New air fryer

An air fryer, a new type of technology, is applied in kitchen utensils, home utensils, roasters/barbecue grills, etc. It can solve the problems of destroying food nutrients, invisible frying process, and poor air circulation, so as to ensure hygiene Clean, efficient cooking, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

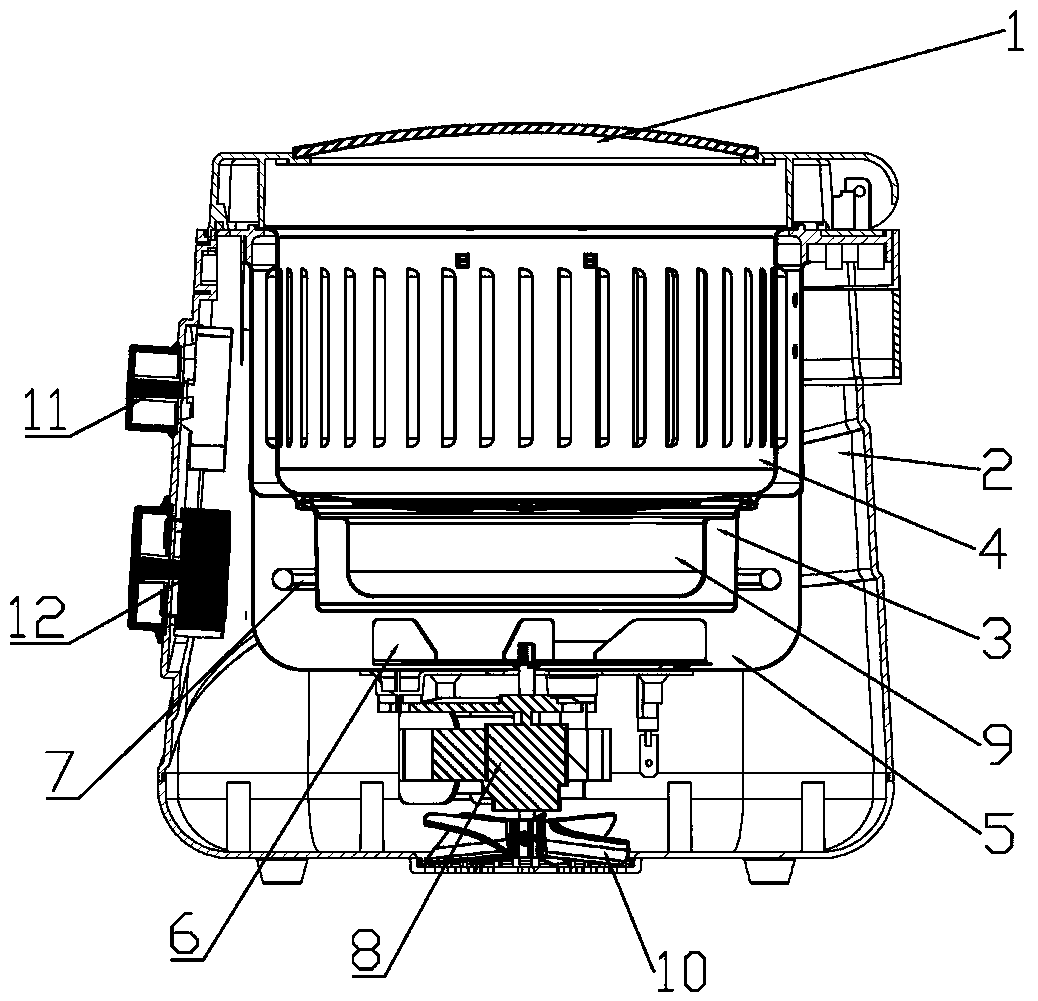

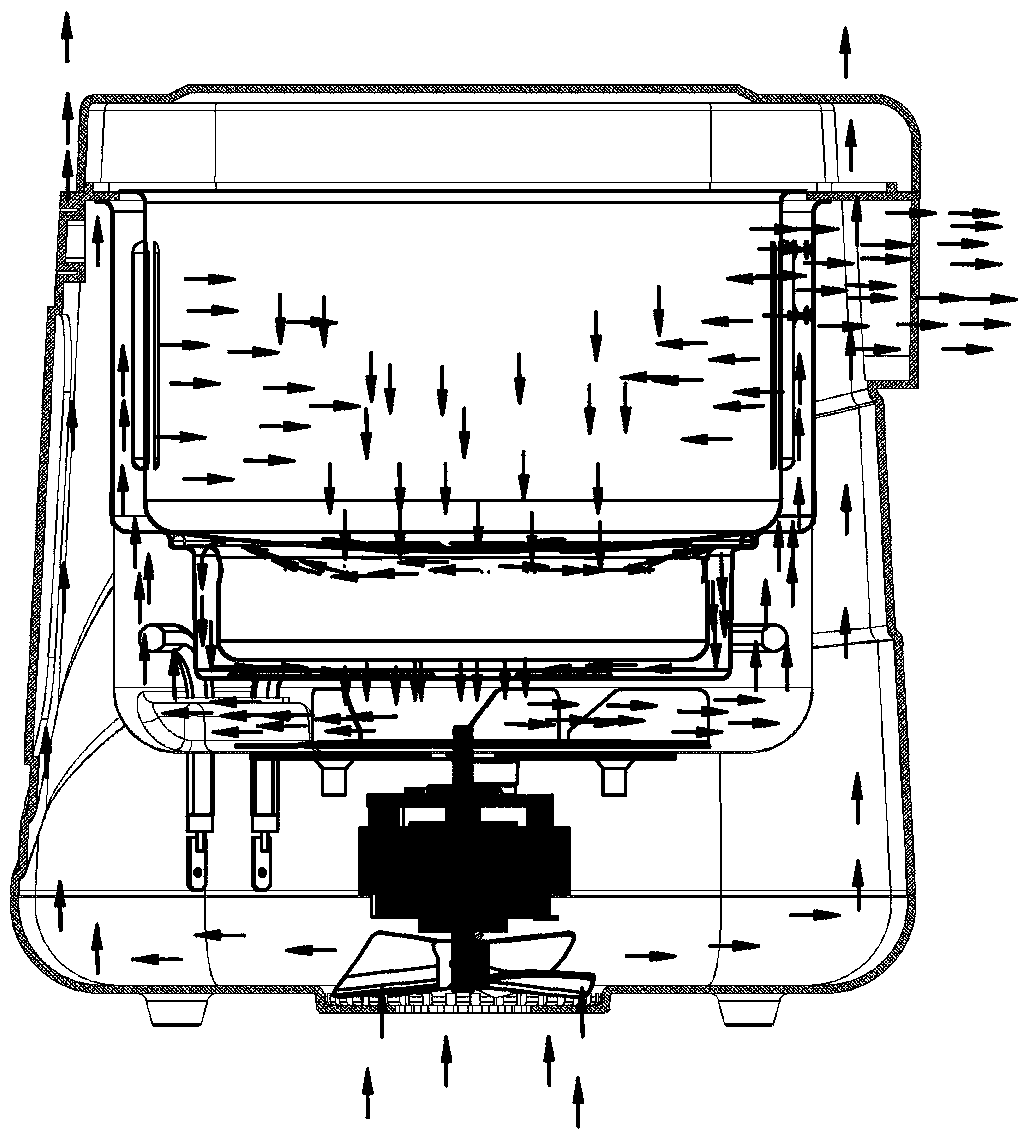

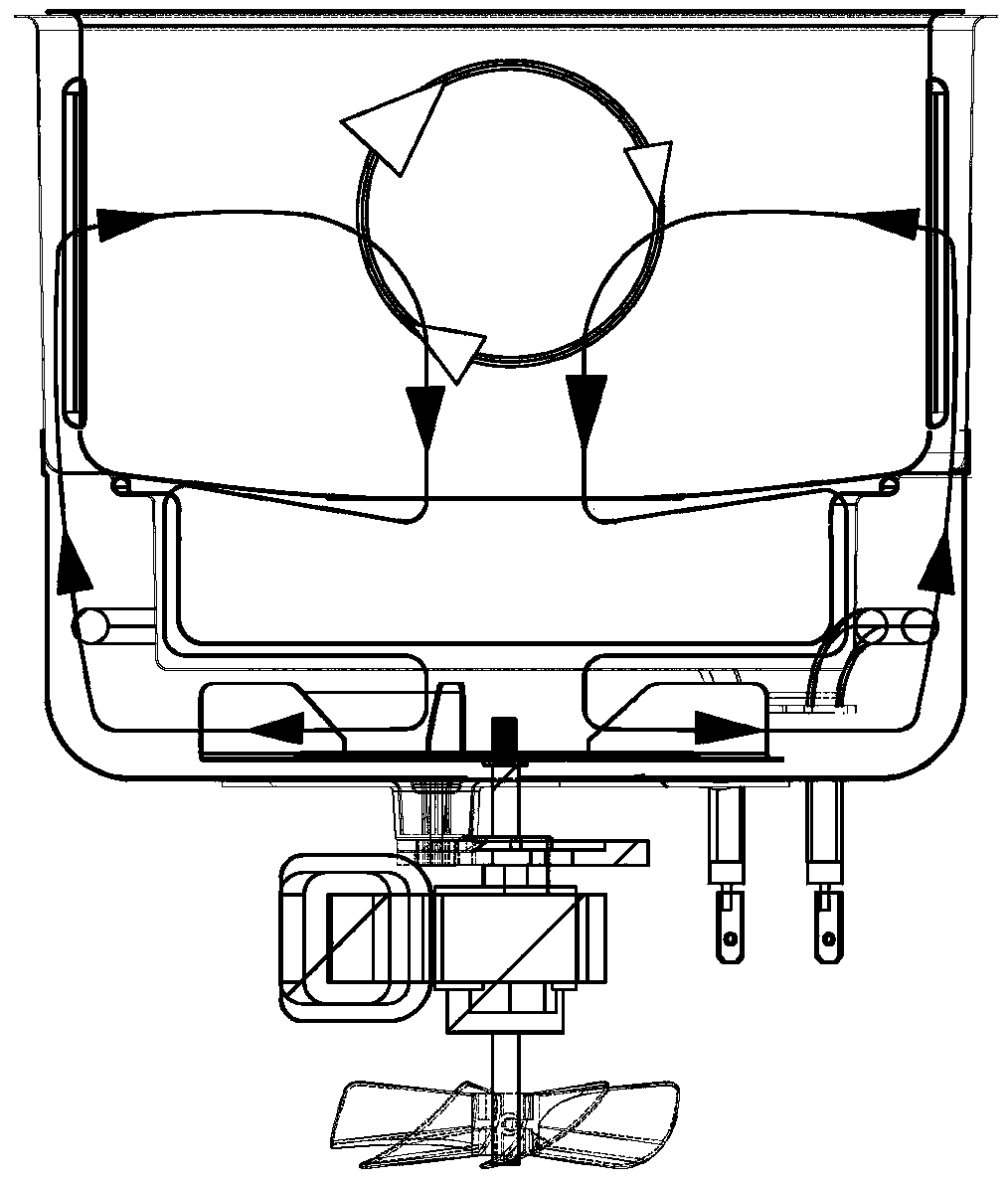

[0023] Such as figure 1 As shown, a novel air fryer comprises a top cover 1, a body 2 and an outer pot 3 inside the body 2, an inner pot 4, and a heat pipe cover 5. The top cover 1 is a transparent glass cover, and the inner pot 4 is placed Inside the outer pot 3, the outer pot 3 is placed on the heating pipe cover 5, and the heating pipe cover 5 at the bottom of the outer pot 3 is provided with a centrifugal fan 6, and the heating pipe 7 surrounds the bottom of the outer pot 3 and is arranged above the centrifugal fan 6. 6 is connected with 8 shafts of the motor, and the external power supply supplies power to the heating tube 7 and the motor 8 respectively. The bottom of the inner pot 4 is provided with an oil receiving box 9, and there is a gap between the oil receiving box 9 and the outer pot 3, such as Figure 6 As shown, the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com