High-temperature high-pressure oil and water two-phase metering device

A technology of high temperature and high pressure, measuring device, applied in measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of high requirements on the use environment of the balance, inability to measure instantaneous flow, glass tube not bearing pressure, etc. , to solve the pressure problem, increase the amount of pre-added water, and facilitate processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

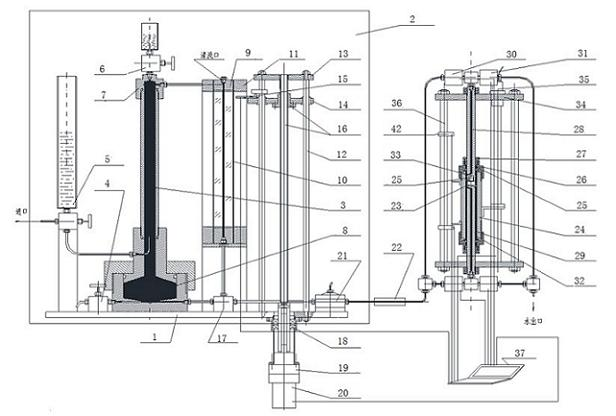

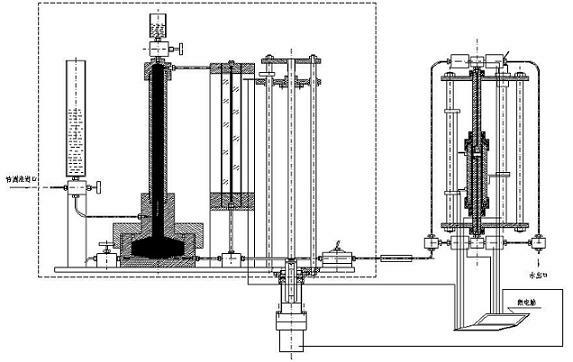

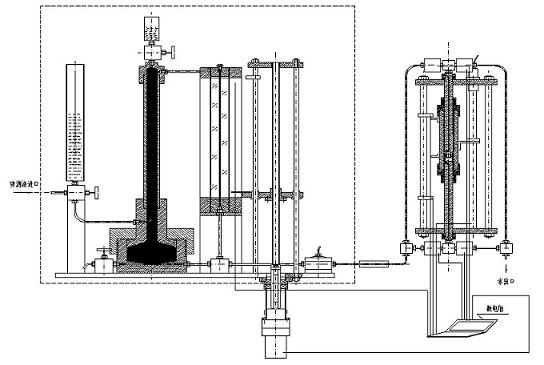

[0035] The high-temperature and high-pressure oil-water two-phase metering device of the present invention is characterized in that it includes a bottom plate 1, a constant temperature box 2, a microcomputer 37, an oil-water separation part, a high-pressure window part with a glass window, an oil volume metering part with a scanning device 15 and The total volume measurement part, in which the oil-water separation part, the high-pressure window part and the oil volume measurement part are arranged in a row in sequence, installed on the bottom plate 1, and placed in the constant temperature box 2, the outside of the constant temperature box is closely connected to the total volume measurement part, and the total volume measurement Part of the inlet is connected to the tee joint 17 at the lower end of the high-pressure window, and a back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com