Organic Rankine cycle system

A circulatory system, organic technology, applied in the field of organic Rankine cycle system, can solve problems affecting heat recovery, thermal efficiency and net output power, pinch point effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

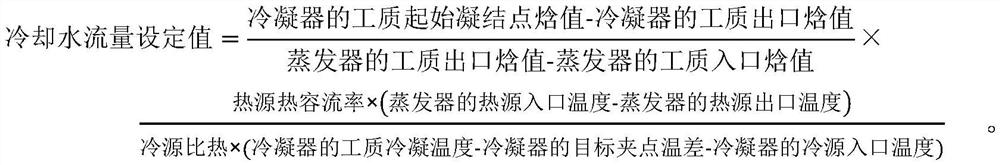

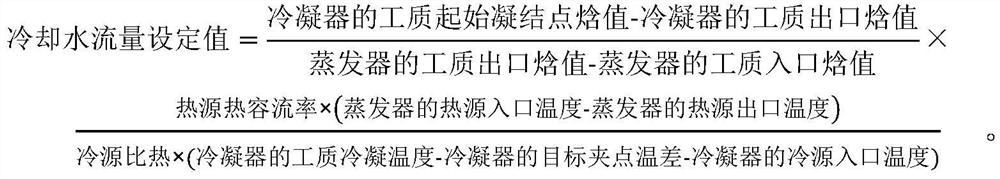

[0027] Studies have shown that when the temperature difference at the pinch point of the condenser is maintained by changing the cooling water flow rate, there is a turning point of the cooling water flow rate change rate. When the operating evaporation pressure is greater than the evaporation pressure corresponding to the turning point, the cooling water flow rate will rise rapidly, resulting in cooling. The power consumption of the pump is greatly increased, resulting in a waste of electricity and a reduction in net output power.

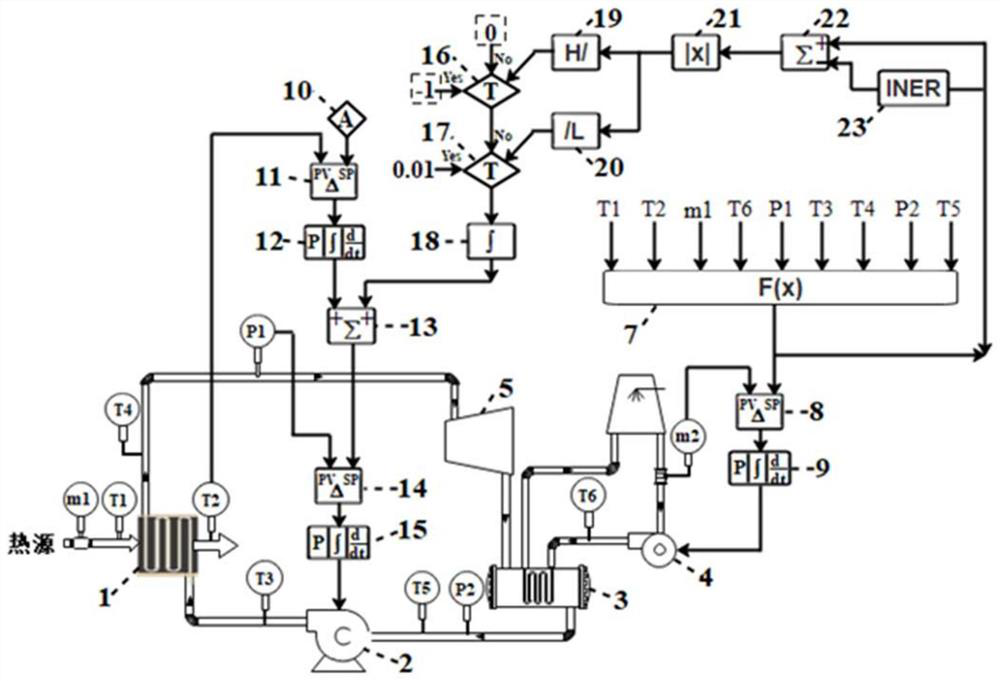

[0028] This embodiment provides an organic Rankine cycle system in order to solve the problem that the traditional control method will affect the pinch point and change the flow rate of cooling water to maintain the temperature difference at the pinch point of the condenser. figure 1As shown, it includes a first deviation calculation block 11, a cascade adjustment main adjustment PID adjustment block 12, an addition block 13, a second deviation cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com