Temperature reduction method for hot gas and device thereof

A technology of high-temperature exhaust gas and cooling device, which is applied to heat exchange equipment, fixed tubular conduit components, heat exchanger types, etc., can solve the problem of increasing the composition and volume flow of high-temperature exhaust gas, difficult to control the heat exchange process, and low heat exchange efficiency. and other problems, to achieve the effect of saving investment cost, solving thermal expansion, and reducing pressure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

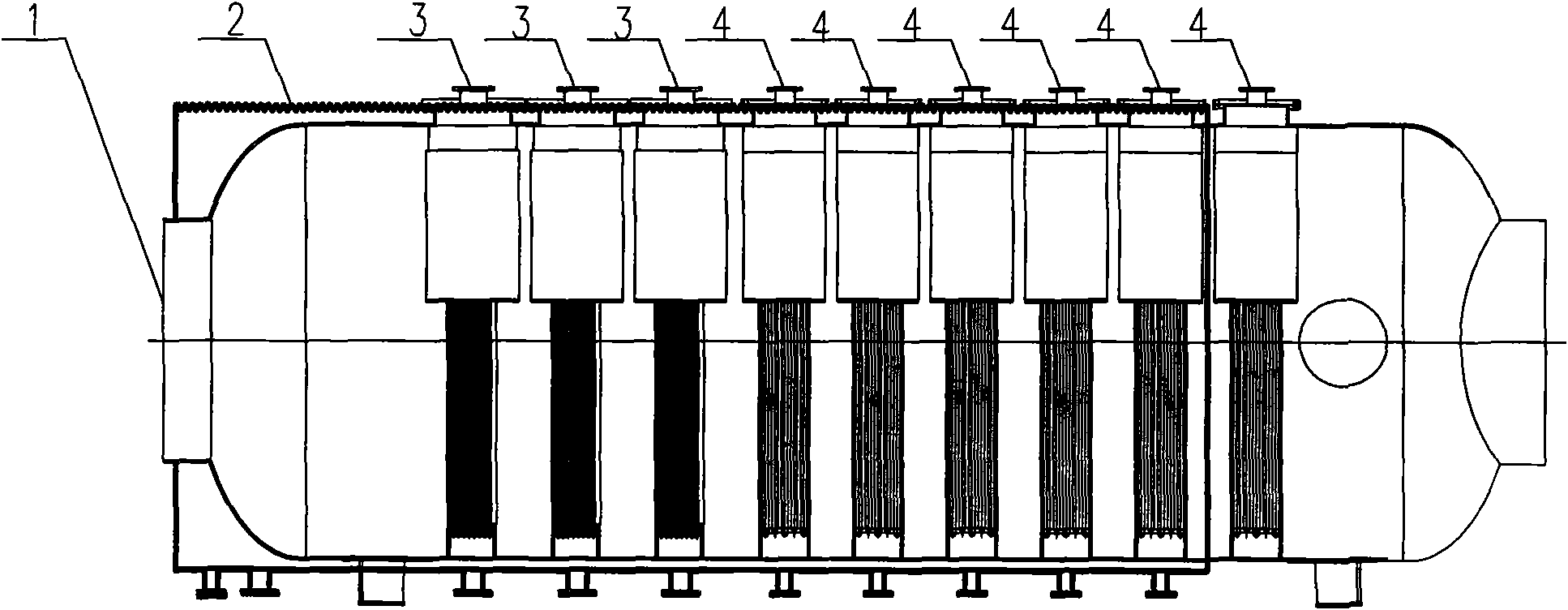

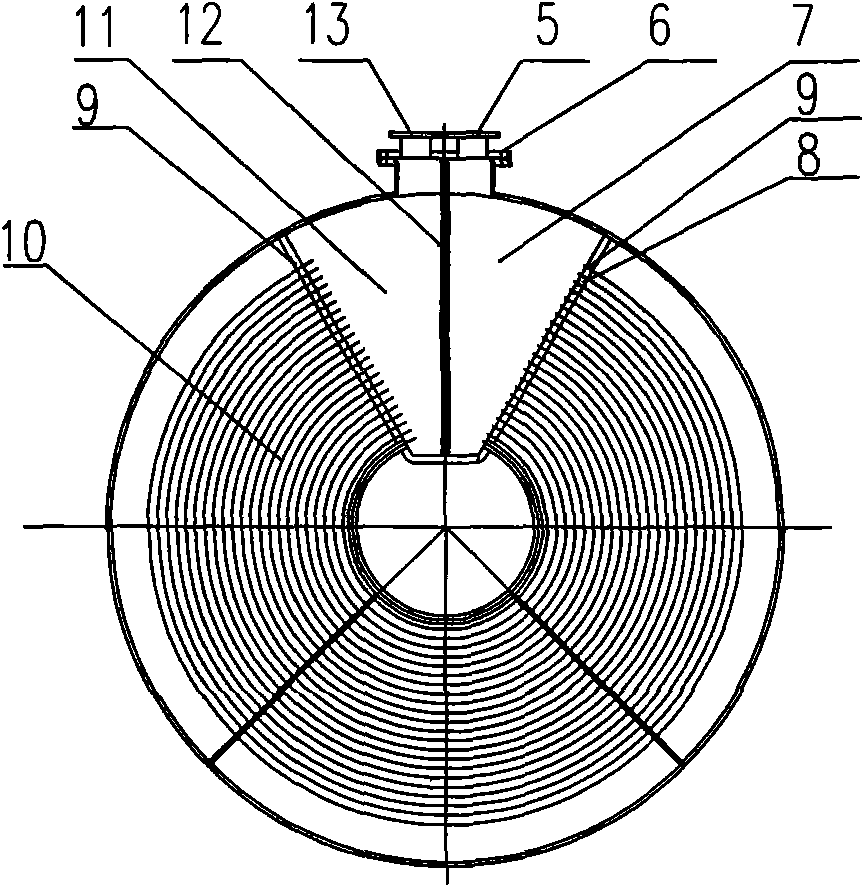

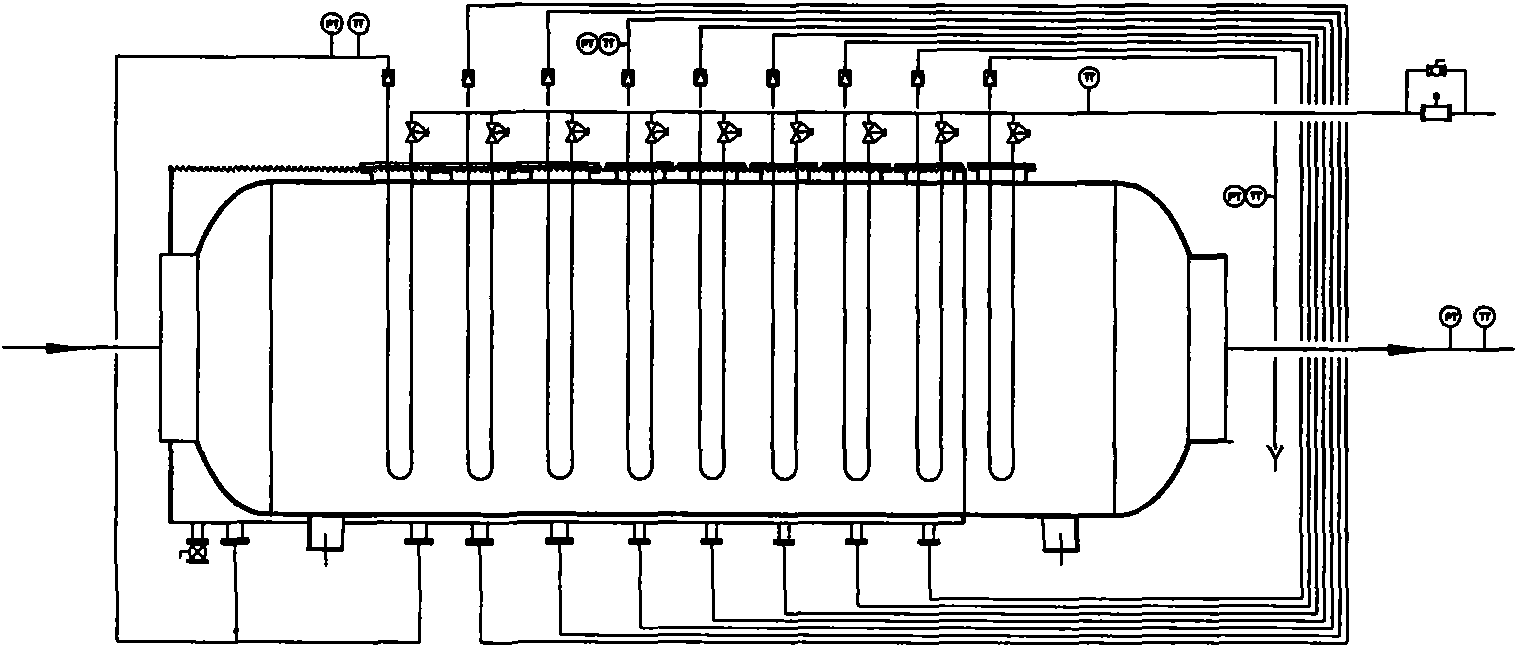

[0020] The heat exchange tube group of the tube bundle cooling device of the present invention adopts an annular heat exchange group, and the ring structure can solve the problem of thermal expansion of the heat exchange tubes during the heat exchange process. The heat exchange tube components are divided into two types: bare tube heat exchange group and finned tube heat exchange group. The bare tube heat exchange group is made of 0Cr18Ni9 material. , not only to ensure the practicability of the material, but also to ensure the cooling effect. The finned tube heat exchange group adopts Q345R. The water inlet distribution plate adopts Q345R, and its main function is to distribute the circulating cooling water so that the flow of cooling water entering each heat exchange tube meets the process design requirements to ensure the heat exchange effect. The main function of the outer jacket of the cooler is to use the circulating cooling water in the jacket to cool down the barrel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com