Fuel cell cooling circulation system

A circulation system and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as increased water pump power, unfavorable integration settings, and increased stack inlet pressure to ensure safety and service life, is conducive to integrated layout, and increases the effect of net output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

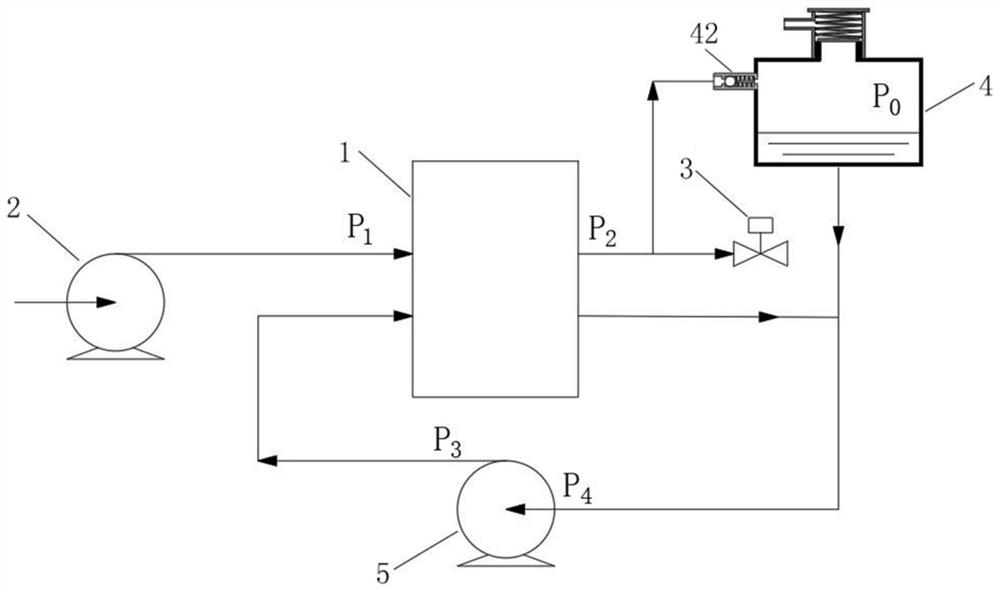

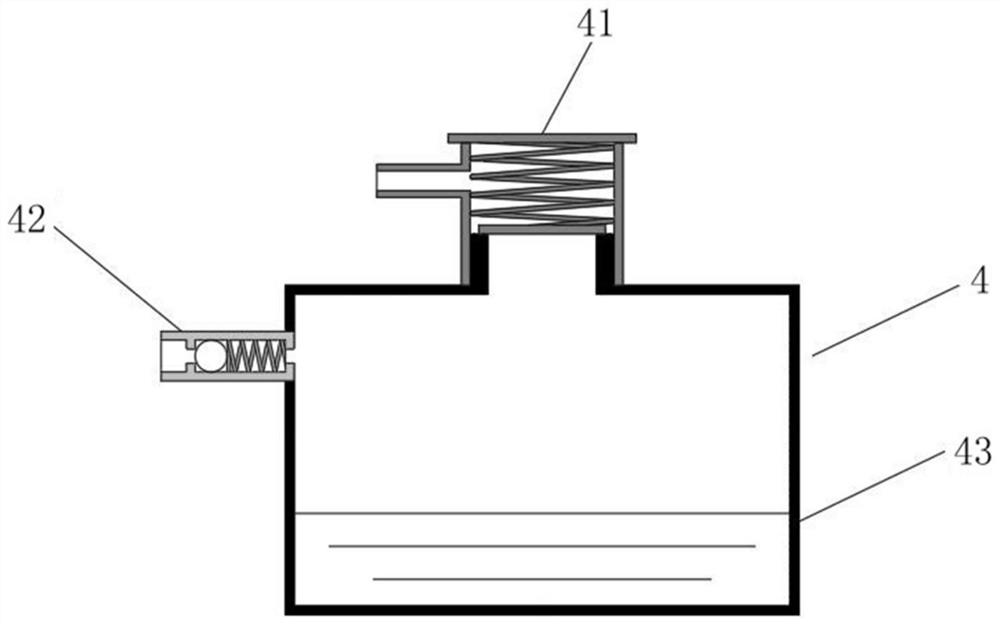

[0033] A fuel cell cooling cycle system, such as figure 1 As shown, including stack 1, air circuit, cooling circuit and pressure circuit;

[0034] The air circuit includes an air compressor 2. The air compressor 2 is used to compress the air. The compressed air passes into the stack 1 from the air inlet of the cathode of the stack 1, and the compressed air in the stack 1 comes from the air outlet of the cathode of the stack 1. Discharge the stack 1; in order to ensure the normal operation of the fuel cell, the air circuit also includes a filter, an intercooler and a humidifier. The filter is arranged upstream of the air compressor 2 for filtering air. Between the machine 2 and the stack 1, the compressed high-temperature air is cooled, and the humidifier is installed between the intercooler and the stack 1 to humidify the air, and the humidified air passes into the stack 1.

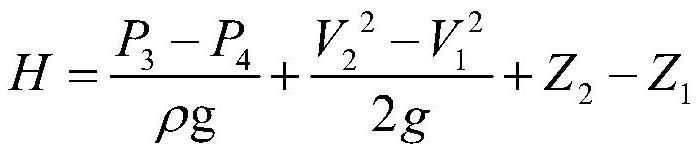

[0035] The air circuit also includes an intake pipe and an exhaust pipe. The air intake pipe connects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com