A microwave hot air drying device for corrugated base paper for carton production

A technology of corrugated base paper and microwave hot air, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of waste heat not being utilized, high energy consumption, and reduced cleanliness, so as to improve the dehumidification effect and ensure information security Safe and cleanliness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

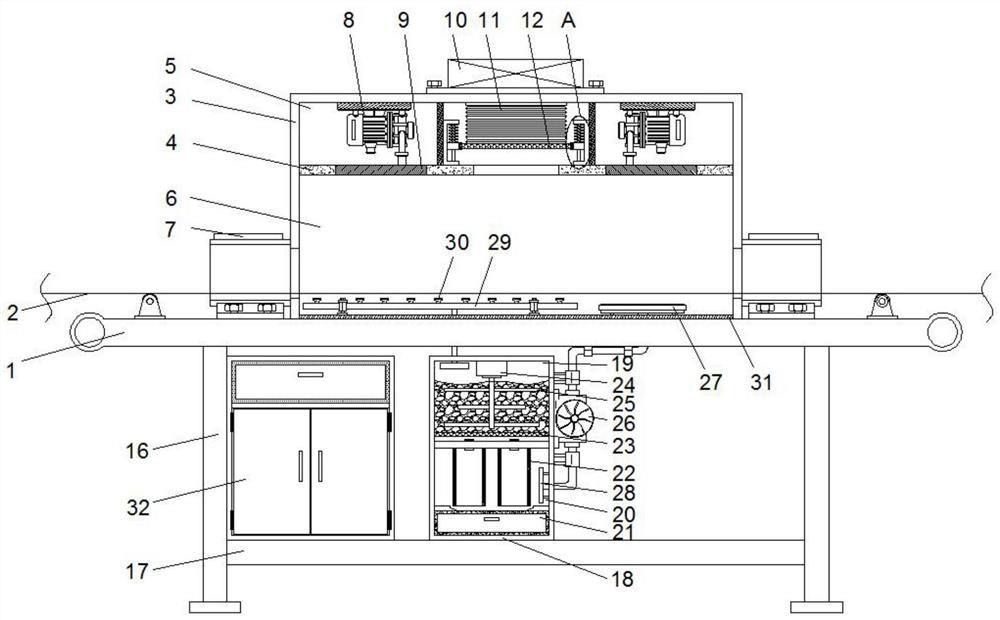

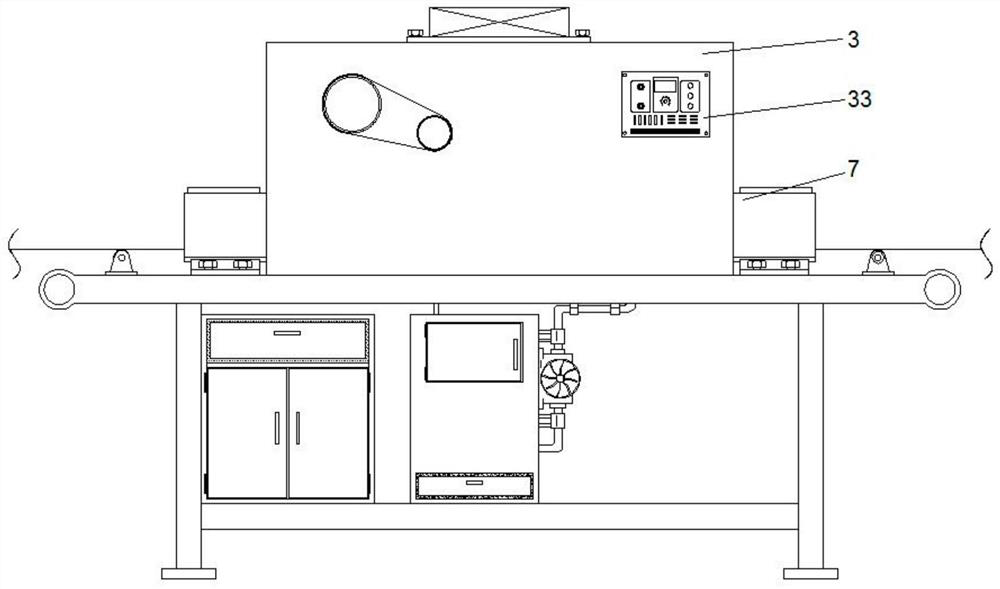

[0018] A microwave hot air drying device for corrugated base paper for carton production, including a worktable 1, on which a transmission device 2 is installed, the transmission device is composed of a driving wheel, a driven wheel, a conveyor belt and a driving motor, and the driving wheel and the driven wheel pass through the installation The frames are respectively installed on both sides of the workbench 1, and the driving wheel is driven by the driving motor, while the driving wheel and the driven wheel are connected through the transmission belt, and the surface friction of the conveyor belt is distributed with several anti-slip lines. By placing the corrugated base paper on On the conveyor belt, the corrugated base paper is transported into the protective casing 3 by the conveyor device.

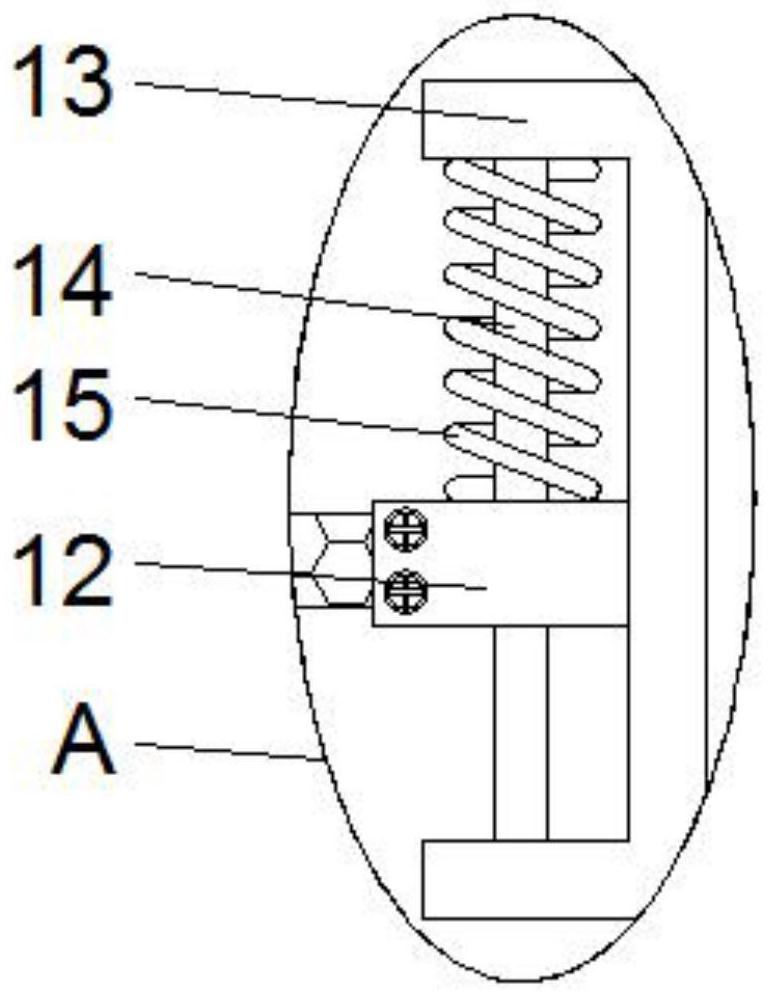

[0019] A protective shell 3 is fixedly installed on the workbench 1, and a microwave suppressor 7 is installed on the inlet and outlet of the protective shell 3, and the interior of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com