Drying method in corrugated paper production process

A production process and technology of corrugated paper, applied in the field of corrugated paper, can solve the problems of unutilized waste heat, high energy consumption, waste of resources, etc., and achieve the effects of improving cleanliness, ensuring information security, and improving dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

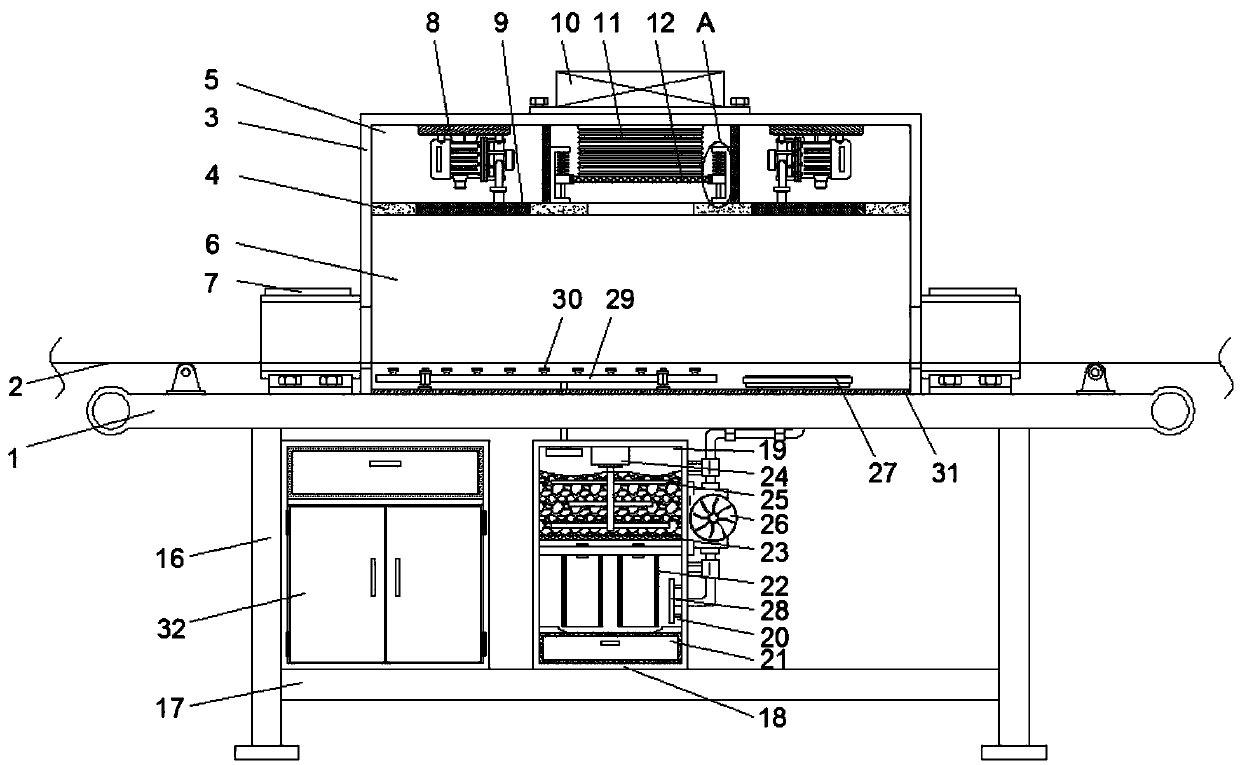

[0031] Embodiment: the drying method in a kind of corrugated paper production technology of the present invention, comprises the following steps:

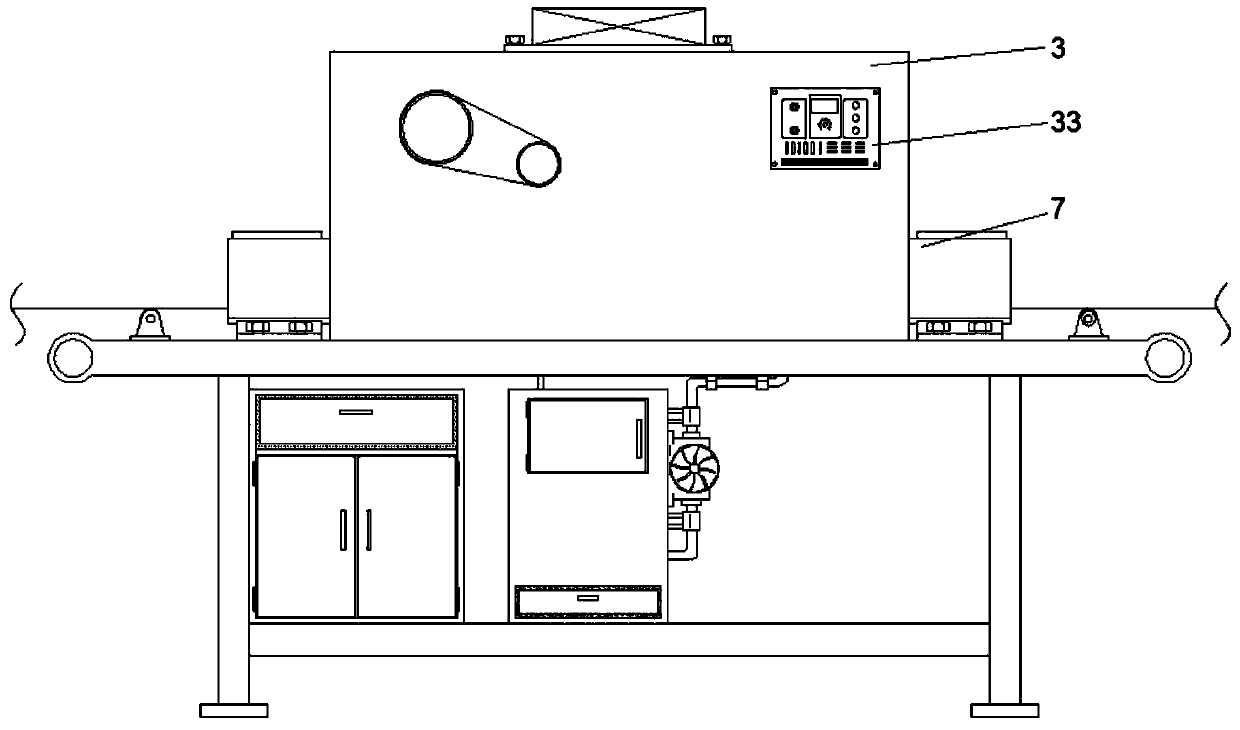

[0032] In the first step, the corrugated base paper is placed on the conveyor belt of the conveying device 2, and the corrugated base paper is transported into the protective shell 3 by the conveying device 2;

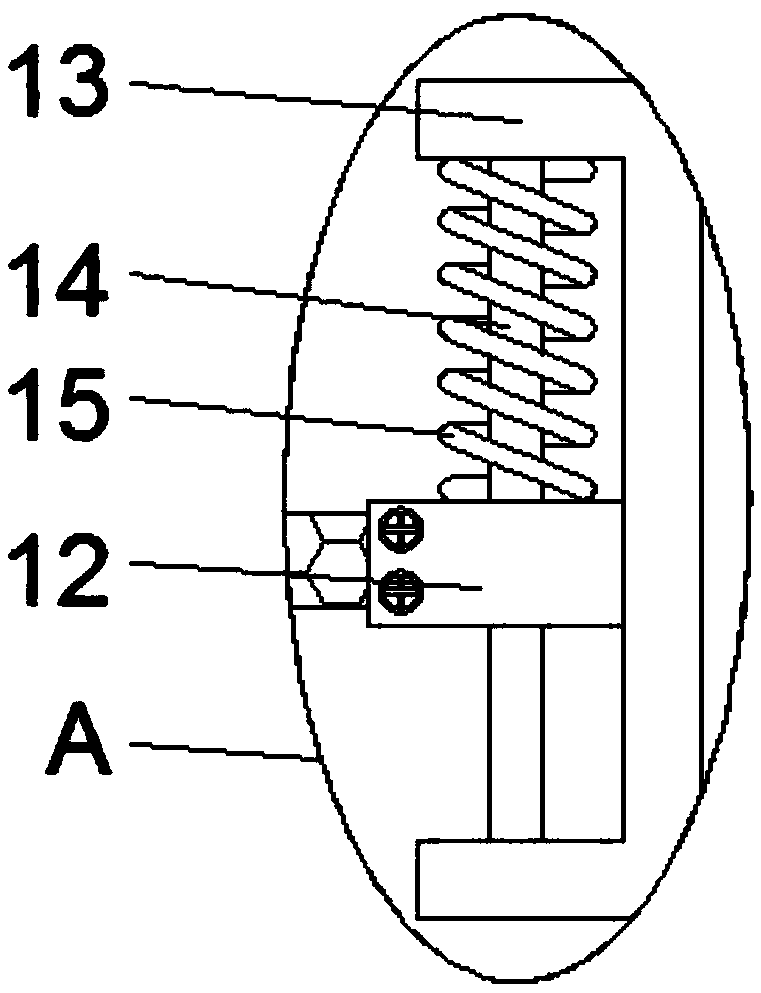

[0033] In the second step, the air blower 10 is turned on and the incoming air is filtered by the filter plate 12. The two ends of the filter plate 12 slide along the slide bar 14 under the impact of the air volume, and the spring 15 is stretched to move the filter plate 12. To protect the buffer, the two microwave generators 8 cooperate with the air blower 10 to dry the corrugated base paper entering the drying chamber 6;

[0034] In the third step, calcium carbonate is added in the dehumidification chamber 19;

[0035] In the fourth step, the drying chamber 6 discharges the internal moisture into the dehumidification box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com