Method for preparing high-purity silicon nitride powder by ammonolysis method

A technology of silicon nitride powder and silicon nitride, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of slow production efficiency of silicon nitride, and achieve the effect of easy control and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

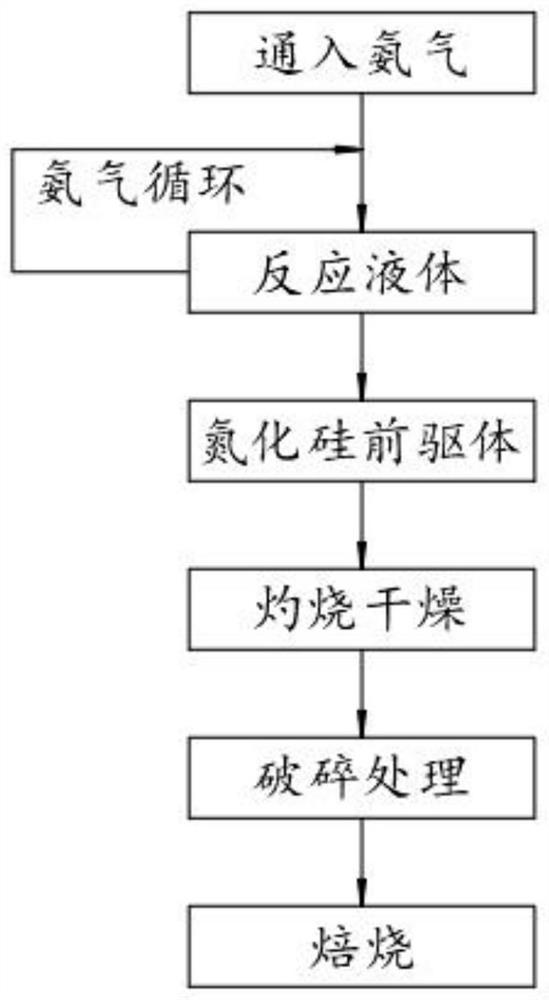

[0030] like figure 1 As shown, the embodiment of the present invention provides a method for preparing high-purity silicon nitride powder by ammonia ammonia solution, comprising the following steps:

[0031] 1. Preparation of silicon nitride precursor

[0032] 1.1. Add solvent and silicon tetrachloride to the reaction vessel. The types of solvents are dichloroethane and hexane. Both dichloroethane and hexane are insoluble in water, that is, ensure that the solvent is dry and avoid silicon tetrachloride from being damp. The reaction occurs, which affects the preparation of high-purity silicon nitride, and the molar mass ratio of the two is arbitrary. The molar ratio between the solvent and silicon tetrachloride is 0:1, and the temperature in the container is controlled at -25°C. The pressure is the value at which the ammonia gas just starts to liquefy at the current temperature. After decompression, the liquid ammonia can be vaporized. At the same time, the liquid ammonia, sol...

Embodiment 2

[0041] like figure 1 As shown, the embodiment of the present invention provides a method for preparing high-purity silicon nitride powder by ammonia ammonia solution, comprising the following steps:

[0042] 1. Preparation of silicon nitride precursor

[0043] 1.1. Add solvent and silicon tetrachloride to the reaction vessel. The types of solvents are dichloroethane and hexane. Both dichloroethane and hexane are insoluble in water, that is, ensure that the solvent is dry and avoid silicon tetrachloride from being damp. The reaction will affect the preparation of high-purity silicon nitride, and the molar mass ratio of the two is arbitrary. The molar ratio between the solvent and silicon tetrachloride is 4:1, and the temperature in the control container is -25~-35°C , the pressure in the container is the value at which the ammonia gas has just started to liquefy at the current temperature. After decompression, the liquid ammonia can be vaporized, and at the same time, the liqu...

Embodiment 3

[0051] like figure 1 As shown, the embodiment of the present invention provides a method for preparing high-purity silicon nitride powder by ammonia ammonia solution, comprising the following steps:

[0052] 1. Preparation of silicon nitride precursor

[0053] 1.1. Add solvent and silicon tetrachloride to the reaction vessel. The types of solvents are dichloroethane and hexane. Both dichloroethane and hexane are insoluble in water, that is, ensure that the solvent is dry and avoid silicon tetrachloride from being damp. The reaction occurs, which affects the preparation of high-purity silicon nitride, and the molar mass ratio of the two is arbitrary. The molar ratio between the solvent and silicon tetrachloride is 1:1, and the temperature in the container is controlled at -30°C. The pressure is the value at which the ammonia gas just starts to liquefy at the current temperature. After decompression, the liquid ammonia can be vaporized. At the same time, the liquid ammonia, sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com