Oil and water two-phase metering device

A metering device and oil-water technology, applied in the field of petroleum instruments, can solve the problems of inability to read, the glass tube is not under pressure, and the oil volume reaction lags, etc., to reduce the amount of pre-fueling, facilitate processing and manufacturing, and improve processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

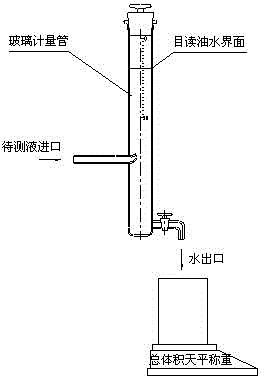

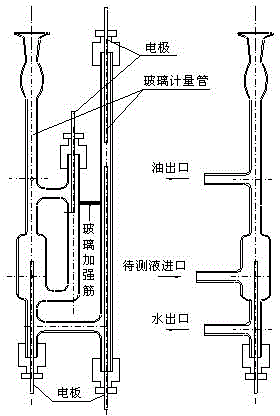

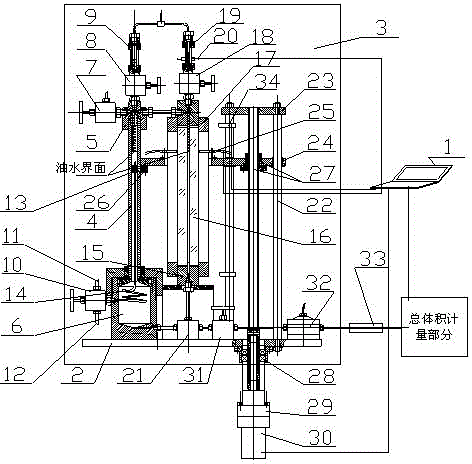

[0027] Such as image 3 As shown, the oil-water two-phase metering device of the present invention includes a microcomputer (1), a bottom plate (2), a constant temperature box (3), an oil-water separation part, a high-pressure window part, an oil volume metering part and a total volume metering part. The oil-water separation part, the high-pressure window part, and the oil volume metering part are arranged in a line in sequence, and are arranged on the bottom plate (2) and placed in the constant temperature box (3);

[0028] in,

[0029] The oil-water separation part includes a vertical metering tube (4), an upper cap (5) connected to the upper end of the metering tube (4), a water pool (6) connected to the lower end of the metering tube (4), and an upper cap (5) ) connected to the pre-refueling valve (7) and the first venting ball valve (8), the first small window (9) connected to the first venting ball valve (8), the reversing valve (10) connected to the pool (6), The liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com