High pressure star-like feeder

A star-shaped feeding and high-pressure technology, which is applied in the direction of granular/powdered fuel gasification, can solve the problems of increasing motor power and increasing shaft friction, so as to reduce shaft friction, prevent coal powder leakage, and run at high speed small moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

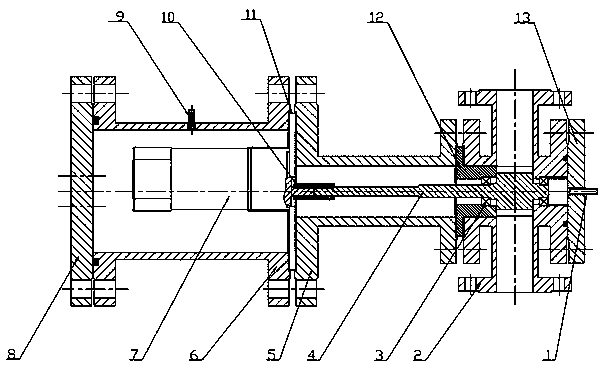

[0017] Such as figure 1 As shown, a high-voltage star feeder includes a motor 7, a rotor 4 and a star feeder housing 2, the star feeder housing 2 is fixed outside the rotor 4, and the output shaft of the rotor 4 and the motor 7 connect. In particular, the front end of the rotor 4 is connected to the star feeder housing 2 through the rotating bearing 3, which can achieve the minimum operating torque, and the end of the rotor 4 is connected to the output shaft of the motor 7 through a rigid coupling 10; the front end of the rotor 4 The star-shaped feeder housing 2 is provided with a housing end cover 13 for sealing; a bearing compression ring 12 is provided between the outside of the rotating bearing 3 and the star-shaped feeder housing 2, and one end of the bearing compression ring 12 is provided There is a right-angle flange, and the flange of the bearing compression ring 12 is tightly connected to the star feeder housing 2 and the pressure cover 5 of the reducing section for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com