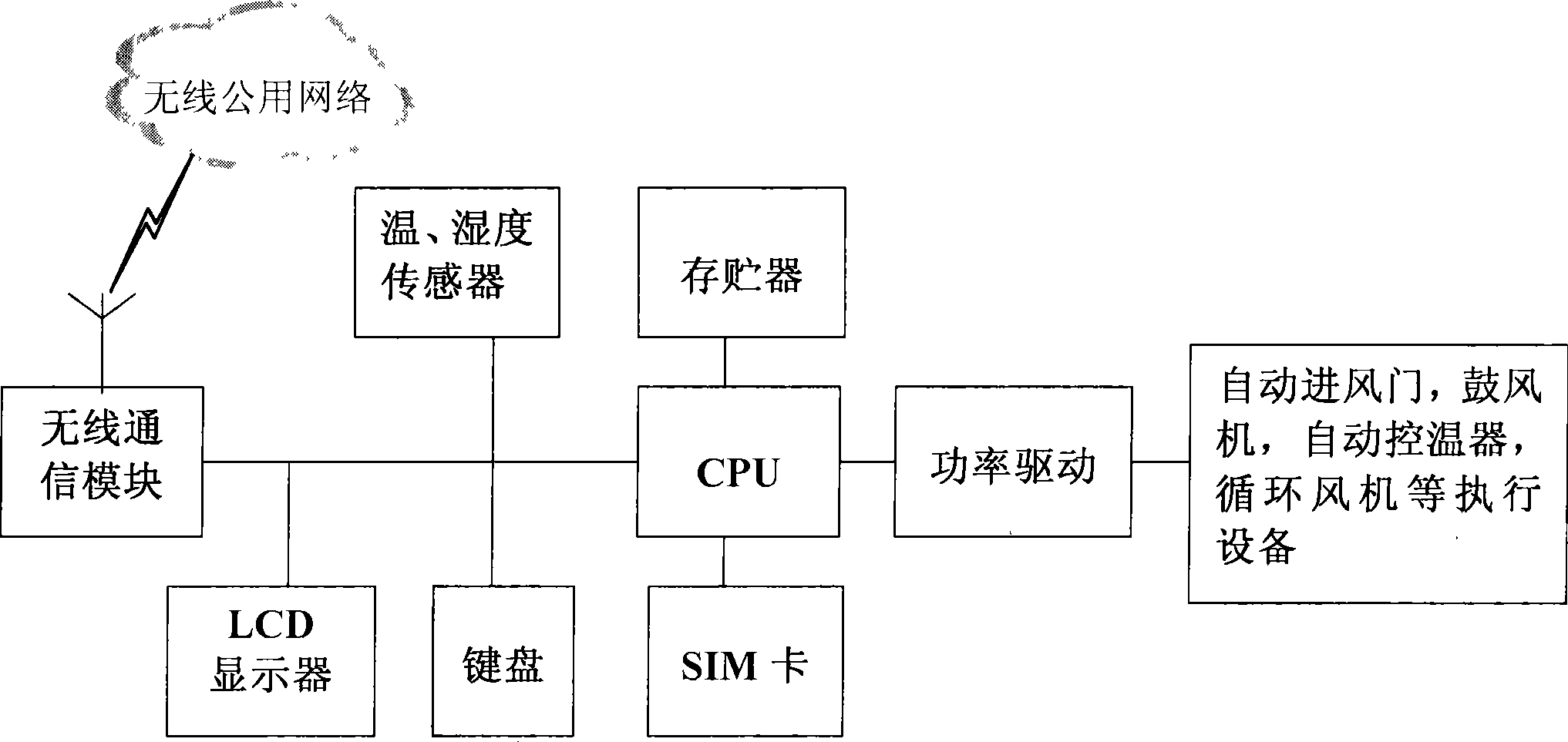

[0030] refer to figure 2 , the automatic to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com