ORC composite power generation system suitable for LNG hybrid power ship

A power generation system and hybrid power technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of no utilization, etc., and achieve the effects of ensuring heat exchange efficiency, improving energy utilization, and reducing flue gas emission temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

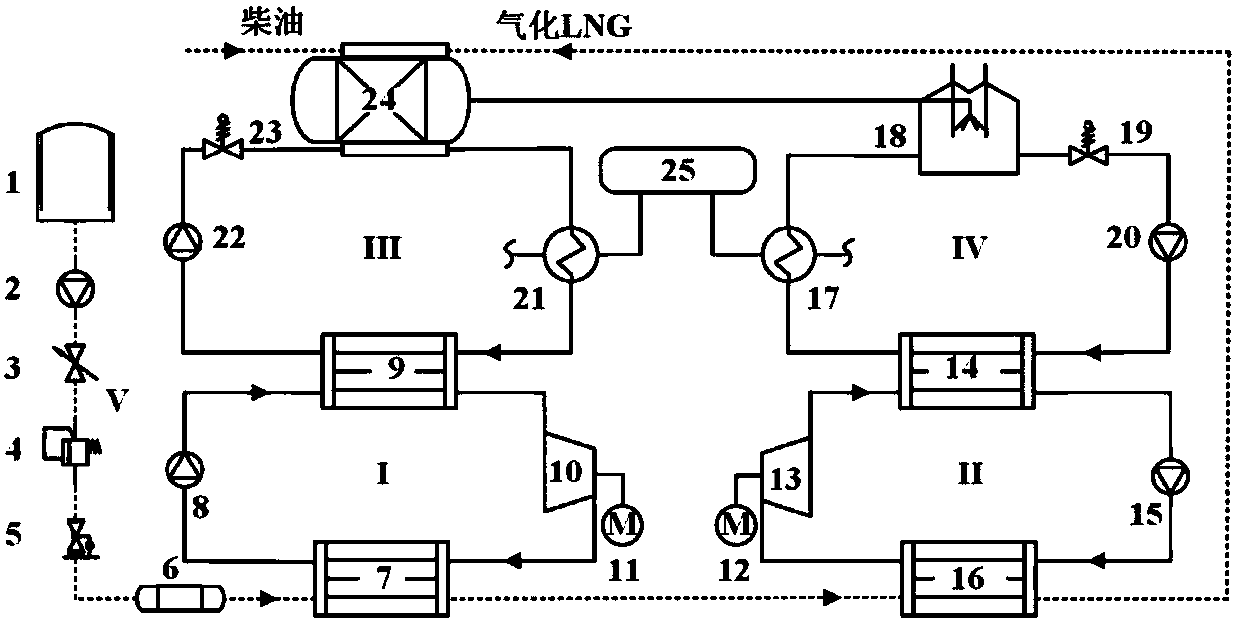

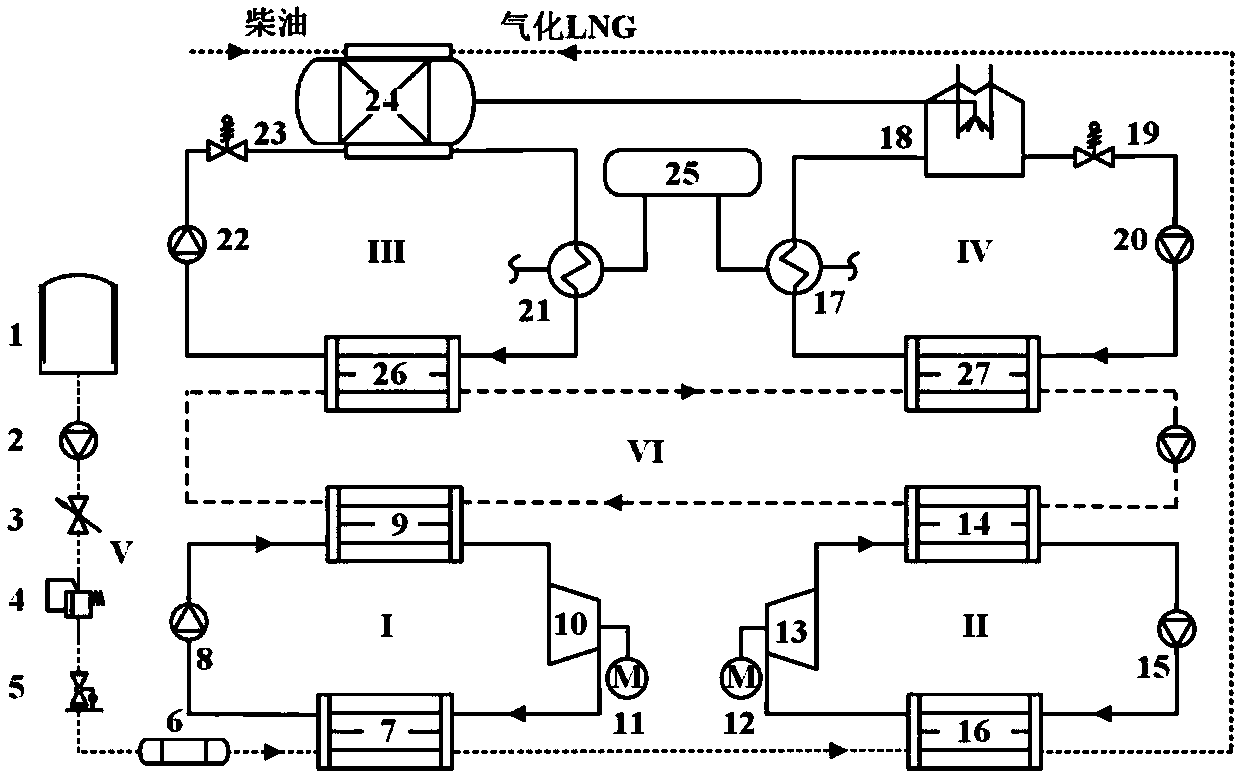

[0031] Such as figure 1 As shown, an ORC composite power generation system suitable for LNG hybrid ships, the system includes: a primary ORC circuit (I), a secondary ORC circuit (II), an LNG / diesel dual-fuel main engine cylinder liner cooling water circuit (III ), flue gas cooling circuit (IV) and LNG gasification circuit (V).

[0032] The above-mentioned primary ORC loop (I) includes a primary condenser 7, a primary working fluid circulation pump 8, a primary evaporator 9, a primary turbine 10 and a primary generator 11. The above primary ORC circuit (I) uses the main engine liner cooling water as the heat source, and the circulating working medium passes through the primary evaporator 9 to absorb the heat in the LNG / diesel dual fuel main engine liner cooling water circuit (III) and turn it into high-temperature steam Then enter the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com