a pressing machine

A pressing machine and frame technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of large cylinder volume and air consumption, uneconomical, bulky pressing machine, etc., to achieve gas saving and structure Small and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

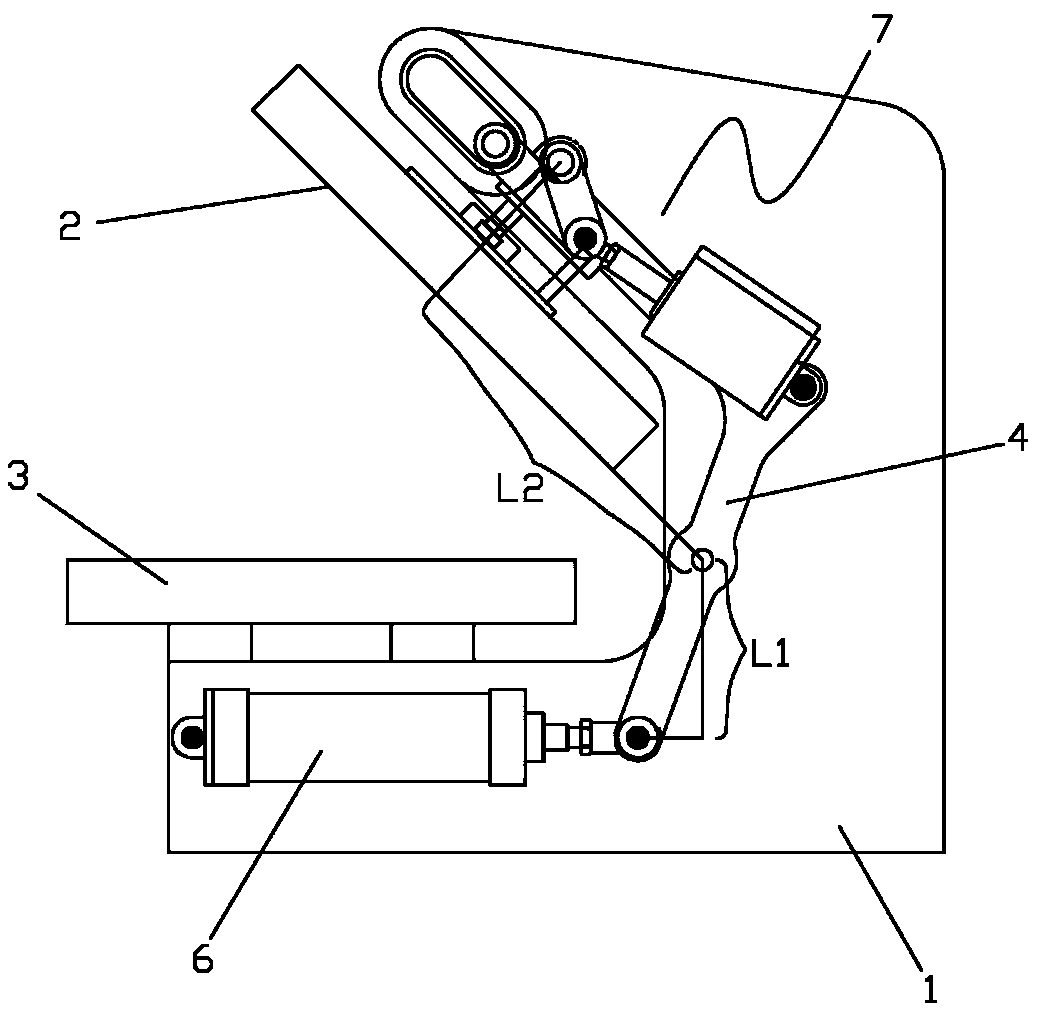

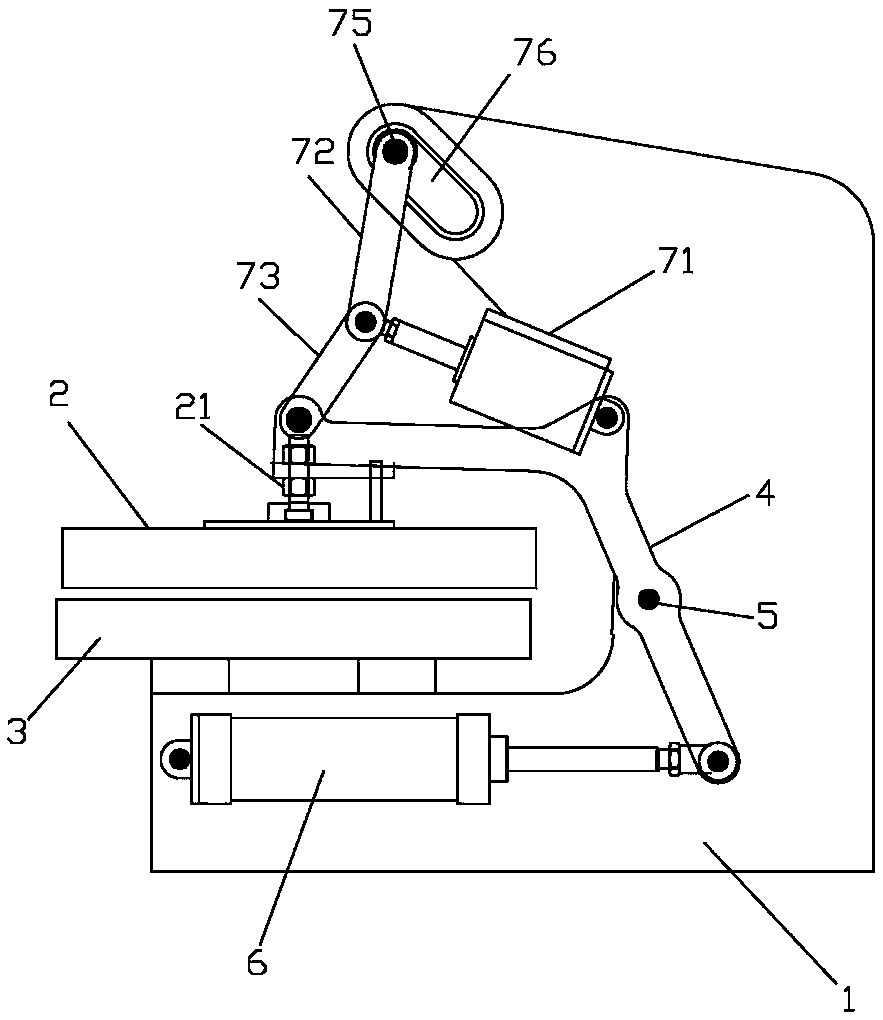

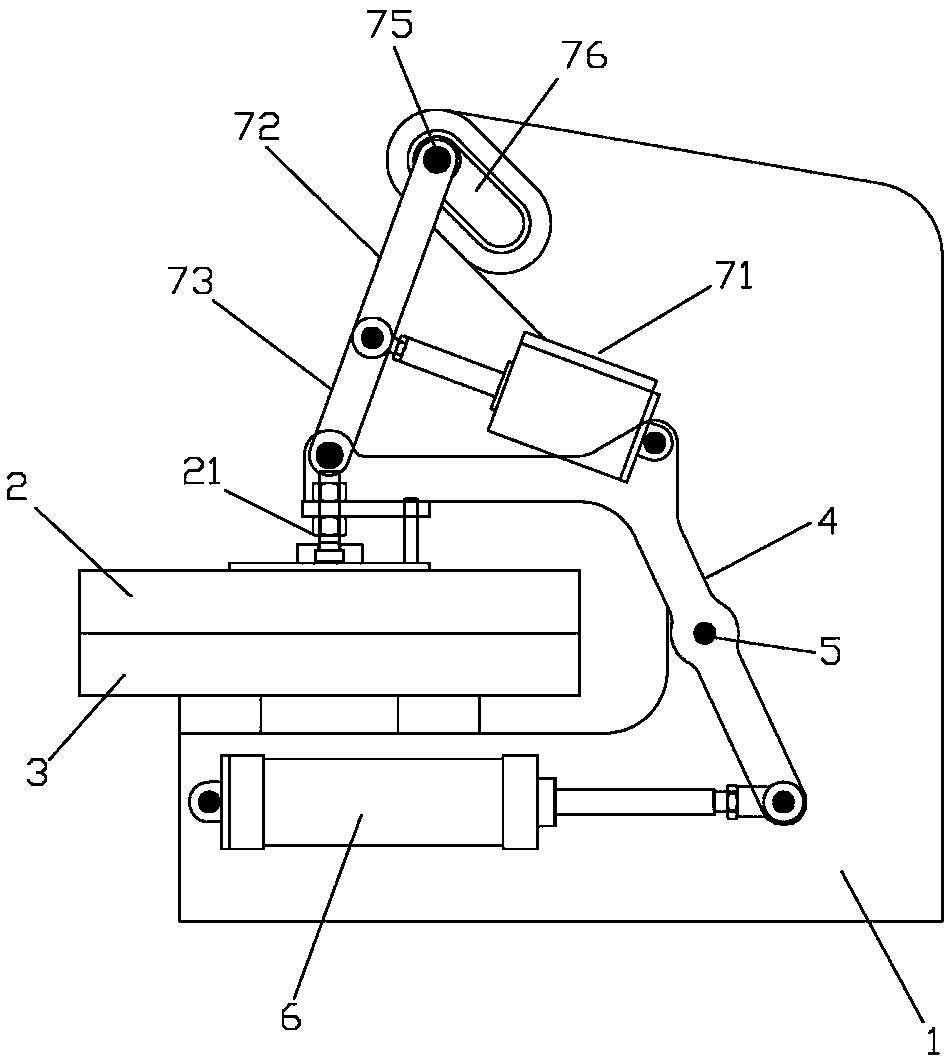

[0018] Such as Figure 1-6 As shown, a pressing machine includes a frame 1, a pressing device and a controller. The pressing device includes an upper pressing board 2 and a lower pressing board 3, and the lower pressing board 3 is fixed on the frame 1 It is characterized in that: the upper pressing plate 2 is hinged on one end of a driving lever 4, the middle part of the driving lever 4 is pivotally connected to the frame 1 through a pivot 5, and the other end of the driving lever 4 is connected to the frame 1 Connected by the stroke cylinder 6, the moment length of the power arm L1 from the hinge point of the stroke cylinder 6 and the drive lever 4 to the pivot 5 is less than the length of the resistance arm L2 from the hinge point of the upper pressing plate and the drive lever 4 to the pivot 5; A pressure device 7 is also arranged between the ironing plate 2 and the frame 1. When the stroke cylinder 6 drives the upper pressing plate 2 to approach or touch the lower pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com