Marine heat-pipe-type lead-bismuth reactor waste heat discharge system

A waste heat removal system and heat pipe technology, applied in reactors, reduction of greenhouse gases, nuclear engineering, etc., can solve problems such as size and weight control of unfavorable marine lead-bismuth reactors, condensation of steam generators, etc., to ensure shutdown safety and improve Excellent safety and adjustable thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

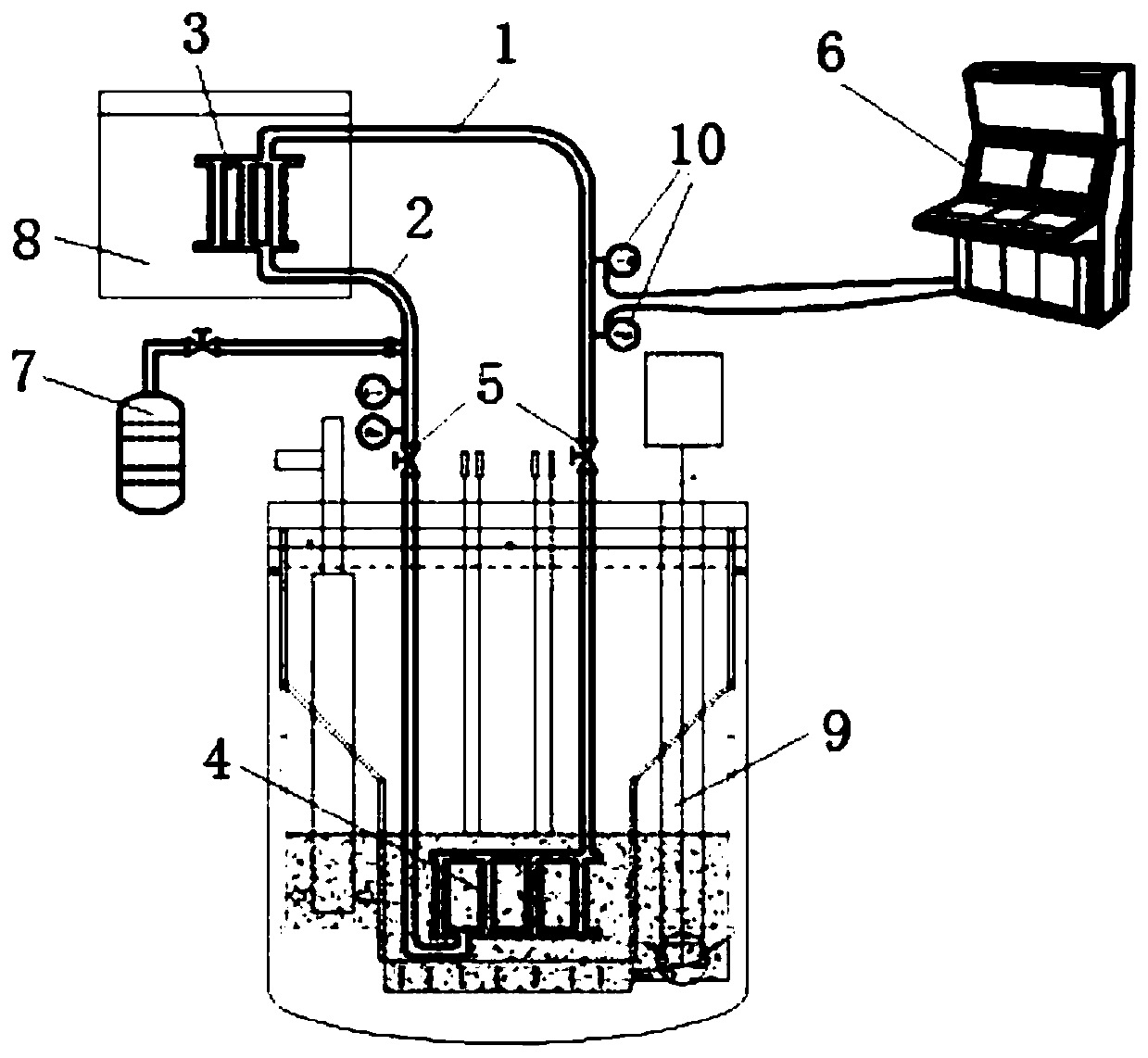

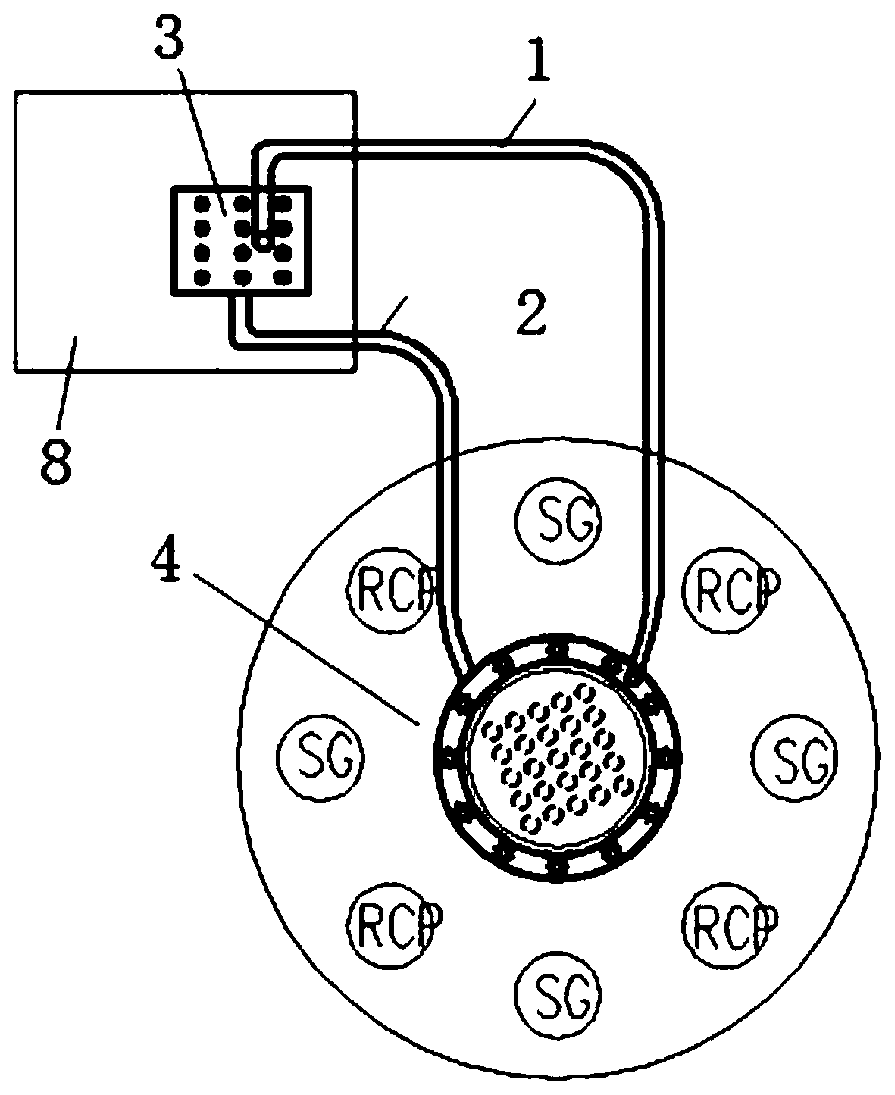

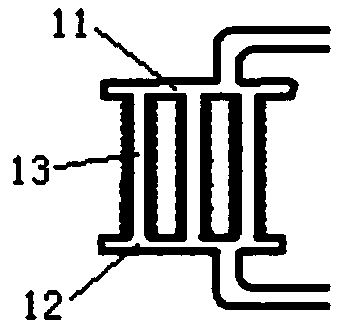

[0025] like figure 1 and figure 2 A kind of marine heat pipe type lead-bismuth reactor waste heat discharge system shown, comprises hot end heat exchanger 4, cold end heat exchanger 3 and cooling water pool 8, is provided with lead-bismuth coolant in lead-bismuth reactor 9, and described hot end The heat exchanger 4 is immersed in the lead-bismuth coolant, the outlet of the hot end heat exchanger 4 communicates with the inlet of the cold end heat exchanger 3 through the hot gas pipe 1, and the cold end heat exchanger 3 is arranged above the hot end heat exchanger 4 In the cooling water pool 8 (the cooling water pool 8 is equipped with cooling sea water, the cold end heat exchanger 3 is immersed in the cooling sea water), and the outlet of the cold end heat exchanger 3 is communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com