Edible mushroom baking room with gas exchange function and manufacture method

A technology of drying room and edible fungus, applied in application, food processing, food science, etc., to achieve the effect of promoting air convection, avoiding softening and deformation, and remarkable drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

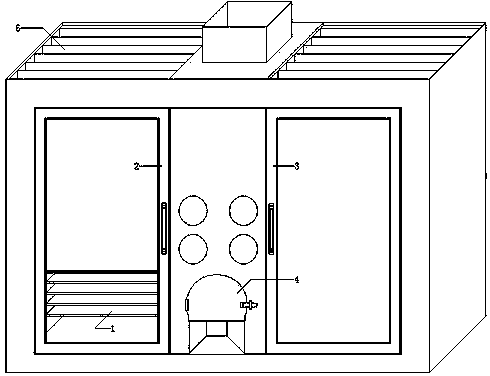

[0012] figure 1 Show the situation of the drying room device of the present invention, as for the use of edible fungi growers and edible fungi production enterprises, first the bamboo sieve 1 that has been paved with fresh mushrooms is placed on the sieve frame of the drying room, and then Close the airtight door 2 and the airtight door 3, open the furnace door 4 (ignition) and the exhaust fan 5 at the same time to use.

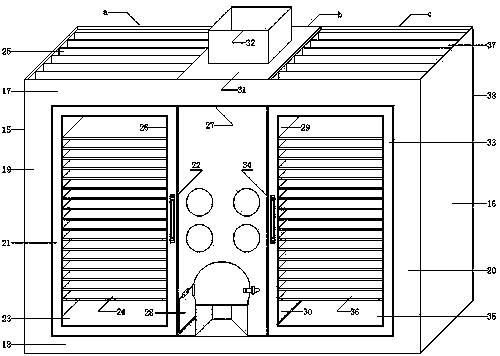

[0013] figure 2 Among them, the drying room device is composed of left drying room a, oven b and right drying room c, and the left drying room a, oven b and right drying room c are connected by brick and concrete. The left side of the drying room is provided with a left wall 15, the right side of the drying room is provided with a right side wall 16, the upper part of the drying room front is provided with a beam 17, the lower part of the drying room front is provided with a bottom beam 18, and the drying room The left side of the drying room is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com