Patents

Literature

36results about How to "Increase net output power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

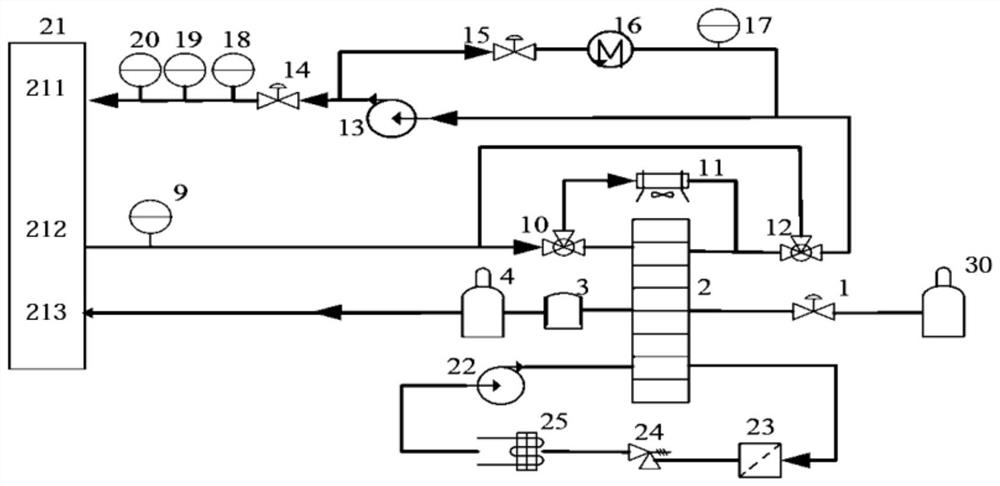

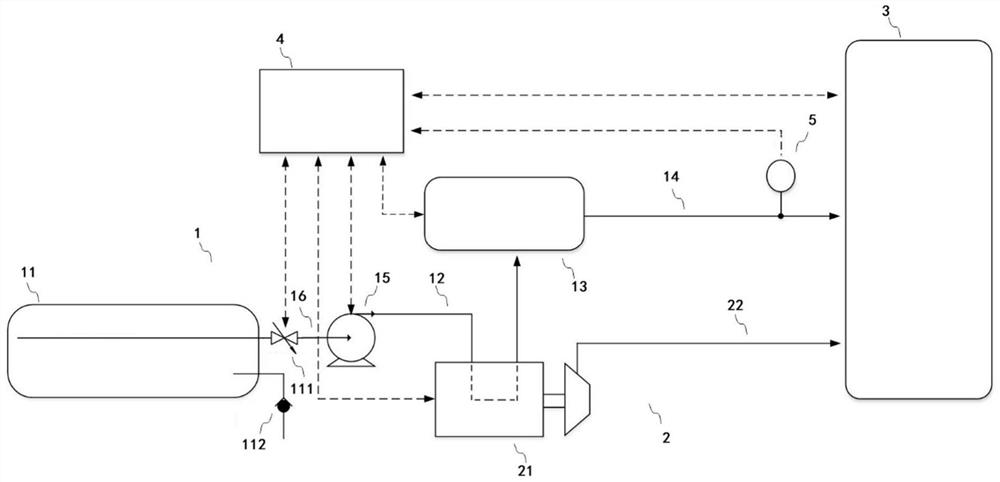

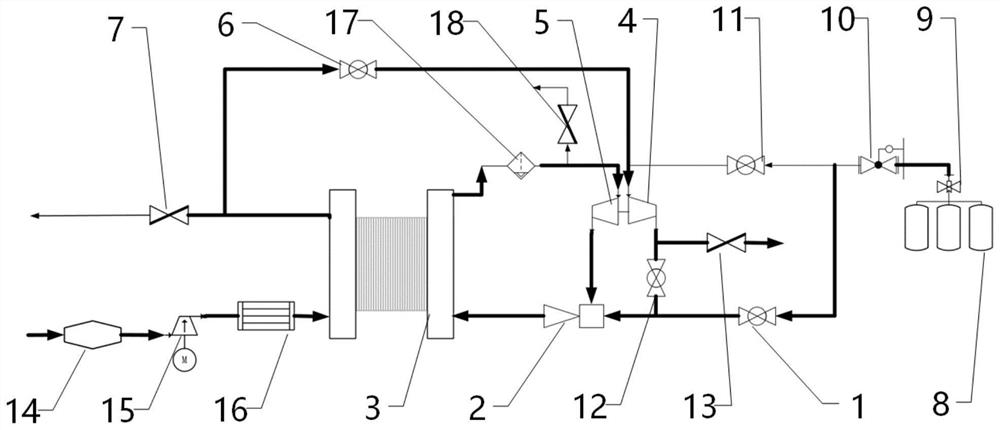

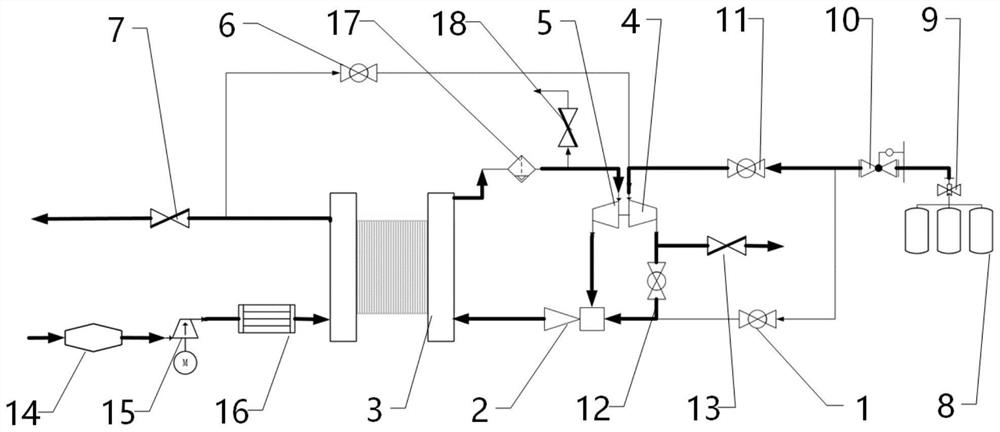

New energy automobile fuel cell system, working method, hydrogen inlet flow calculation method and efficiency evaluation method

The invention discloses a new energy automobile fuel cell system, a working method, a hydrogen inlet flow calculation method and an efficiency evaluation method, Belongs to the technical field of newenergy. Keys points of the new energy automobile fuel cell system are that the new energy automobile fuel cell system comprises an air supply system, a hydrogen supply system and a fuel cell stack, wherein the air supply system provides fresh air for the fuel cell stack, and the system comprises an air filter, a centrifugal air compressor, a gas heat exchanger, a humidifying and intercooling assembly, a throttle valve, a water segregator, a drain valve, a turbine and a back pressure valve; the hydrogen supply system provides fresh hydrogen for the fuel cell stack and comprises a hydrogen tank,a pressure reducing valve, an ejector, a water distributor, a water distribution valve, a nitrogen discharger, a nitrogen discharge valve, a first one-way valve, a circulating pump and a second one-way valve; and the fuel cell stack is a place where hydrogen and air react, and chemical energy is converted into electric energy to provide kinetic energy for accessory mechanisms and loads. The invention aims to provide the new energy automobile fuel cell system, the working method, the hydrogen inlet flow calculation method and the efficiency evaluation method, the stability of the fuel cell isimproved, and the efficiency of the fuel cell is conveniently calculated and evaluated.

Owner:擎能动力科技(苏州)有限公司

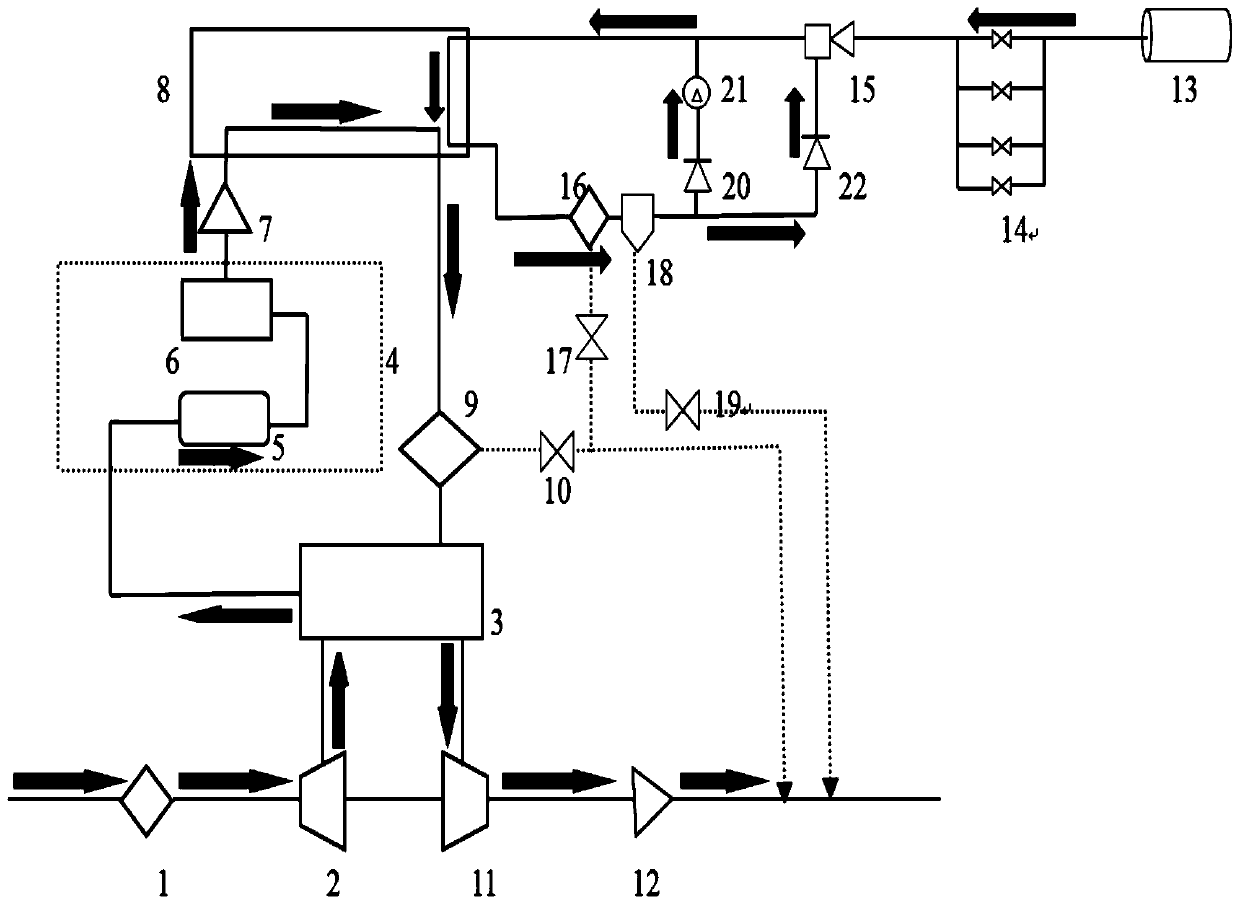

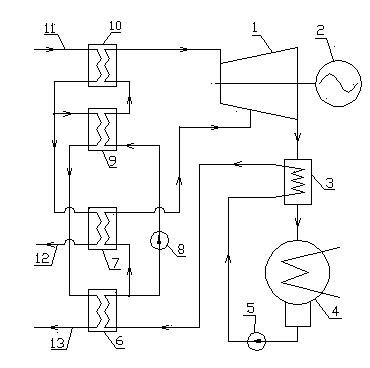

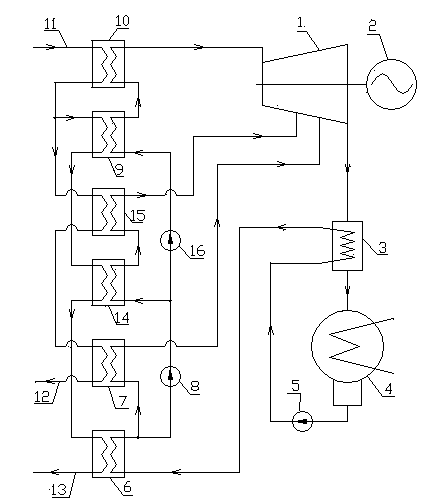

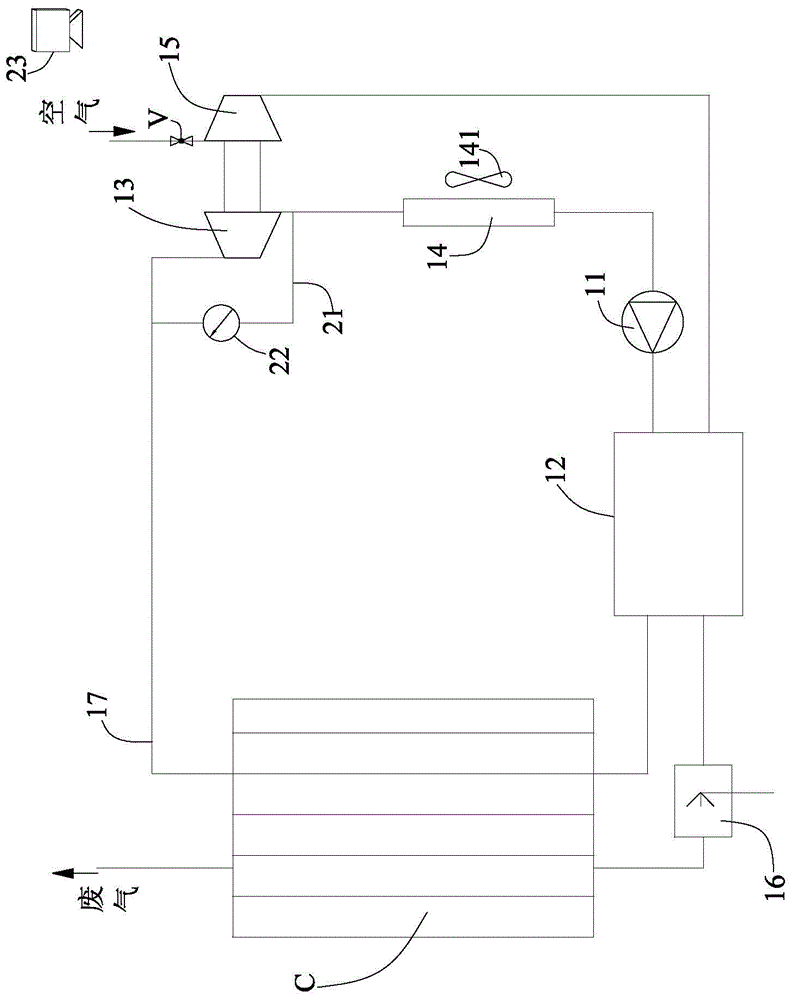

Waste heat and pressure utilization-based fuel cell air supply system

ActiveCN104485469ADoes not consume output powerIncrease net output powerFuel cell auxillariesElectrochemical responseFuel cells

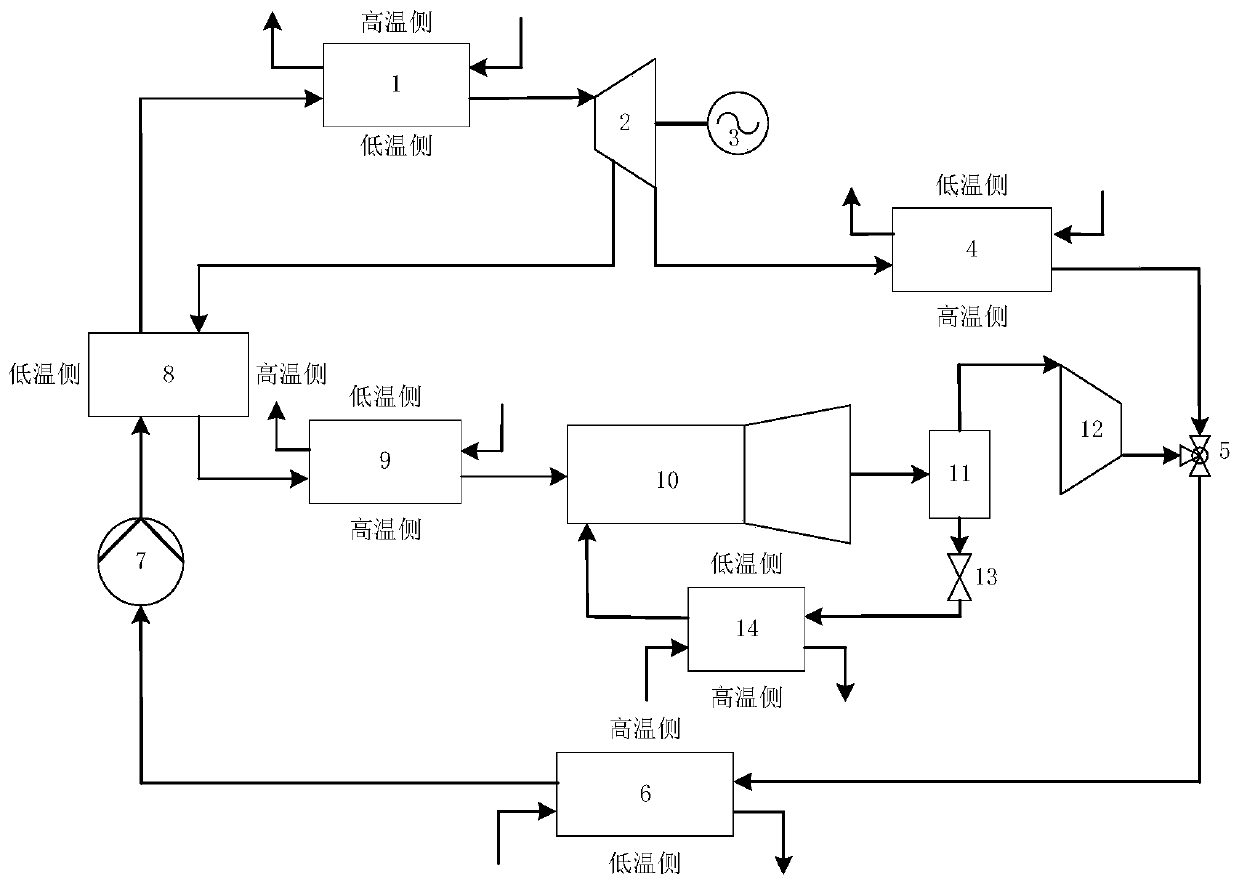

The invention provides a waste heat and pressure utilization-based fuel cell air supply system which comprises an organic Rankine cycle-based waste heat recycle loop and a pressurized air supply system, wherein the organic Rankine cycle-based waste heat recycle loop comprises an organic working medium pump, an expansion machine, an organic working medium pipeline and a condenser; the pressurized air supply system comprises a first control valve, a turbocharging bypass loop, a second control valve, a turbocharger, a first intercooler, a compressor, a second intercooler and a humidifier. According to the waste heat and pressure utilization-based fuel cell air supply system, the pressurized air supply system is used for recycling and converting the dynamic energy from the waste gas of a fuel cell into mechanical work which is used for driving the turbocharger to compress the external air for the first time; the air compressed for the first time is used as supply air compressed by the compressor; the organic Rankine cycle-based waste heat recycle loop is used for recycling and converting the waste heat from the electrochemical reaction of the fuel cell into mechanical work which is used for driving the compressor of the pressurized air supply system to compress the supply air.

Owner:TSINGHUA UNIV

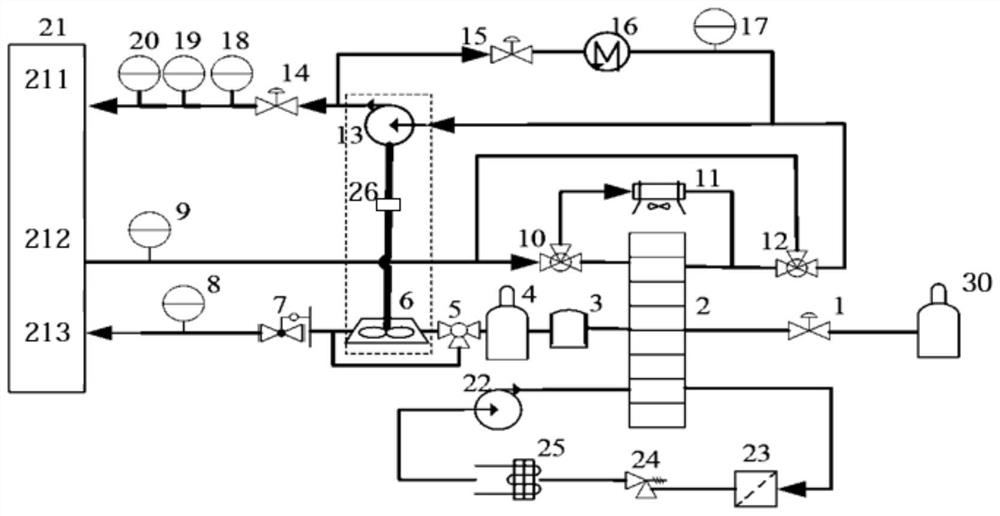

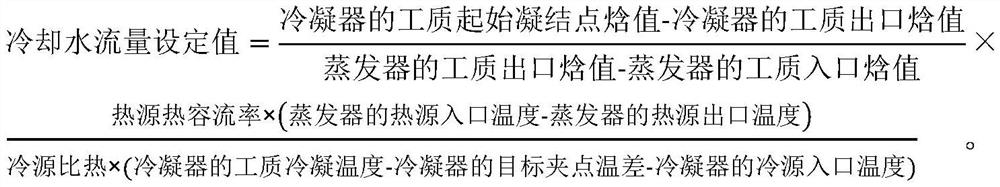

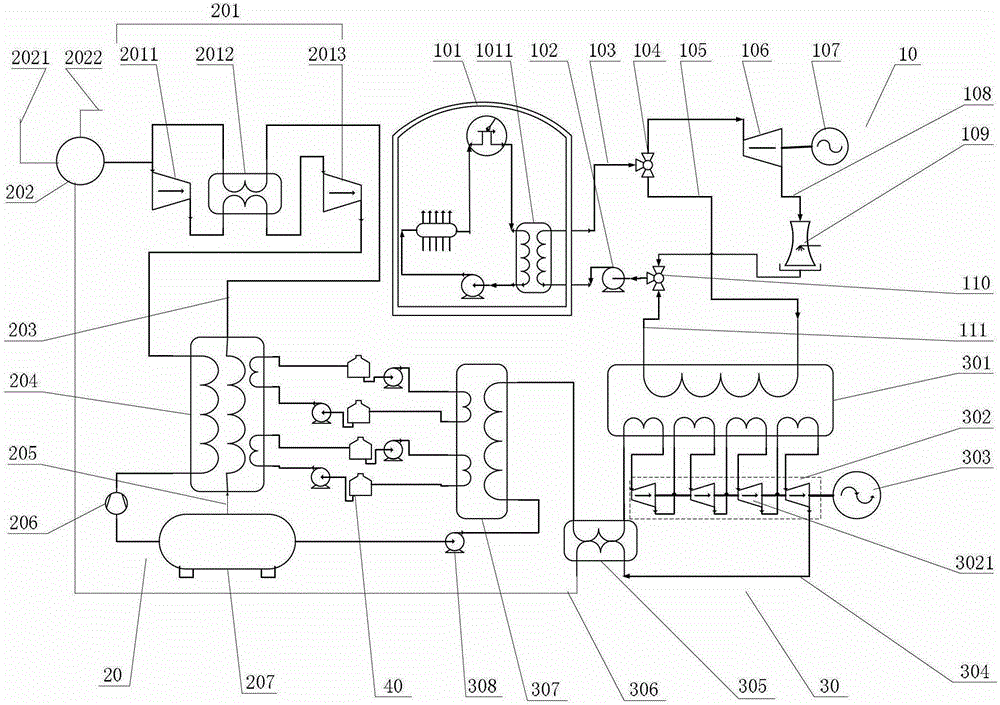

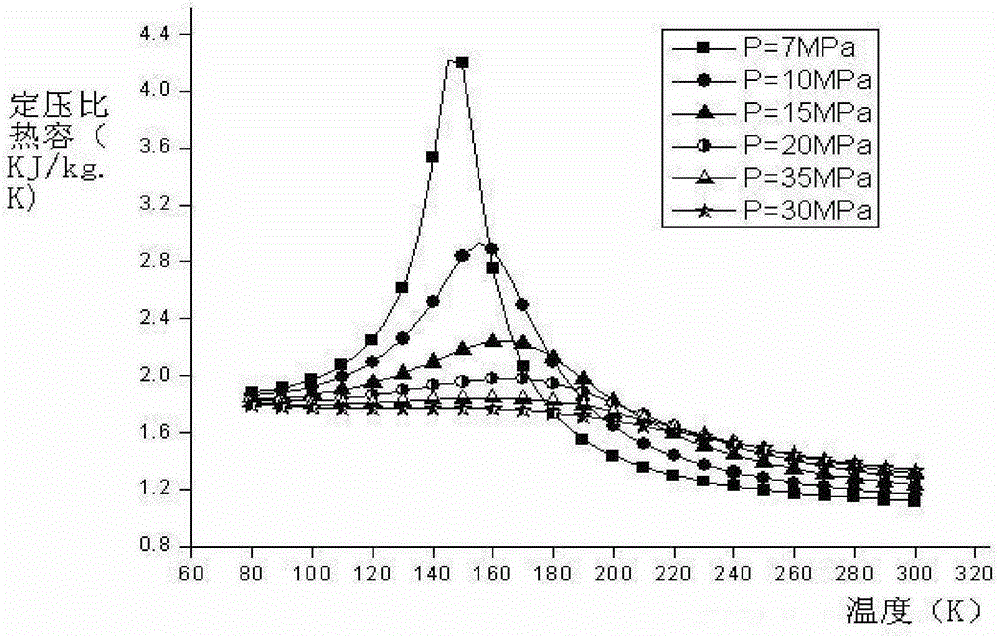

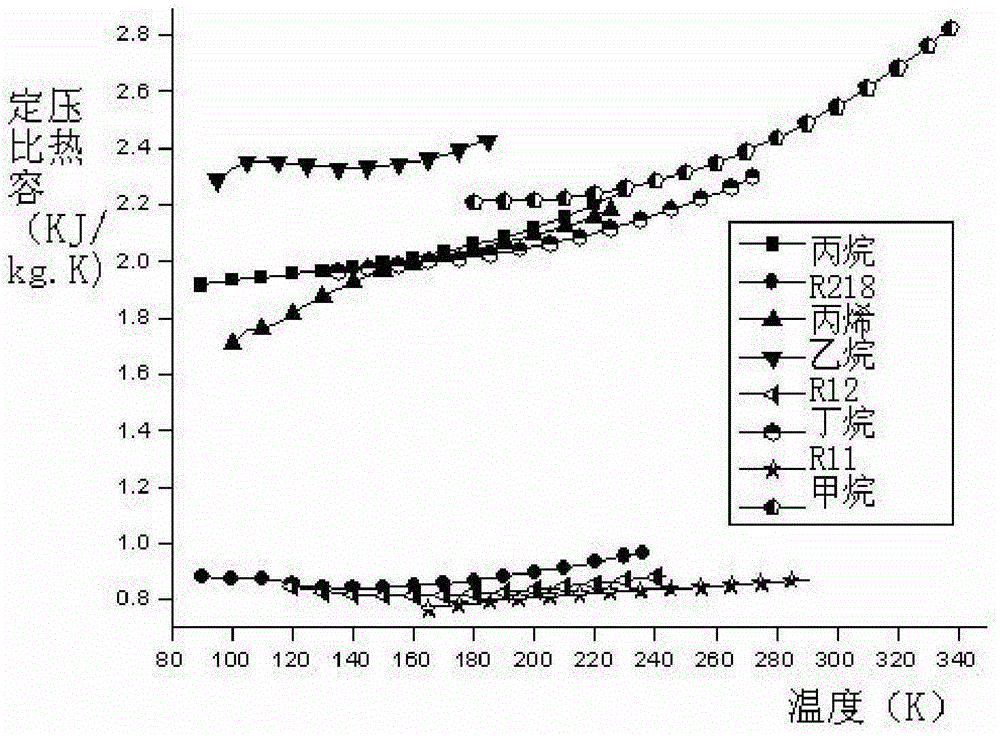

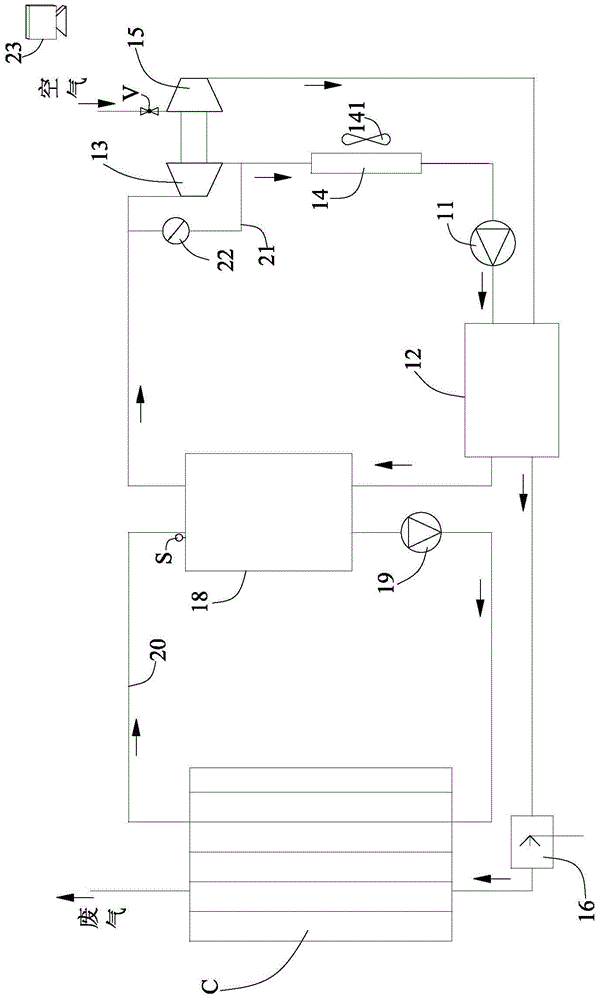

Energy self-supplying type carbon dioxide cold and hot electricity co-generation system used for low-grade heat source

ActiveCN110887278ASave compression workIncrease net output powerCompression machinesFluid circulation arrangementGas compressorCogeneration

The invention discloses an energy self-supplying type carbon dioxide cold and hot electricity co-generation system used for a low-grade heat source. The energy self-supplying type carbon dioxide coldand hot electricity co-generation system comprises a transcritical carbon dioxide reheat Rankine dynamic cycle system and a transcritical carbon dioxide injection refrigeration cycle system; the energy self-supplying type carbon dioxide cold and hot electricity co-generation system integrates reheat Rankine dynamic cycle and injection refrigeration cycle, adopts carbon dioxide as a single workingmedium, converts low-grade heat energy to useful work through a extraction turbine of the transcritical carbon dioxide reheat Rankine dynamic cycle system and supplies the heat energy to users by using a water heater. The transcritical carbon dioxide injection refrigeration cycle system utilizes high-pressure exhaust waste heat of the extraction turbine to drive an injector to output cold energy to the users. Through reasonable arrangement of the system, the system can output more electric energy. By adoption of a working medium pump and a low-pressure-ratio gas compressor, the energy self-supplying type carbon dioxide cold and hot electricity co-generation system reduces compression power efficiently during the system operation and improves net electric generation and conversion efficiency of the low-grade heat energy of the system.

Owner:北京绿卡科技有限公司

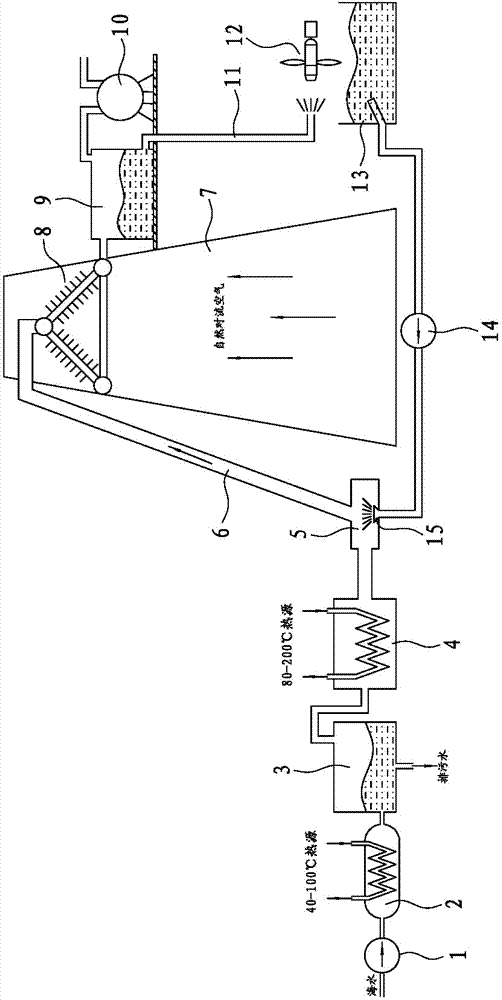

Fuel cell air supply system based on waste heat utilization

ActiveCN104538656ADoes not consume output powerIncrease net output powerFuel cell heat exchangeFuel cellsOrganic Rankine cycle

The invention provides a fuel cell air supply system based on waste heat utilization. The fuel cell air supply system comprises an organic working medium pump, a first heat exchanger, an expansion machine, a condenser, an air compressor and a humidifier. The organic working pump is communicated with an organic working medium liquid storage tank on the outside. A waste heat recycling and circulating loop based on organic Rankine cycle is formed by the organic working medium liquid storage tank, the organic working medium pump, the first heat exchanger, the expansion machine and the condenser. A pressurized air supply path is formed by the air compressor, the first heat exchanger and the humidifier. The organic working medium pump conveys the liquid organic working medium pump in the organic working medium liquid storage tank to the first exchanger. The first heat exchanger receives liquid organic working media conveyed by the organic working medium pump. Heat exchange is carried out between the liquid organic working media passing through the first heat exchanger and a fuel cell, so that the waste heat of the fuel cell is absorbed and the liquid organic working media are evaporated to gas organic working media, the gas organic working media enter the expansion machine and drive the expansion machine to act, and exhaust gas generated after acting enters the condenser and is cooled to be liquid and conveyed to the organic working medium liquid storage tank.

Owner:TSINGHUA UNIV

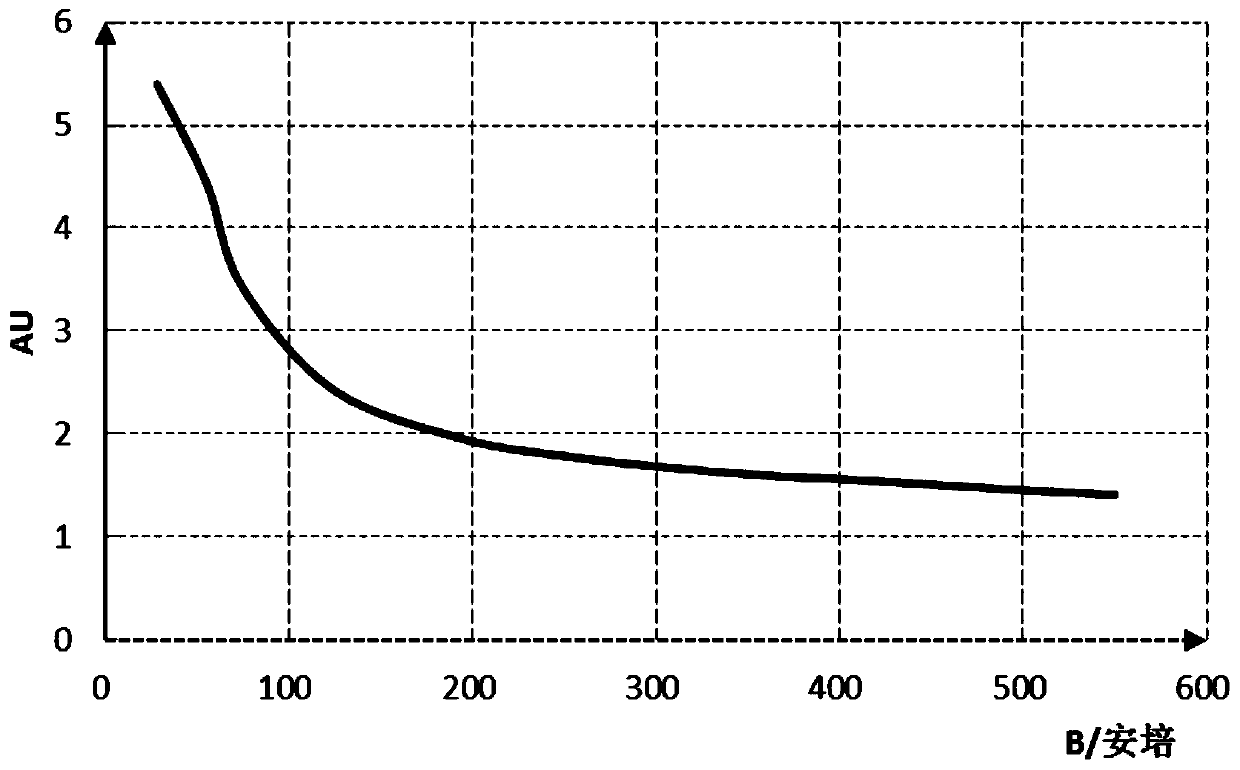

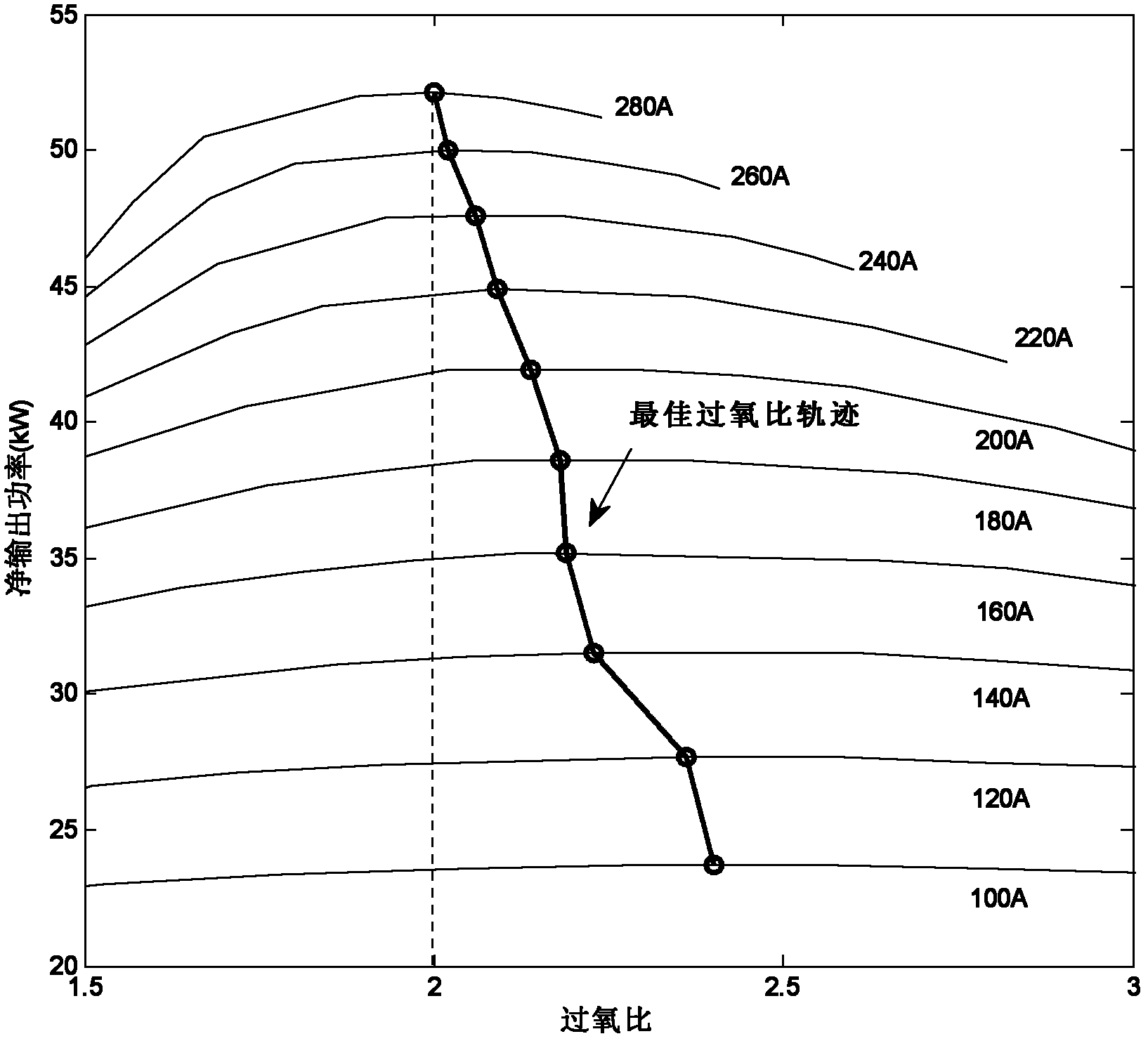

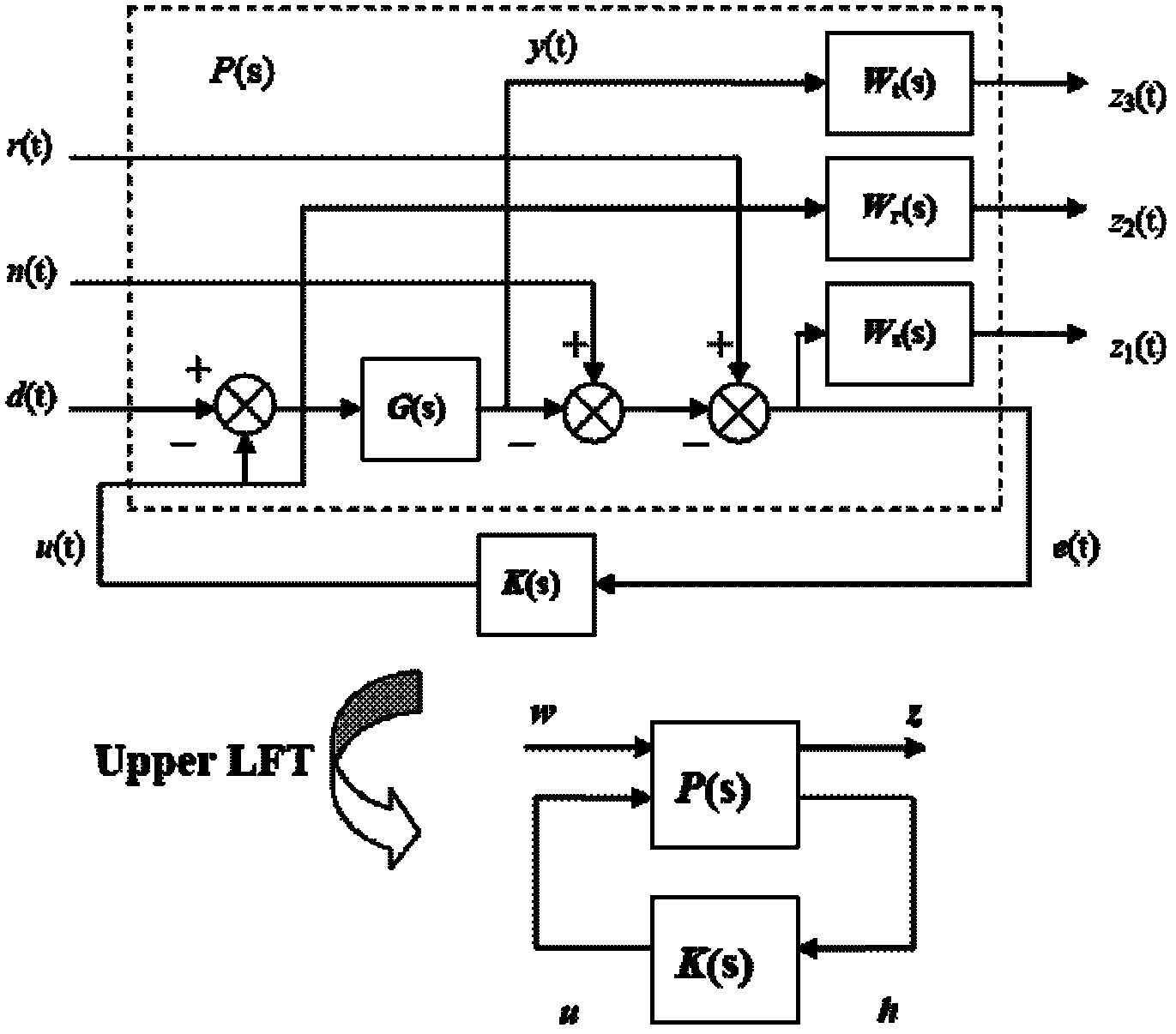

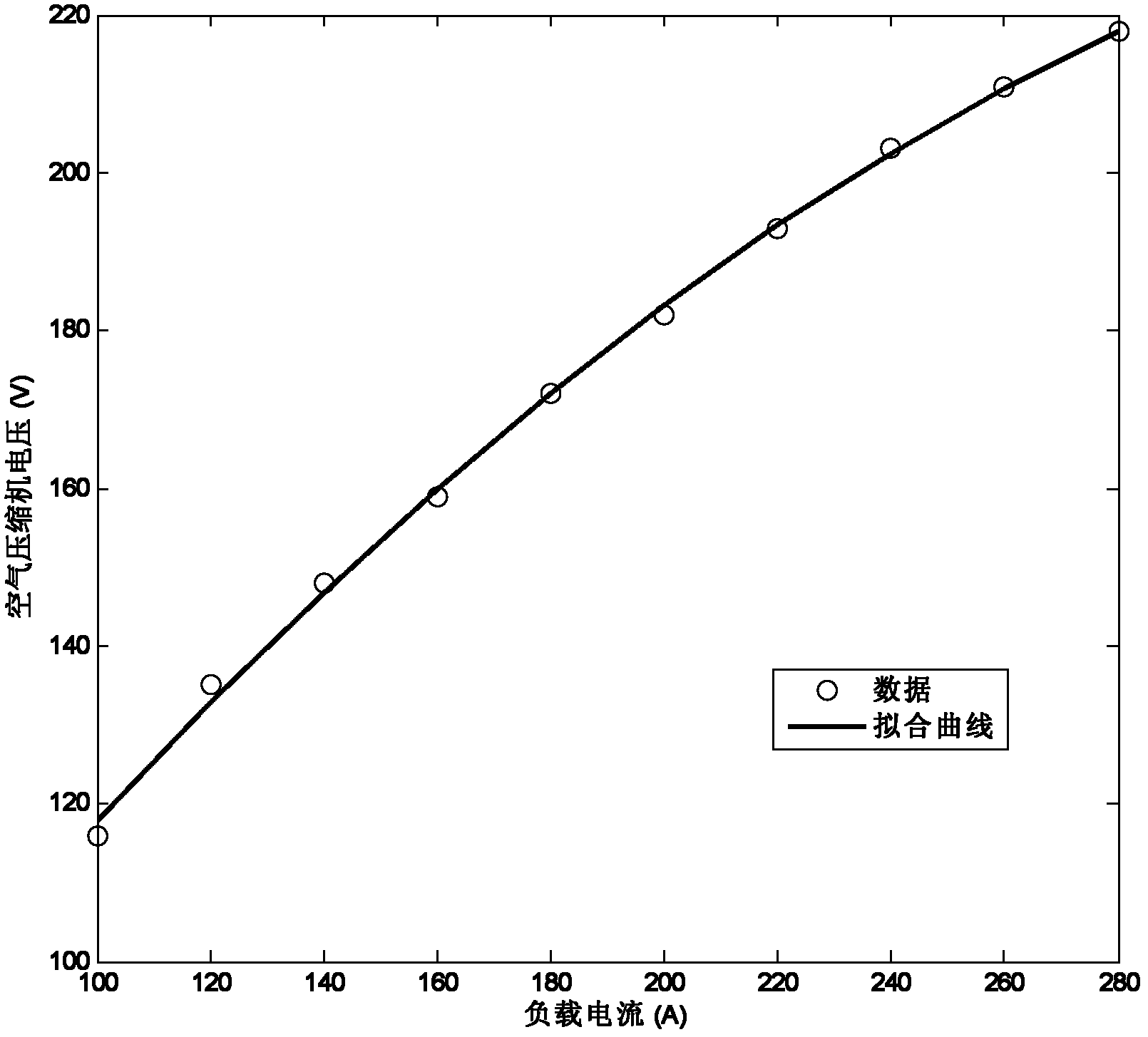

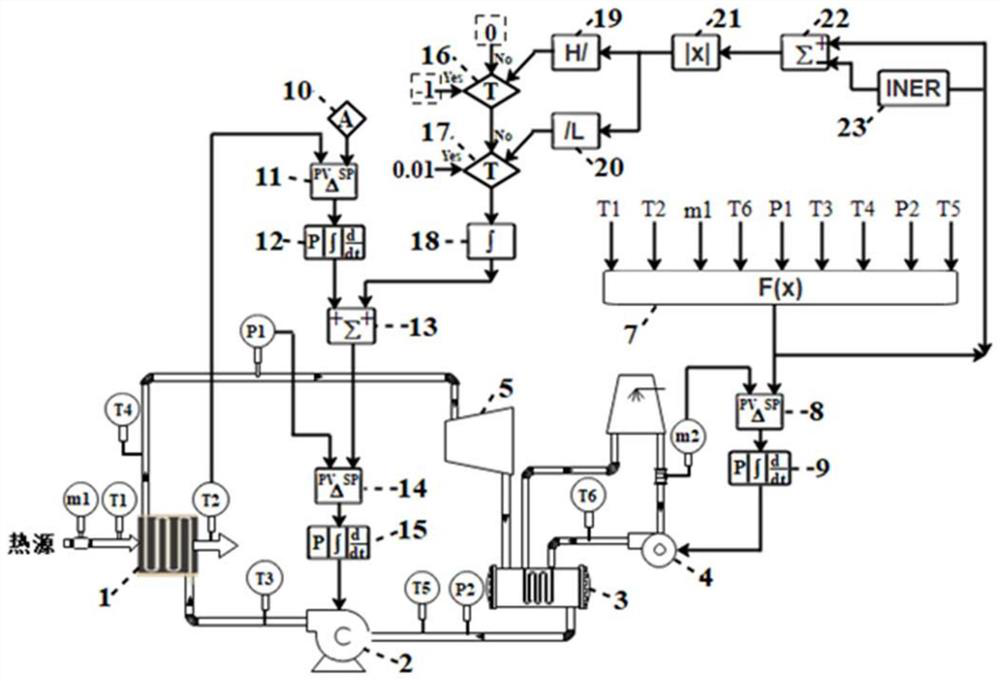

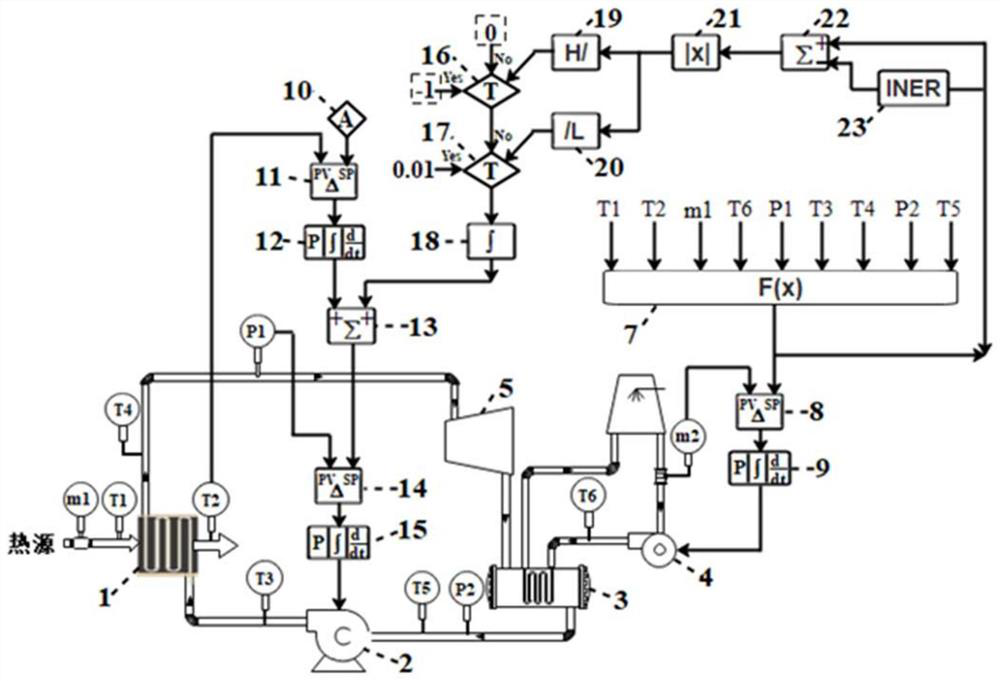

Control method for two degrees of freedom (2DOF) of proton exchange membrane type fuel cell (PEMFC) system based on optimal oxygen enhancement ratio (OER)

InactiveCN102520613AReduce parasitic power consumptionIncrease net output powerFuel cell auxillariesAdaptive controlDecompositionOxygen enhancement ratio

The invention discloses a control method for two degrees of freedom (2DOF) of proton exchange membrane type fuel cell (PEMFC) system based on an optimal oxygen enhancement ratio (OER). According to the control method, an H-order supreme feedback control (HSFC) method and a feedforward control (FFC) method are combined, a variable to be controlled via dual functions of the two methods, wherein the HSFC method adopts a linear matrix inequality (LMI) method for solution, and FFC adopts a polynomial fitting technique based on the QR (orthogonal matrix / upper triangular matrix) decomposition of the Vandermonde matrix for design. By adopting the control method, the optimal OER trajectory of the system can be tracked under conditions with large load current fluctuations, parameter perturbation and environmental interference noise, the parasitic power consumption of the system can be reduced, and the net output power of the system can be improved. Moreover, the method has good robustness and reasonable servo control behaviors, and the optimal OER and the maximum net output power of the system can be ensured.

Owner:SOUTHWEST JIAOTONG UNIV

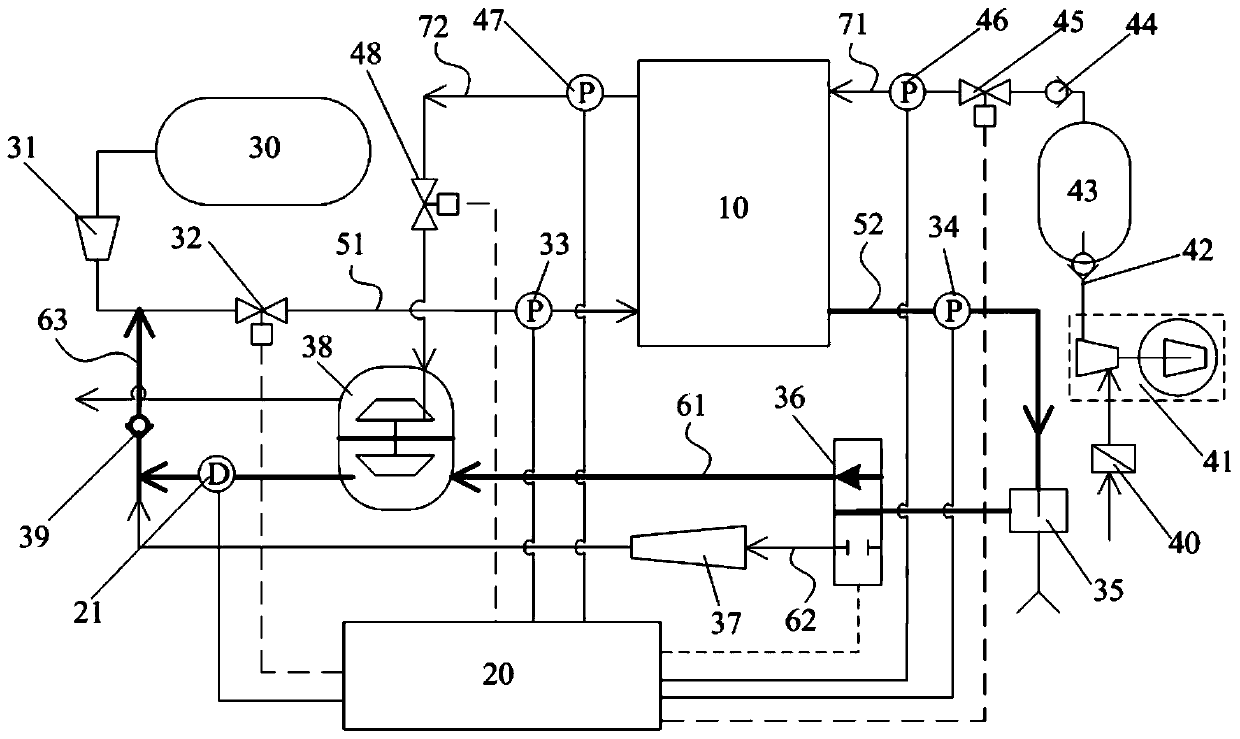

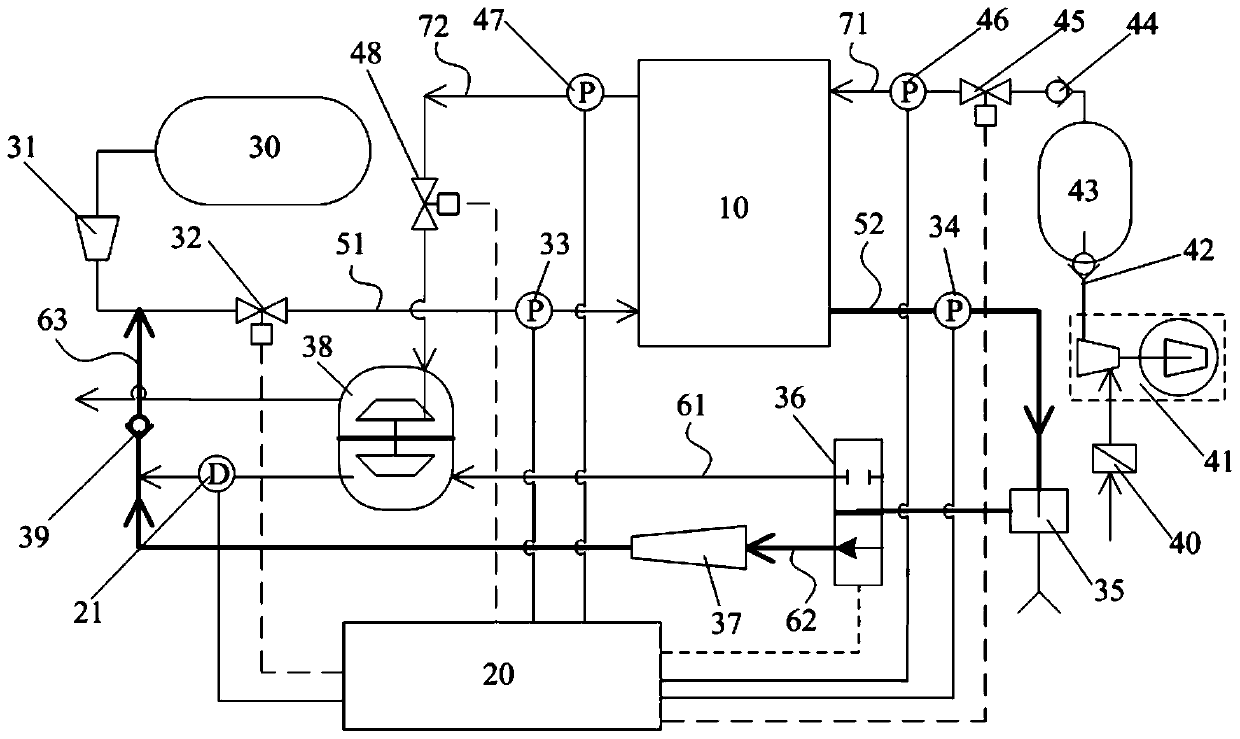

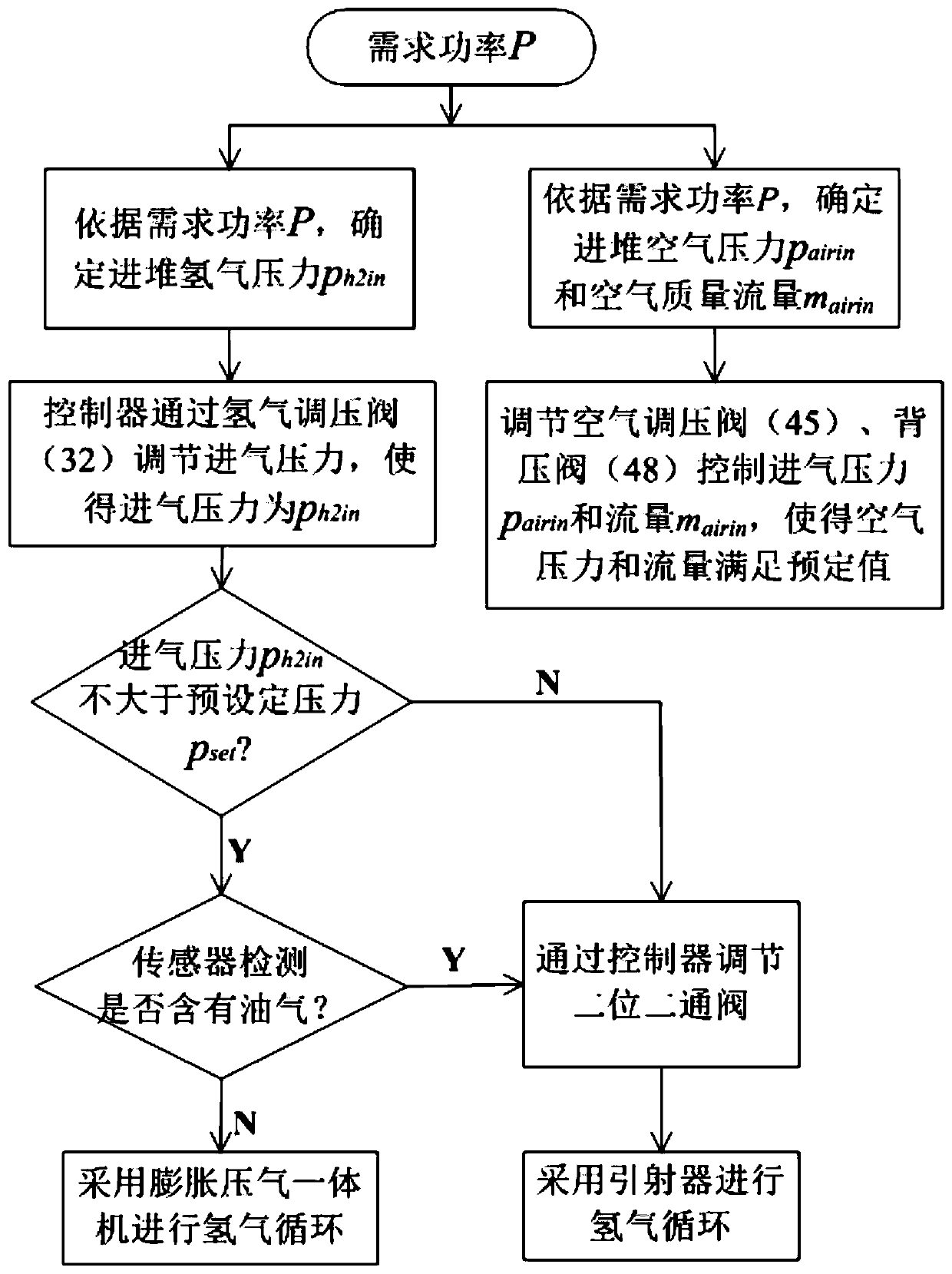

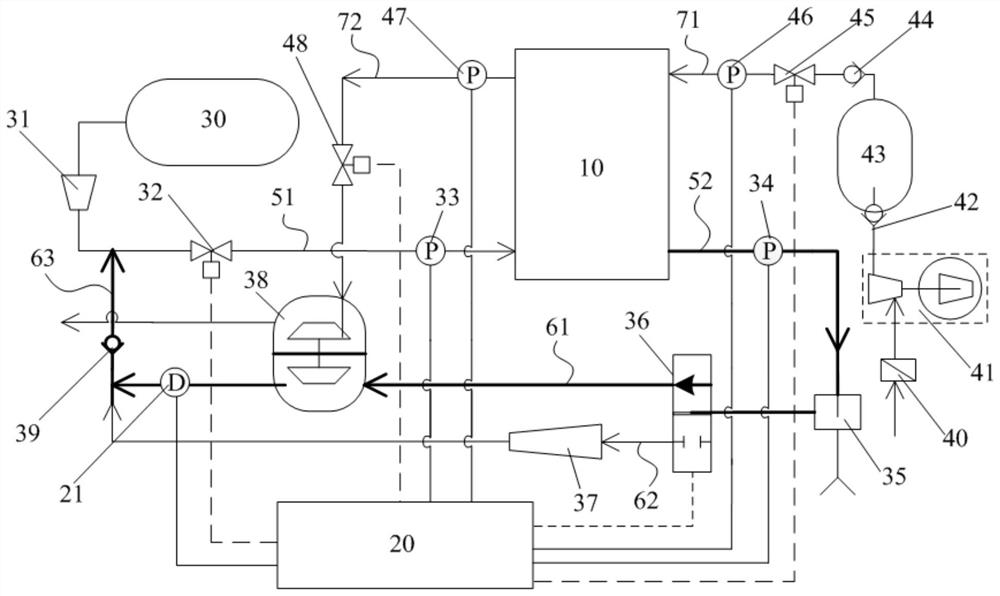

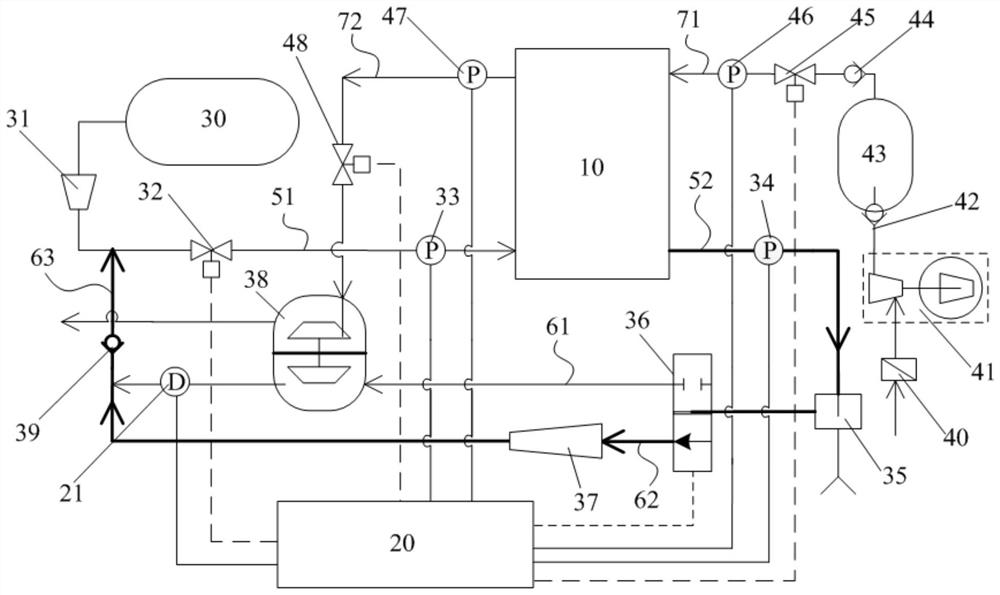

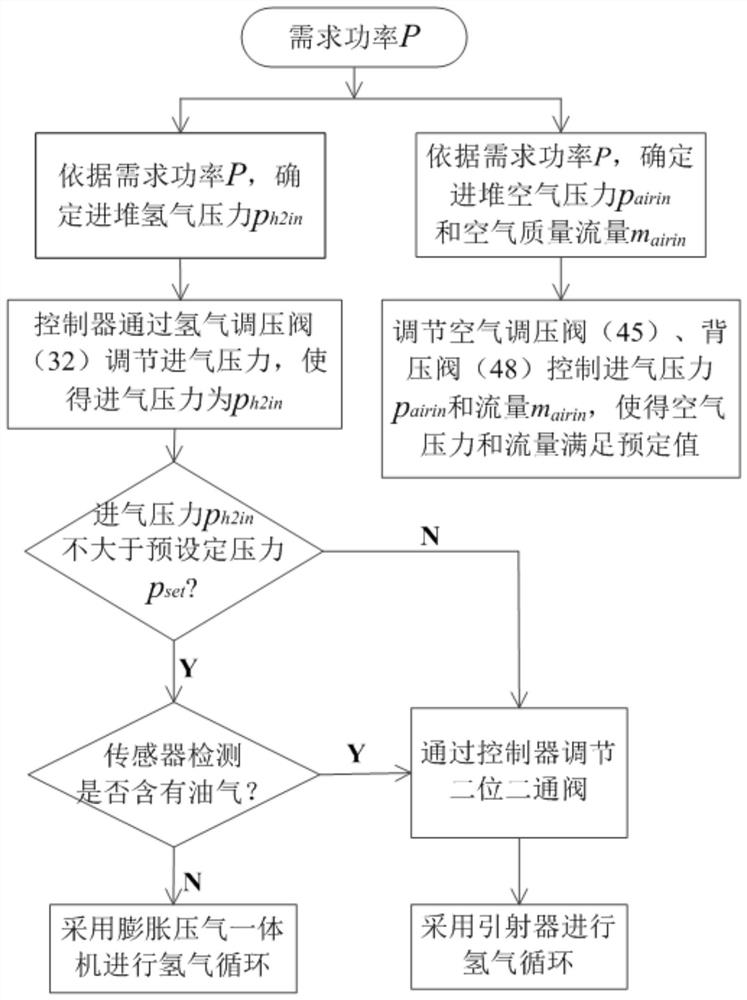

Fuel cell engine system and air supply system thereof, and control method

ActiveCN110649287AReduce parasitic loadIncrease net output powerReactant parameters controlGas compressorHydrogen pressure

The invention discloses a fuel cell engine system and an air supply system thereof, and a control method. The air supply system comprises a hydrogen supply system and an air supply system; a hydrogenoutlet pipeline is connected with a two-position two-way valve; the two-position two-way valve is connected with a first hydrogen circulating pipeline and a second hydrogen circulating pipeline in parallel; the first hydrogen circulating pipeline is connected to an inlet of a gas compressor of an expansion and gas compression all-in-one machine; and the outlet of the gas compressor is connected toa hydrogen circulation main pipeline, the hydrogen circulation main pipeline is connected to a hydrogen inlet pipeline, a second hydrogen circulation pipeline is connected to the hydrogen circulationmain pipeline through a hydrogen ejector, an inlet hydrogen pressure detection device is arranged on the hydrogen inlet pipeline, and an air outlet pipeline is connected to an expansion machine of the expansion and gas compression all-in-one machine. High-pressure tail gas exhausted by the air supply system is effectively used for driving the expansion and gas compression all-in-one machine to achieve hydrogen cyclic utilization, parasitic loads of the auxiliary system are reduced, and the net output power of the stack is improved.

Owner:WEICHAI POWER CO LTD

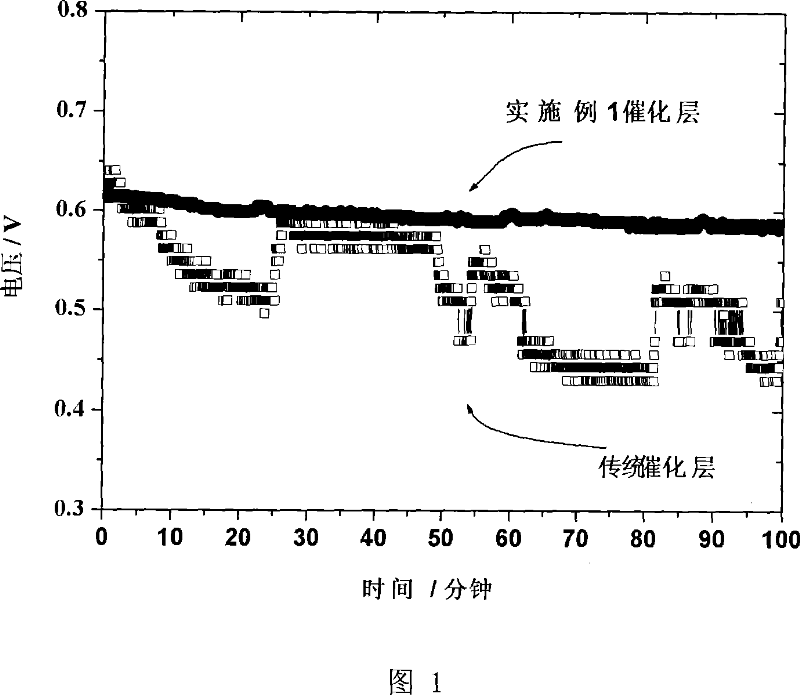

Method for preparation of membrane electrode of water-keeping proton exchange film fuel cells

InactiveCN101038966AImprove water retentionIncrease net output powerCell electrodesFuel cell detailsOrganic solventPolymer modified

The invention relates to a method for preparing membrane electrode of proton exchange membrane fuel cell. A method for preparing membrane electrode of water-conserving proton exchange membrane fuel cell is characterized by including following steps: 1) preparing proton conduction polymer modified by inorganic oxide nano-particles: a) firstly, the PH value of the solution containing 1.2 to 10 wt. % proton conduction polymer is regulated to 6.5 to 7.5 by NaOH, and then the solution is transferred into anhydrous organic solvent, thus, solution A can be obtained, in succession, the solution A is distilled to obtain solution B; b) according to the weight ratio of inorganic oxide to proton conduction polymer 0.01 : 1 to 0.1 : 1, the inorganic oxide precursor of the inorganic oxide is added into the solution B prepared in step a) and then is churned for 20 to 30 minute thereby obtaining inorganic oxide precursor solution; c) the preparation of proton conduction polymer modified by inorganic oxide nano-particles; 2) preparing membrane electrode. The membrane electrode prepared by the invention has good water-conserving capacity.

Owner:WUHAN UNIV OF TECH

Multi-pressure steam compensation type low-boiling-point organic working medium Rankine cycle system

InactiveCN103758595AIncrease net output powerExtend your lifeSteam engine plantsWorking fluidBoiling point

The invention discloses a multi-pressure steam compensation type low-boiling-point organic working medium Rankine cycle system. Hot liquid or smoke at 100 DEG C to 350 DEG C is mainly used by the system, a low-boiling-point organic working medium serves as working fluid of a Rankine cycle, full absorption and gradient utilization of waste heat of the hot liquid or the smoke are achieved through at least two levels of evaporators, and generated steam enters a steam compensation type ORC turbine and acts in an expanding mode so that an electric generator or other devices can be dragged to rotate. According to the multi-pressure steam compensation type low-boiling-point organic working medium Rankine cycle system, a heat source of the hot liquid or the smoke at the medium and low temperature of 100 DEG C to 350 DEG C is efficiently utilized and compared with a common ORC, the net output power of a device is increased by about 30%.

Owner:SHANDONG QINGNENG POWER

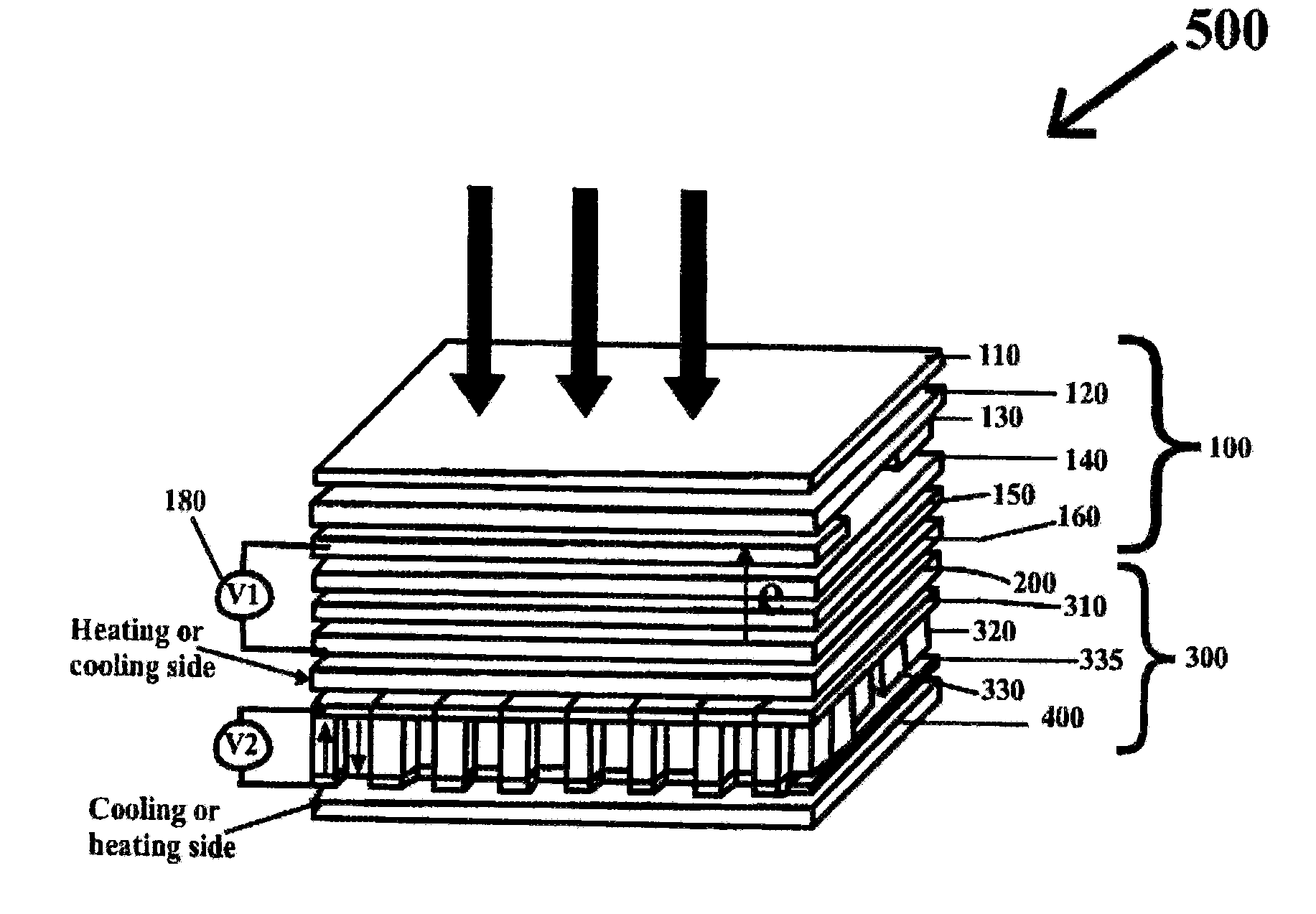

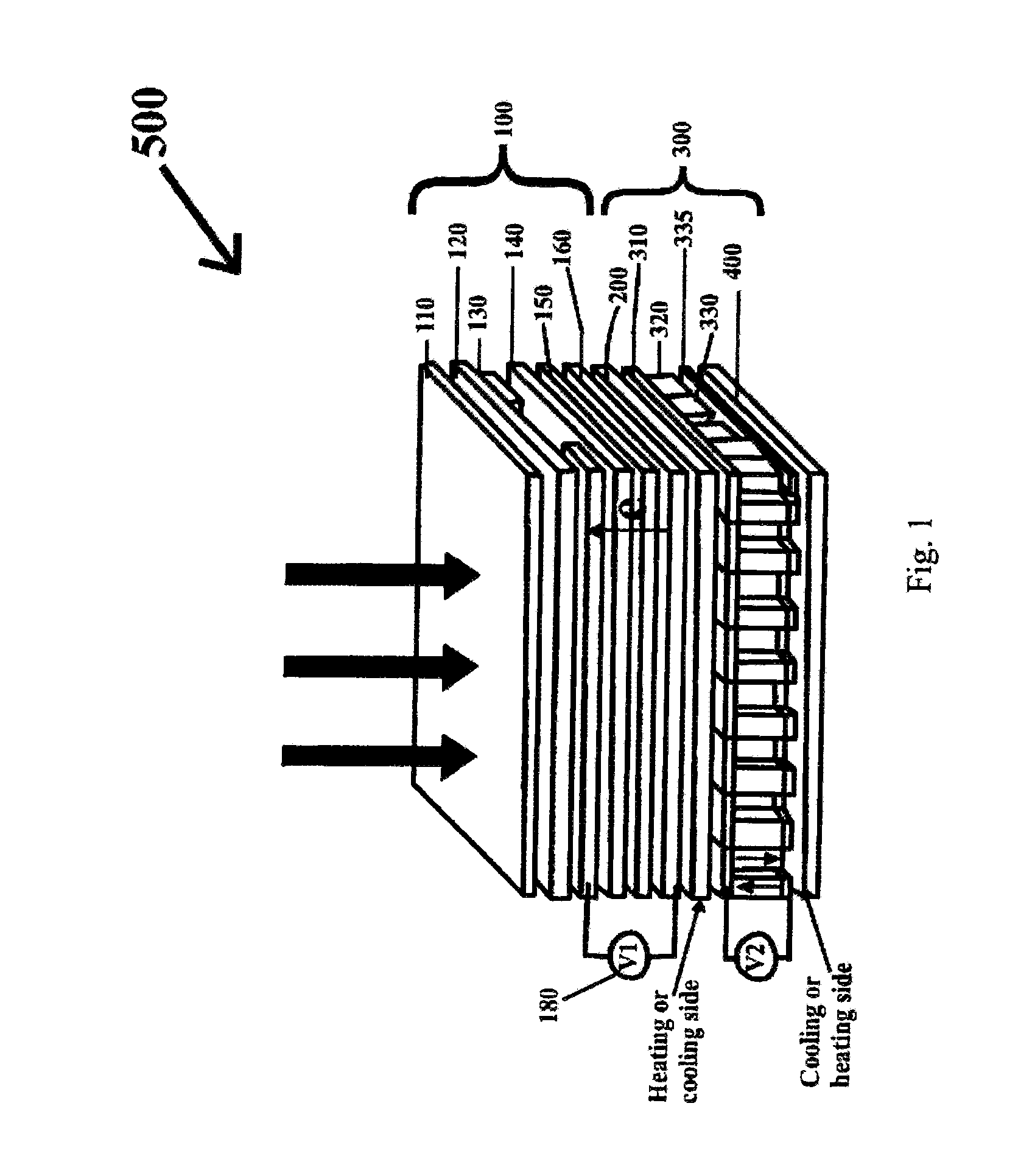

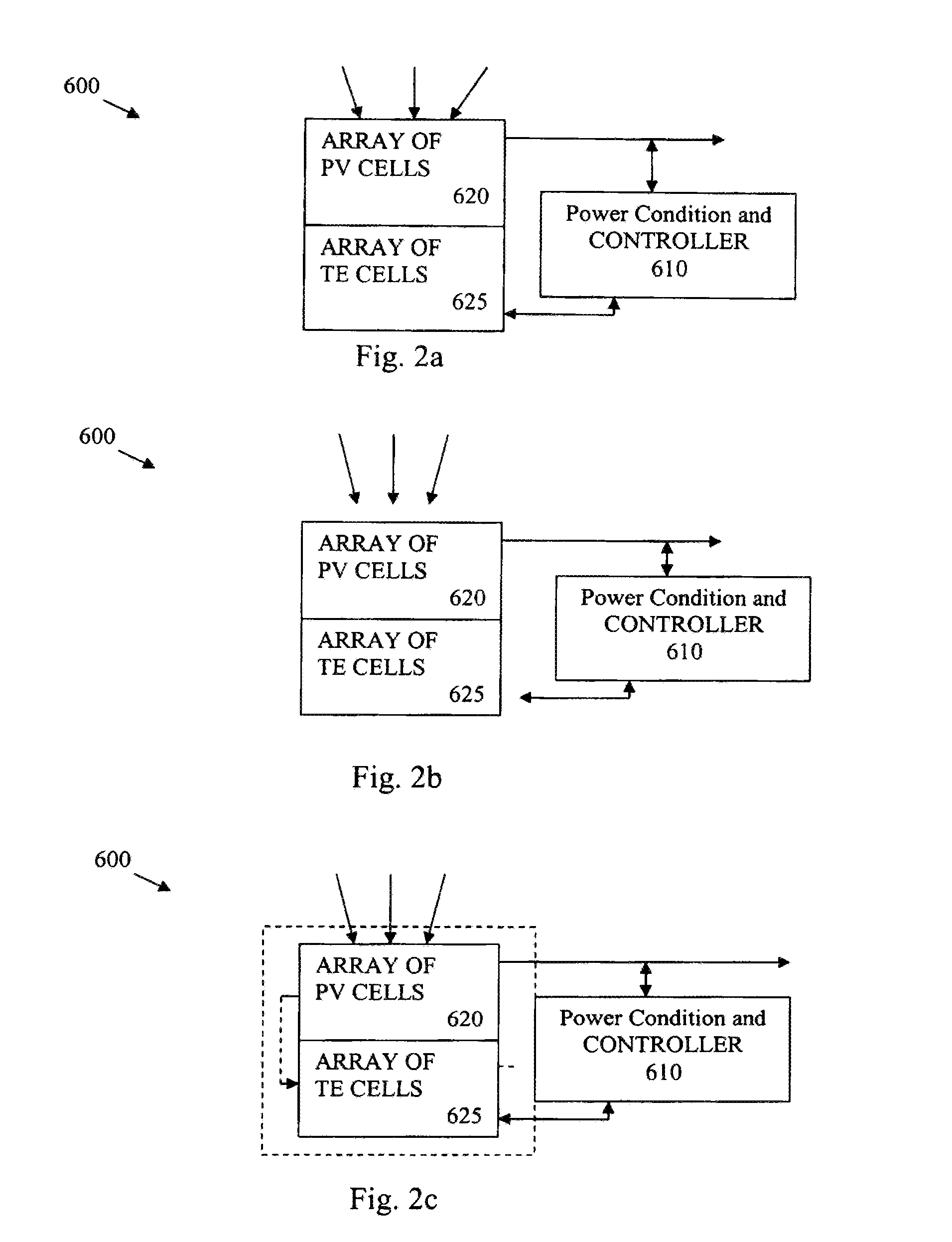

Hybrid Solar Cell Integrating Photovoltaic and Thermoelectric Cell Elements for High Efficiency and Longevity

InactiveUS20130220393A1Effective areaIncrease net output powerThermoelectric device with peltier/seeback effectPV power plantsEngineeringOperation mode

Methods, systems and apparatus for a solar cell integrating photovoltaic and thermoelectric cell elements to form a hybrid solar cell having increased efficiency and longevity by combining operation of the photovoltaic and thermoelectric elements in at least three different modes of operation to increase electrical output per unit of panel area and to increase cell life, improve performance, and provide operational benefits under different environmental conditions.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

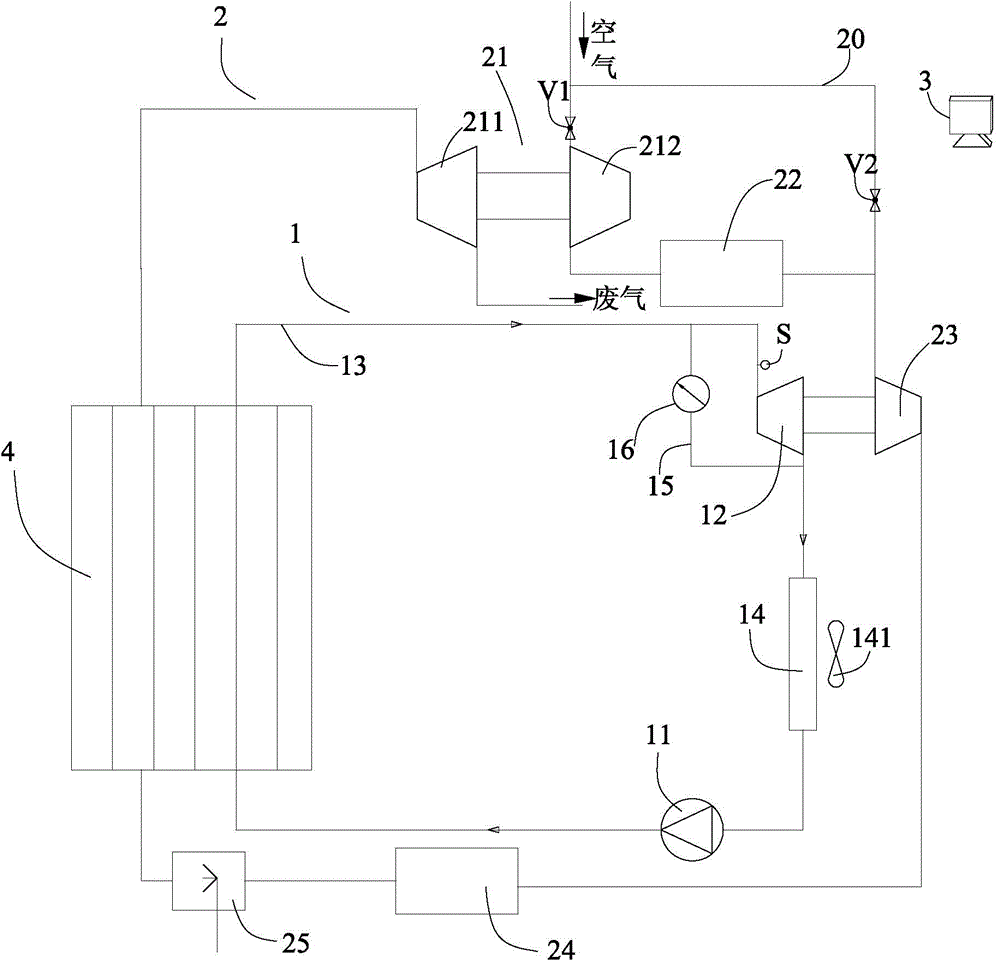

Fuel cell and thermal management control system thereof

The invention relates to a fuel cell and a thermal management control system thereof.The thermal management control system at least comprises a hydrogen supply pipeline and a cooling liquid loop, at least one heat exchanger is arranged between a hydrogen storage tank of the hydrogen supply pipeline and an anode of a galvanic pile, and one end of the heat exchanger is connected with a cooling outlet of the galvanic pile; the other end of the heat exchanger is connected with a cooling inlet of a galvanic pile through a pump, under the condition that hydrogen exchanges heat with a cooling medium through the heat exchanger, the hydrogen absorbs heat energy of the cooling medium to be gasified, and the hydrogen with the increased pressure drives a turbine pressure reduction mechanism to perform pressure reduction action; and / or the heat exchanger further enables the refrigerant to communicate with the air conditioning system loop in a mode of passing through the heat exchanger, so that the refrigerant in the air conditioning system loop exchanges heat energy with the hydrogen. The method has the advantages that firstly, the cold energy of the liquid hydrogen is effectively utilized; and secondly, by arranging the heat exchanger, the power of the radiator is reduced or even the radiator is omitted, and energy consumption is saved.

Owner:SHANGHAI EVERPOWER TECHNOLOGIES LTD

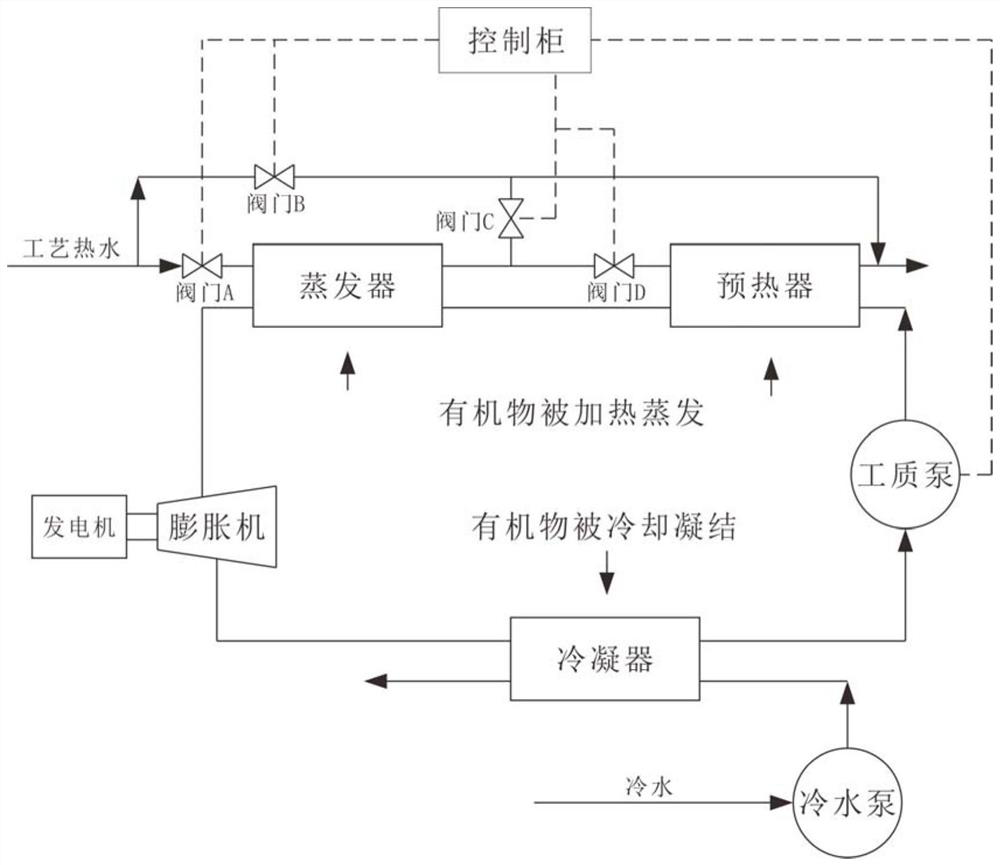

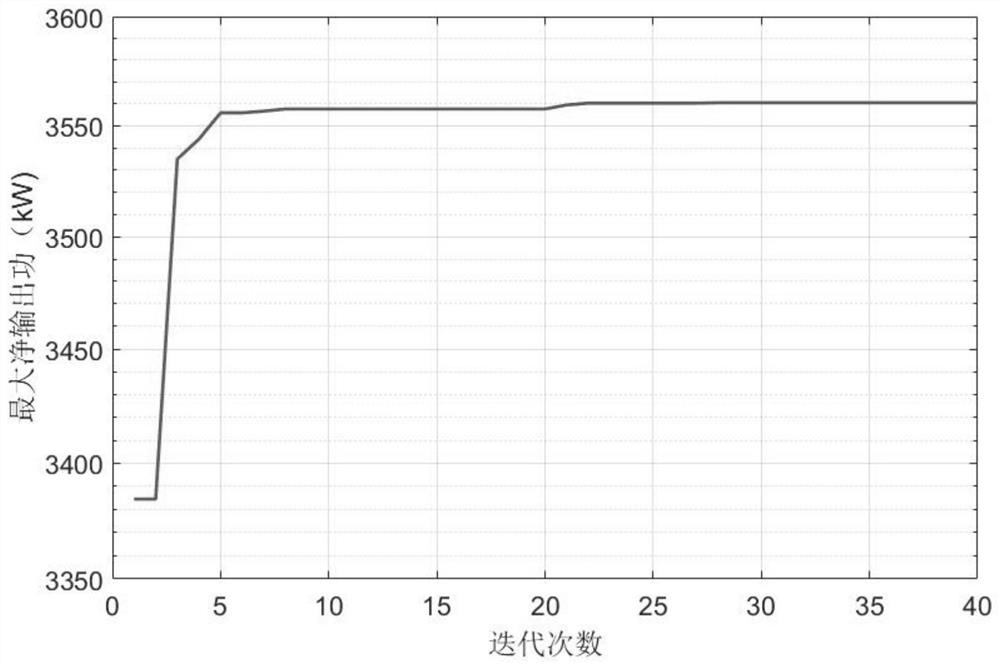

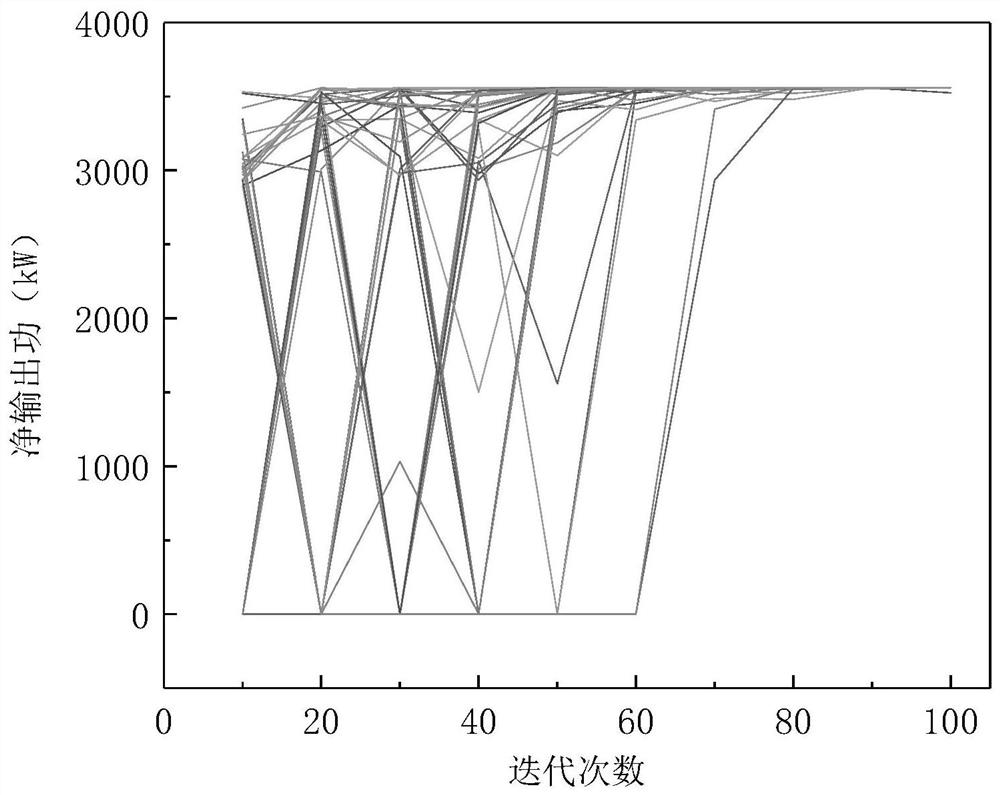

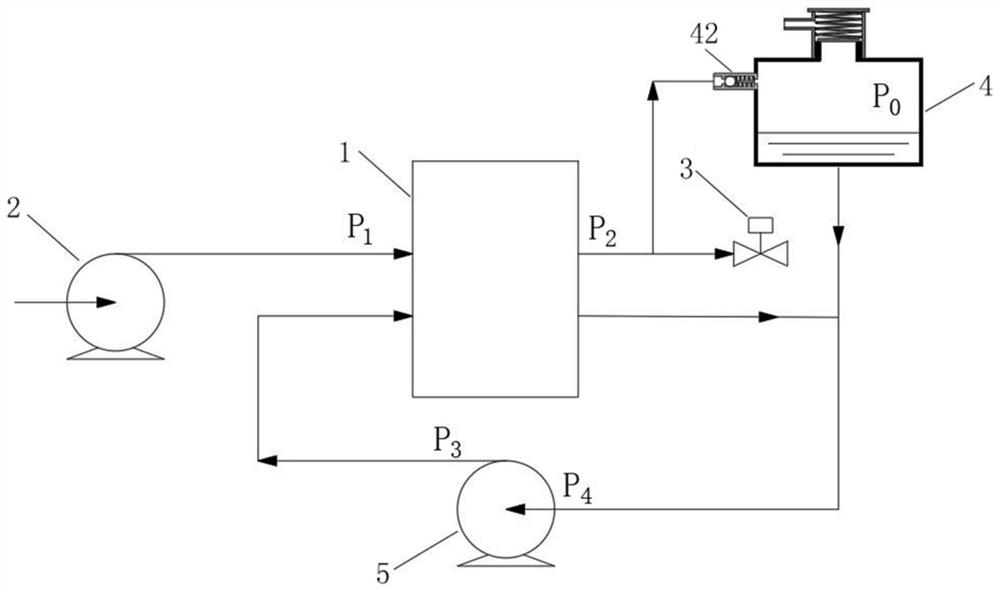

Heat source shunting type waste heat power generation system and particle swarm optimization control method thereof

ActiveCN112836419AIncrease net output powerOptimum operationGeometric CADArtificial lifeGenetics algorithmsWater pipe

The invention discloses a heat source shunting type waste heat power generation system and a particle swarm optimization control method thereof. The heat source shunting type waste heat power generation system comprises an evaporator and a preheater, the evaporator is connected with an expansion machine, the preheater is connected with a working medium pump, the working medium pump is connected with a condenser, the expansion machine is connected with the condenser, and the condenser is connected with a cold water pump; the cold water pump is connected with the cold water pipe; the particle swarm optimization control method comprises the following steps: setting a variable change interval based on a particle swarm algorithm program in Matlab, calculating the fitness of particles, and obtaining an optimal evaporation temperature tevap' by using a genetic algorithm; the optimal primary split ratio is rsp1', the secondary split ratio is optimized to be rsp2', and the maximum net output power Wnet'; and optimizing the shunting flow of the system. The particle swarm optimization is used as an optimization control method, and the particle swarm optimization is used for optimizing the independent variables of the heat source shunting waste heat power generation system under the non-design working condition, so that the maximum net output power operated under the optimal control independent variable condition is obtained.

Owner:SOUTHWEST JIAOTONG UNIV

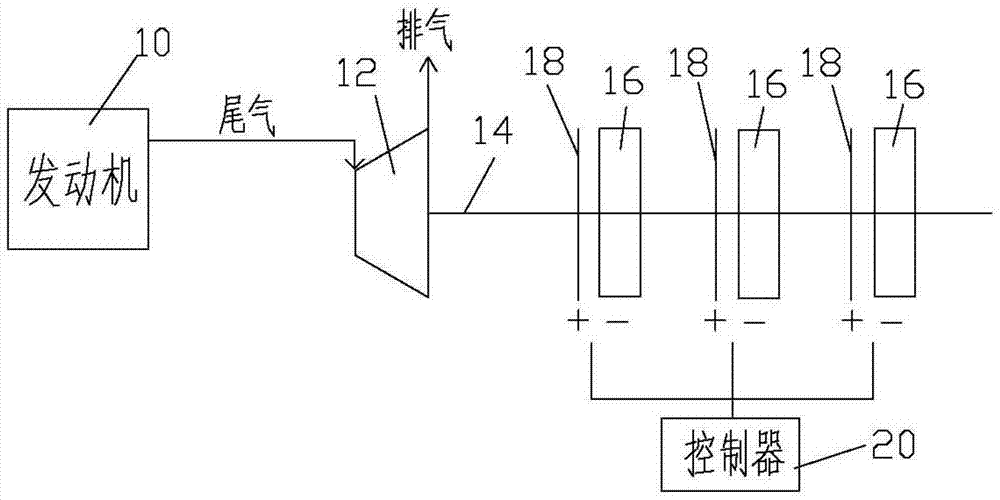

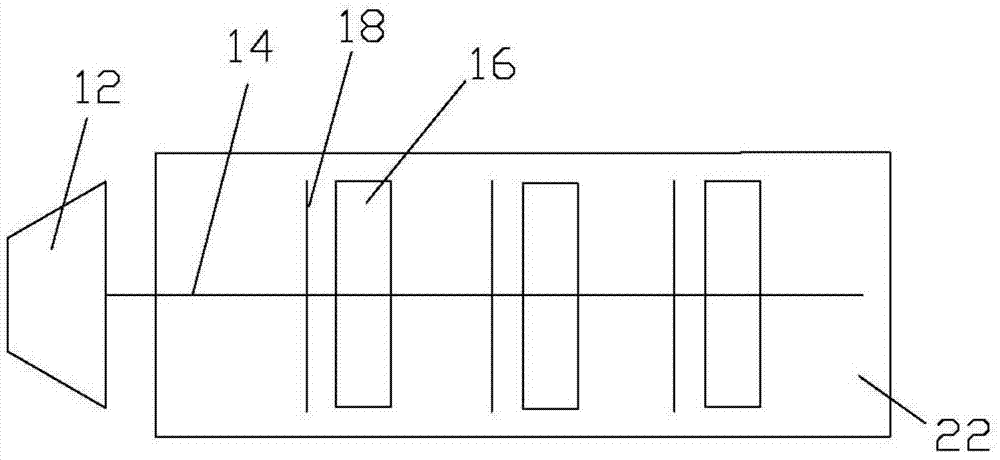

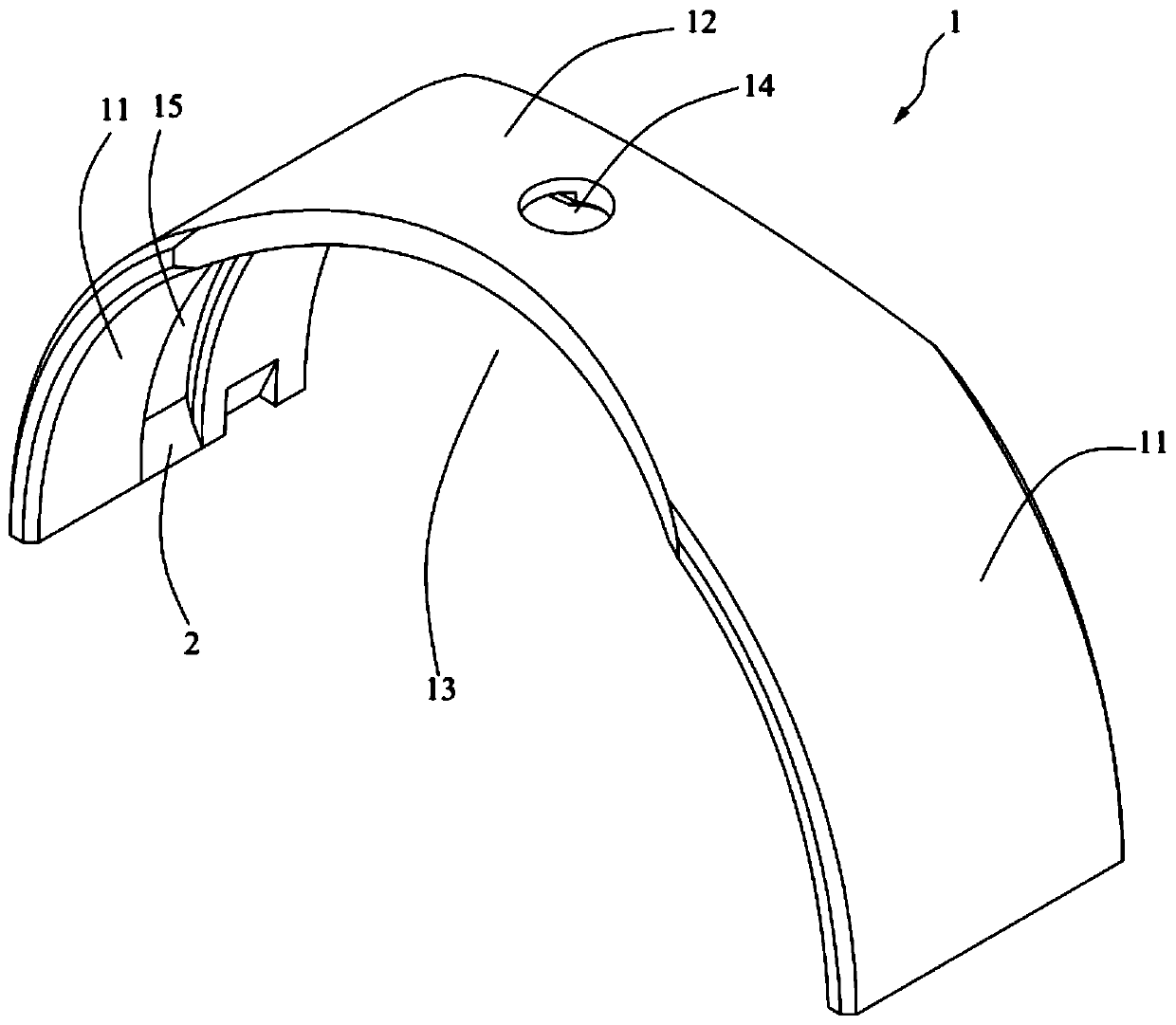

Driving device for shaft belt equipment, shaft belt equipment module and power system

ActiveCN104494424AIncrease net output powerImprove efficiencyPropulsion unit gas exhaustControl devicesEngineeringTurbine

The invention provides a driving device for shaft belt equipment. The driving device comprises a turbine, a rotating shaft and at least one connecting structure, wherein the turbine is used for receiving exhausted gas from an engine so as to be driven to rotate by the exhausted gas; the rotating shaft is connected with the turbine so as to be driven to rotate by the turbine; the connecting structure is connected between the rotating shaft and at least one shaft belt equipment. The state of the connecting structure can be converted between engagement and separation; in the state of engagement, the kinetic energy of the rotating shaft in the rotating state can be transmitted to the at least one shaft belt equipment through the connecting structure so as to drive the at least one shaft belt equipment, and while in the state of separation, the rotating shaft stops driving the at least one shaft belt equipment.

Owner:SHENZHEN WISDOM ENERGY TECH CO

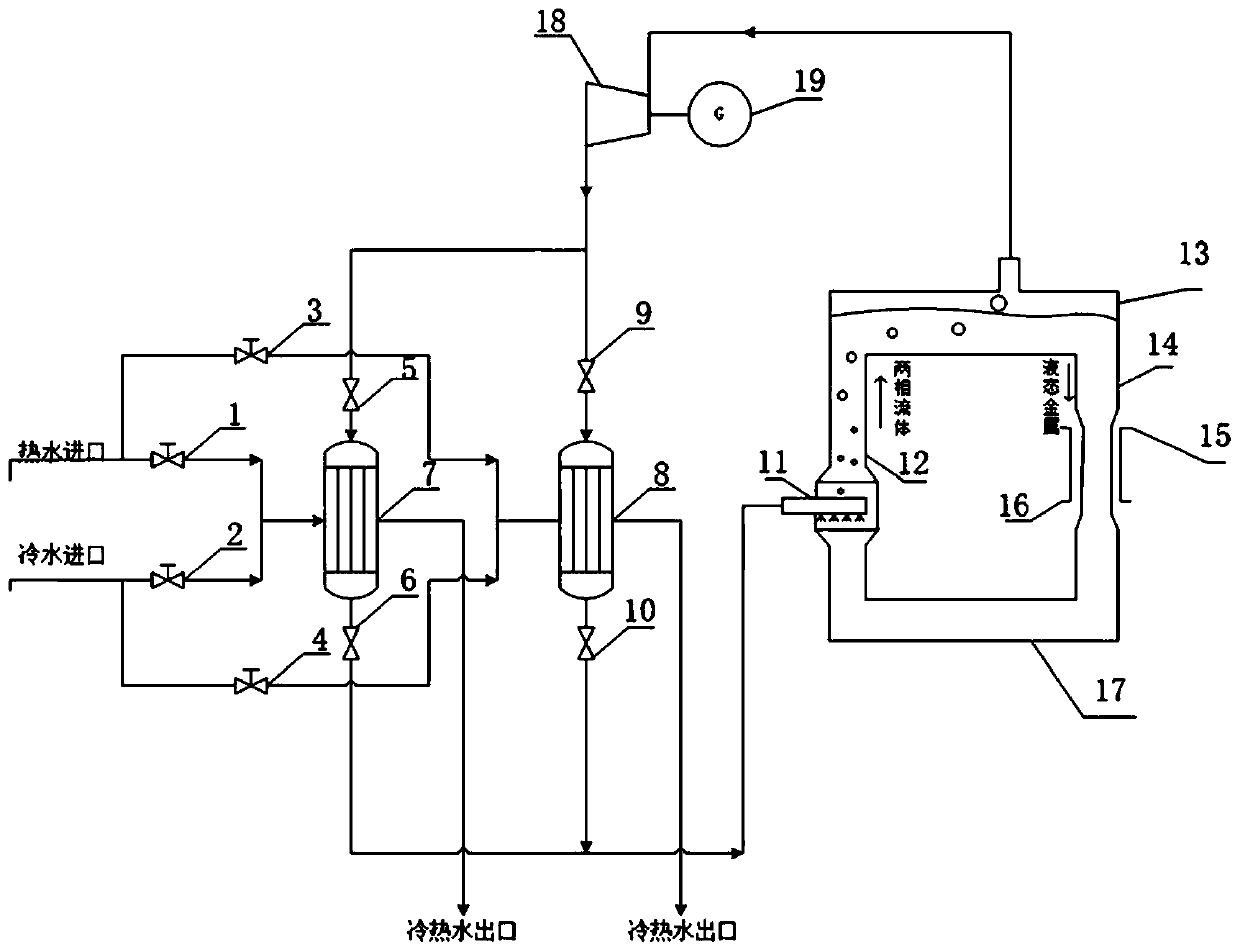

Pump-free Rankine cycle and liquid metal combined power generation system

PendingCN111237019AReduce energy consumptionIncrease net output powerSteam engine plantsKinetic-electric generatorElectric generatorCirculating pump

The invention discloses a pump-free Rankine cycle and liquid metal combined power generation system which comprises an adsorption-Rankine cycle power generation cycle module and a liquid metal magnetofluid power generation cycle module. The adsorption-Rankine cycle power generation cycle module comprises a generator, an expansion machine, an adsorption bed a, an adsorption bed b and an aeration pipe; and the liquid metal magnetofluid power generation cycle module is composed of an annular channel structure and liquid metal. The adsorption beds alternately work to replace a working medium circulating pump, the input power of the working medium circulating pump can maximally account for 45% of the output power of the expansion machine, the working medium circulating pump is eliminated, the energy consumption of the system is reduced, and the net output power of the system is improved. The outlet pressure of the expansion machine in the adsorption-Rankine cycle is reduced through the adsorption process of the adsorption beds, and the net output power of the system is further improved. The temperature of the liquid metal in the annular channel structure is more uniform, and the flow ofthe liquid metal is facilitated.

Owner:DALIAN MARITIME UNIVERSITY

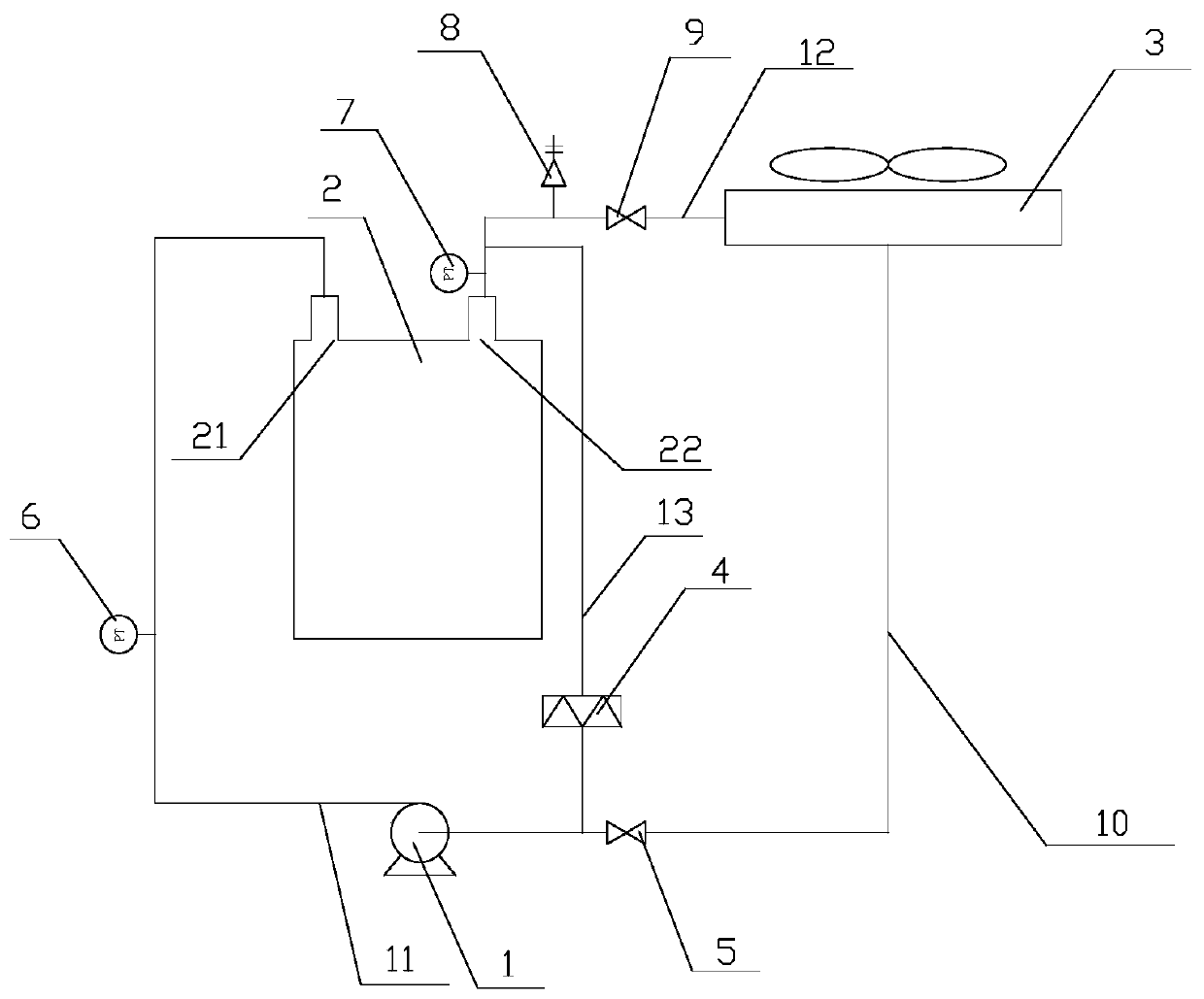

Fuel cell cooling system adopting organic working medium

The invention provides a fuel cell cooling system adopting an organic working medium. The fuel cell cooling system comprises a circulating pump, a fuel cell stack, a condenser, a PTC heater and a control device, wherein a water inlet and a water outlet are formed in the fuel cell stack; the coolant added in the fuel cell stack is a low-boiling-point organic working medium; the outlet of the condenser is communicated with the inlet of the circulating pump, and the outlet of the circulating pump is communicated with the water inlet of the fuel cell stack; the a water outlet of the fuel cell stack is communicated with the inlet of the condenser and one end of the PTC heater; the other end of the PTC heater is communicated with the outlet of the condenser; the control device controls opening or closing of the PTC heater and the circulating pump; when the temperature of the coolant in the fuel cell stack is lower than zero, the control device starts the PTC heater to heat the coolant; and when the temperature of the coolant in the fuel cell stack is higher than a rated temperature, the control device closes the PTC heater, and a gaseous coolant in the fuel cell stack flows into the condenser to be condensed.

Owner:武汉泰歌氢能汽车有限公司

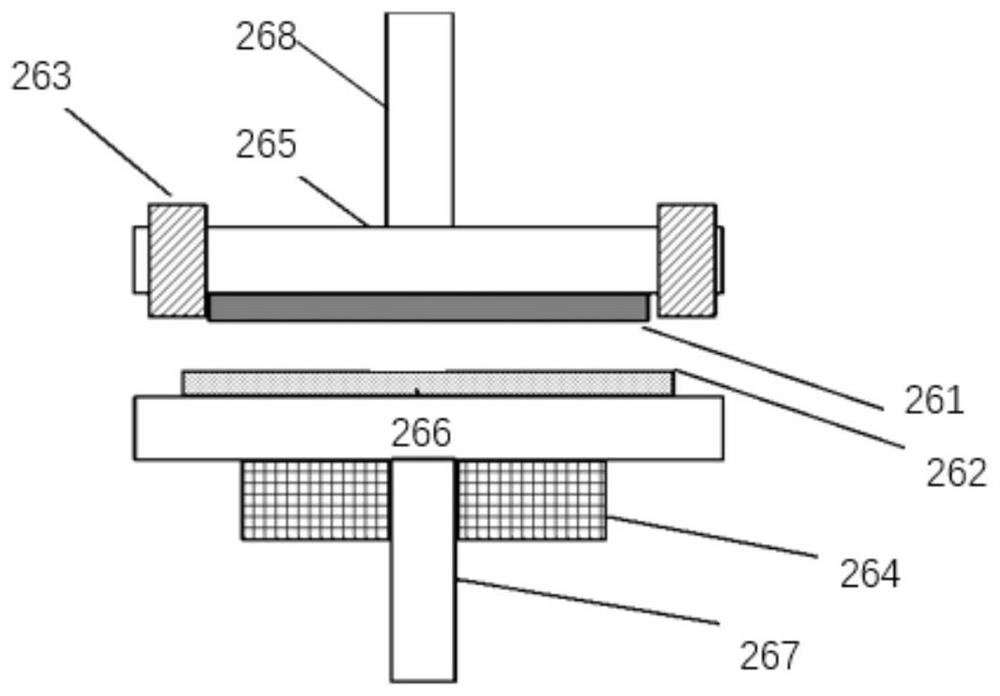

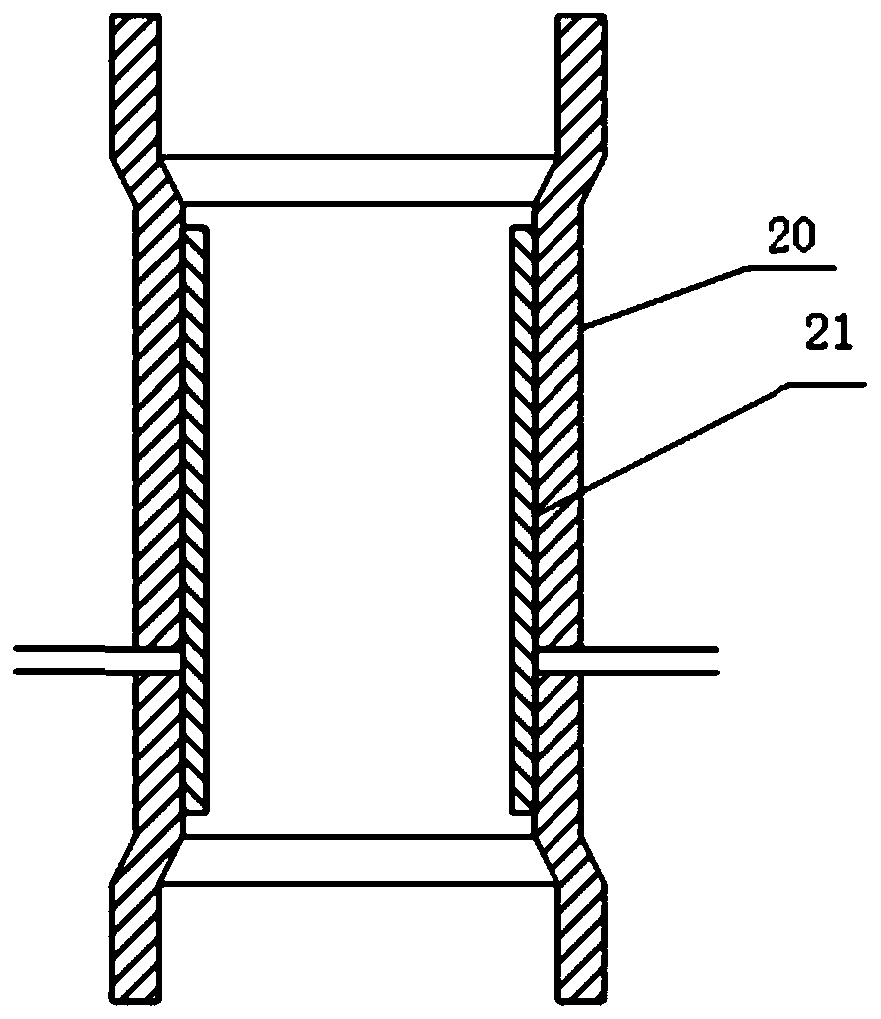

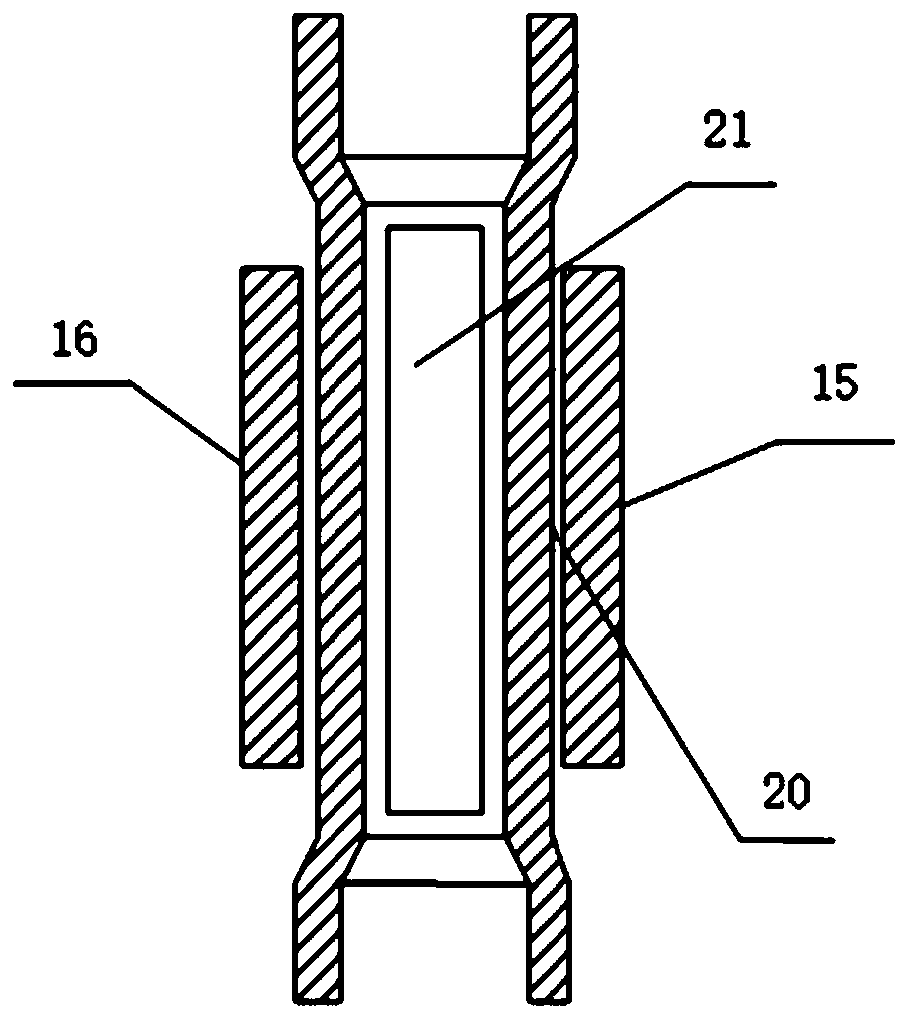

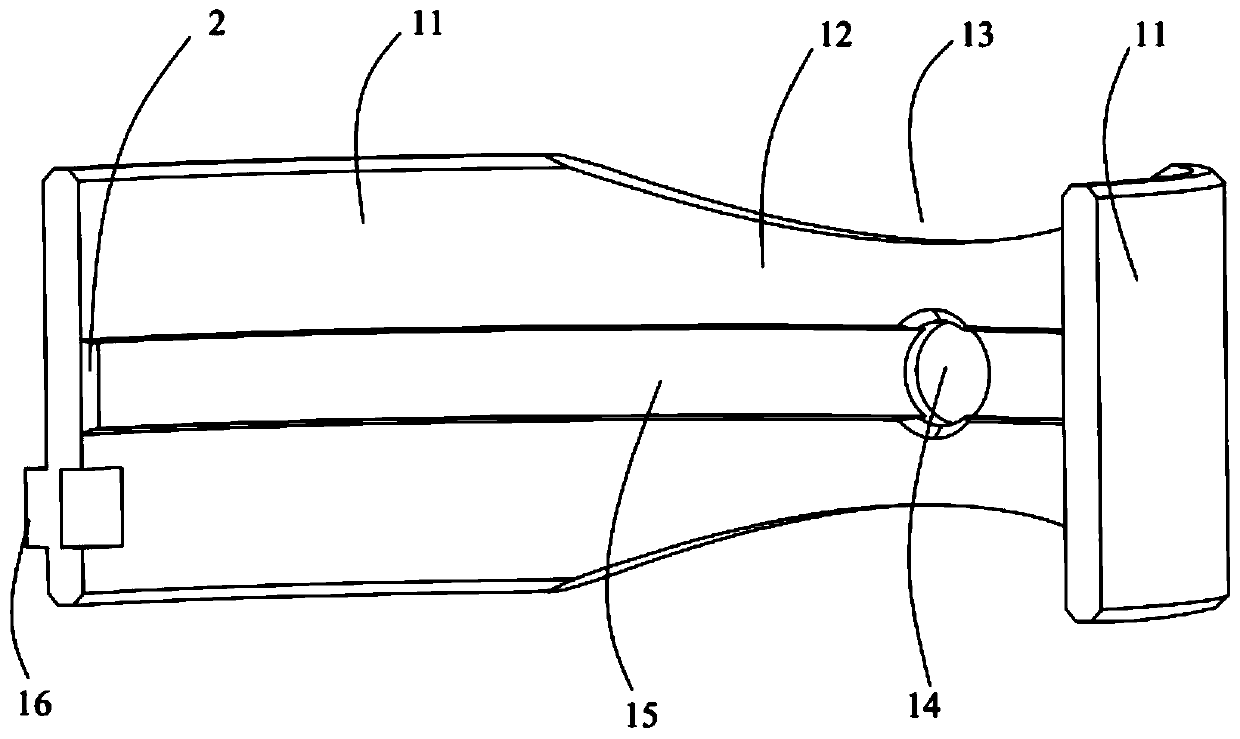

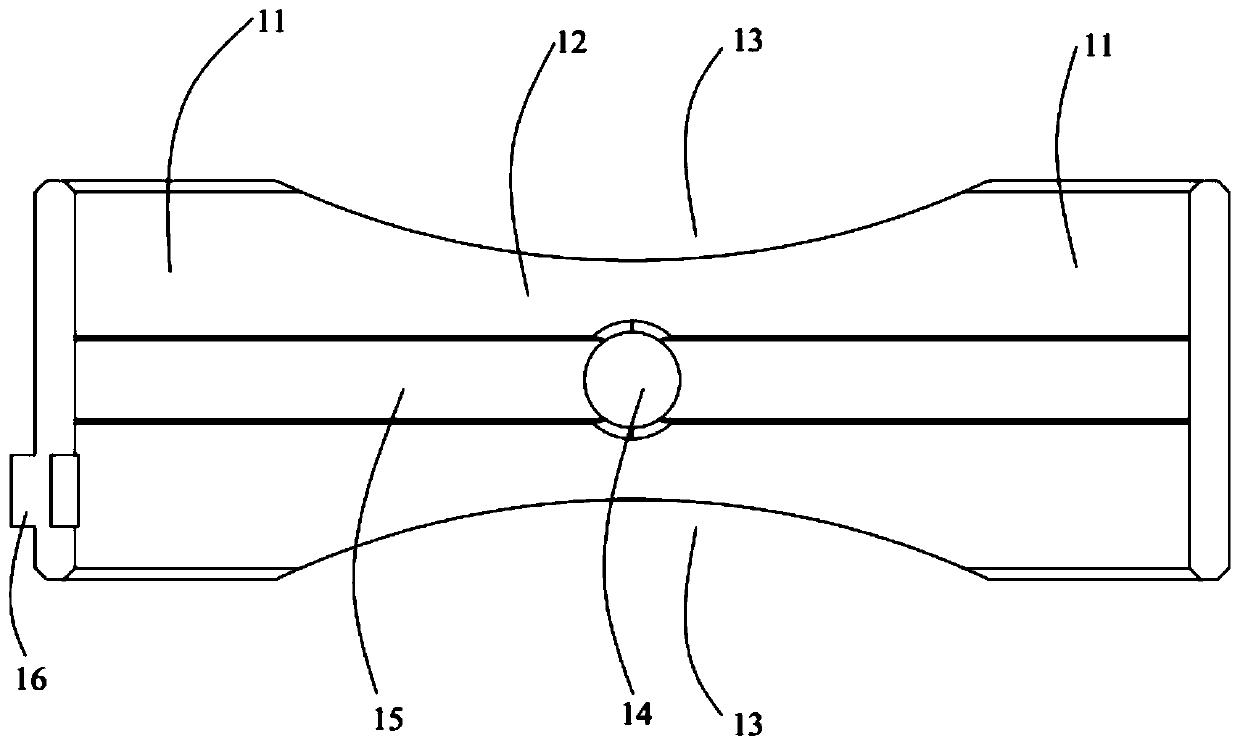

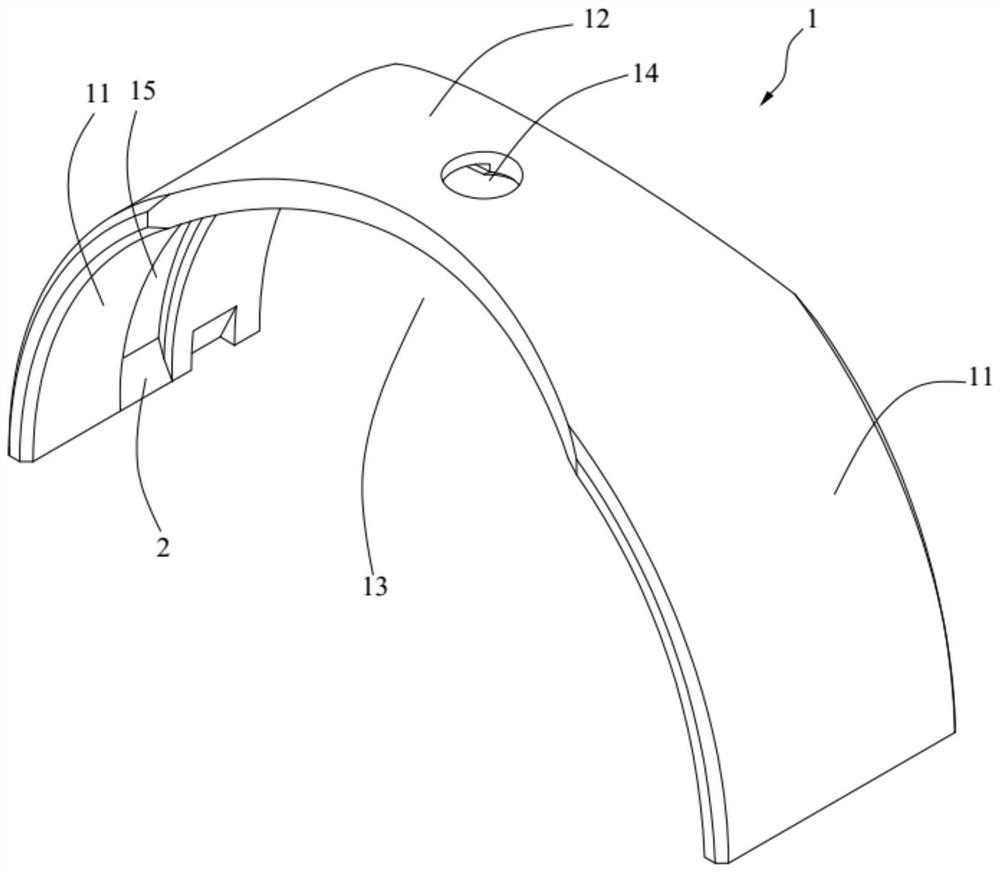

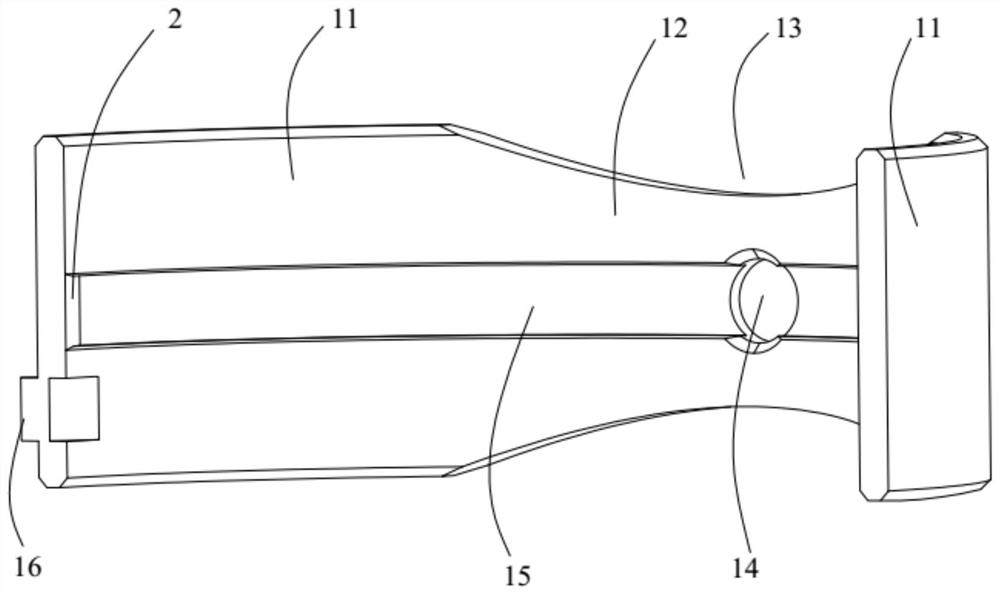

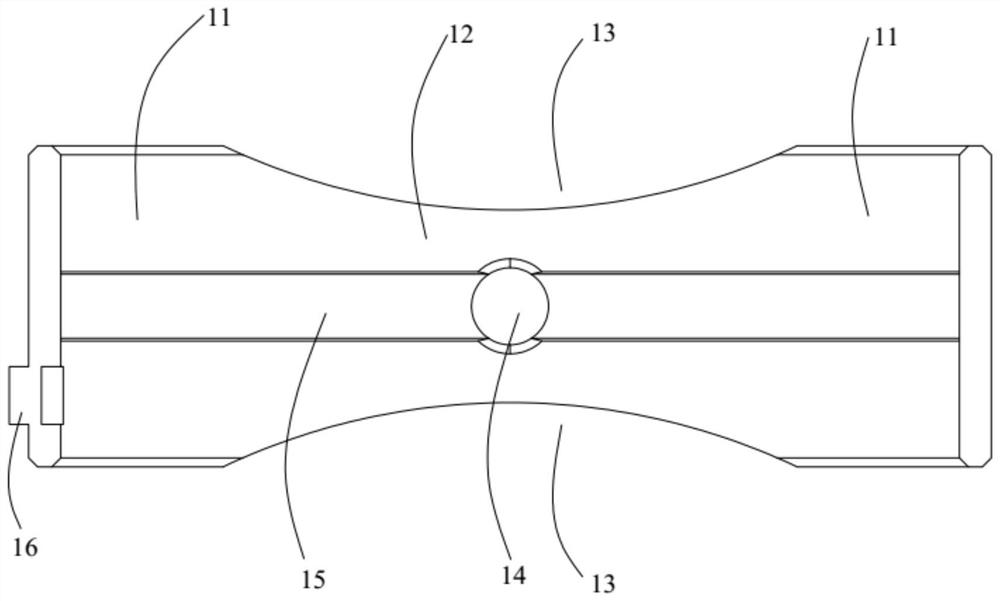

Main bearing bush and mounting structure

The invention belongs to the technical field of engines and discloses a main bearing bush and a mounting structure. The main bearing bush comprises an upper bearing bush and a lower bearing bush, the two ends of the upper bearing bush abut against the two ends of the lower bearing bush, the upper bearing bush comprises a first transition portion and two supporting portions, the two ends of the first transition portion are connected to the two supporting portions, and the axial width of the first transition portion is smaller than the axial width of the supporting portions. The upper bearing bush of the main bearing bush adopts a variable cross section manner, the partial cross section of the upper bearing bush is reduced, the contact area between the upper bearing bush and a main journal of a crankshaft is reduced through the upper bearing bush, friction force between the upper bearing bush and the main journal of the crankshaft is reduced, and the friction loss is reduced. Meanwhile, compared with the prior art, on the premise of ensuring the strength of the upper bearing bush, the weight of the upper bearing bush is equivalently reduced, the weight reducing effect is achieved, the whole vehicle dead load fuel consumption is reduced, and the aims of improving the net output power of the engine and reducing the fuel consumption are achieved.

Owner:WEICHAI POWER CO LTD

A main bearing bush and its mounting structure

ActiveCN110285143BReduce sectionGuaranteed StrengthBearing componentsFriction lossStructural engineering

The invention belongs to the technical field of engines, and discloses a main bearing bush and an installation structure. The main bearing bush includes an upper bearing bush and a lower bearing bush. The two ends of the upper bearing bush are respectively abutted against the two ends of the lower bearing bush. For the two supporting parts, the axial width of the first transition part is smaller than the axial width of the supporting part. The upper bearing bush of the main bearing bush adopts a variable cross-section method to reduce part of the cross section of the upper bearing bush, which is used to reduce the contact area between the upper bearing bush and the main journal of the crankshaft, so that the friction between the upper bearing bush and the main journal of the crankshaft is reduced. to reduce friction loss. At the same time, compared with the existing technology, under the premise of ensuring the strength of the upper bearing pad, it is equivalent to reducing the weight of the upper bearing pad, which plays a role in weight reduction, thereby reducing the fuel consumption of the whole vehicle, so as to increase the net output power of the engine and reduce fuel consumption. the goal of.

Owner:WEICHAI POWER CO LTD

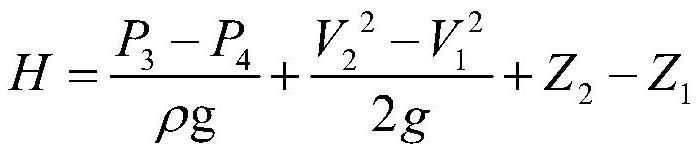

Method and device for generating electricity and preparing fresh water using low-temperature heat source

InactiveCN103449545BIncrease lift heightIncrease lift trafficGeneral water supply conservationSeawater treatmentWater turbineEngineering

Owner:JIMEI UNIV

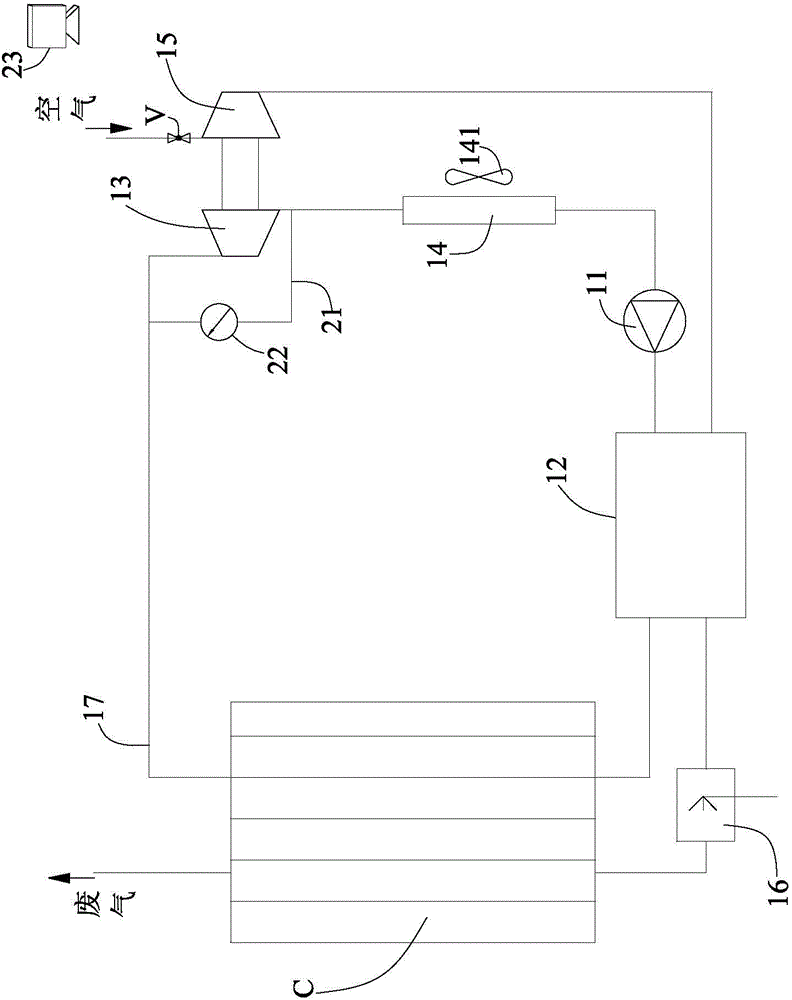

Fuel cell system

PendingCN113540499AImprove efficiencyImprove power densityFuel cell heat exchangeReactant parameters controlFuel cellsElectric machine

The invention provides a fuel cell system, and the system comprises a hydrogen assembly, an air assembly and a galvanic pile; the air assembly comprises an air compressor and an air pipeline, and the hydrogen assembly comprises a first pipeline for conveying liquid hydrogen; the air compressor is driven by a superconducting motor, and the air compressor is communicated with an air inlet of the galvanic pile through the air pipeline; the hydrogen assembly is communicated with a hydrogen inlet of the galvanic pile, the hydrogen assembly vaporizes liquid hydrogen and then sends the liquid hydrogen into the galvanic pile, and the first pipeline is connected with a cooling pipeline of the air compressor so that the liquid hydrogen in the first pipeline can enable a superconducting motor of the air compressor to be cooled to the working temperature. The fuel cell system has the advantages that the low-temperature characteristic of liquid hydrogen is effectively utilized; the net output power is improved; and the power density of the fuel cell system is improved.

Owner:BEIJING SINOHYTEC

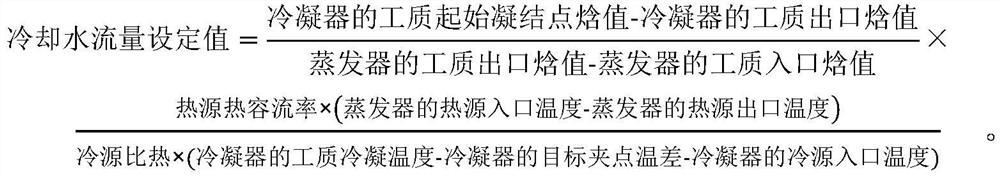

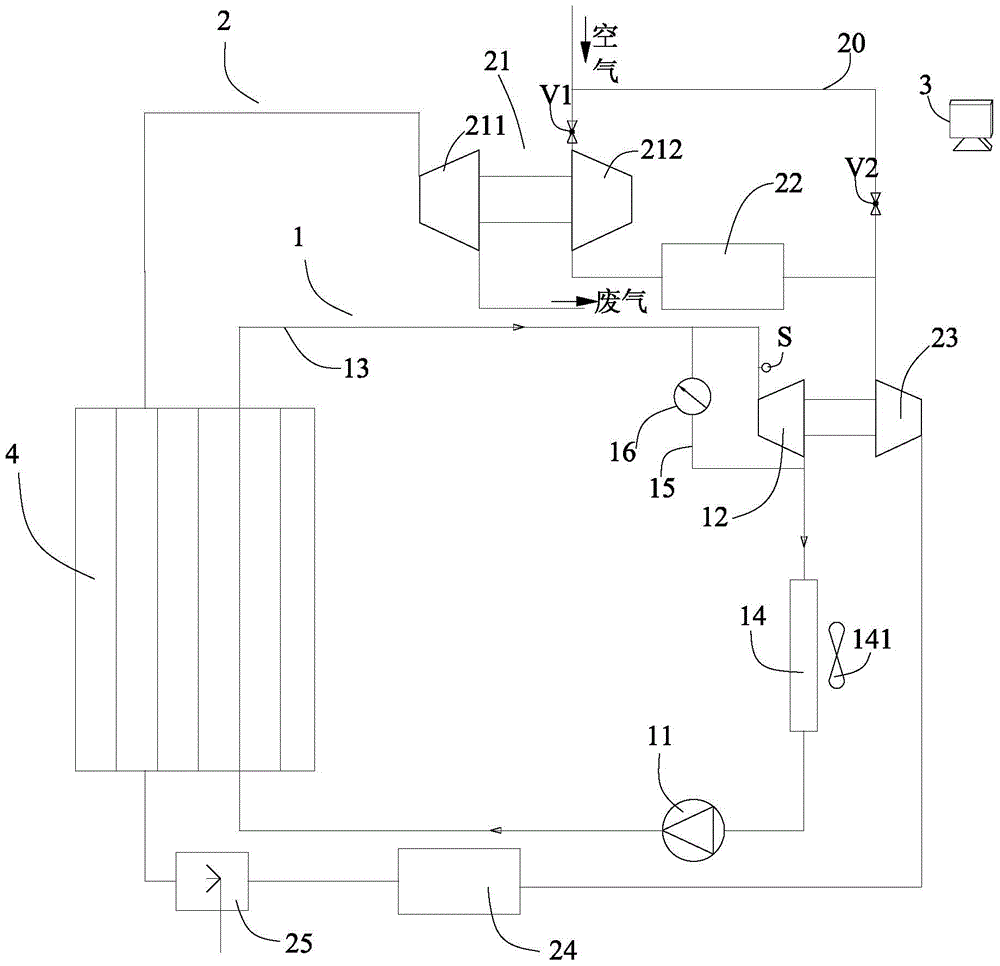

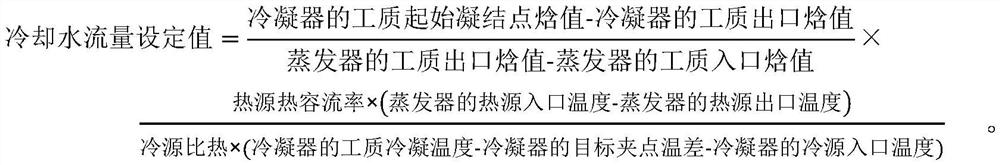

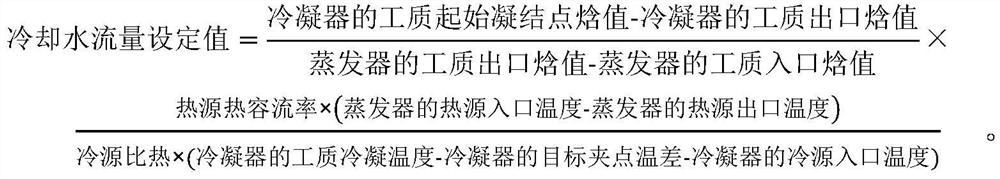

An organic Rankine cycle system

ActiveCN111794820BGuaranteed heat transfer efficiencyImproved heat recoveryPump controlSteam engine plantsWorking fluidOrganic Rankine cycle

The invention relates to an organic Rankine cycle system, which includes a working medium pump, an evaporator, a condenser and a cooling pump, and also includes a working medium pump speed control loop and a cooling pump speed control loop. The working medium pump speed control loop includes sequentially connected The first deviation calculation block, the cascade adjustment main adjustment PID adjustment block, the second deviation calculation block and the cascade adjustment sub-regulator PID adjustment block, the first deviation calculation block inputs the heat source outlet temperature of the evaporator and the heat source outlet temperature set value , the second deviation calculation block inputs the output of the cascade adjustment main adjustment PID adjustment block and the working medium outlet pressure of the evaporator, the cascade adjustment sub-regulator PID adjustment block is connected with the working medium pump, and the cooling pump speed control loop includes the third deviation The calculation block and the third PID adjustment block, the third deviation calculation block inputs the cooling water flow set value and the inlet cooling water flow of the cooling pump, and the third PID adjustment block is connected with the cooling pump. Compared with the existing technology, the heat recovery and thermal efficiency are improved, and the net output power is increased.

Owner:TONGJI UNIV

Fuel cell air supply system based on waste heat and pressure utilization

ActiveCN104485469BDoes not consume output powerIncrease net output powerFuel cellsElectrochemical responseFuel cells

The invention provides a waste heat and pressure utilization-based fuel cell air supply system which comprises an organic Rankine cycle-based waste heat recycle loop and a pressurized air supply system, wherein the organic Rankine cycle-based waste heat recycle loop comprises an organic working medium pump, an expansion machine, an organic working medium pipeline and a condenser; the pressurized air supply system comprises a first control valve, a turbocharging bypass loop, a second control valve, a turbocharger, a first intercooler, a compressor, a second intercooler and a humidifier. According to the waste heat and pressure utilization-based fuel cell air supply system, the pressurized air supply system is used for recycling and converting the dynamic energy from the waste gas of a fuel cell into mechanical work which is used for driving the turbocharger to compress the external air for the first time; the air compressed for the first time is used as supply air compressed by the compressor; the organic Rankine cycle-based waste heat recycle loop is used for recycling and converting the waste heat from the electrochemical reaction of the fuel cell into mechanical work which is used for driving the compressor of the pressurized air supply system to compress the supply air.

Owner:TSINGHUA UNIV

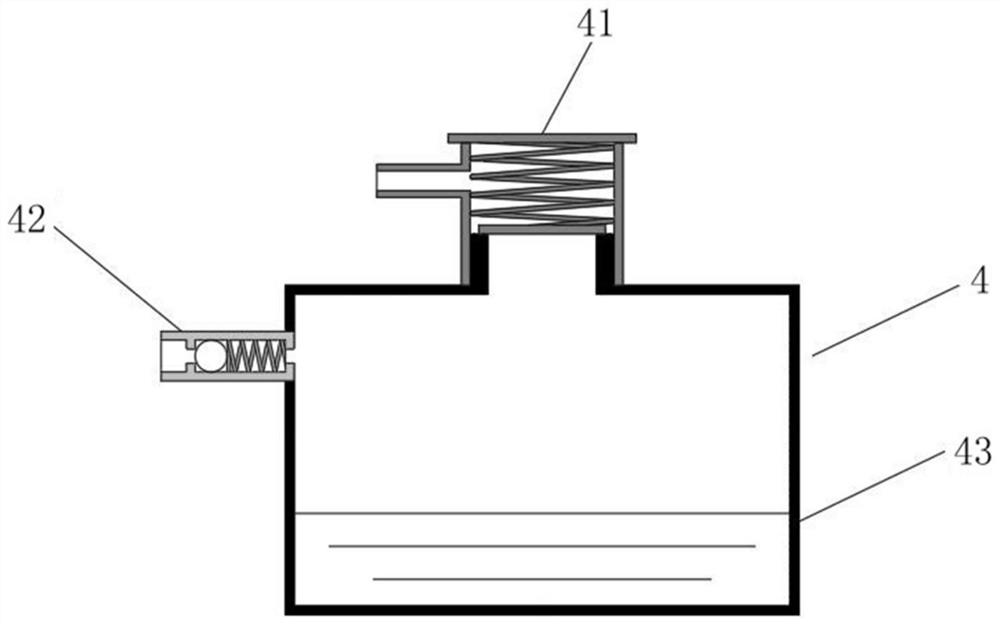

Fuel cell cooling circulation system

The invention relates to a fuel cell cooling circulation system which comprises an electric pile, an air loop, a cooling loop and a pressure loop, wherein the air loop comprises an air compressor, and air compressed by the air compressor is introduced into the electric pile from an air inlet of the electric pile and is discharged out of the electric pile from an air outlet of the electric pile; the cooling loop comprises an expansion water tank and a water pump, cooling liquid is introduced into the electric pile under the action of the water pump and flows back to a water inlet of the water pump from the electric pile, and the expansion water tank supplements the cooling liquid for the cooling loop; the pressure loop comprises an air delivery pipe and a one-way valve, the air delivery pipe is connected with the air outlet of the electric pile and the expansion water tank, and the one-way valve is arranged between the air outlet of the electric pile and the expansion water tank. Compared with the prior art, the gas with certain pressure at the air outlet of the electric pile is introduced into the expansion water tank, so that the requirement of the fuel cell on the lift of the water pump is reduced, the cost of the fuel cell is reduced, and the power of the water pump with smaller lift is also smaller, so that the net output power of the system of the fuel cell is increased.

Owner:上海澄朴科技有限公司

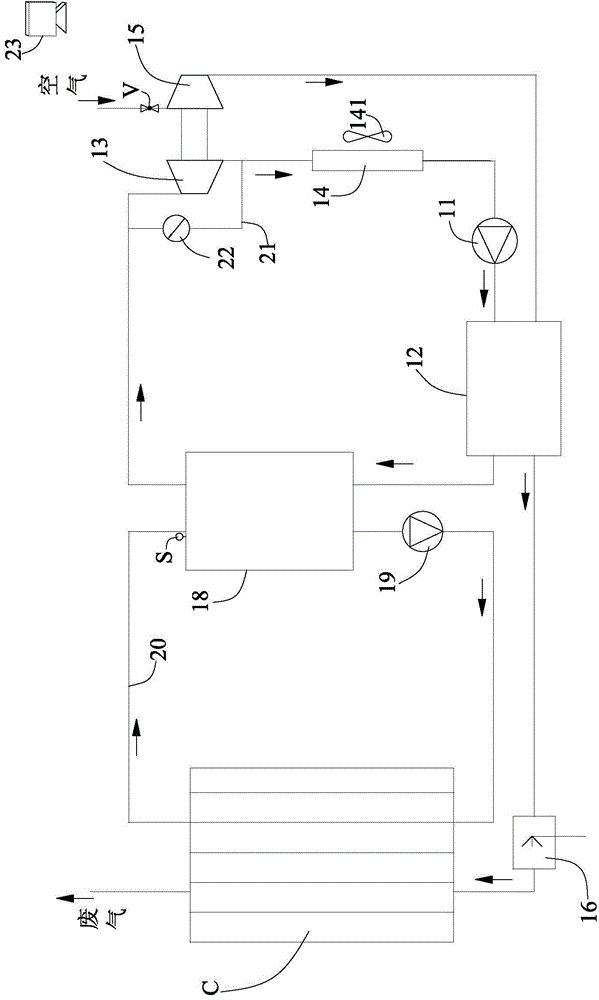

Hydrogen circulating system and vehicle

PendingCN114883595AImprove ejection effectIncrease net output powerReactant parameters controlThermodynamicsHigh pressure hydrogen

The invention belongs to the technical field of fuel cells, and discloses a hydrogen circulation system and a vehicle, the hydrogen circulation system comprises a hydrogen supply assembly, a gas supply assembly, a first switch valve, an ejector, a galvanic pile, an expansion machine and a hydrogen circulation pump, and high-pressure hydrogen of the hydrogen supply assembly enters the ejector through the first switch valve; the gas supply assembly conveys air into the electric pile at the same time, hydrogen ejected by the ejector reacts with the air in the electric pile, unreacted hydrogen is ejected into the electric pile again through the hydrogen circulating pump, unreacted air is conveyed through a pipeline to impact the expansion machine, and by improving the hydrogen return pressure of the fuel cell, the ejector can achieve a good ejection effect; the expansion machine does work on the hydrogen circulating pump, and hydrogen can be injected back into the electric pile with a very small pressure rise rate, so that the hydrogen circulating pump can realize hydrogen circulation with very small or no electric power consumption, and the net output power of the fuel cell system is increased under the condition of meeting the hydrogen circulation.

Owner:FAW JIEFANG AUTOMOTIVE CO

A nuclear power peak shaving system based on cryogenic energy storage

ActiveCN104279012BImprove power generation efficiencyIncrease net outputSteam engine plantsThermal energyElectric power system

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Organic Rankine cycle system

ActiveCN111794820AGuaranteed heat transfer efficiencyImproved heat recoveryPump controlSteam engine plantsOrganic Rankine cycleWater flow

The invention relates to an organic Rankine cycle system. The organic Rankine cycle system. The organic Rankine cycle system. The organic Rankine cycle system comprises a working medium pump, an evaporator, a condenser and a cooling pump, and further comprises a working medium pump rotating speed control loop and a cooling pump rotating speed control loop. The working medium pump rotating speed control loop comprises a first deviation calculation block, a cascade adjustment main adjustment PID adjusting block, a second deviation calculation block and a cascade adjustment auxiliary adjustment PID adjusting block which are connected in sequence. The first deviation calculation block inputs the outlet temperature of a heat source of the evaporator and a set value of the outlet temperature ofthe heat source. The second deviation calculation block inputs output of the cascade adjustment main adjustment PID adjusting block and the pressure a working medium outlet of the evaporator. The cascade adjustment auxiliary adjustment PID adjusting block is connected with the working medium pump. The cooling pump rotating speed control loop comprises a third deviation calculation block and a third PID adjusting block. The third deviation calculation block inputs the cooling water flow set value and the inlet cooling water flow of the cooling pump. The third PID adjusting block is connected with the cooling pump. Compared with the prior art, the organic Rankine cycle system. The organic Rankine cycle system has the advantages of improving the heat recovery amount and the heat efficiency and increasing the net output power.

Owner:TONGJI UNIV

Making method for core component of water-reservation proton exchange film fuel battery

InactiveCN100454636CImprove water retentionReduce dependenceCell electrodesFinal product manufactureOrganic solventCore component

The invention relates to a proton exchange membrane fuel cell core module preparation method. The preparation method, its characteristic lies in that it includes the following steps: 1)prepares the proton conduction polymer for decorating an inorganic oxide compound nanometer granule: a) first the weight concentration 1.2% -10% of the proton conductionpolymer solution adjusts with NaOH to the pHvalue 6.5-7.5, then changes over to the anhydrous organic solventin, obtains the solution A, then distills this solution to obtain solution B; b) according to inorganic oxide compound and proton conduction polymerload ratio 0.01: 1-0.1: 1, joins this inorganic oxide compound inorganic oxide compound forerunner body in solution B which prepares in step a) to stir 20-30 minutes, makes the inorganic oxide compound forerunner body solution; c) prepares the proton conduction polymer for decorating an inorganic oxide compound nanometer granule; 2) prepares the fuel cell core module. The guarantee water proton exchange membrane fuel cell core module of the invention preparation has good guarantee water ability.

Owner:WUHAN UNIV OF TECH

A distributed energy generation system and method for multi-stage utilization of waste heat

ActiveCN106089344BHigh thermal efficiencyIncrease net output powerSteam engine plantsOrganic Rankine cycleLithium bromide

The invention relates to a distributed energy power generation system and method for multi-level waste heat utilization. A distributed energy system is high in fuel gas price, and a waste heat utilization system is low in efficiency. The distributed energy power generation system comprises a fuel gas internal combustion engine generator set, a waste heat boiler and a steam type lithium bromide unit, and is characterized by further comprising a multi-level organic Rankine cycle system, and the multi-level organic Rankine cycle system comprises a first heat regenerator, a first evaporator, a second heat regenerator, a preheater, a third expansion machine, a third condenser and a steam hot water type heat exchanger; a first working medium pump, the first heat regenerator, the first evaporator and the first expansion machine are sequentially connected, and the first expansion machine and the first heat regenerator are connected; a second working medium pump, the second heat regenerator, the preheater, a second evaporator, a second expansion machine and a second condenser are sequentially connected; and a third heat regenerator, a third evaporator, the third expansion machine and the third condenser are sequentially connected. The distributed energy power generation system is reasonable in structural design and high in heat efficiency.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

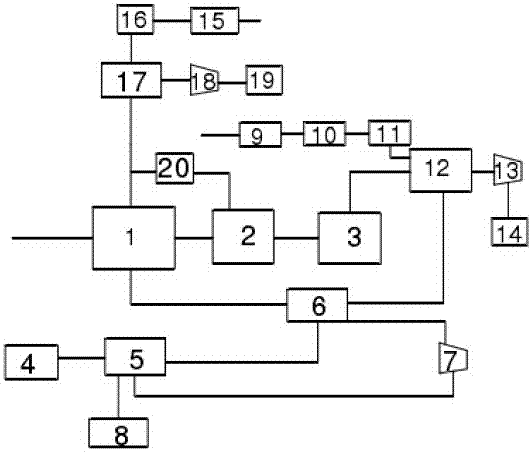

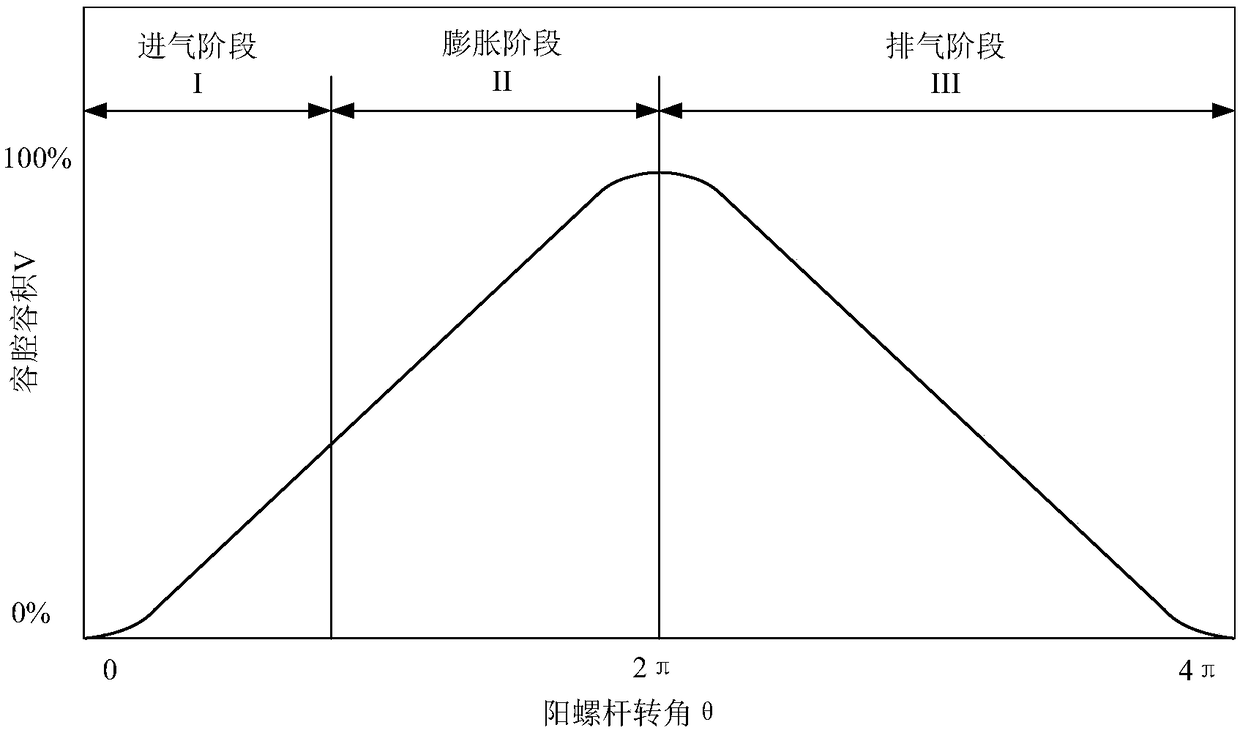

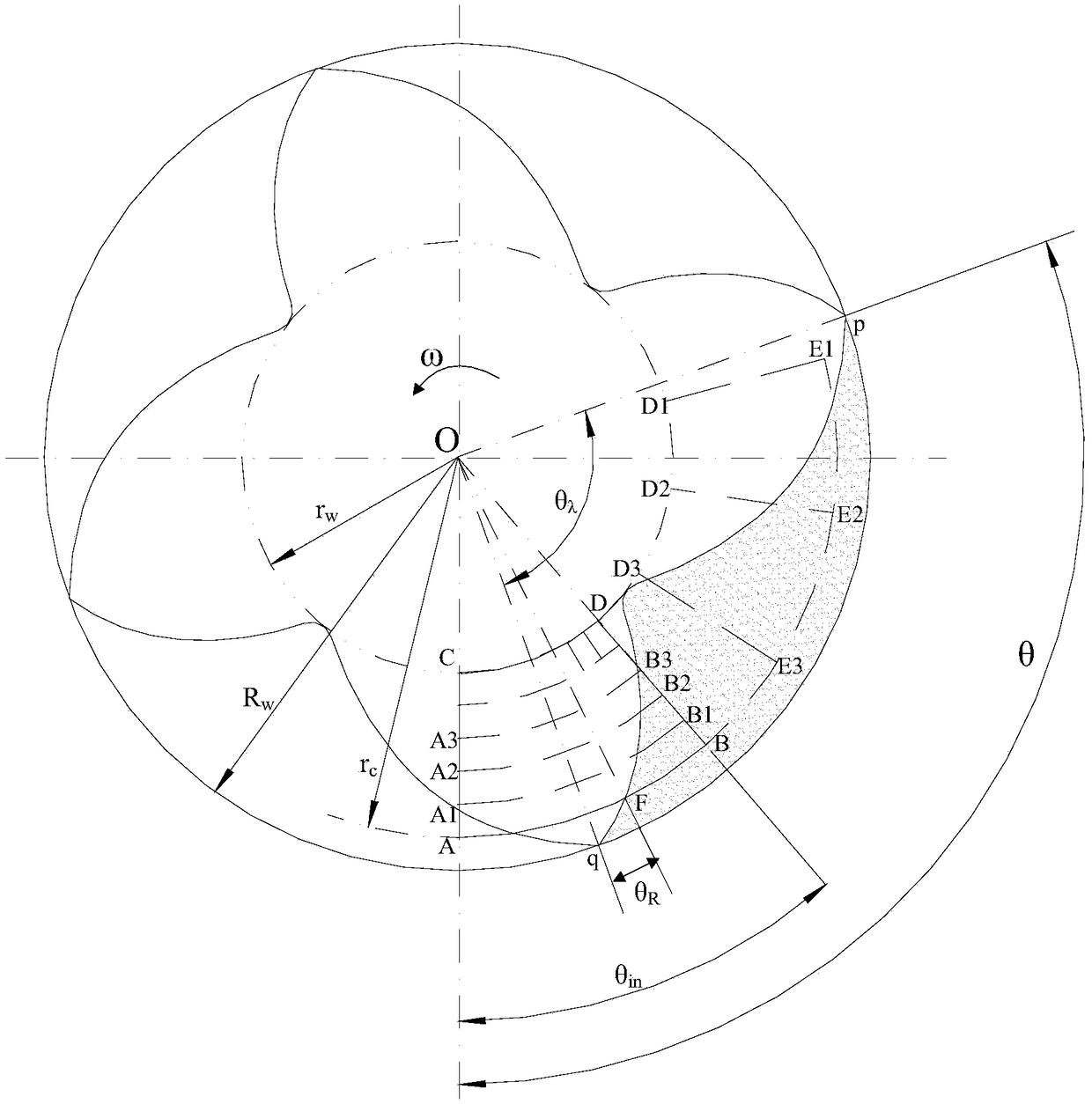

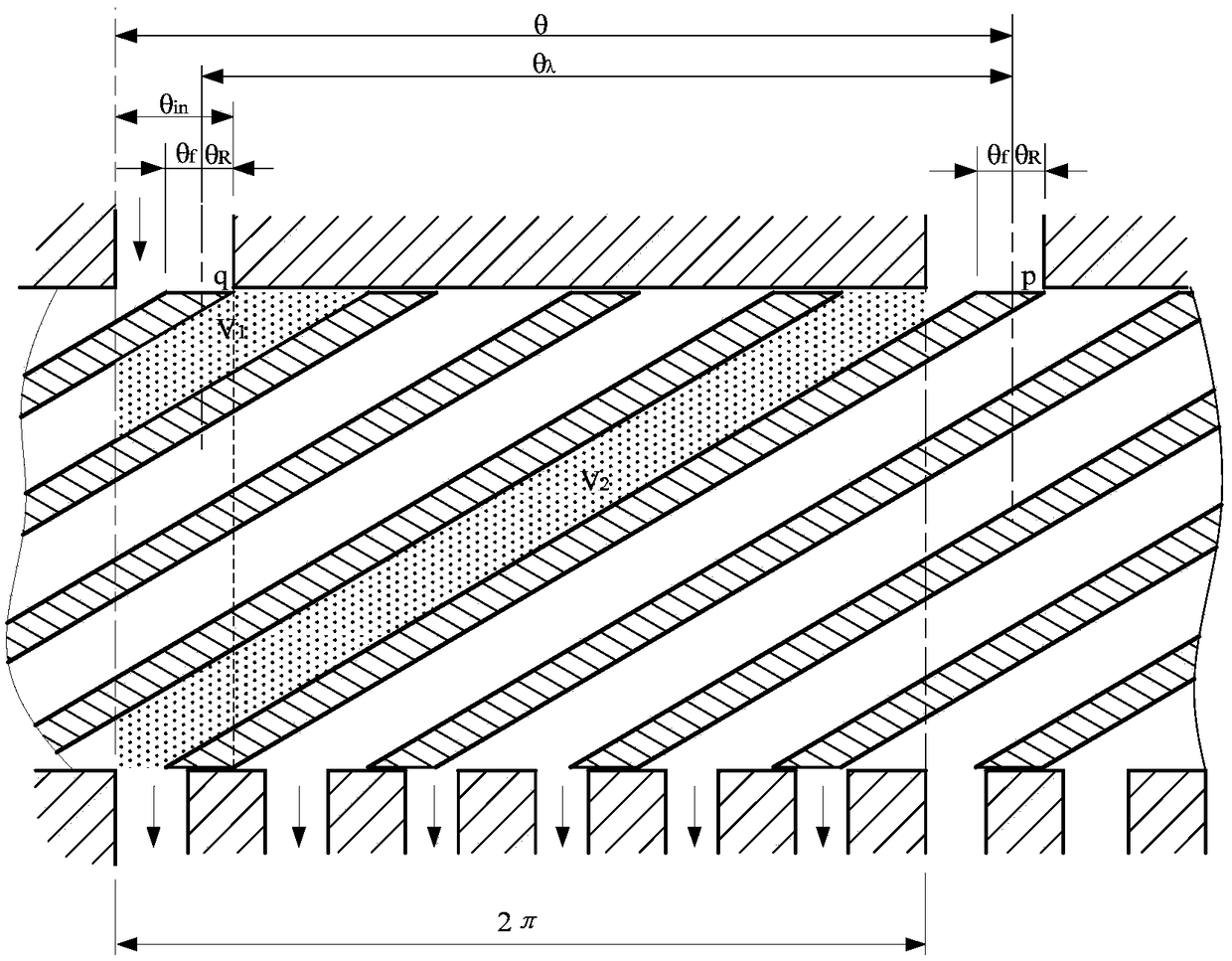

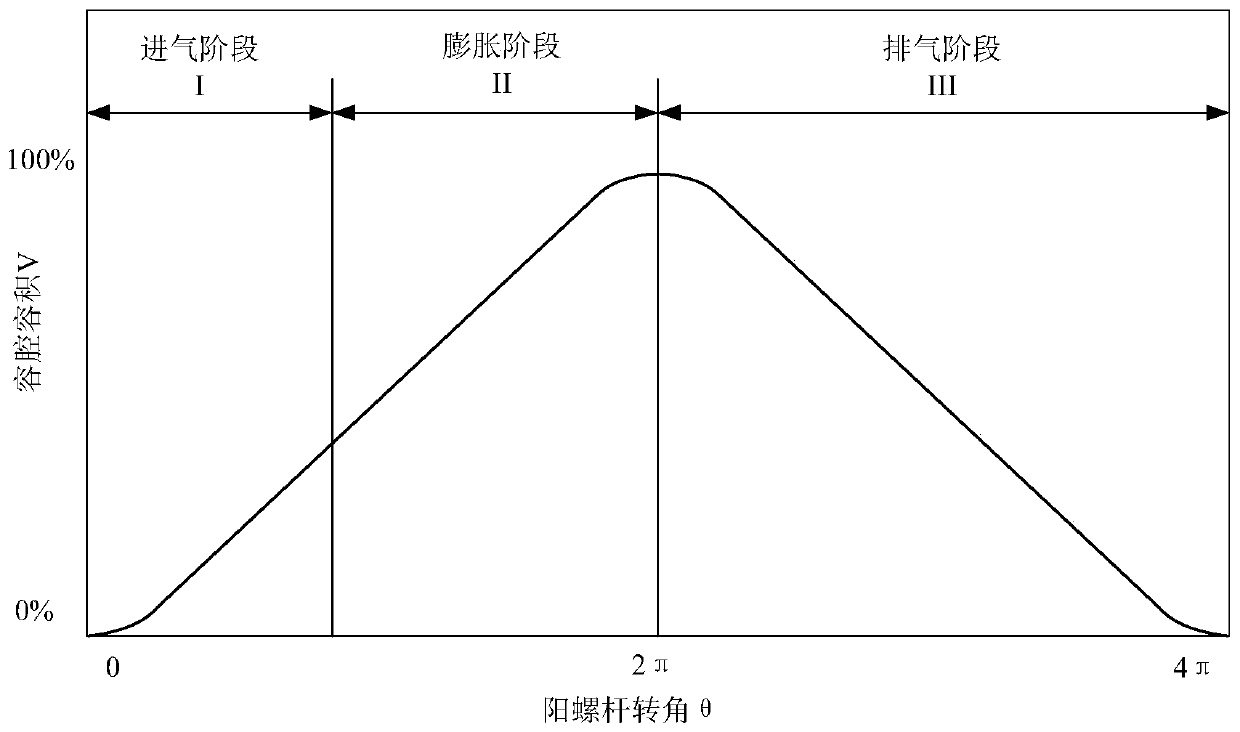

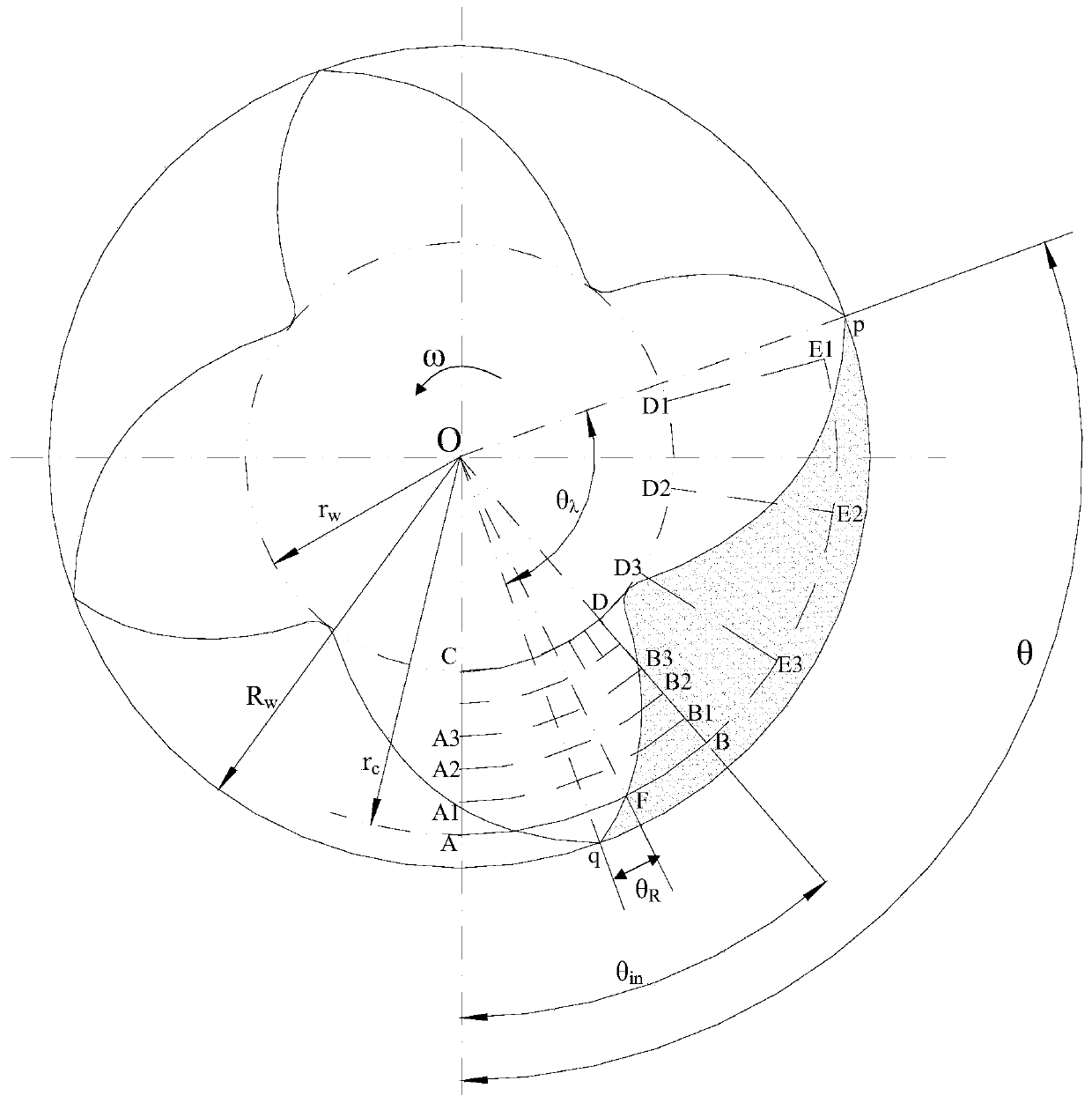

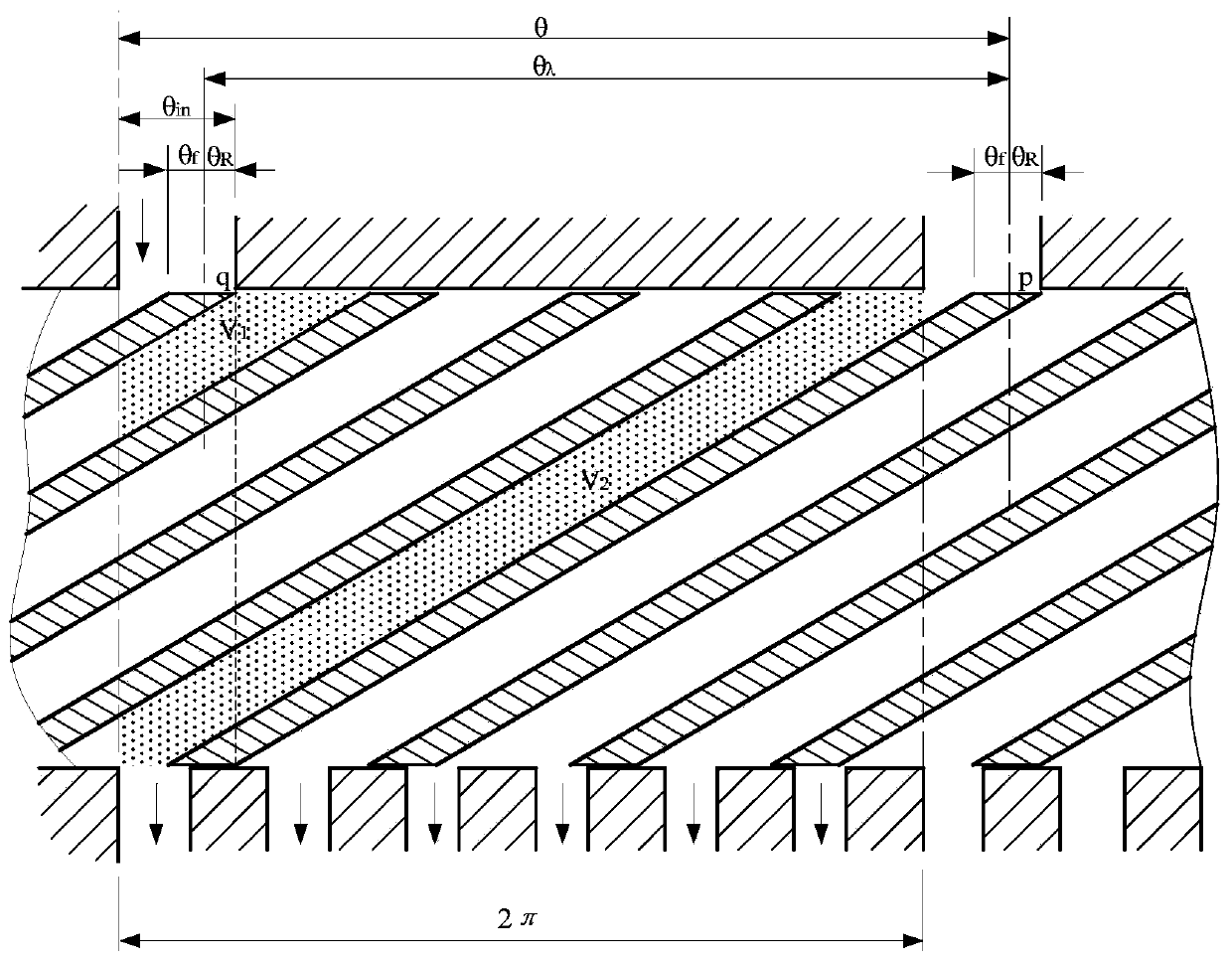

Screw expansion (compression) machine with variable volume ratio

ActiveCN109026162ASimple configurationAdjustable built-in volume ratioPump componentsEngine of intermeshing engagement typeDrive shaftCam

The invention discloses a screw expansion (compression) machine with variable volume ratio. The screw expansion (compression) machine comprises a box body (300), an upper supporting end cover (400), an air inlet end cover (500) and a valve core cover plate (600). The upper supporting end cover (400) is fixedly connected with the box body (300) to form a closed cavity (408), the air inlet end cover(500) and the valve core cover plate (600) are arranged in the cavity (408), and the valve core cover plate (600) is arranged below the air inlet end cover (500). A screw expansion machine further includes a main drive shaft (401), an adjusting operating rod (402) and a driven shaft (403), wherein the main drive shaft (401), the adjusting operating rod (402) and the driven shaft (403) are arranged in parallel to each another. The screw expansion machine further includes an air inlet adjusting mechanism arranged in the cavity (408), and the air inlet adjusting mechanism comprises a half-gear cam (700), an adjusting gear (800), a valve core pushing rod (900), a radial sliding spool (603) and a circumferential sliding valve core (604). The screw expansion (compression) machine has an adjustable built-in volume ratio, the optimal matching between the built-in volume ratio and the actual operating pressure ratio of a system can be kept to the greatest extent, and the overall operating efficiency of the screw expansion machine under variable operating conditions is improved.

Owner:朱三立

A screw expansion (compression) machine with variable volume ratio

ActiveCN109026162BSimple configurationAdjustable built-in volume ratioPump componentsEngine of intermeshing engagement typeDrive shaftGear wheel

The invention discloses a screw expansion (compression) machine with variable volume ratio. The screw expansion (compression) machine comprises a box body (300), an upper supporting end cover (400), an air inlet end cover (500) and a valve core cover plate (600). The upper supporting end cover (400) is fixedly connected with the box body (300) to form a closed cavity (408), the air inlet end cover(500) and the valve core cover plate (600) are arranged in the cavity (408), and the valve core cover plate (600) is arranged below the air inlet end cover (500). A screw expansion machine further includes a main drive shaft (401), an adjusting operating rod (402) and a driven shaft (403), wherein the main drive shaft (401), the adjusting operating rod (402) and the driven shaft (403) are arranged in parallel to each another. The screw expansion machine further includes an air inlet adjusting mechanism arranged in the cavity (408), and the air inlet adjusting mechanism comprises a half-gear cam (700), an adjusting gear (800), a valve core pushing rod (900), a radial sliding spool (603) and a circumferential sliding valve core (604). The screw expansion (compression) machine has an adjustable built-in volume ratio, the optimal matching between the built-in volume ratio and the actual operating pressure ratio of a system can be kept to the greatest extent, and the overall operating efficiency of the screw expansion machine under variable operating conditions is improved.

Owner:朱三立

A fuel cell engine system, its gas supply system and a control method

ActiveCN110649287BReduce parasitic loadIncrease net output powerReactant parameters controlGas compressorHydrogen pressure

The invention discloses a fuel cell engine system and an air supply system thereof, and a control method. The air supply system comprises a hydrogen supply system and an air supply system; a hydrogenoutlet pipeline is connected with a two-position two-way valve; the two-position two-way valve is connected with a first hydrogen circulating pipeline and a second hydrogen circulating pipeline in parallel; the first hydrogen circulating pipeline is connected to an inlet of a gas compressor of an expansion and gas compression all-in-one machine; and the outlet of the gas compressor is connected toa hydrogen circulation main pipeline, the hydrogen circulation main pipeline is connected to a hydrogen inlet pipeline, a second hydrogen circulation pipeline is connected to the hydrogen circulationmain pipeline through a hydrogen ejector, an inlet hydrogen pressure detection device is arranged on the hydrogen inlet pipeline, and an air outlet pipeline is connected to an expansion machine of the expansion and gas compression all-in-one machine. High-pressure tail gas exhausted by the air supply system is effectively used for driving the expansion and gas compression all-in-one machine to achieve hydrogen cyclic utilization, parasitic loads of the auxiliary system are reduced, and the net output power of the stack is improved.

Owner:WEICHAI POWER CO LTD

Fuel cell air supply system based on waste heat utilization

ActiveCN104538656BDoes not consume output powerIncrease net output powerFuel cell heat exchangeFuel cellsOrganic Rankine cycle

The invention provides a fuel cell air supply system based on waste heat utilization. The fuel cell air supply system comprises an organic working medium pump, a first heat exchanger, an expansion machine, a condenser, an air compressor and a humidifier. The organic working pump is communicated with an organic working medium liquid storage tank on the outside. A waste heat recycling and circulating loop based on organic Rankine cycle is formed by the organic working medium liquid storage tank, the organic working medium pump, the first heat exchanger, the expansion machine and the condenser. A pressurized air supply path is formed by the air compressor, the first heat exchanger and the humidifier. The organic working medium pump conveys the liquid organic working medium pump in the organic working medium liquid storage tank to the first exchanger. The first heat exchanger receives liquid organic working media conveyed by the organic working medium pump. Heat exchange is carried out between the liquid organic working media passing through the first heat exchanger and a fuel cell, so that the waste heat of the fuel cell is absorbed and the liquid organic working media are evaporated to gas organic working media, the gas organic working media enter the expansion machine and drive the expansion machine to act, and exhaust gas generated after acting enters the condenser and is cooled to be liquid and conveyed to the organic working medium liquid storage tank.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com