Patents

Literature

54results about How to "Improved heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

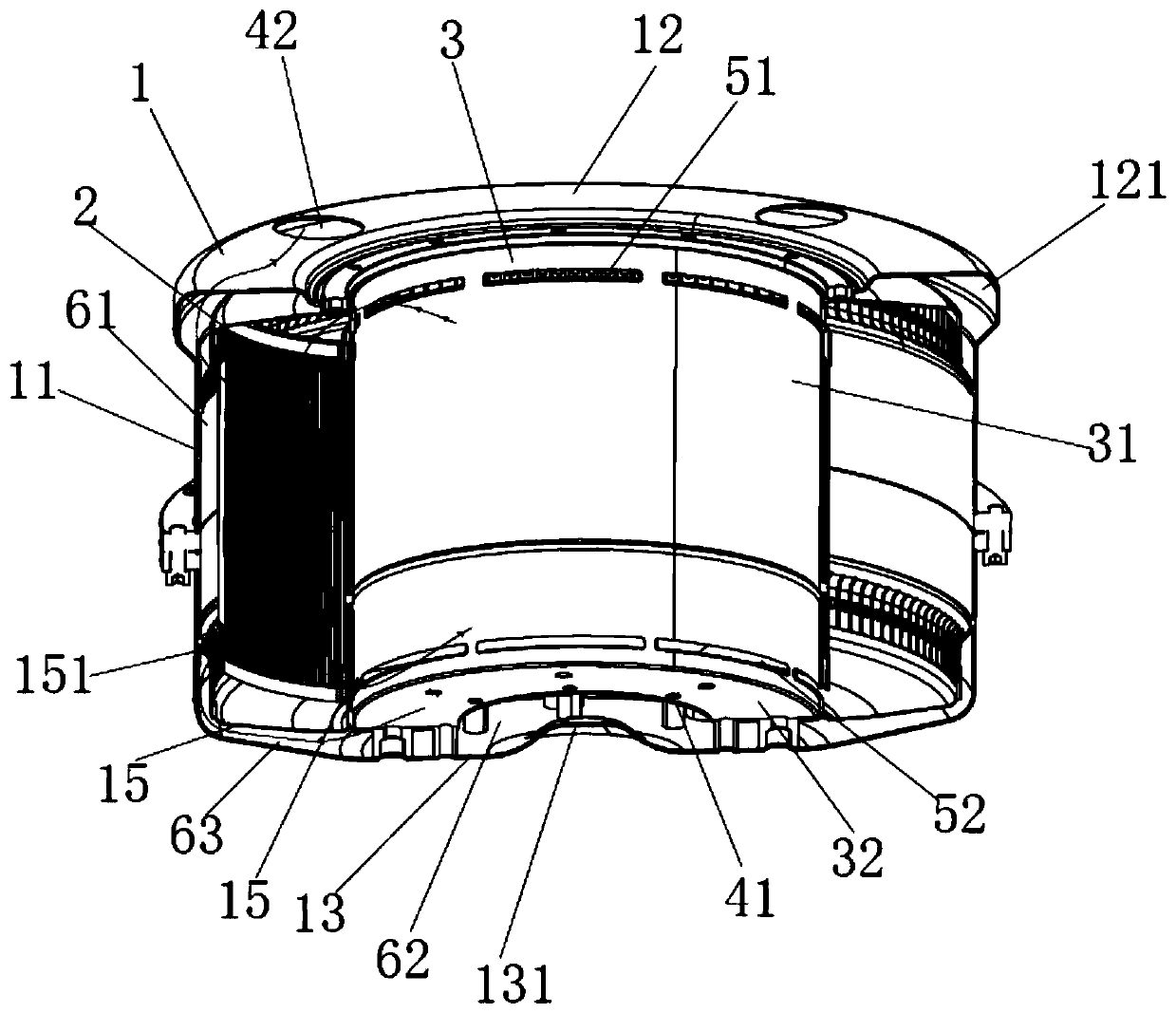

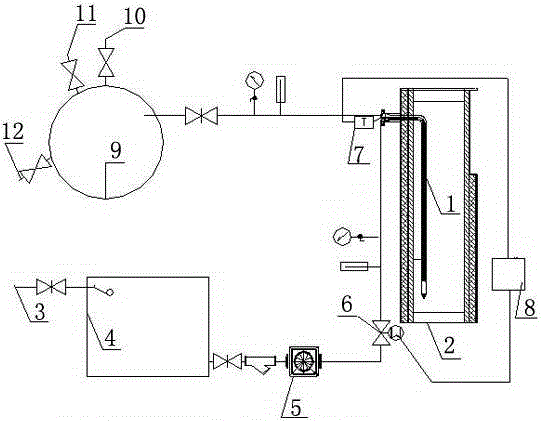

Gas-liquid separator, air source heat recovery system, water chiller and heat pump

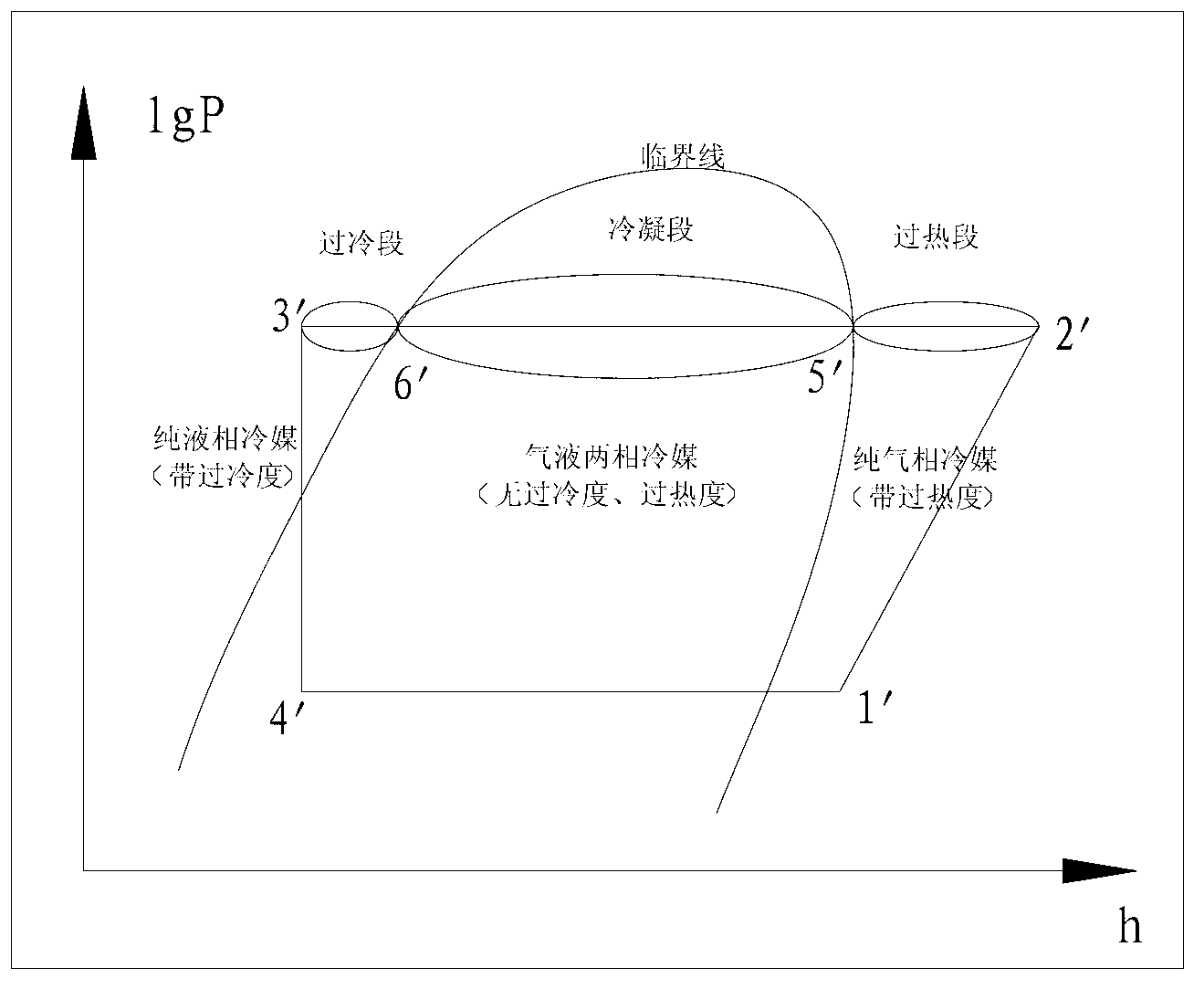

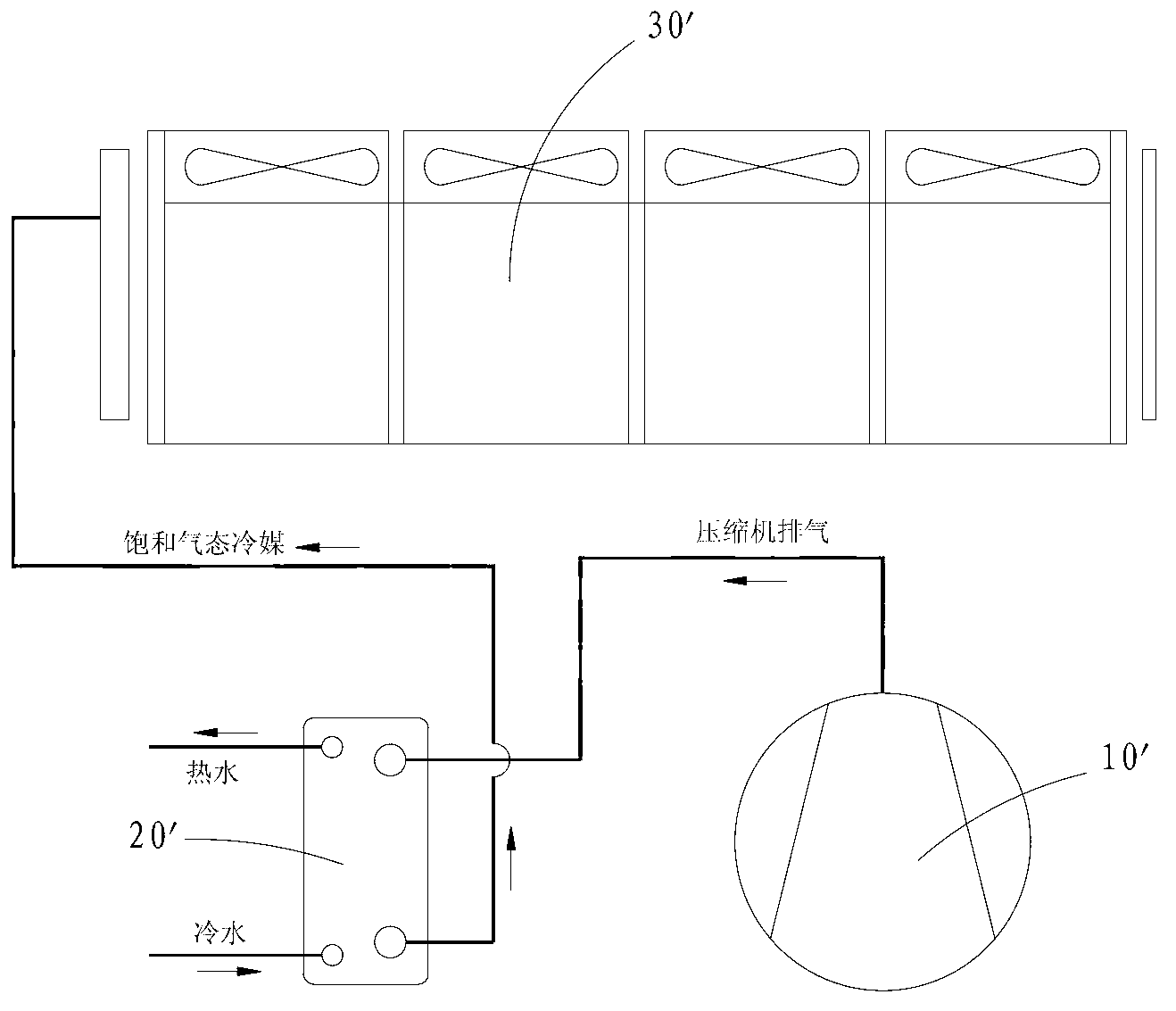

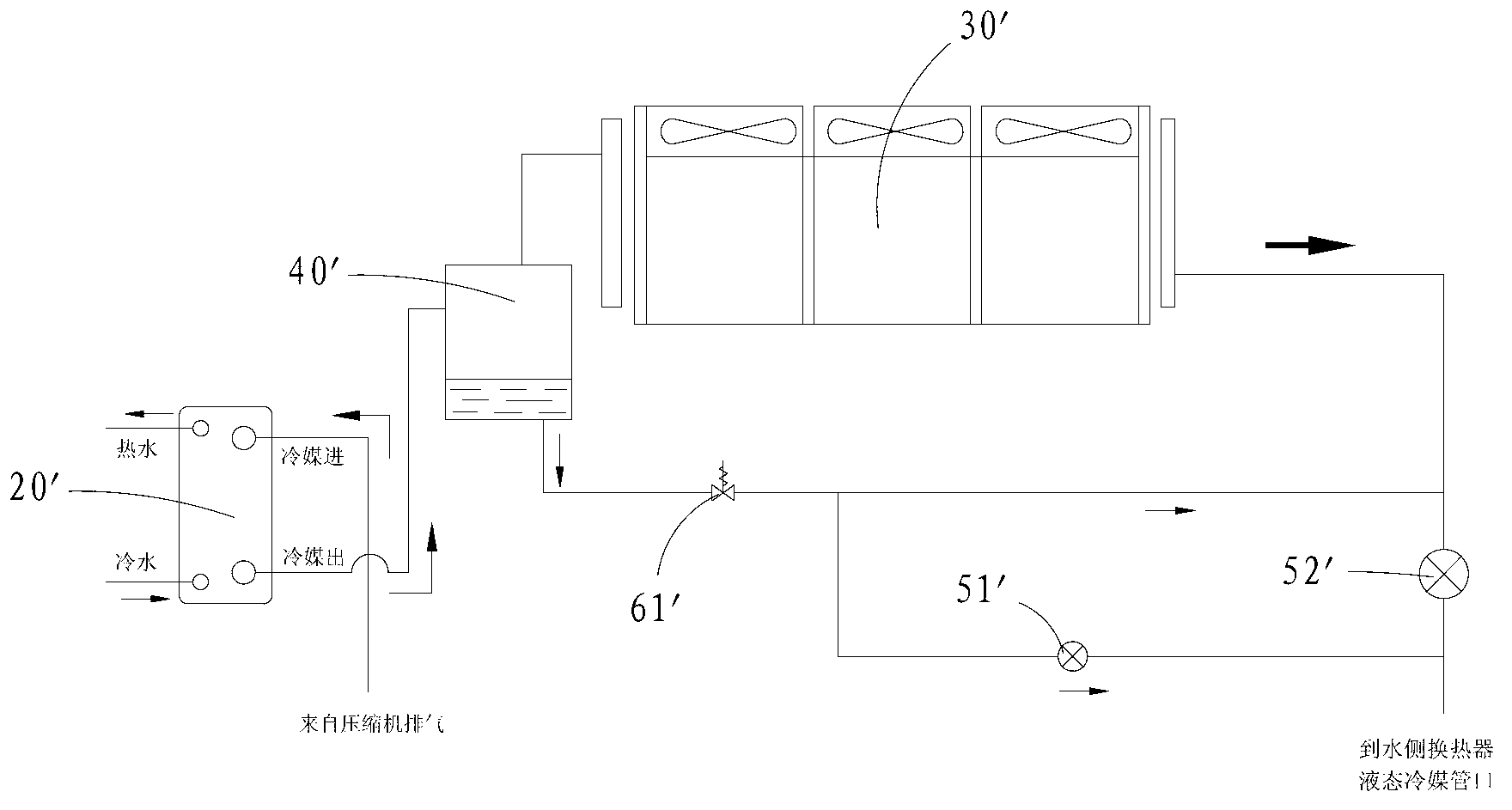

ActiveCN103225935AGuaranteed uptimeImprove energy efficiencyMechanical apparatusFluid circulation arrangementThermodynamicsMechanical engineering

The invention provides a gas-liquid separator, an air source heat recovery system comprising the gas-liquid separator, a water chiller and a heat pump, wherein the gas-liquid separator can synchronously detect two liquid levels through arranging a low liquid level switch and a high liquid level switch, outputs two switching value signals, can very conveniently judges whether condensate is generated in part of heat recovery devices and whether a condensate cold medium is enough to be used by an economizer, discharges or does not discharge a liquid according to the situation that whether the liquid exists or not, and does not affect the operation of a main system. According to the invention, the water chiller and the heat pump completely solve the problem that as the condensate is formed on cold medium side of part of the heat recover devices of part of the conventional air source heat recovery unit, pressure drop of the pipeline is increased and further performance of the whole machine and oil return of the compressor are affected are solved. In addition, heat recovery capacity can be improved to a great extent, and system capacity and efficiency are also improved.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

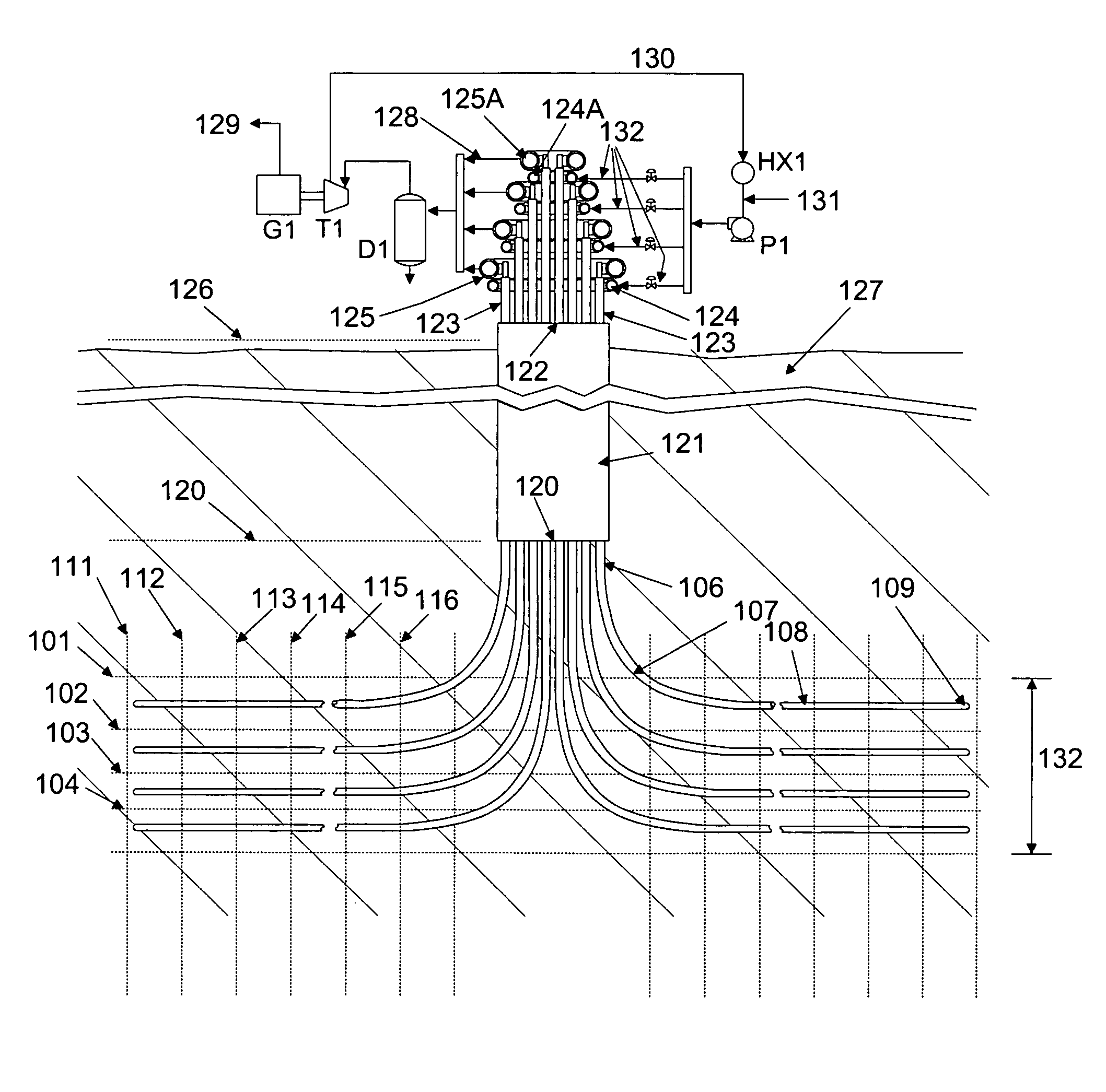

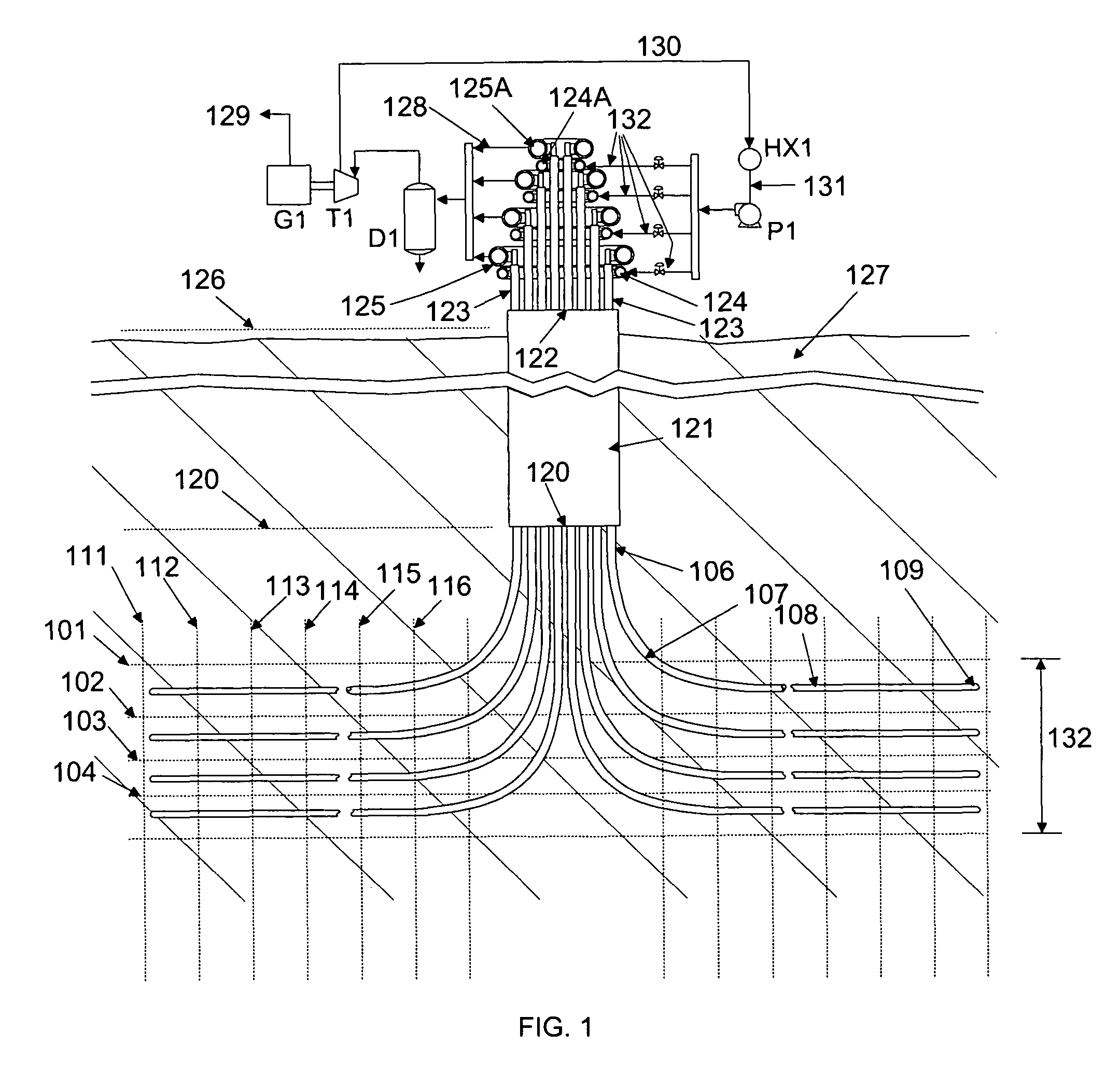

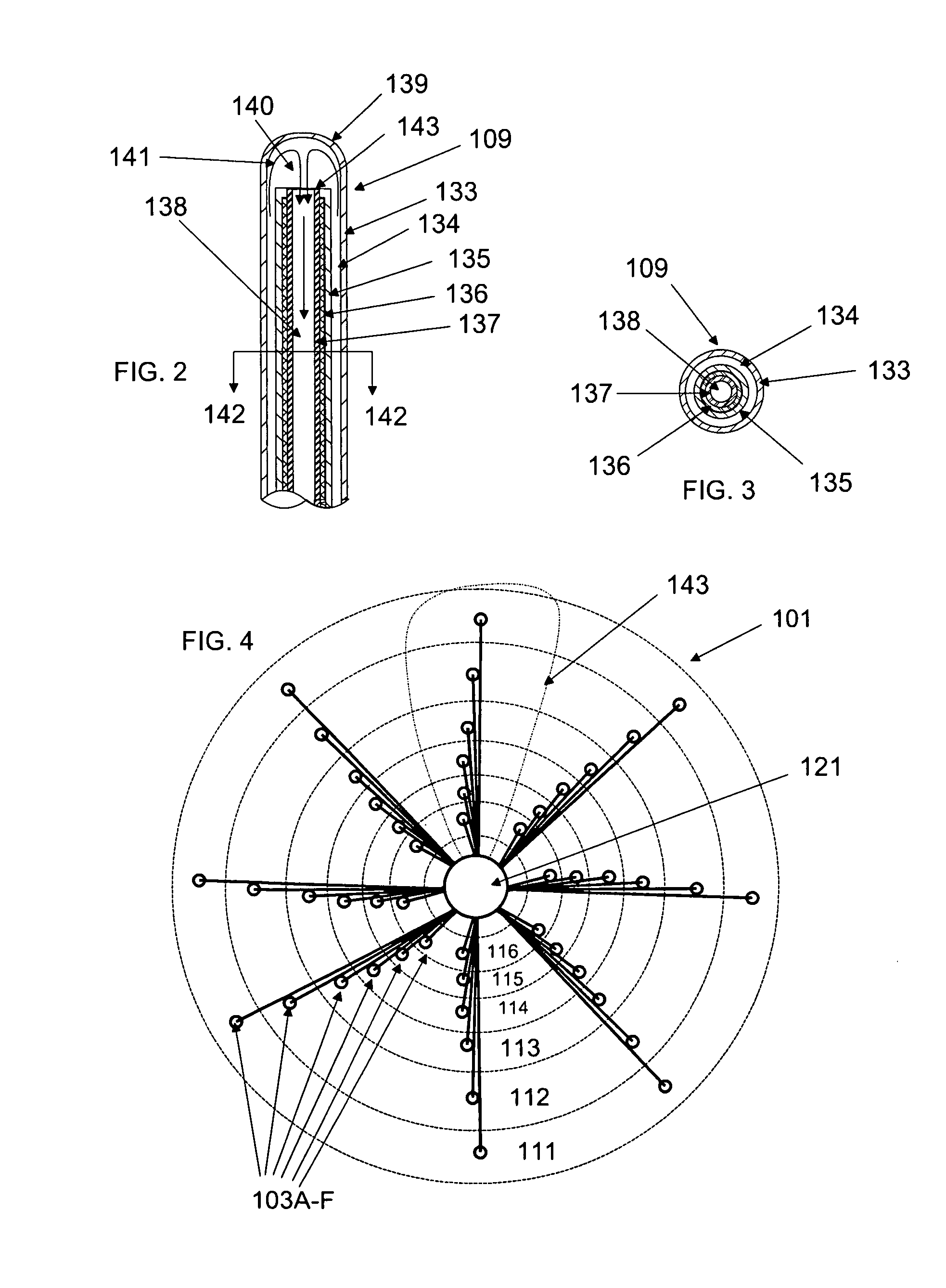

Closed loop, hot dry rock heat recovery process

InactiveUS8020382B1High precisionCalculateCollector components/accessoriesLighting and heating apparatusElectric energyEngineering

The present invention is a closed loop system of heat recovery in hot dry rock or in water-containing formations for generation of electrical power. Recovery of heat from such formations is accomplished by way of multiple horizontal levels of generally radially drilled bores from a central shaft. Heat transfer is accomplished either by way of terminal end heat exchangers or by way of heat transfer to conduits extending from the central shaft.

Owner:GEOTHERMIC SOLUTION

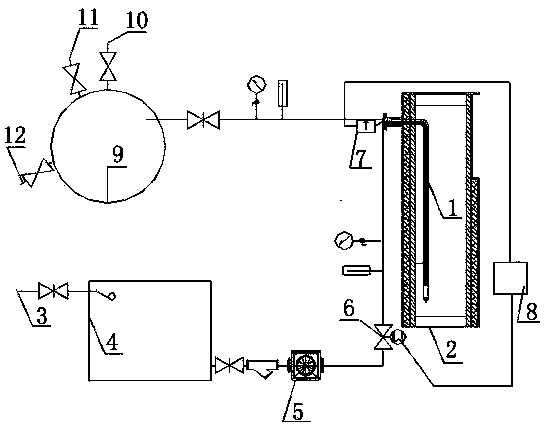

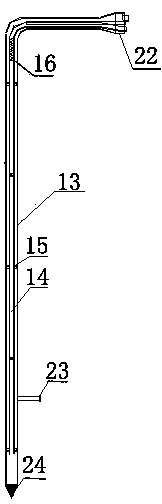

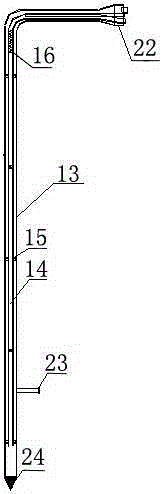

Ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device

ActiveCN104059676AUnique structureComplete anti-coking technologyBoiler cleaning apparatusEnergy inputPipingEngineering

The invention relates to an ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device, and belongs to the technical field of coking furnace ascending pipe raw gas waste heat recycling. According to the technical scheme, a steam outlet pipe (13) and a water inlet pipe (14) are bent together to be of an L-type structure (1), the end of the horizontal segment of the L-type structure is provided with a detachable connector (22), the end of the perpendicular segment is provided with an anti-coking head (24), the steam outlet pipe is connected with a steam pocket (9), the water inlet pipe is connected with a water inlet system, raw gas and the water inlet pipe are isolated through the steam outlet pipe, the temperature of the exterior of the steam outlet pipe is not lower than the coking temperature, and meanwhile steam ascends gradually to heat inflowing water, so that the inflowing water is completely gasified. According to the ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device, the temperature is detected through a high-temperature thermocouple in the heat exchange process, the water yield of the inflowing water is controlled, and therefore coking of the exterior of the device is avoided; raw gas waste heat can be recycled, completely independent installation is achieved, the problems that a heat exchange device inside an ascending pipe is prone to coking, the ascending pipe is prone to explosion, installation is difficult, and the replacement and maintenance cost is high are solved, and the heat exchange amount is large.

Owner:TANGSHAN BAOKAI TECH

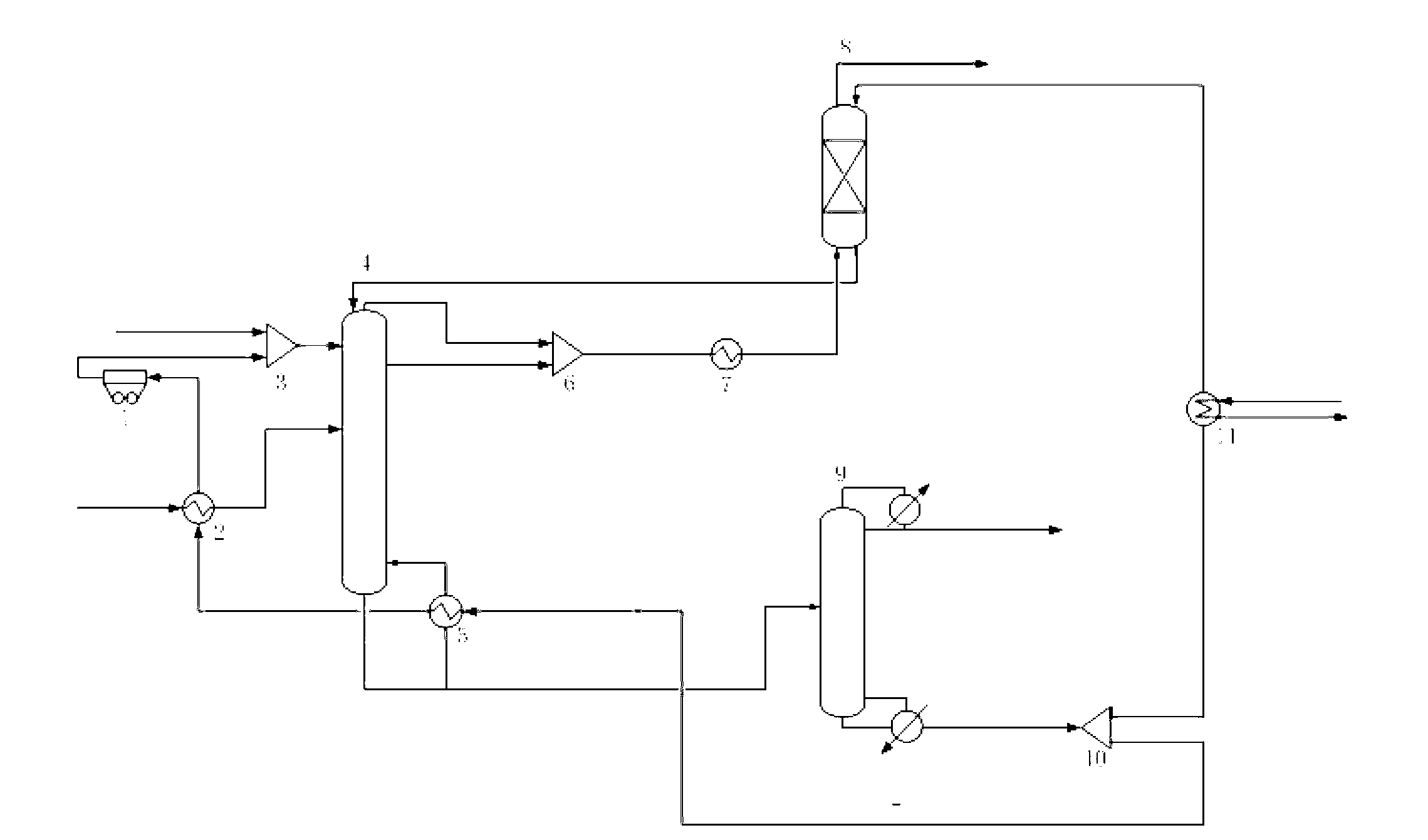

Aromatic hydrocarbon purification apparatus and process used in hydrofining of coking crude benzene

InactiveCN103232317AReduce consumptionImproved heat recoveryDistillation purification/separationExtraction purification/separationProcess systemsExchange network

The invention provides an aromatic hydrocarbon purification apparatus and process used in hydrofining of coking crude benzene. The apparatus comprises an extractive distillation tower, a liquid-liquid extraction tower, an aromatic hydrocarbon stripping tower, a crude benzene preheater, a hydrogenated oil preheater, a cooler, an air cooler, a raw material mixer, a discharging mixer and a distributor. The process comprises the following steps: allowing raw hydrogenated oil and a poor solvent N-formyl morpholine to enter into the extractive distillation tower, coupling a gas phase and a liquid phase in the extractive distillation tower and the liquid-liquid extraction tower, extracting a gas phase at a side line of a distillation section of the extractive distillation tower, mixing the gas phase with a tower top discharge, cooling an obtained mixture and allowing the mixture to enter into the liquid-liquid extraction tower for separation into two phases; re-introducing an aromatic hydrocarbon-rich heavy phase into the top of the extractive distillation tower as reflux, with an aromatic hydrocarbon-poor light phase mainly being non-aromatic hydrocarbons; and allowing a rich solvent at the bottom of the extractive distillation tower to enter into the aromatic hydrocarbon stripping tower for separation, wherein pure aromatic hydrocarbon is obtained at the top of the aromatic hydrocarbon stripping tower, and the poor solvent N-formyl morpholine is obtained at the bottom of the aromatic hydrocarbon stripping tower and is recycled. In the flow path of the process, process system engineering methodology is employed for realizing integration of mass and heat and optimization of a comprehensive heat exchange network, thereby realizing recovery of waste heat, improvement of a separation effect of aromatic hydrocarbon and reduction in operating cost.

Owner:DALIAN UNIV OF TECH

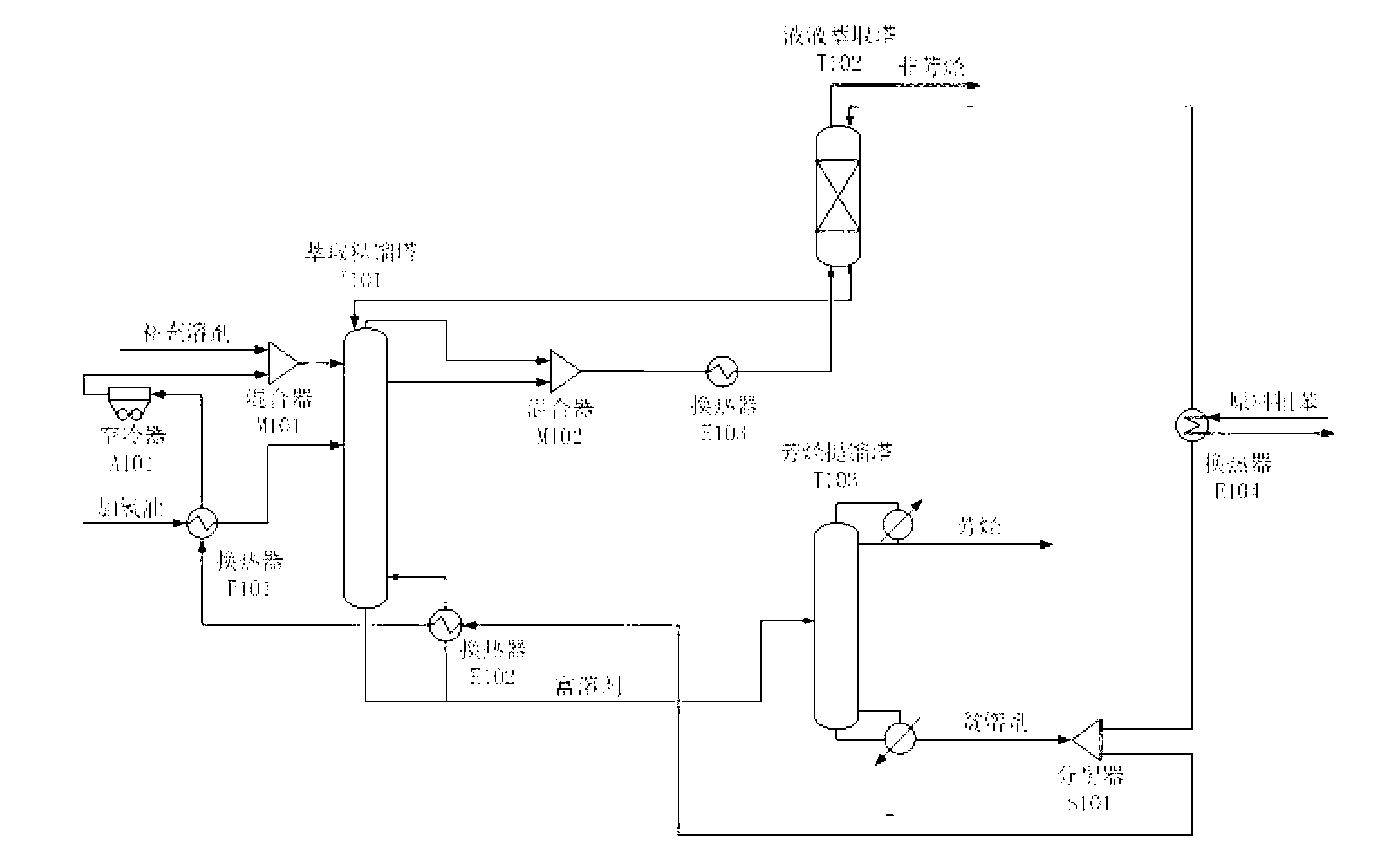

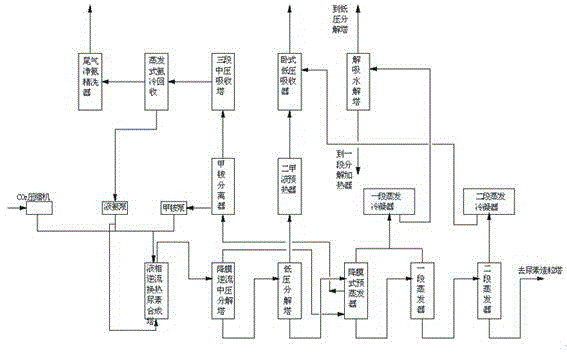

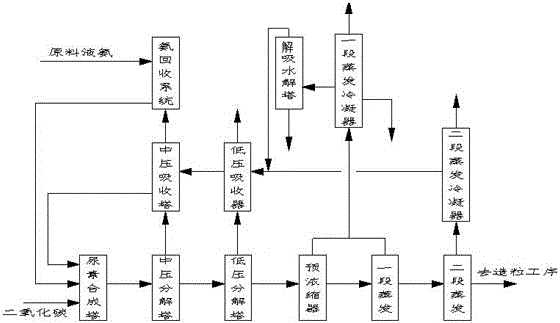

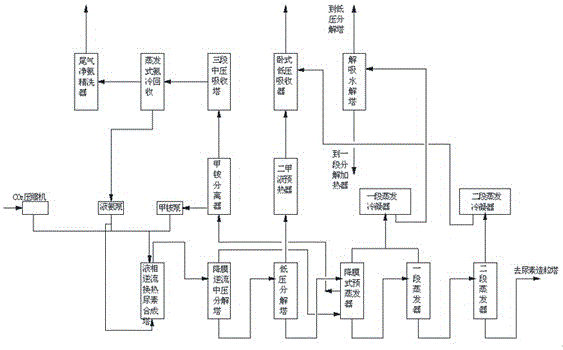

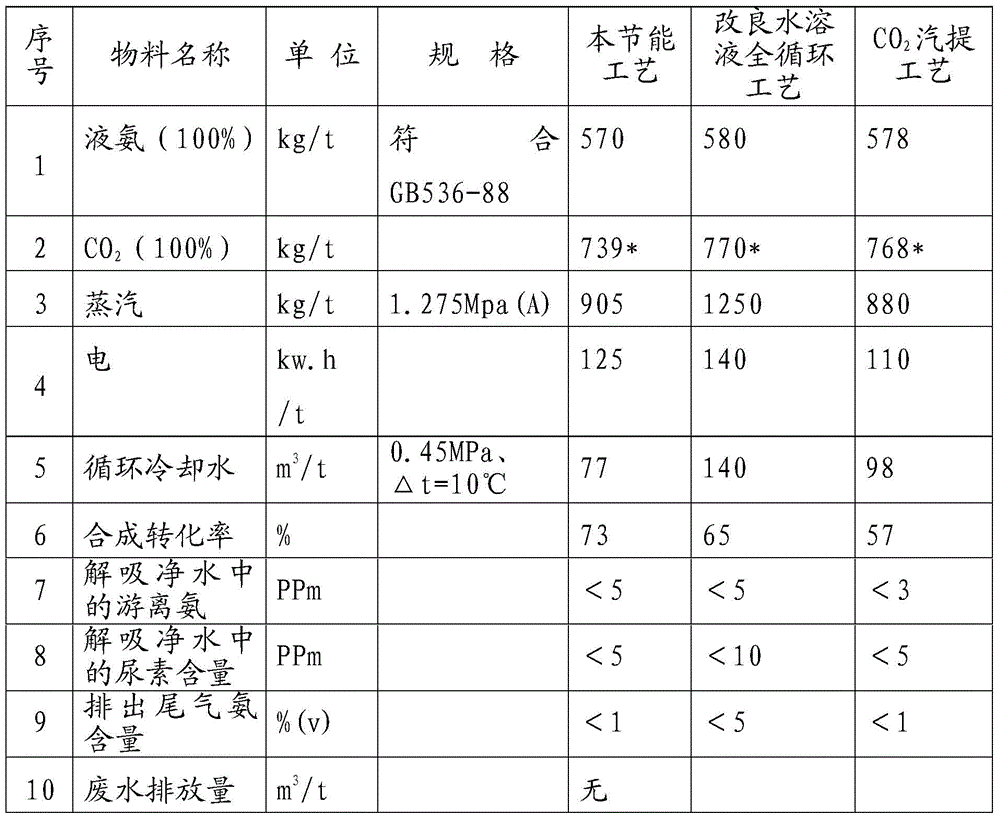

Energy-saving urea production system and production process thereof

ActiveCN104829494AReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

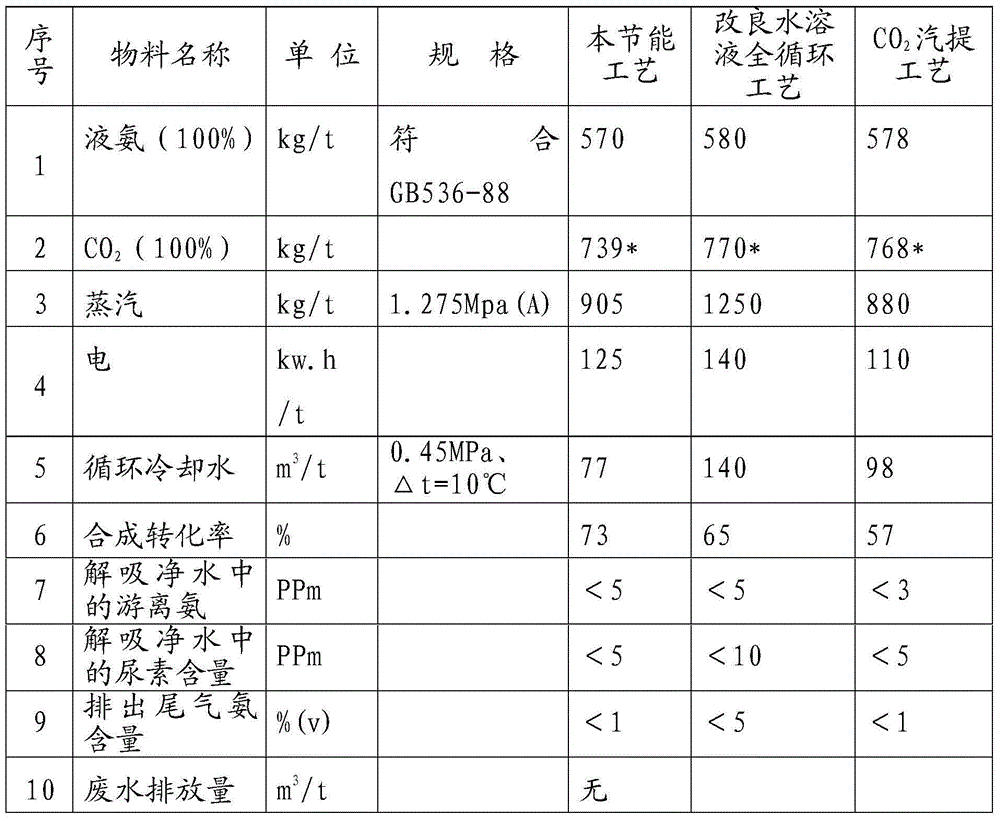

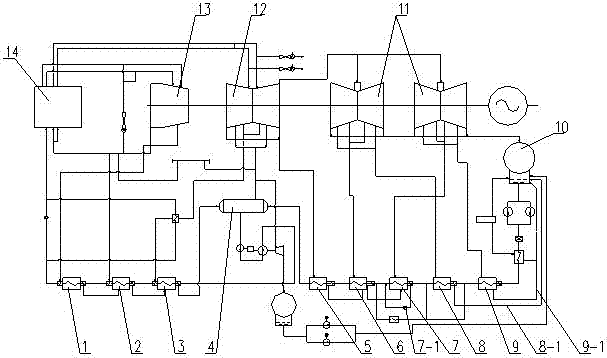

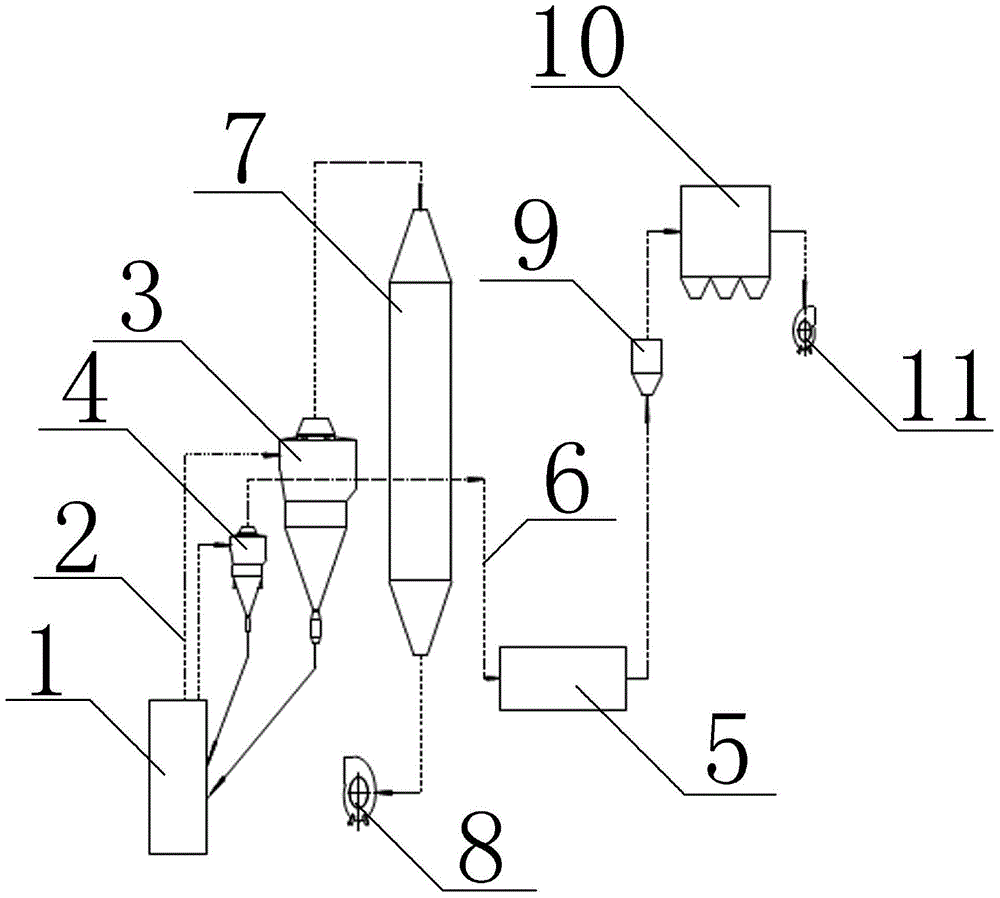

Fully dry process purification recovery method for converter gas heat energy and device

PendingCN107739771AIncrease heat recoveryGuaranteed uptimeIncreasing energy efficiencyManufacturing convertersRecovery methodWear resistant

The invention relates to a fully dry process purification recovery method for converter gas heat energy and a device. The device is characterized by comprising a dust collecting gas collecting hood, an evaporative cooling flue, a primary dust collecting device, a heat energy recovery device, an anti-explosive wear-resistant variable frequency fan, a silencer, a coal gas analyzer and a switching station communicated successively through a pipeline, wherein an ash outlet of the primary dust collecting device corresponds to a first coarse ash conveying system, an ash outlet of the heat energy recovery device corresponds to a second coarse ash conveying system, and ash outlets of the first and second coarse ash conveying systems correspond to an ash storage bin. The method and the device provided by the invention have the advantages that high-temperature sensible heat of the converter gas is utilized deeply; the temperature of flue gas is continuously cooled 600-700 DEG C from 1000 DEG C in a radiation heat transfer section of the evaporative cooling flue, so that the recovered waste heat quantity and the like are increased.

Owner:BEIJING RUIDA HONGXIN TECH CO LTD

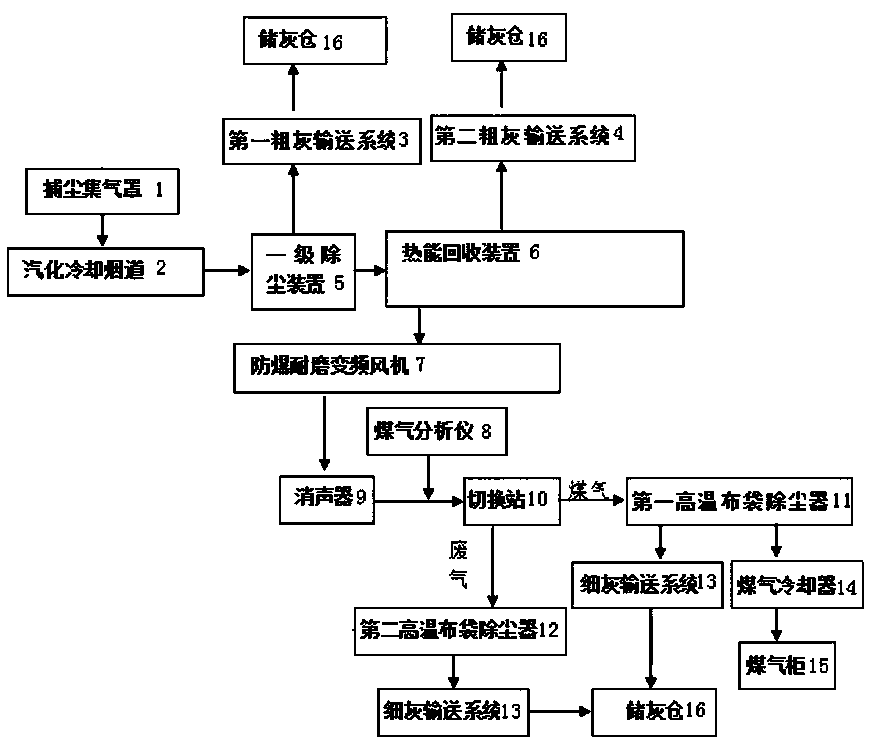

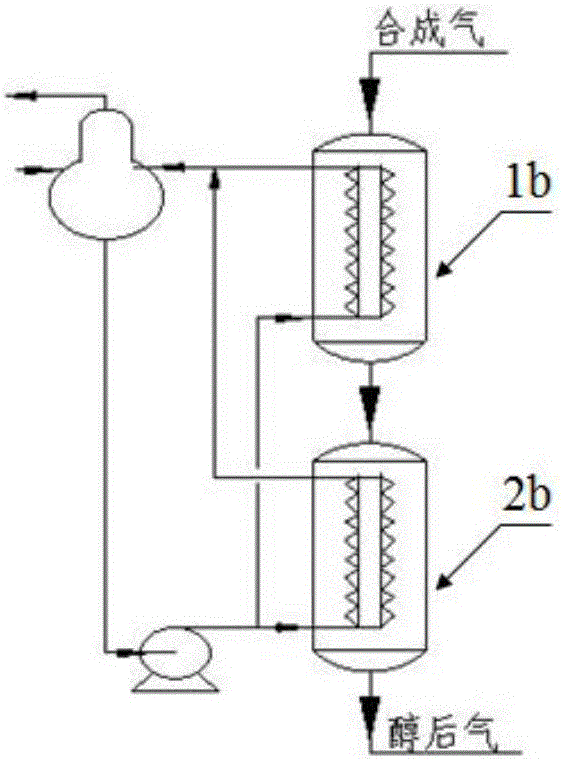

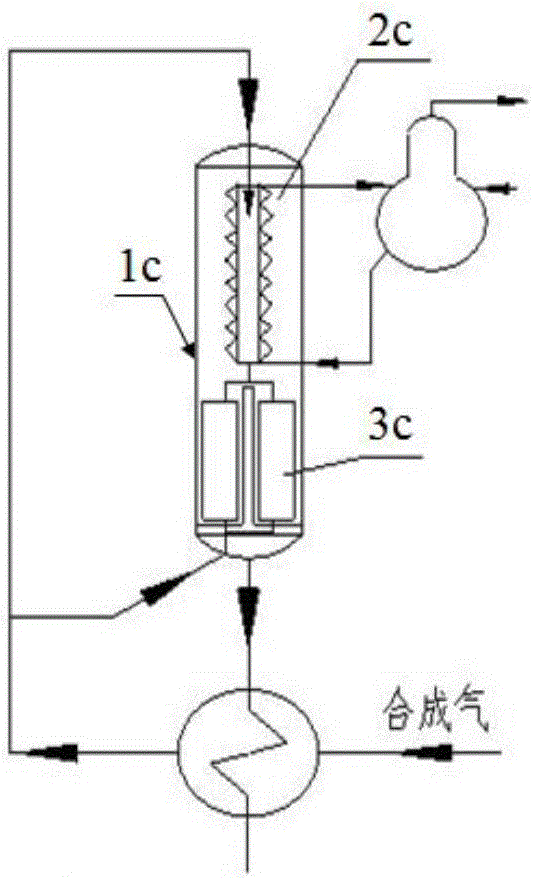

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

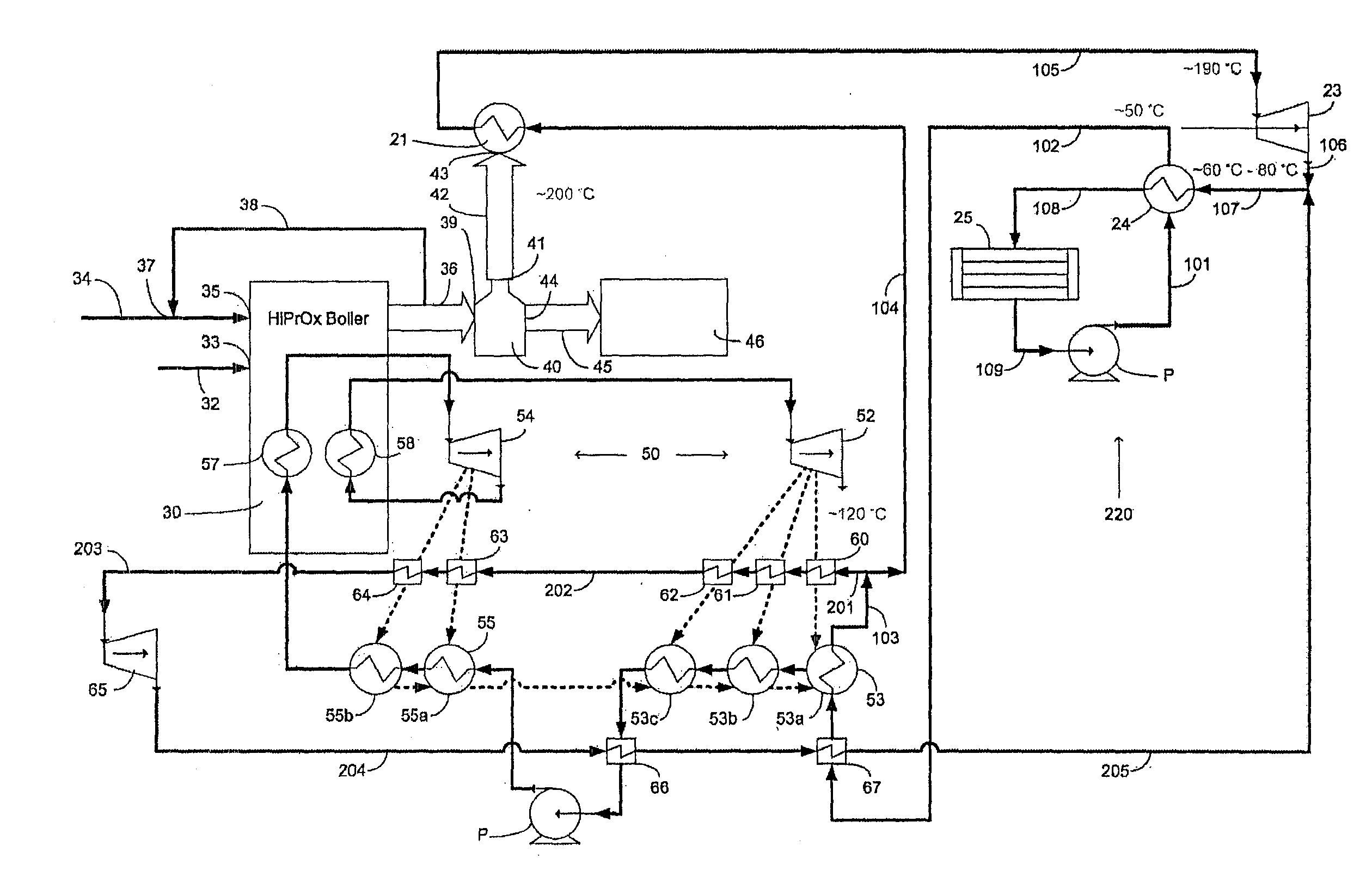

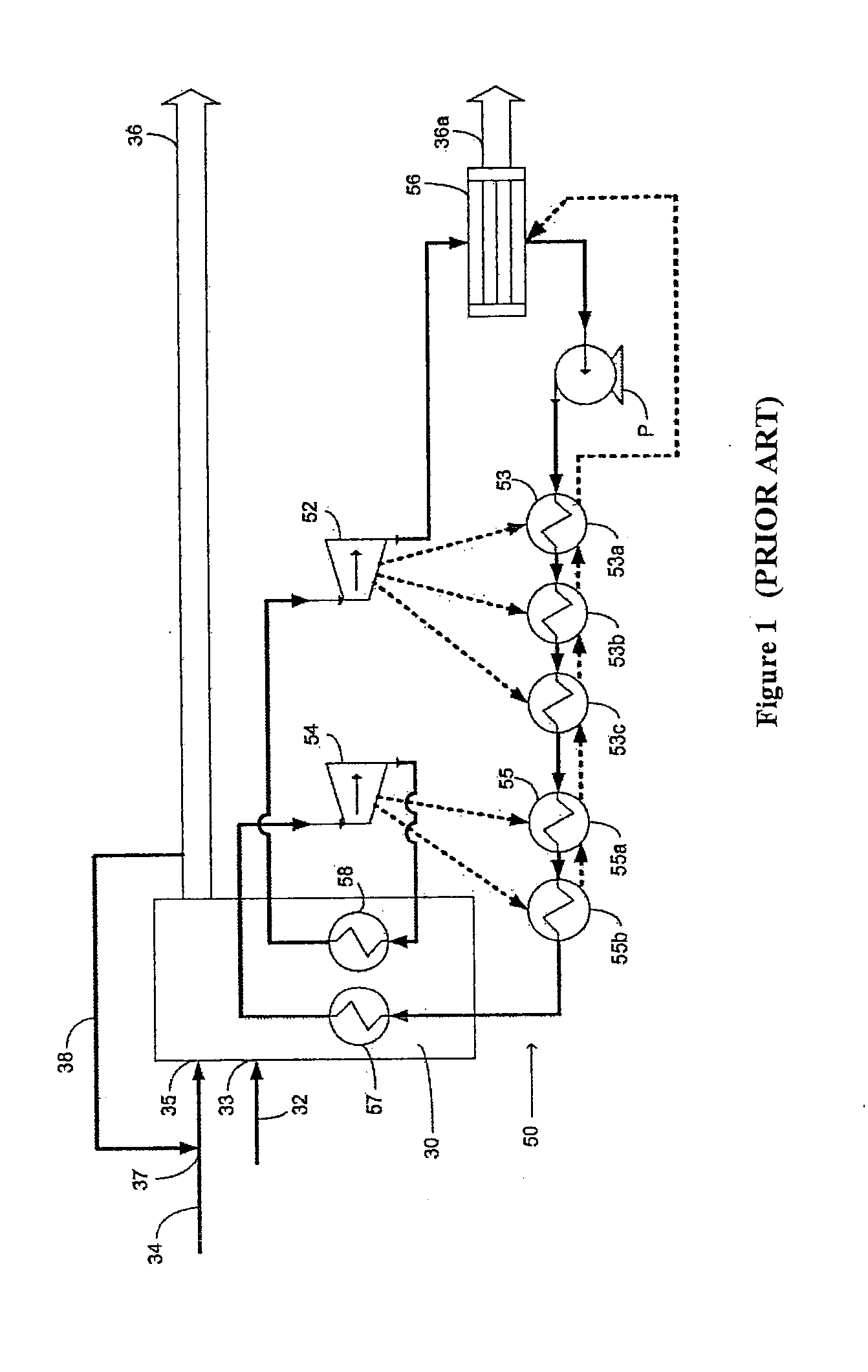

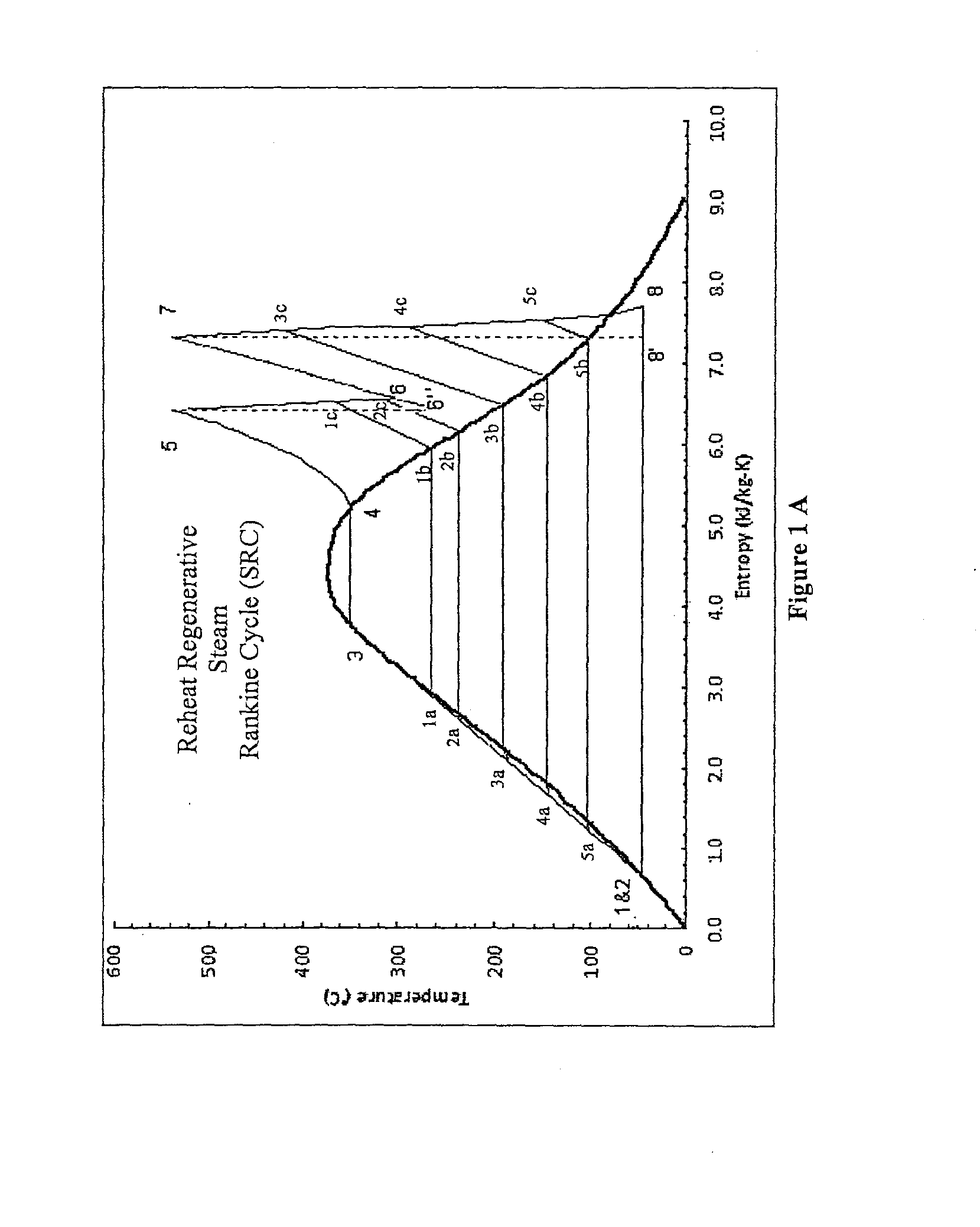

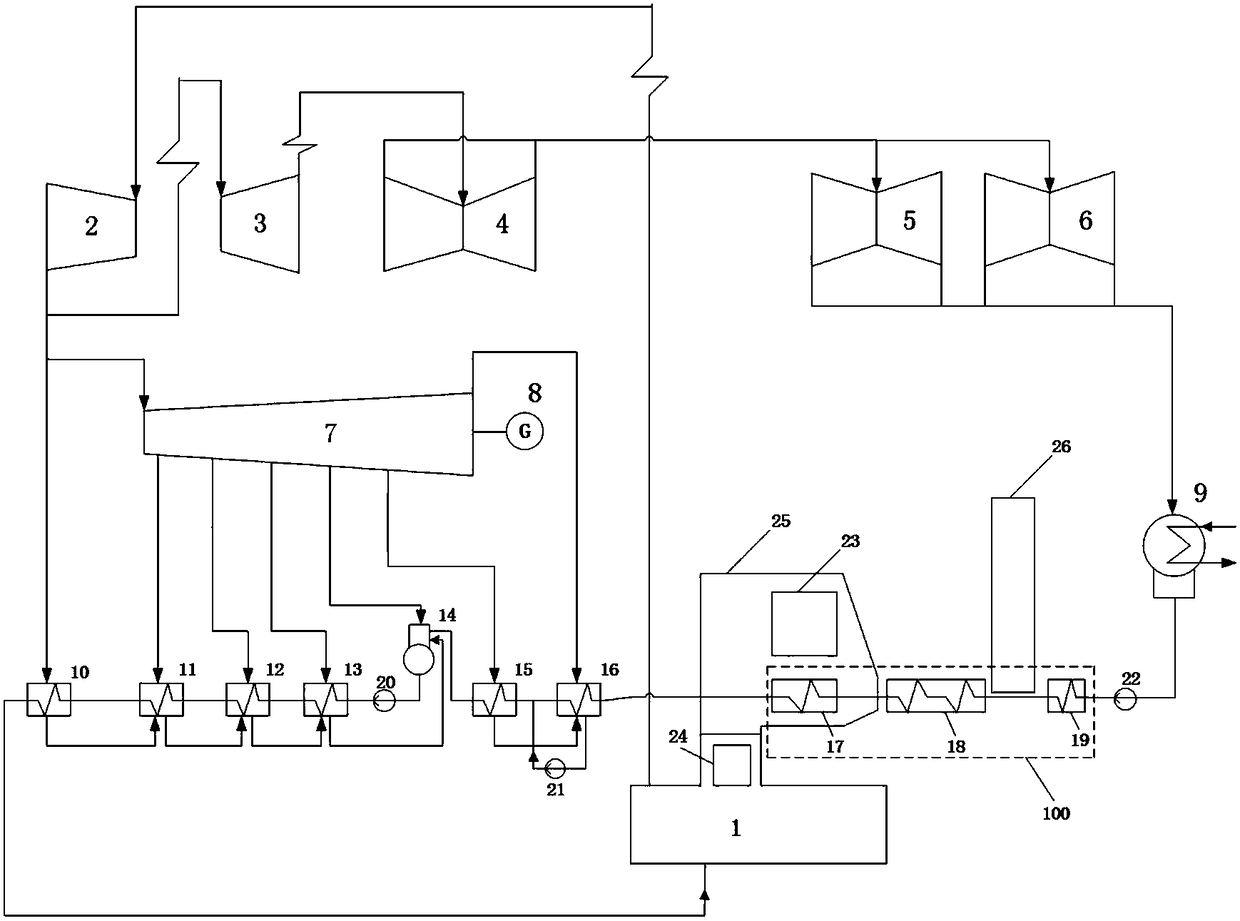

Hybrid rankine cycle

ActiveUS20150267567A1Maximize energy conversionEnhanced couplingSteam generation heating methodsIndirect carbon-dioxide mitigationWorking fluidFlue gas

A system using hybrid Rankine cycles is provided. The system includes a first Rankine cycle system using a first working fluid, the first system producing exergy loss and residual energy from at least one of turbine extraction, turbine condensation and boiler flue gas; and a second Rankine cycle system using a second working fluid to recover the exergy loss and residual energy. The second working fluid comprises a first stream and a second stream, wherein the first stream exchanges heat with the first system via at least one first heat exchanger, and the second stream exchanges heat with the first system via the at least one first heat exchanger and at least one second heat exchanger. A turbine of the first system is configured to allow the first working fluid to exit at a sufficiently high pressure and temperature to provide heat to the second system instead of expanding to a low pressure and temperature and discharging heat to ambient using a condenser.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

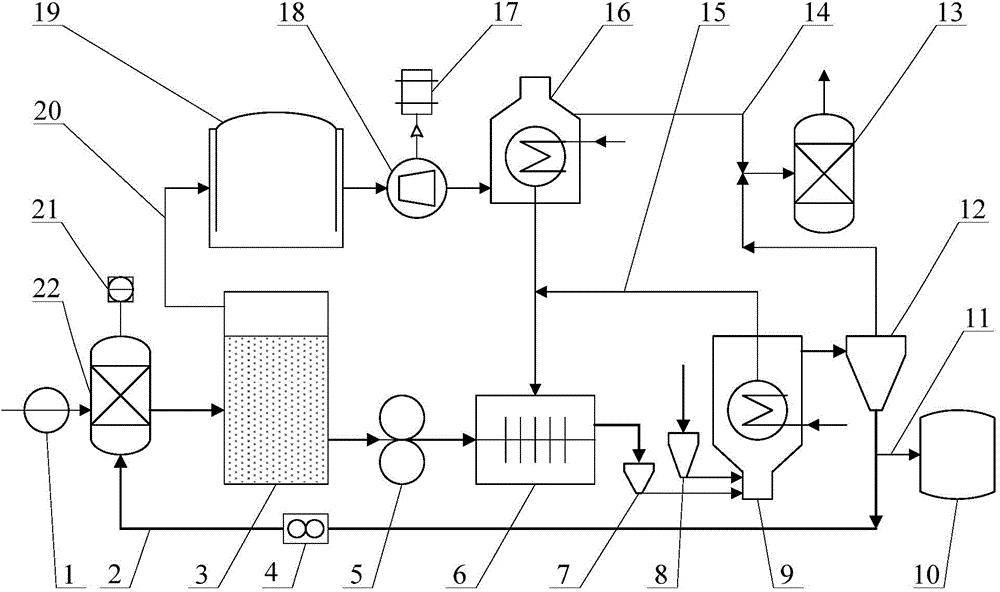

Sludge resource utilization system and method

ActiveCN104154546AReduce moisture contentLow costIncinerator apparatusCombined combustion mitigationSludgeResource utilization

The invention relates to a sludge resource utilization system and method. Surplus calcium oxide is used as agents of a whole sludge treatment process. The system and method have the advantages of being harmless and stable in sludge processing, reduction is achieved, reutilization is achieved, desulfurizing agent consumption is small, and the reutilization rate is high. According to the technical scheme, the system comprises a preprocessor for sludge organic matter decomposing, an outlet of the preprocessor is communicated with an anaerobic fermentation tank, a methane outlet of the anaerobic fermentation tank is connected with a methane tank, a sludge outlet of the anaerobic fermentation tank is connected with a dehydrator and a dryer in sequence, a sludge outlet of the dryer and an inlet of an incinerator are communicated, a smoke outlet of the incinerator is connected with a dust collector, a flying ash outlet of the dust collector is divided into two ways which are connected with a flying ash inlet of the preprocessor and an ash storeroom respectively, an outlet of the methane tank is communicated with an electricity generating fuel machine, a smoke outlet of the fuel machine is connected with a waste heat boiler, and the incinerator and the waste heat boiler provide heat for the dryer through heat supplying pipes.

Owner:凤阳县经济发展投资有限公司

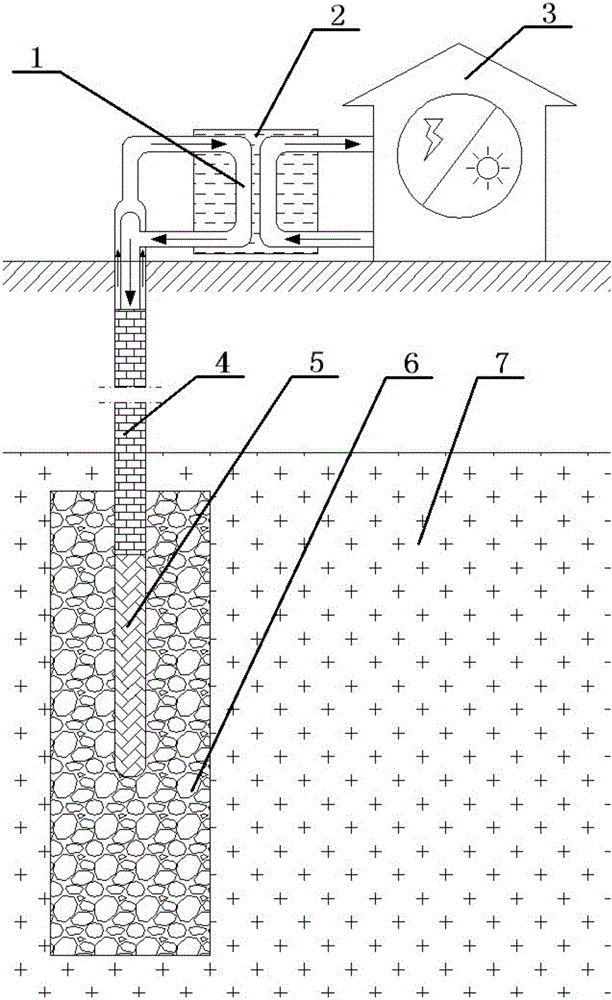

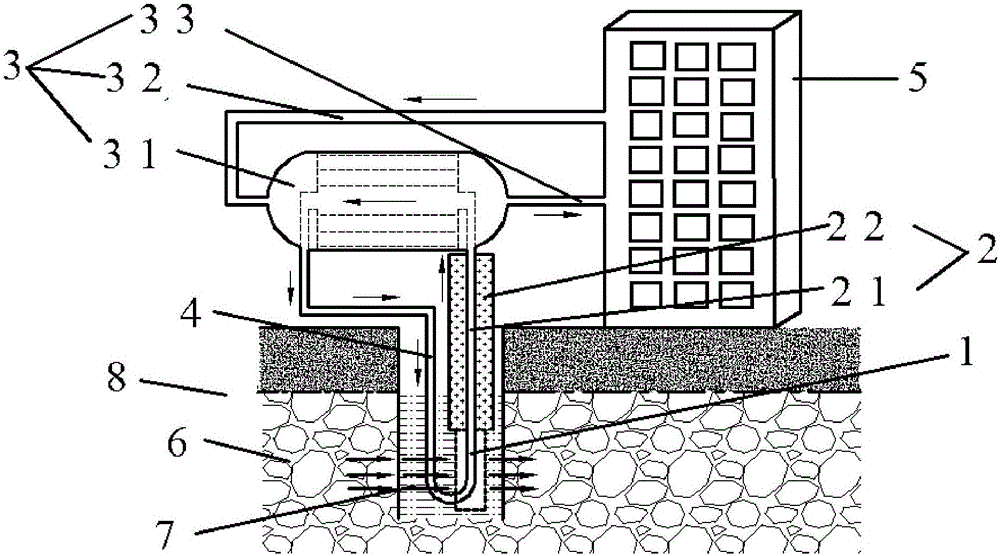

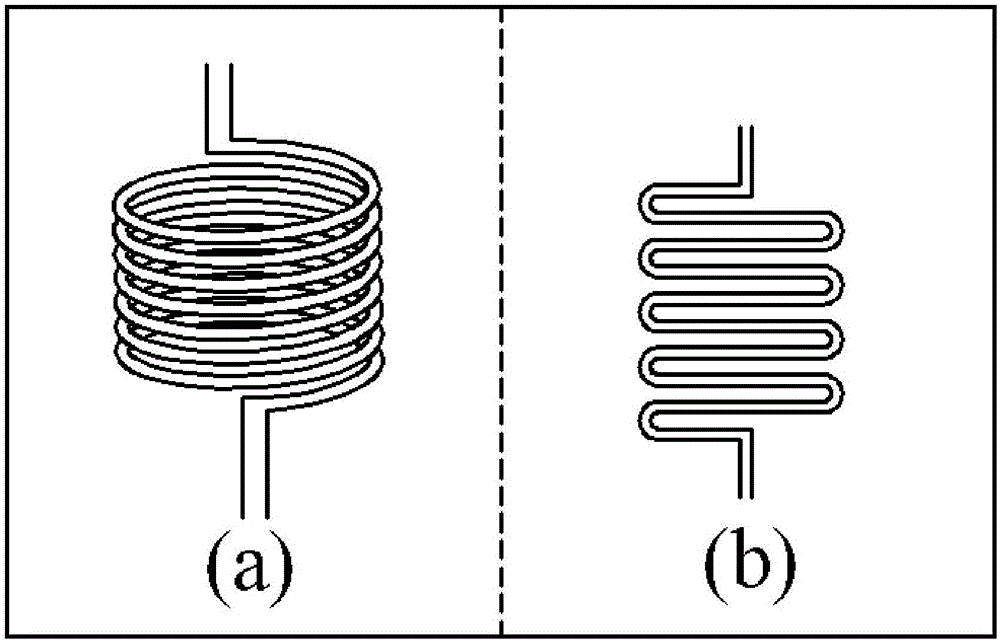

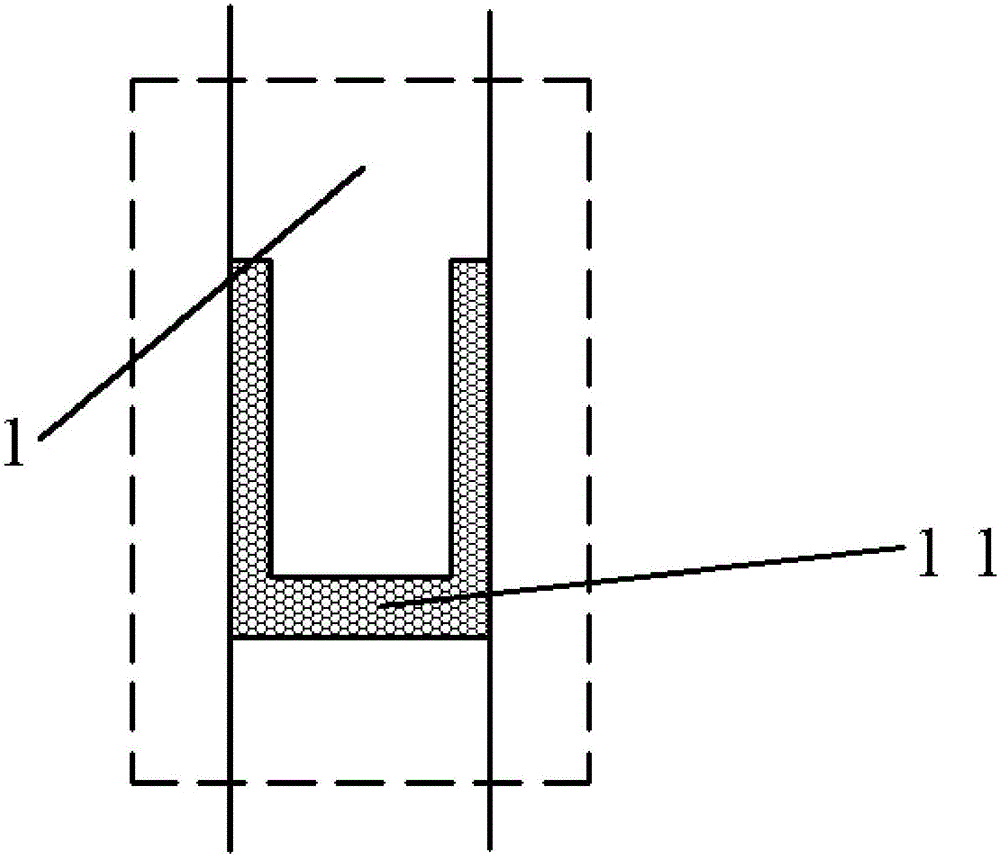

System for efficiently exploiting geothermal energy in dry-hot rock by means of heat pipe

The invention discloses a system for efficiently exploiting geothermal energy in dry-hot rock by means of a heat pipe. The system comprises the geothermal heat pipe, hypertonicity geothermal reservoirs formed in a high-temperature dry-hot rock target area and filled with fluid working mediums, and a heat exchanger and a heat utilization device which are located on the ground. The geothermal heat pipe is provided with heat pipe condensation sections, a heat pipe heat insulation section and a heat pipe evaporation section, wherein the heat pipe condensation sections, the heat pipe heat insulation section and the heat pipe evaporation section communicate sequentially. The heat pipe evaporation section penetrates through the hypertonicity geothermal reservoirs, the heat pipe condensation sections and the heat utilization device conduct heat exchanging through the heat exchanger. According to the system for efficiently exploiting the geothermal energy in the dry-hot rock by means of the heat pipe, the problem that the heat recovery rate of a conventional geothermal heat pipe heat recovery technology is too low is solved. The geothermal energy in the dry-hot rock is exploited through the geothermal heat pipe, and the heat evaporation section of the geothermal heat pipe is arranged in the geothermal reservoirs, by means of the thermal convection effect of the fluid working mediums in the geothermal reservoirs, the heat recovery quantity of the heat pipe is greatly increased, and the economy of the heat pipe mining dry-hot rock geothermal technology is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

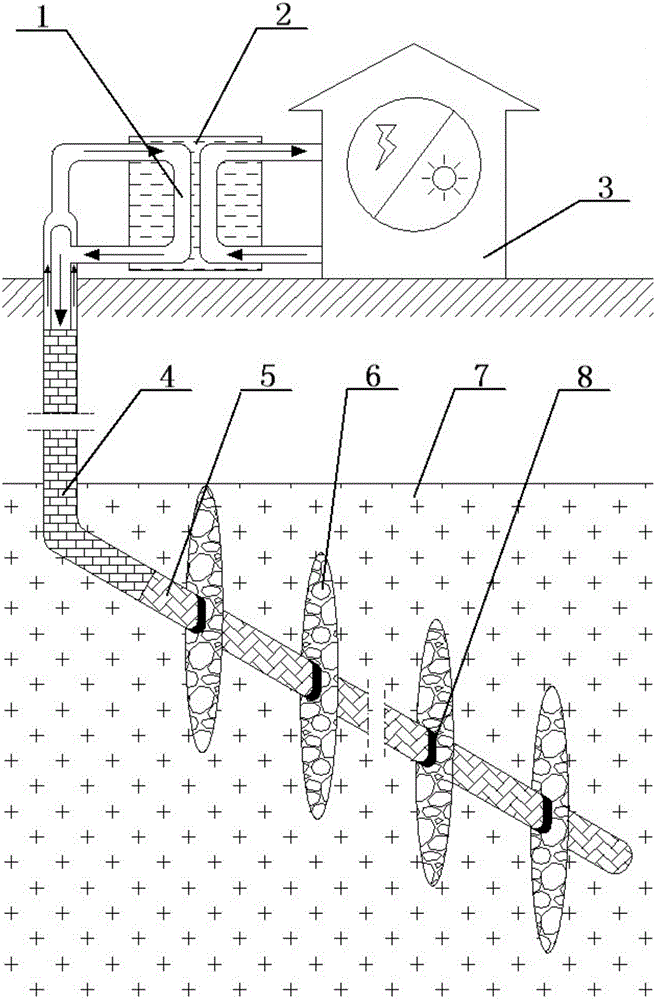

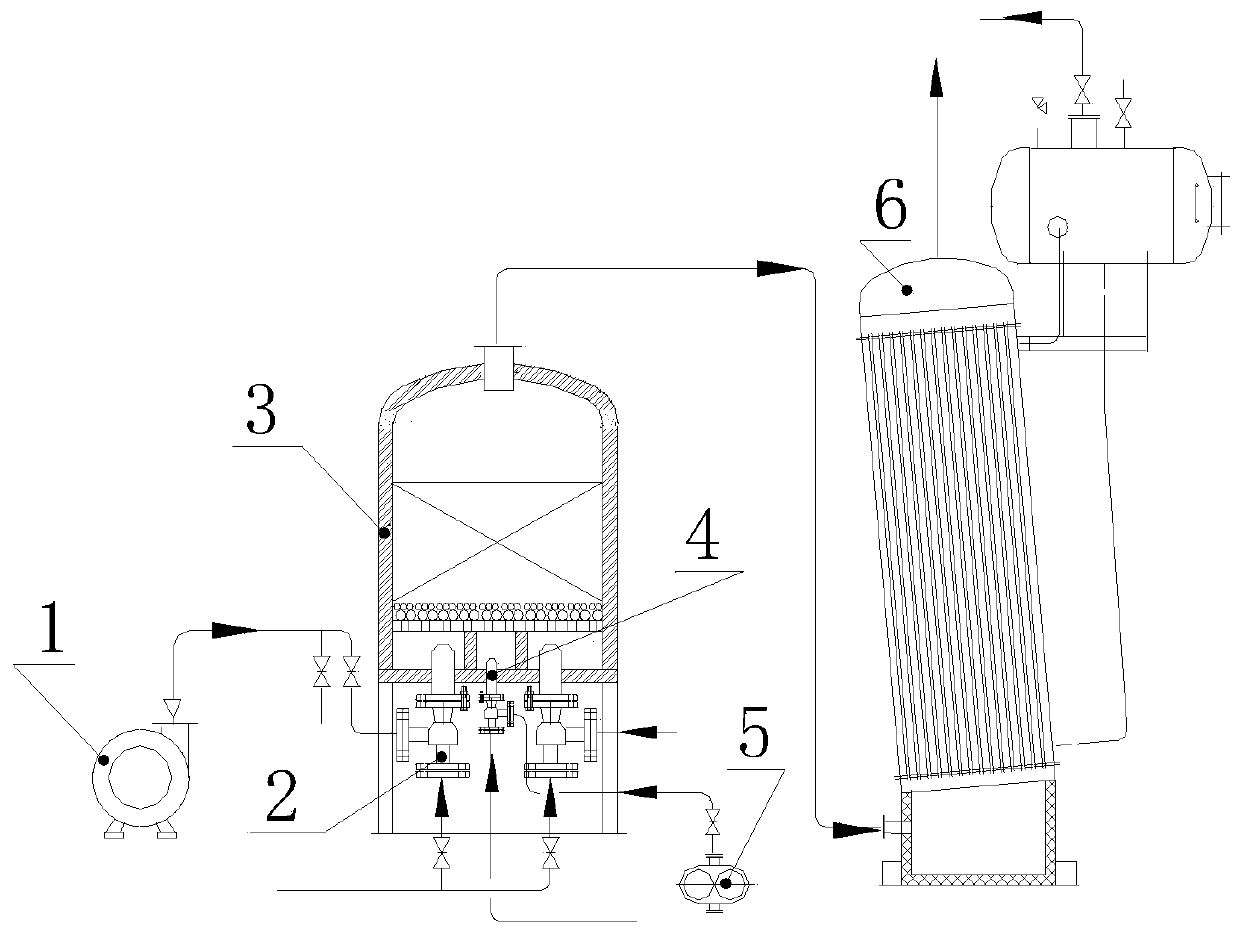

Loop type heat pipe exploitation middle-shallow layer hydrothermal type geothermal system

InactiveCN106705720AAchieve miningAvoid conflictOther heat production devicesGeothermal energy generationEvaporationHeat transfer efficiency

The invention discloses a loop type heat pipe exploitation middle-shallow layer hydrothermal type geothermal system which comprises a loop type heat pipe, a heat utilization device and a middle-shallow layer groundwater hypertonicity geothermal reservoir. The loop type heat pipe is provided with a loop type heat pipe evaporation section, a loop type heat pipe heat insulation section, a loop type heat pipe condenser and a loop type heat pipe fluid pipeline section which are located in the hypertonicity geothermal reservoir; the loop type heat pipe heat insulation section comprises a steam pipeline section and a heat insulation material layer for tightly wrapping the outer wall of the steam pipeline section; and one end of the loop type heat pipe evaporation section is communicated with one end of the loop type heat pipe fluid pipeline section, the other end of the loop type heat pipe fluid pipeline section is communicated with one end of the steam pipeline section through the heat release side of a heat exchanger, and the other end of the steam pipeline section is communicated with the other end of the loop type heat pipe evaporation section. By means of the loop type heat pipe exploitation middle-shallow layer hydrothermal type geothermal system, the problem about self starting of the overall geothermy exploitation system can be solved; and meanwhile, the heat long-distance transportation can be achieved, the problem of conflicts of steam flow and liquid flow of a tradition heat pipe is solved, and the heat transferring efficiency is greatly improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Secondary reheating system and method achieving efficient regeneration and steam exhaust optimization

The invention discloses a secondary reheating system and method achieving efficient regeneration and steam exhaust optimization, and relates to the field of thermal power generation. The system mainlycomprises a boiler, a regeneration steam turbine and a waste heat recovery system, wherein the waste heat recovery system replacing a traditional low-pressure heater is arranged between a condensatewater pump and feedwater of a seventh-stage low-pressure heater, condensate water is preliminarily heated by the waste heat recovery system through flue gas of the boiler and pipeline leaking steam ofthe regeneration steam turbine, and the waste heat recovery system is composed of a flue gas cooler, a low-temperature coal economizer and a sealing heater. The flue gas cooler, the low-temperature coal economizer and the sealing heater replace the traditional low-pressure heater to heat the feedwater, and steam exhaust energy losses of the steam turbine are reduced while heat of the boiler is recovered. The arrangement of a unit is optimized as a whole, efficient regeneration is further enhanced, and the complexity of the system is lowered. The coal consumption can be reduced by 2 g / kW.h to3 g / kW.h while the power supply efficiency of a traditional 1,000 MW secondary reheating unit is improved by 0.2% to 0.3%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

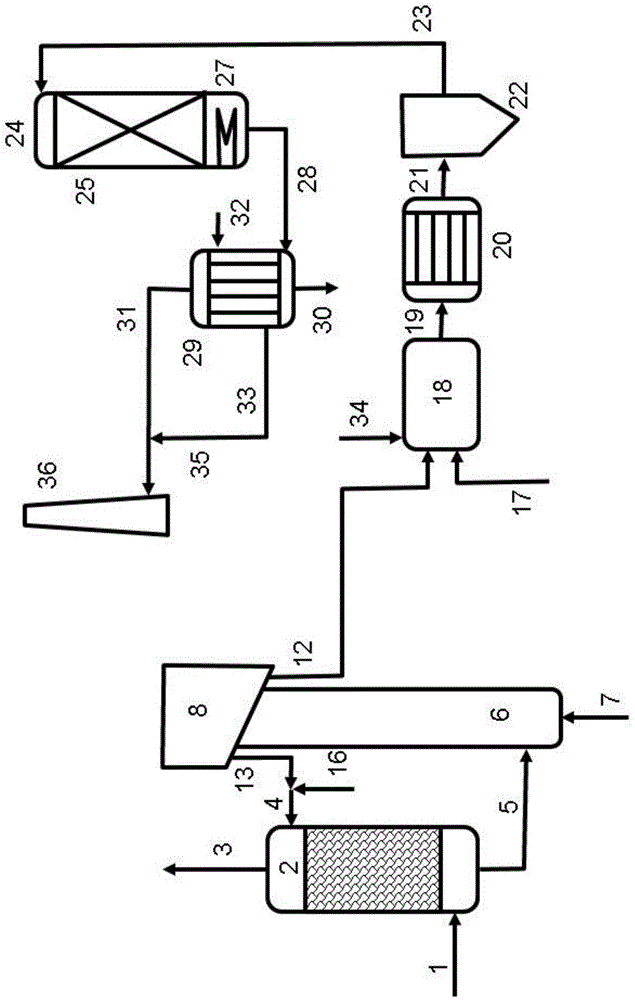

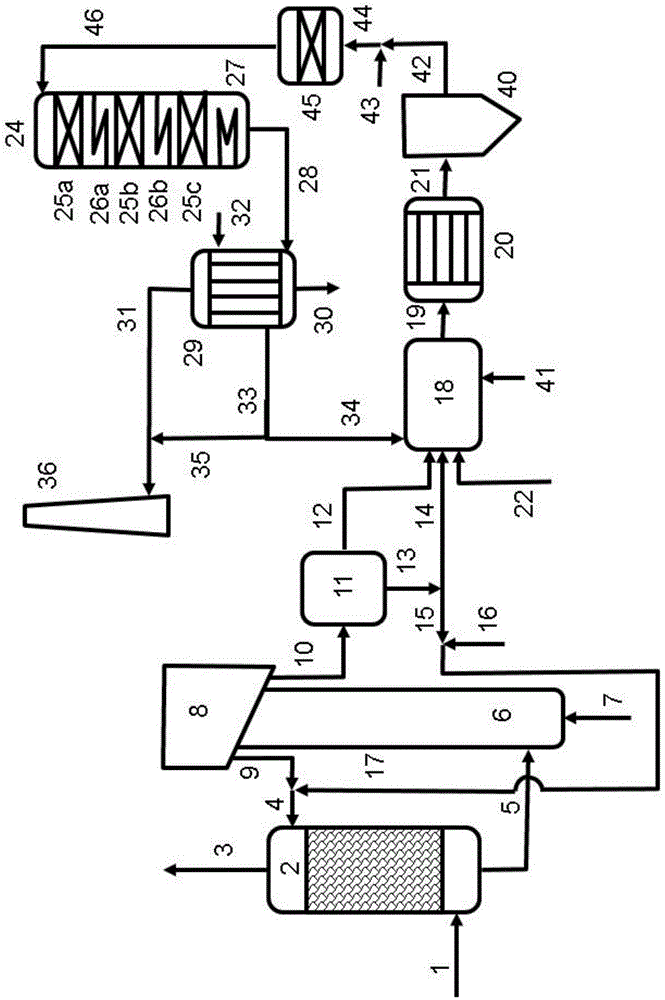

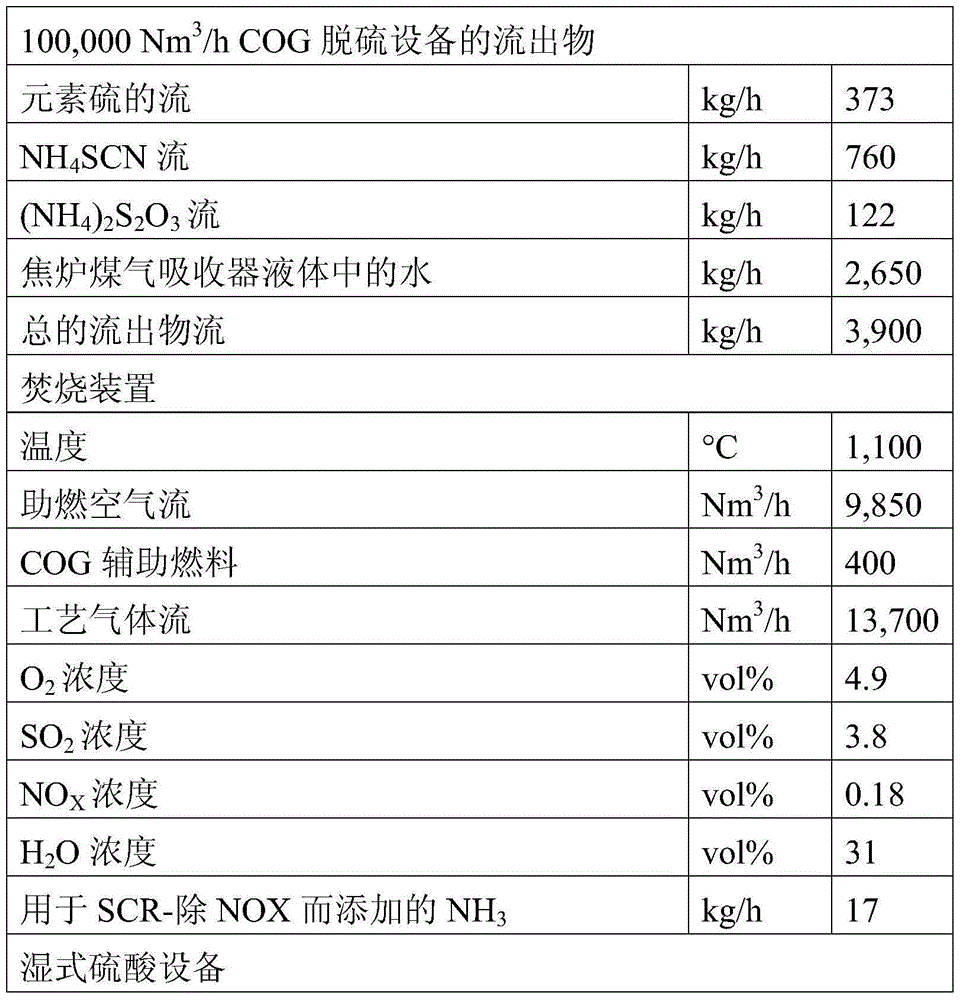

Production of sulfuric acid from coke oven gas desulfurization product

InactiveCN105084326AAvoid emissionsReduce the impactGas treatmentDispersed particle separationSulfurSludge

The present invention relates to a process and a process plant for the production of sulfuric acid from a gas comprising H 2 S and HCN characterized by the following steps; directing said gas to an alkaline absorber containing a liquid ammonia absorbent solution and a material catalytically active in oxidation of H 2 S to elemental sulfur providing a liquid slurry comprising sulfur and coke oven gas absorber liquid, separating at least a portion of said elemental sulfur from coke oven gas absorber liquid by mechanical means of separation as a sulfur sludge, combining said sulfur sludge with a support fuel and a first gas comprising oxygen in or upstream an incinerator, incinerating said mixture, providing an incinerated gas comprising SO 2 and NO x , optionally adding a second gas comprising oxygen to said incinerated gas, selectively removing the formed NO x by chemical reduction with NH 3 , contacting said process gas with a material active in oxidation of SO 2 to SO 3 providing an oxidized process gas, optionally adding water to said oxidized process gas and condensing concentrated sulfuric acid formed in said oxidized process gas.

Owner:HALDOR TOPSOE AS

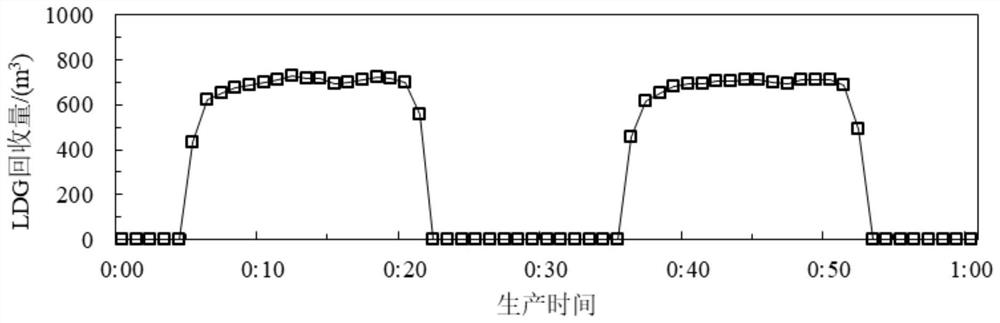

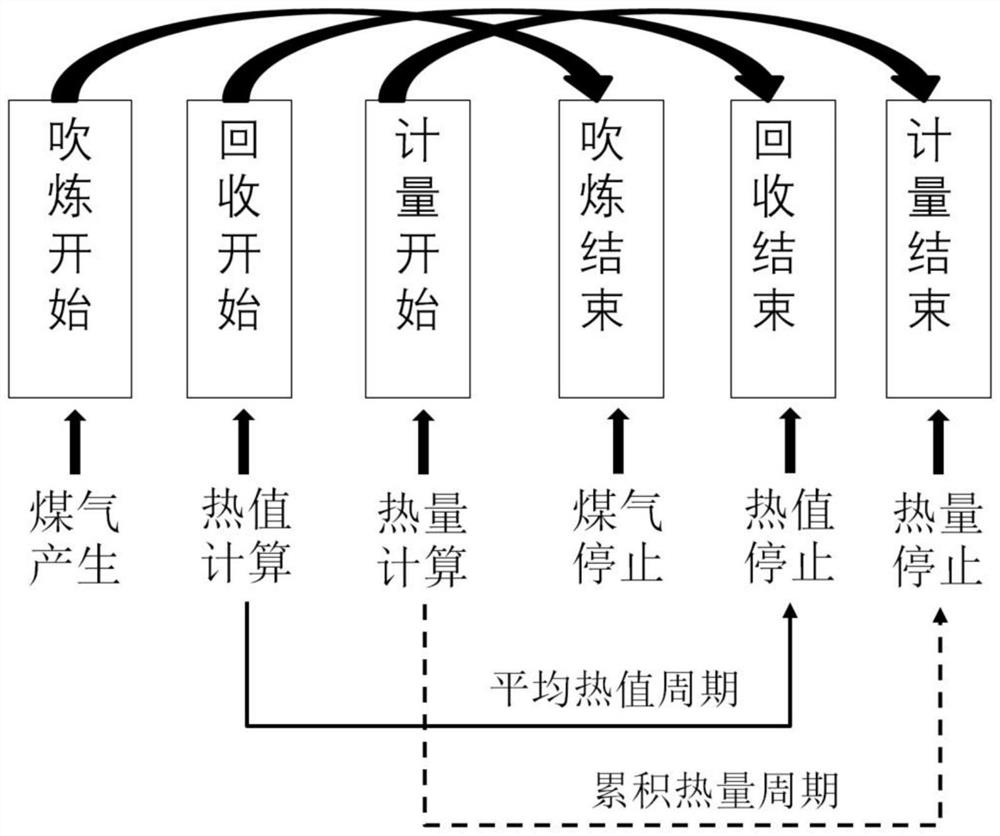

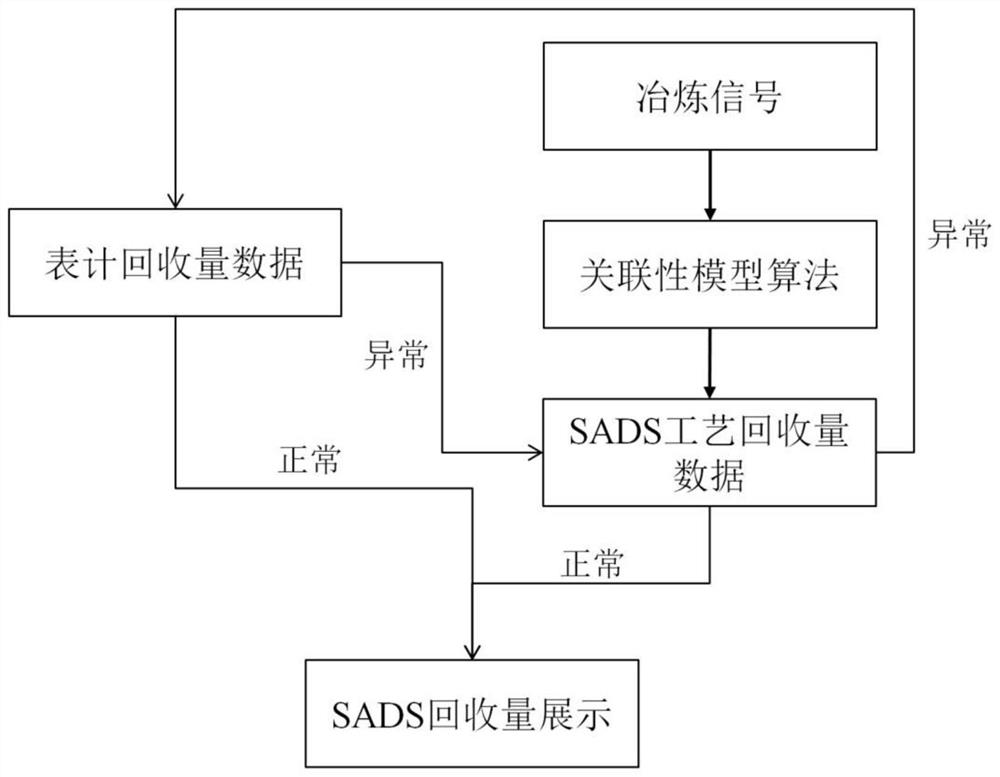

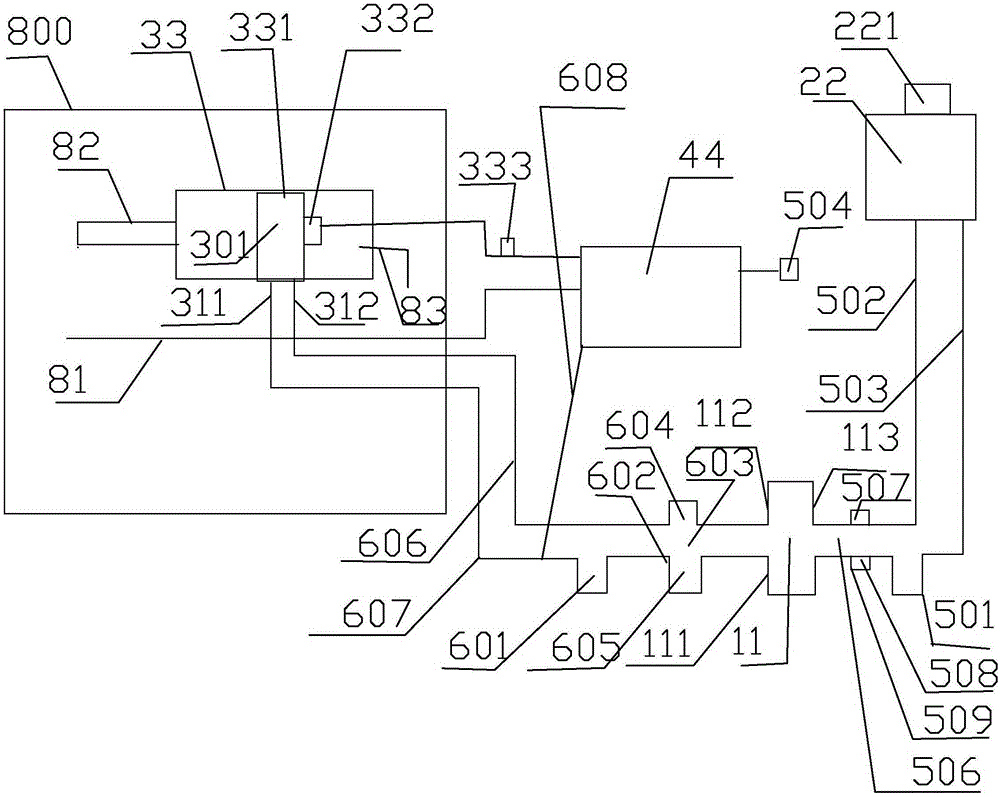

Converter on-line diagnosis energy-saving and consumption-reducing SADS system

ActiveCN112226570AImproved heat recoverySolve the heat recovery problemSteel manufacturing process aspectsForecastingSteelmakingProcess engineering

Disclosed is a converter on-line diagnosis energy-saving and consumption-reducing SADS system. The system solves the problems that in the existing converter steelmaking process, the heat recovery rateof converter gas is low, the energy consumption of converter steelmaking is high, and the gas generated by a converter cannot be effectively utilized. The system is based on a multi-signal-source process analysis means, depends on a metallurgical physicochemical model algorithm in the converter steelmaking process, and guarantees that the converter gas recovery amount and the converter gas heat value are always in an ideal state in the converter steelmaking process through self-adaptive calculation and intelligent analysis, and the converter gas recovery heat is made maximum. Moreover, the optimal converter steelmaking production process rhythm is provided, and the process rhythm not only ensures smooth operation of the steelmaking process but also ensures the maximization of gas recoveryheat. Under the condition that the use amount of the gas consumption end is kept unchanged, more gas can be used for gas-fired boiler power generation, and greater economic benefits can be created for a steel mill.

Owner:NANJING HANHUA FLUID TECH CO LTD

Nine-stage regenerative extraction steam system of 1000MW thermal power generating unit turbine

ActiveCN103573308AIncreased heat recoveryHigh thermal efficiencyMachines/enginesEngine componentsSteam pressureLow load

The invention discloses a nine-stage regenerative extraction steam system of a 1000MW thermal power generating unit turbine. The nine-stage regenerative extraction steam system comprises a condenser, a turbine low-pressure cylinder, a turbine intermediate-pressure cylinder, a turbine high-pressure cylinder and a boiler. The turbine high-pressure cylinder is correspondingly connected with a first high-pressure heater and a second high-pressure heater. The turbine intermediate-pressure cylinder is correspondingly connected with a third high-pressure heater, a deaerator and a fifth low-pressure heater. The turbine low-pressure cylinder is correspondingly connected with a sixth low-pressure heater, a seventh low-pressure heater, an eighth low-pressure heater and a ninth low-pressure heater. Low-pressure drainage pumps are arranged on the seventh low-pressure heater. The eighth low-pressure heater and the ninth low-pressure heater directly drain water to the condenser through an eighth drainage pipe and a ninth drainage pipe respectively. The nine-stage regenerative extraction steam system of the 1000MW thermal power generating unit turbine has the advantages that the number of regeneration stages is increased by one, and therefore thermal efficiency is improved; the problem that because steam pressure is low, unsmooth drainage is probably caused in the low-load operation process is solved; although the number of devices is increased, operating cost is reduced, and accordingly the nine-stage regenerative extraction steam system is more economical.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

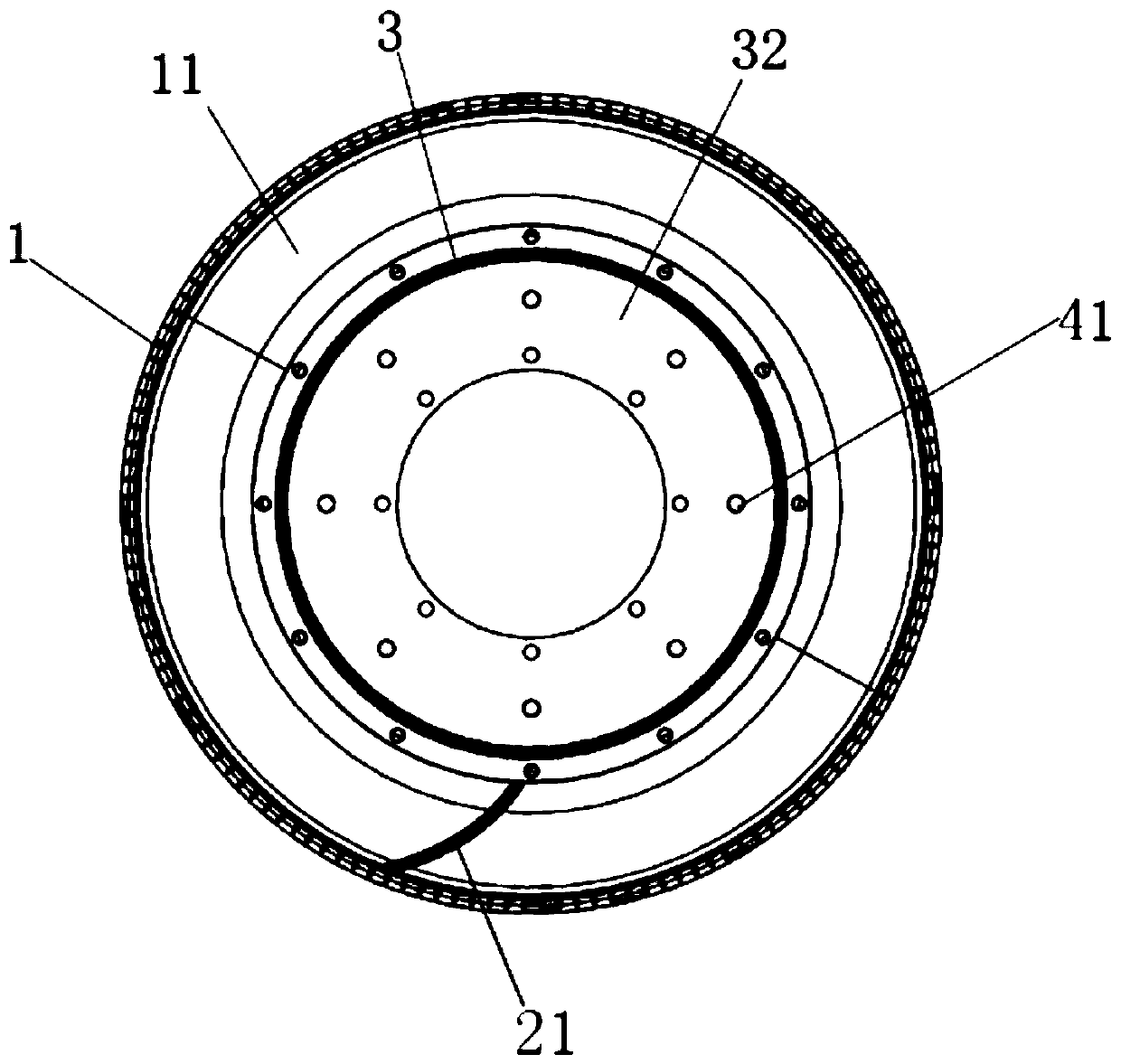

Plate-fin heat regenerator of micro gas turbine

InactiveCN111059932AEfficient heat transfer surfaceIncrease heat transfer areaCombustion processGas turbine plantsMicro gas turbineEngineering

The invention provides a micro gas turbine plate-fin heat regenerator which comprises an outer casing, a fin assembly and a heat insulation casing. A shell cavity is formed in the outer casing, and the heat insulation casing is coated with the outer casing. The fin assembly is arranged in the shell cavity and comprises a plurality of fins. Each fin is of a hollow structure provided with a fin cavity. A first air inlet communicated with the shell cavity is formed in the inner bottom of the shell. A first air outlet communicated with the shell cavity is formed in the top of the shell. A second air inlet communicated with a fin cavity is formed in the end, close to the top of the shell, of the inner side wall of the shell. A second air outlet communicated with a fin cavity is formed in the other end, close to the bottom of the shell, of the inner side wall of the shell. The plate-fin heat regenerator is provided with an efficient heat transfer surface, larger in heat transfer area per unit volume, light in weight, small in volume, convenient to maintain, high in heat regeneration degree, small in resistance and low in price.

Owner:长三角新能源汽车研究院有限公司

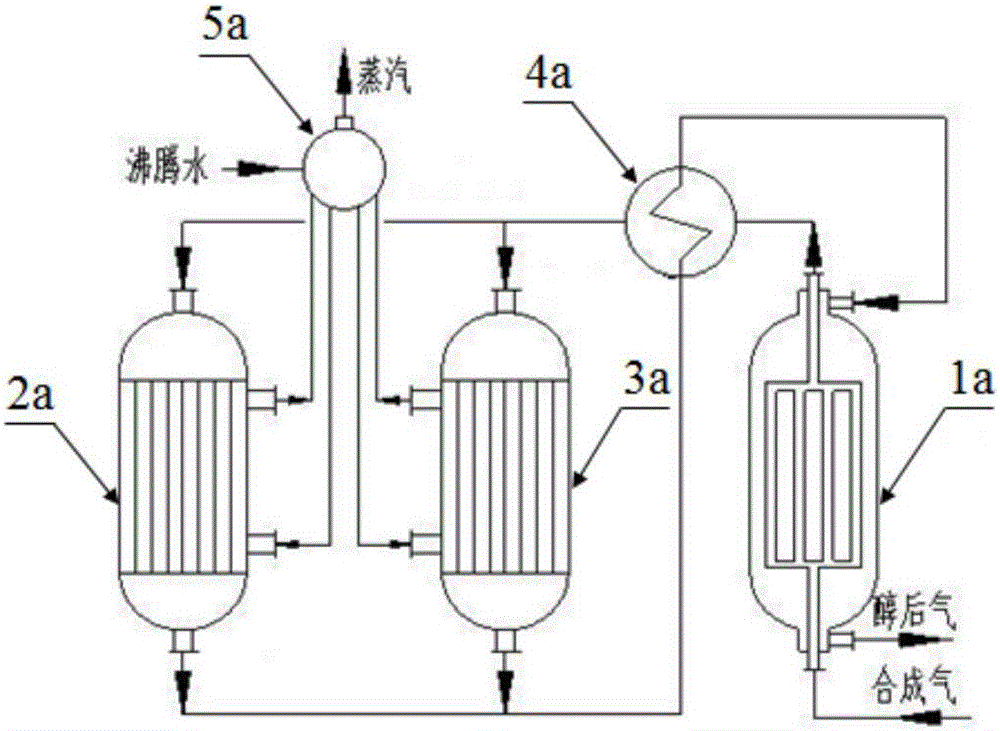

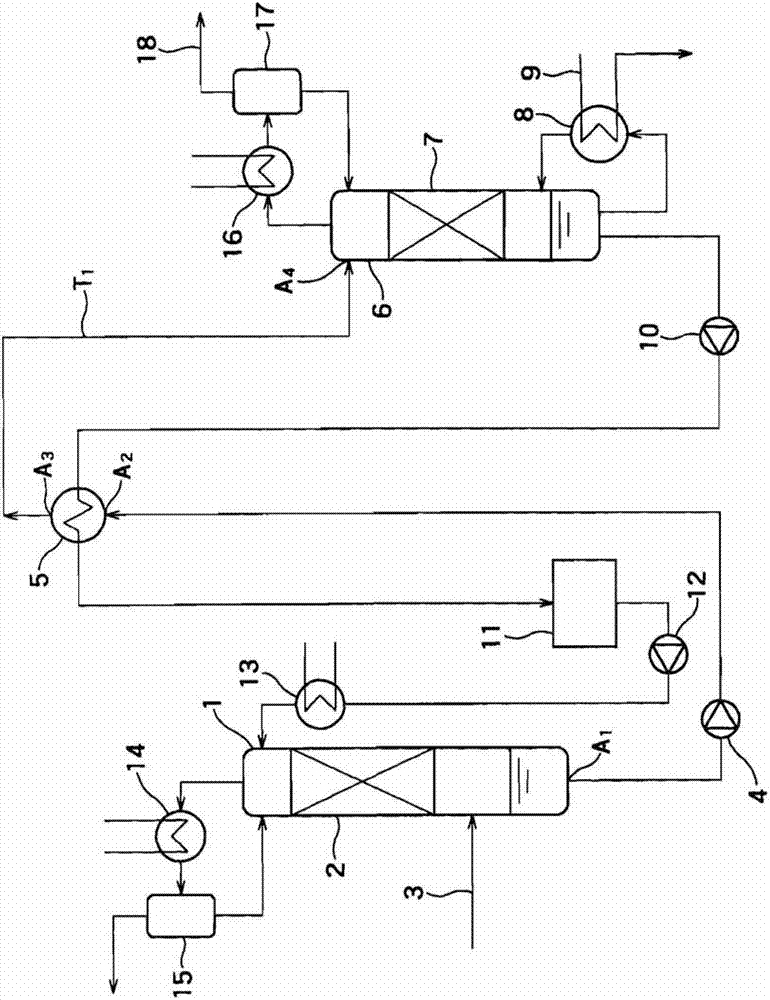

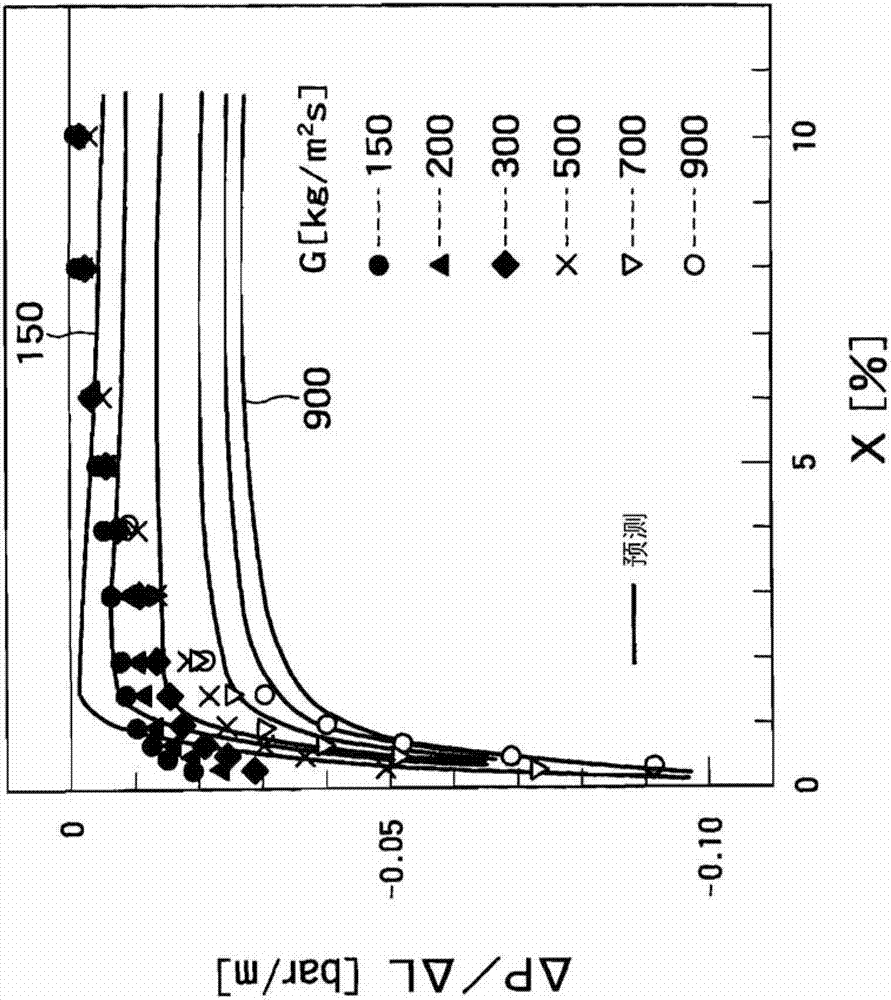

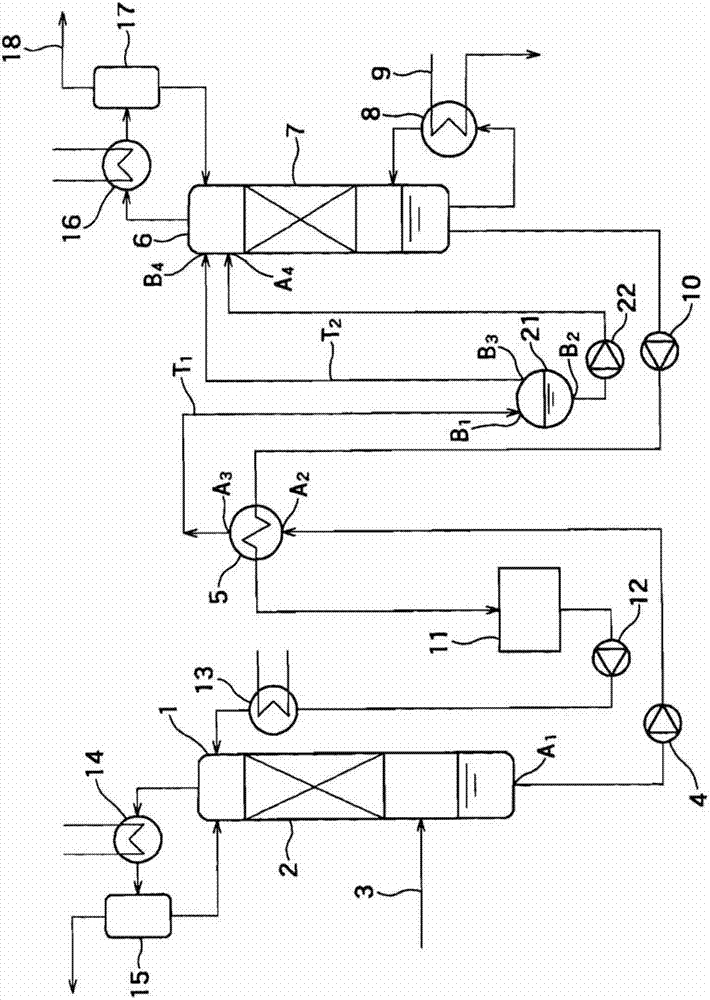

Carbon dioxide separating and collecting system and method of operating same

InactiveCN103285713AImproved heat recoveryCarbon compoundsDispersed particle separationProcess engineeringTower

The invention provides a carbon dioxide separating and collecting system and the method of operating the same which can increase the recovered heat quantity in the regenerative heat exchanger. According to one embodiment, a carbon dioxide separating and collecting system includes an absorbing tower to cause an absorbing liquid to absorb carbon dioxide, and discharge a rich liquid which is the absorbing liquid which has absorbed the carbon dioxide. The system includes a regenerating tower to cause the absorbing liquid to release the carbon dioxide, and discharge a lean liquid which is the absorbing liquid having a dissolved carbon dioxide concentration lower than a dissolved carbon dioxide concentration of the rich liquid. The system further includes a regenerative heat exchanger configured to heat the rich liquid flowing between the absorbing tower and the regenerating tower by using heat of the lean liquid flowing between the regenerating tower and the absorbing tower. A discharge port of the rich liquid of the regenerative heat exchanger is disposed at a higher position than a supply port of the rich liquid of the regenerating tower so that the rich liquid discharged from the regenerative heat exchanger become a gas-liquid two-phase flow.

Owner:KK TOSHIBA

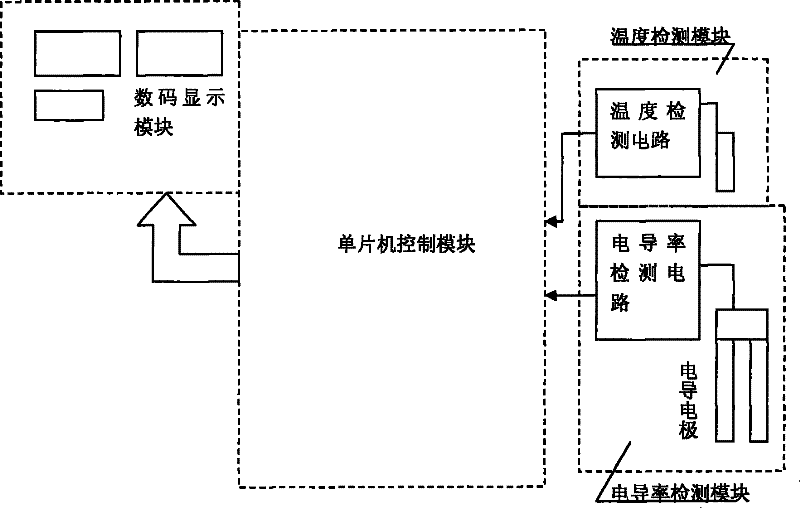

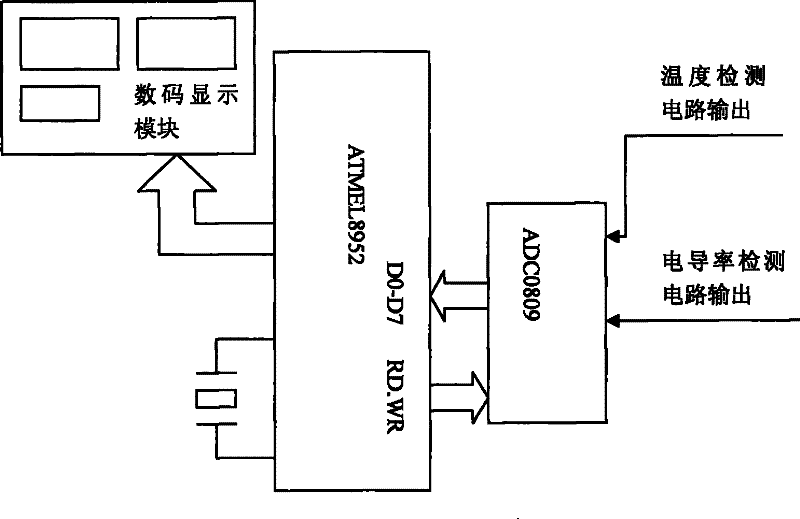

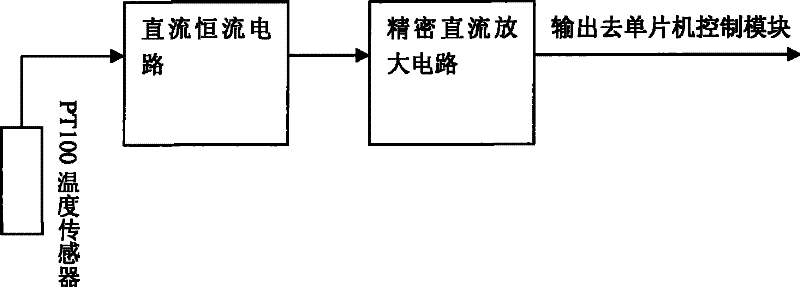

Micro sugar detection device and method thereof

InactiveCN101393154BReduce labor intensityImprove measurement efficiencyMaterial resistanceMicrocontrollerEvaporation

The invention discloses a device for detecting trace sugar and a method thereof. The detecting device comprises a singlechip control module, a digital display module, a temperature detecting module and an electrical conductivity detecting module; the digital display module, and the temperature detecting module and the electrical conductivity detecting module are respectively connected with the singlechip control module. The detecting method comprises the following steps: (1) measuring the temperature and the electrical conductivity of condensed water with sugar; and (2) by using the condensedwater corresponding to the relevant sugar contained numerical relation under the condition of different temperatures and electrical conductivity, substituting the measured temperature and electrical conductivity in a formula to calculate and obtain the sugar content of water. The method can realize on-line measurement of trace sugar, improve precision and efficiency of detection, not only solve the safety problem of the reutilization of the condensed water formed by the evaporation of the prior cane juice and improve the utility ratio of the water and recovery heat energy, but also reduce thepollution of discharged condensed water and has good environmental protection effect.

Owner:SOUTH CHINA UNIV OF TECH

An energy-saving urea production system and its production process

ActiveCN104829494BReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

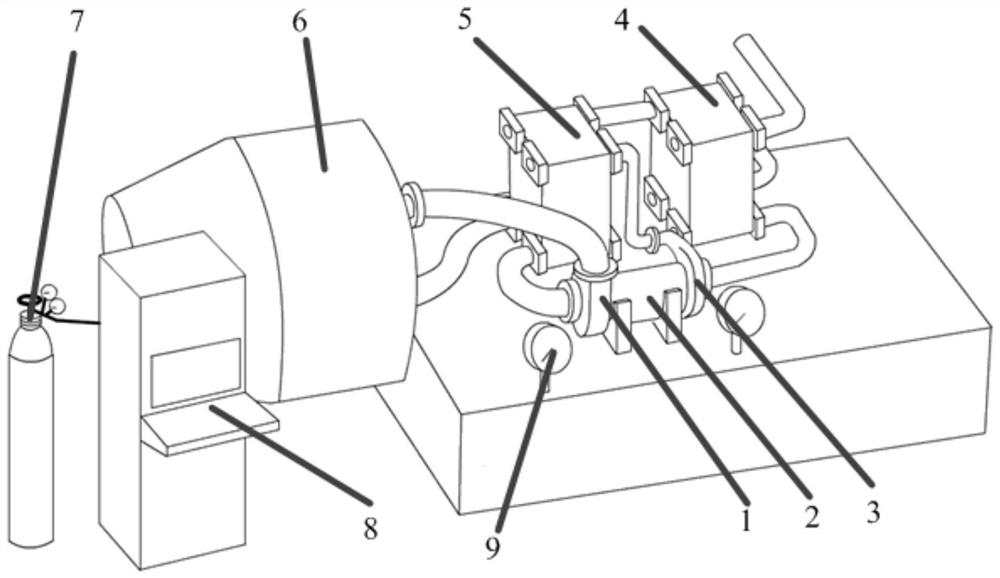

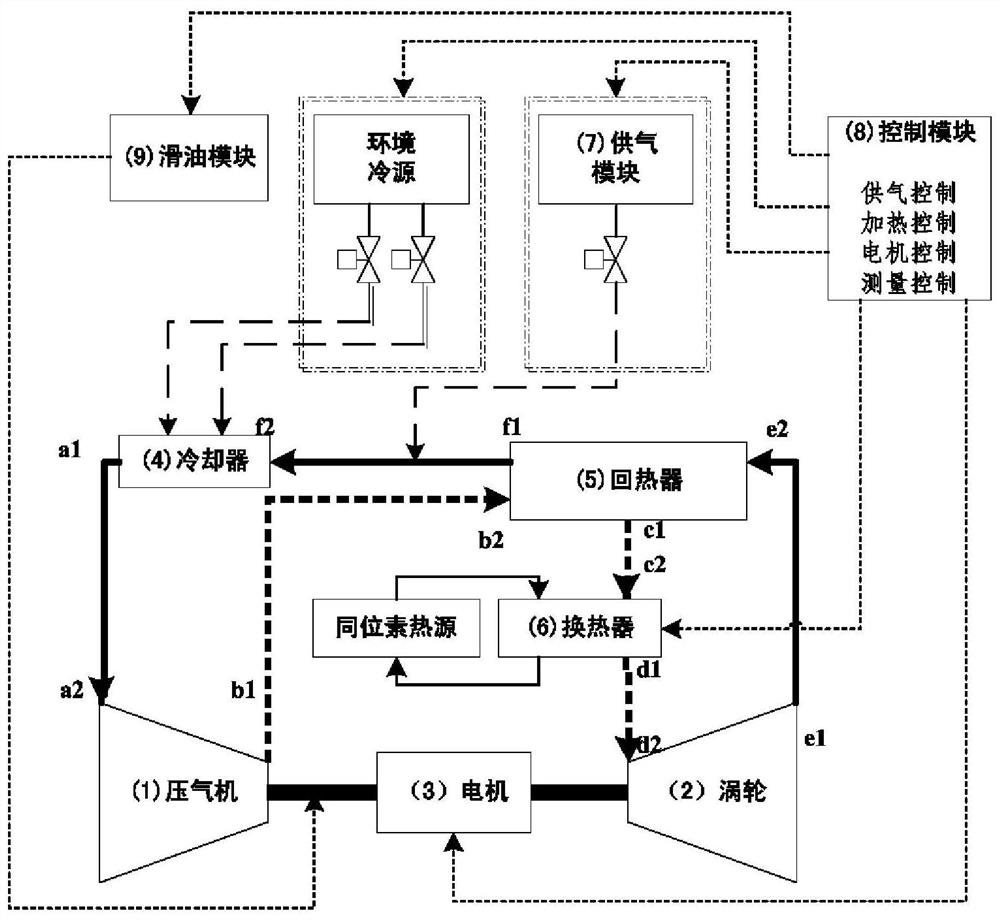

10kW-level space nuclear energy closed type Brayton cycle thermoelectric conversion system

ActiveCN112049692AHigh technical feasibilityStrong heat transferFrom solar energyPump componentsFlight vehicleBrayton cycle

The invention provides a 10kW-level space nuclear energy closed type Brayton cycle thermoelectric conversion system, which is applied to spacecraft power and and is used for converting heat energy generated by an isotope heat source into electric energy and providing electric power for loads such as an electric thruster. The power generation power of the 10kW-level space nuclear energy closed typeBrayton cycle thermoelectric conversion system provided by the invention is 10 kW; a working medium loop is designed according to a closed Brayton cycle; and a working medium is sequentially subjected to a thermodynamic process including adiabatic compression in an air compressor, constant-pressure heating with an isotope source as a heat source, adiabatic expansion in a turbine and constant-pressure cooling. According to the system, the physical properties of the used inert gas working medium are fully considered; the advantages of each component gas in the working medium gas in the aspectsof thermal conductivity, thermal capacity and the like are comprehensively utilized; and by a repeated iteration design, the system has the characteristics of compact layout, high conversion efficiency, high power density, high environmental adaptability and the like and is also suitable for a power system of an underwater vehicle.

Owner:BEIJING INST OF CONTROL ENG

Converter flue gas cleaning and coal gas recovering RD valve dynamic control method

InactiveCN107794337AEliminate the effects of controlsHigh calorific valueManufacturing convertersFlue gasEngineering

The invention provides a converter flue gas cleaning and coal gas recovering RD valve dynamic control method. An RD valve dynamic control program is additionally arranged in a converter PLC; when a converter starts to blow oxygen, the converter PLC controls a valve plate to overturn to adjust the opening degree of an RD valve through an orma executor, the smoke amount of the RD valve is automatically increased to 20000 L / h on the basis of a conventional setting value, and the conventional setting value is recovered after 16 s to 17 s. when the coal gas recovering is started and a three-way valve starts to move, the converter PLC controls the valve plate to overturn to adjust the opening degree of the RD valve through the orma executor, the smoke amount of the RD valve is automatically increased to 20000 L / h on the basis of the conventional setting value, and the conventional setting value is recovered after 16 s to 17 s. By means of the converter flue gas cleaning and coal gas recovering RD valve dynamic control method, influences of adverse factors of adjusting time of the RD valve on control over the smoke amount are eliminated, the problems of smoke overflowing and coal gas recovering heat value losses caused by large-scope smoke reduction are solved, the production smoothness and the cost controllability are guaranteed.

Owner:ANGANG STEEL CO LTD

Coal mill grinding hot air pipe and power generation hot air pipe parallel device

InactiveCN105091611AImproved heat recoveryIncrease power generationSteam engine plantsLump/pulverulent fuel preparationCycloneCyclonic separation

The invention provides a coal mill grinding hot air pipe and power generation hot air pipe parallel device with simple structure and novel design; the device comprises a grate cooler; the features are that the grate cooler is respectively connected with a cyclone separator A and a cyclone separator B through a hot air pipe A and a hot air pipe B; the cyclone separator B is connected with a coal mill through the hot air pipe B; the cyclone separator A is connected with a kiln head through the hot air pipe A; the kiln head is connected with a kiln head waste gas blower through the hot air pipe A; the coal mill is connected with a coal mill powder concentrator through the hot air pipe A; a dust collector is respectively connected with the coal mill powder concentrator and a coal mill system blower through the hot air pipe A; ventilation areas of a power generation system hot air pipe and a whirlwind dust collector are enlarged, air speed is reduced, and dust amount can be reduced. Wearing of the whirlwind dust collector is obviously alleviated with safety and reliability, thus reducing exhaust fan power consumption, increasing generating capacity, improving coal mill output, prolonging whirlwind dust collector and hot air pipe usage period, and reducing coal mill system blast changes.

Owner:武安市新峰水泥有限责任公司

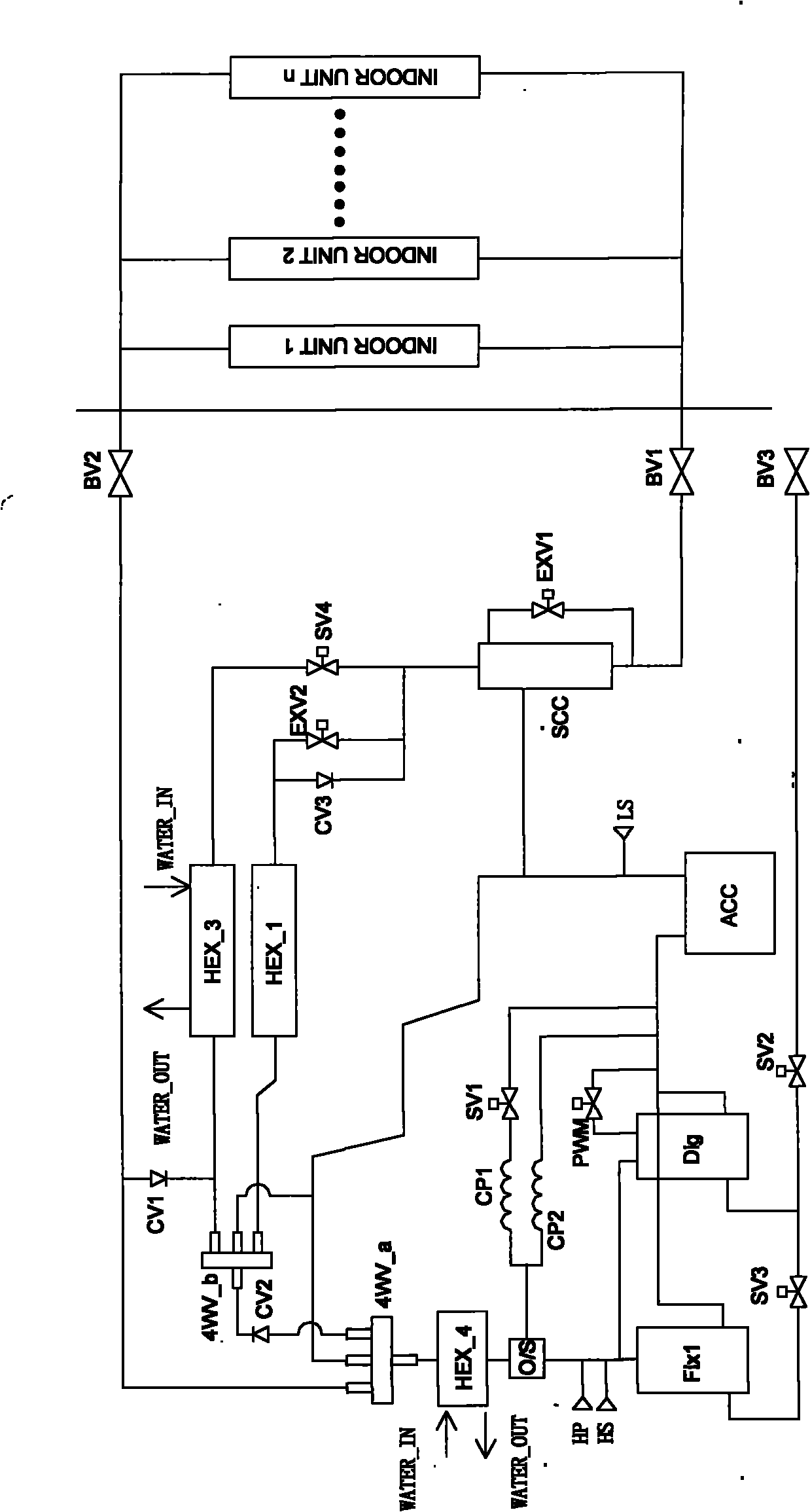

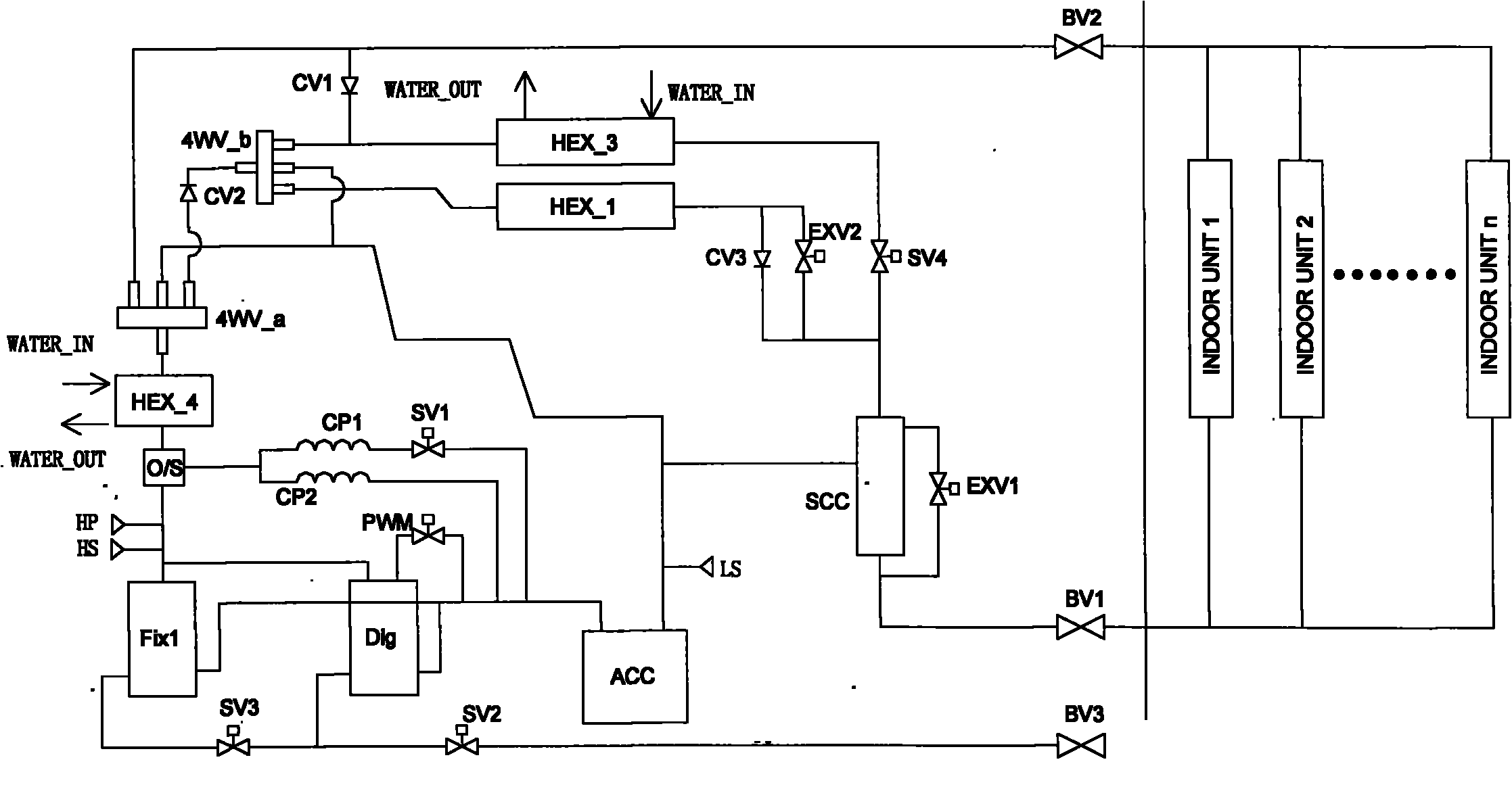

Working method of heat-recovery multi-connected air conditioning unit

InactiveCN101846370AImproved heat recoveryHigh selectivityEnergy recovery in ventilation and heatingHeat recovery systemsFour-way valveEngineering

The invention discloses a working method of a heat-recovery multi-connected air conditioning unit. When a wind-side heat exchanger works and two water-side heat exchangers do not work, a four-way valve can control refrigerating fluid to pass through the wind-side heat exchanger so as to realize the refrigeration or heat production of the unit; when a first water-side heat exchanger and the wind-side heat exchanger do not work and a second water side heat exchanger works, the four-way valve can control the refrigerating fluid to pass through the second water-side heat exchanger so as to realize whole heat recovery; and when the wind-side heat exchanger does not work and the two water-side heat exchangers work, the four-way valve can control the refrigerating fluid to pass through the two water-side heat exchangers so as to realize whole heat recovery and partial heat recovery. Because of varied selectivity, the invention can choose to operate refrigeration or heat production, or add whole heat recovery or add whole heat recovery or partial heat recovery. The invention has varied selectivity, convenient use and energy saving.

Owner:GUANGDONG EUROKLIMAT AIR CONDITIONING & REFRIGERATION

Efficient total heat recovery central air conditioner

InactiveCN106610096AExtended operating rangeIncrease condensing temperature and exhaust temperatureEnergy recovery in ventilation and heatingMechanical apparatusRefrigerantInlet temperature

The invention discloses an efficient total heat recovery central air conditioner which comprises a heat recovery and exchange system, a compression motor, a chilled water temperature sensor, a pressure water pump, a condenser, a temperature and humidity sensor and an integrated chip. The heat recovery and exchange system comprises a heat exchanger and a fan arranged on one side of the heat exchanger, and the heat exchanger is provided with a water inlet and a water outlet. According to a refrigerant control method of the efficient total heat recovery central air conditioner, refrigerants in the efficient total heat recovery central air conditioner is automatically adjusted, the phenomena that condensate depression does not exist at the upstream position of a throttling device of the efficient total heat recovery central air conditioner, and low-pressure protection of part of a heat recovery and exchange unit occurs when the ambient temperature is high and the water inlet temperature of the heat-recovery heat exchanger is low are avoided, and the operation range of the efficient total heat recovery central air conditioner is obviously expanded. Moreover, when the water inlet temperature of the heat-recovery heat exchanger is low and the ambient temperature is low, the condensing temperature and exhaust temperature of the efficient total heat recovery central air conditioner are increased forcedly, the heat exchange capacity of the heat-recovery heat exchanger is enhanced, and it is guaranteed that the efficient total heat recovery central air conditioner has high heat recovery quantity and high heat-recovery water outlet temperature.

Owner:钟舒

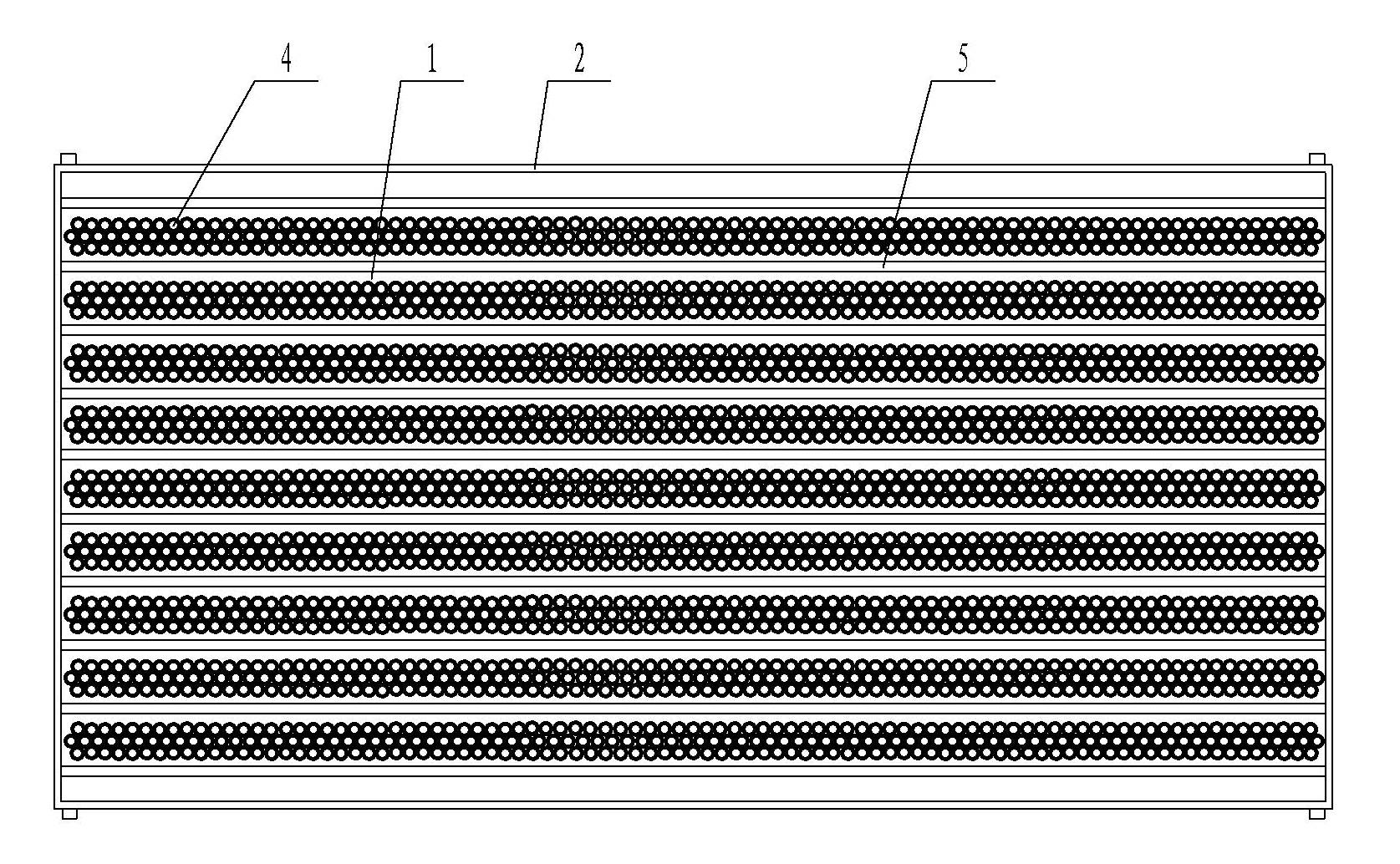

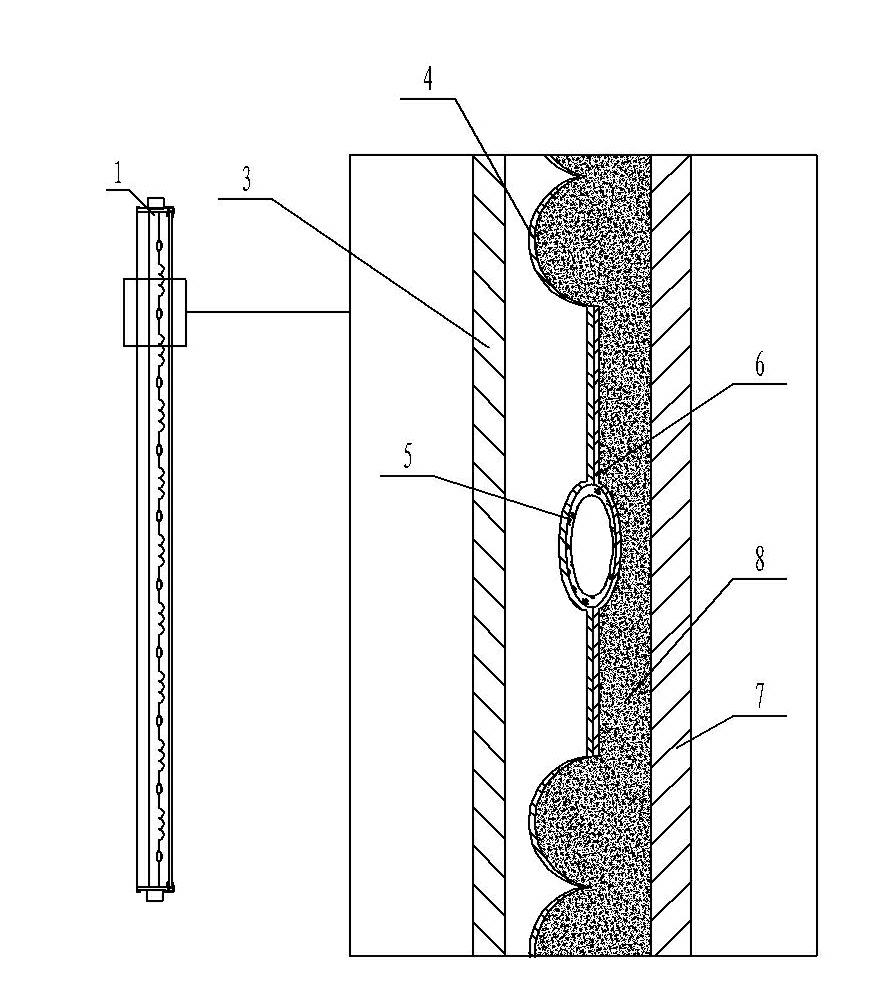

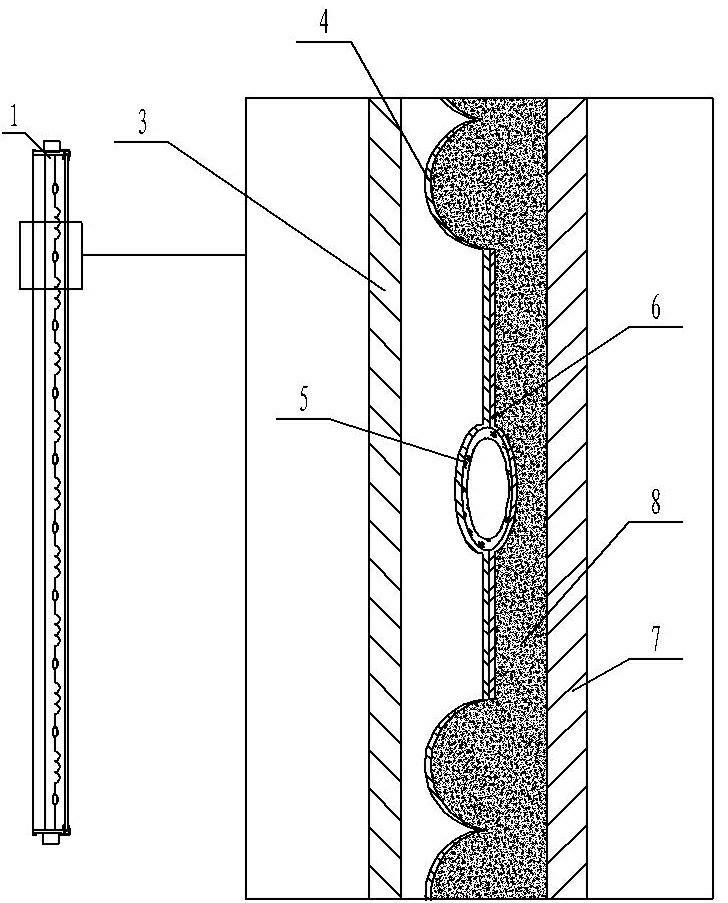

Flat-plate solar collector and manufacturing method thereof

InactiveCN102207339AIncrease contact areaImprove heat transfer efficiencySolar heating energySolar heat devicesFoaming agentSpray coating

The invention relates to an application of solar energy equipment, and particularly relates to a flat-plate solar collector and a manufacturing method thereof. The manufacturing method of the flat-plate solar collector comprises the steps of: 1) molding 0.4mm aluminium sheet by using a rolling machine or a mould pressing machine, thereby enabling rows of round projections and oval projections on an absorber plate; 2) putting a branch pipe in the oval projections and fixing by using aluminum foil belt; 3) fixing a baseboard and the absorber plate, and filling the gap between a double-faced aluminum foil extruded sheet and the absorber plate by using polyurethane foaming agent; 4) spray coating matte black fluorocarbon paint on the surface of the absorber plate, installing frames with glass cotton sliver inside on four sides of the absorber plate, then pressing an euphotic layer and an insulating layer by using depression bars. The invention has low production cost and wide application.

Owner:安国民

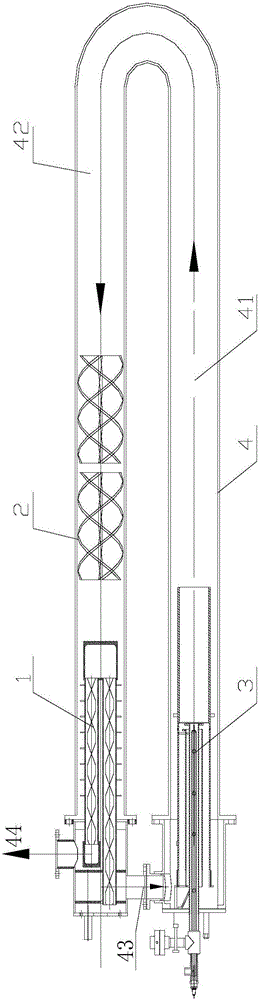

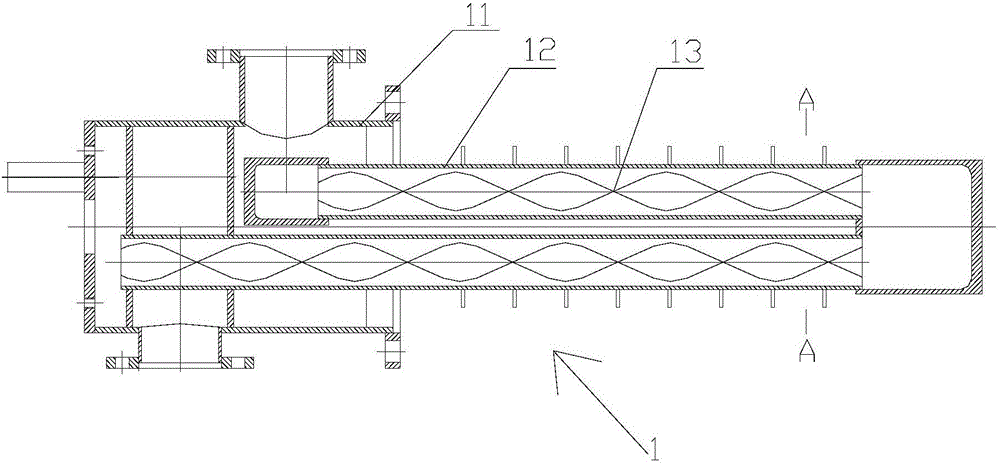

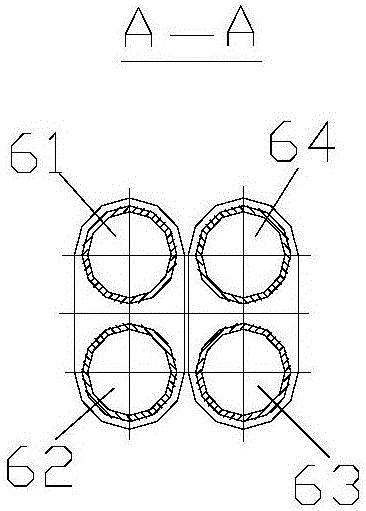

U-shaped radiant tube

InactiveCN106767025ARaise the preheat temperatureEasy to installHeat exchanger casingsStationary tubular conduit assembliesCombustionFlue gas

The invention provides a U-shaped radiant tube. The U-shaped radiant tube is provided with a U-shaped flue gas duct. The U-shaped flue gas duct comprises a smoke exhaust side channel and a combustion side channel. The U-shaped radiant tube comprises a heat exchanger, a nozzle and a rotational flow device made of a non-metal material, wherein the heat exchanger is arranged at the tail end of the smoke exhaust side channel of the U-shaped radiant tube, the nozzle is arranged at the head end of the combustion side channel of the U-shaped radiant tube, and the rotational flow device made of the non-metal material is arranged in the smoke exhaust side channel of the U-shaped radiant tube and located between the heat exchanger and the nozzle. The heat exchanger comprises a pipe body and metal fins arranged in the pipe body. By the adoption of the U-shaped radiant tube, the production energy consumption can be lowered effectively, the capacity of the radiant tube can be improved effectively, and the U-shaped radiant tube is especially suitable for transformation with the requirement of lowering the energy consumption or the requirement of improving the heating capacity of the radiant tube.

Owner:CERI PHOENIX INDAL FURNACE CO TD +2

High-temperature catalytic combustion device and method for liquid nitrogen washing tail gas

ActiveCN110285435ASimple structureLow investment costIncinerator apparatusLiquid nitrogenHot Temperature

The invention belongs to the technical field of energy and environment protection, and particularly relates to a high-temperature catalytic combustion device and method for liquid nitrogen washing tail gas. The high-temperature catalytic combustion device for the liquid nitrogen washing tail gas can achieve high-temperature combustion of the liquid nitrogen washing tail gas, recycled heat is high, the recycled heat can be fully utilized, the using range of the heat is widened, and energy saving and emission reducing are achieved. The high-temperature catalytic combustion device is small in equipment number, small in investment cost, low in running cost, small in energy consumption, and easy, convenient and safe to operate. The high-temperature catalytic combustion device is wide in application range of heat recycled for treating the liquid nitrogen washing tail gas, direct conveying to a pulverized coal drying device is achieved, and drying for pulverized coal is achieved; and conveying to sites needing steam heat supplying is also achieved.

Owner:KUNMING UNIV OF SCI & TECH +1

Garbage incineration equipment and garbage incineration process

The invention discloses garbage incineration equipment. The garbage incineration equipment comprises a pretreatment device and an incineration furnace. The pretreatment device comprises a first shell.A controllable door is arranged in the first shell. A rotating part used for driving a material to rotate is arranged in a drying part. The outer portion of the rotating part is sleeved with a cylindrical heat conductor. A drain pipe is arranged in the position, located at the bottom of the drying part, of the first shell. A second rotary shaft is rotatably mounted on a bearing plate located at the bottom of a screening part. The screening plate is fixedly mounted on the second rotary shaft through a supporting frame. The incineration furnace comprises a second shell. A crushing device and afurnace chamber are arranged in the second shell from top to bottom in sequence. The bottom of the interior of the second shell is provided with an air compression pump. A combustor is mounted on oneside of the second shell. The invention further discloses a garbage incineration process adopting the garbage incineration equipment. The garbage incineration equipment and the garbage incineration process have the beneficial effects that the treatment efficiency is high, secondary pollution is not likely to occur, the heat recovery rate and reutilization rate are high, as the cost is low.

Owner:YIKANG TECH CO LTD

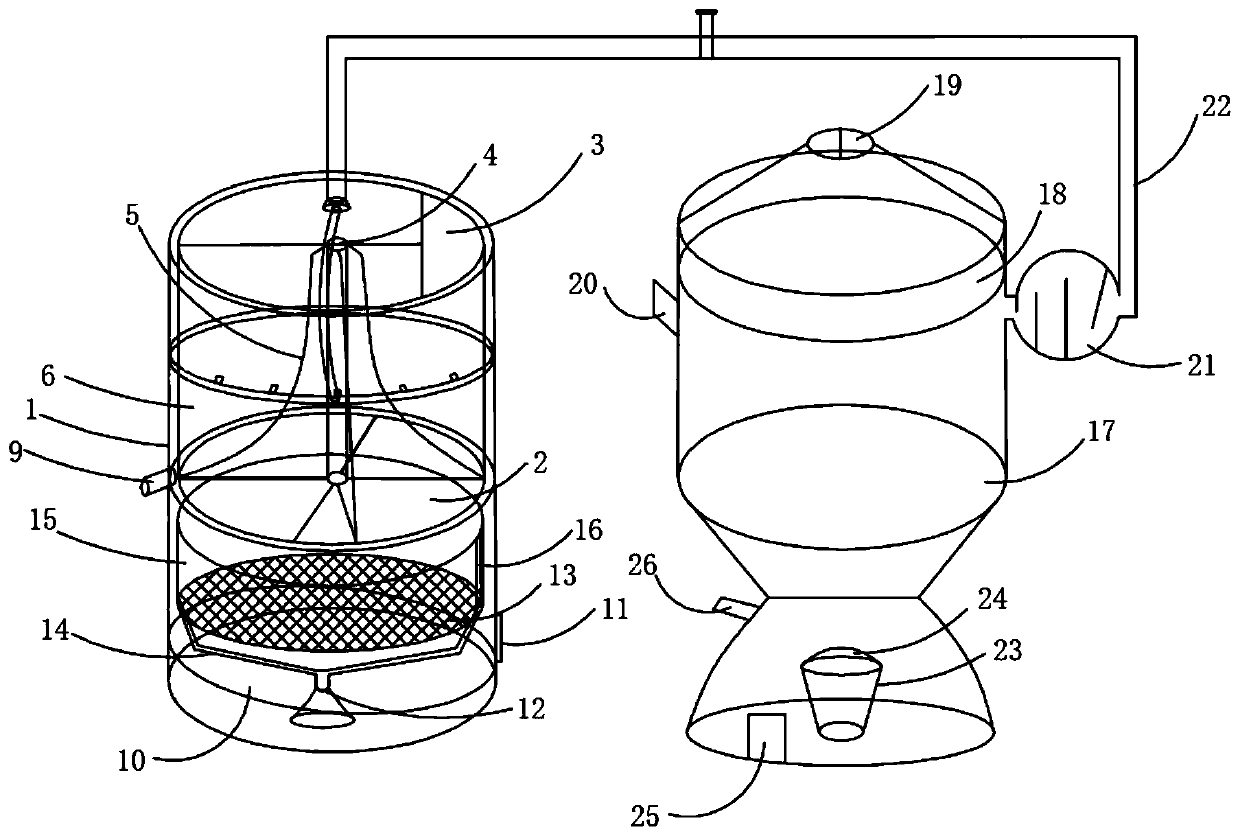

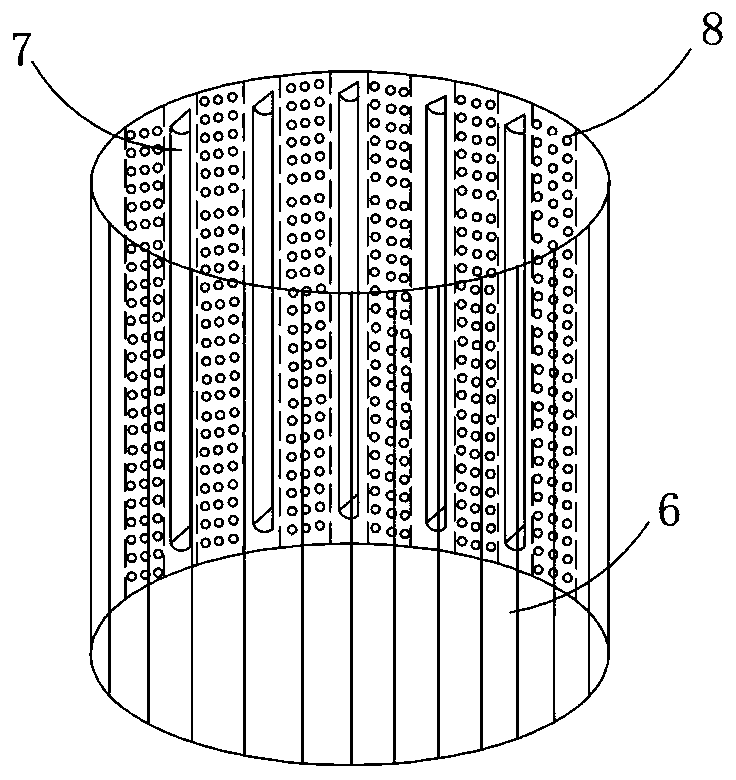

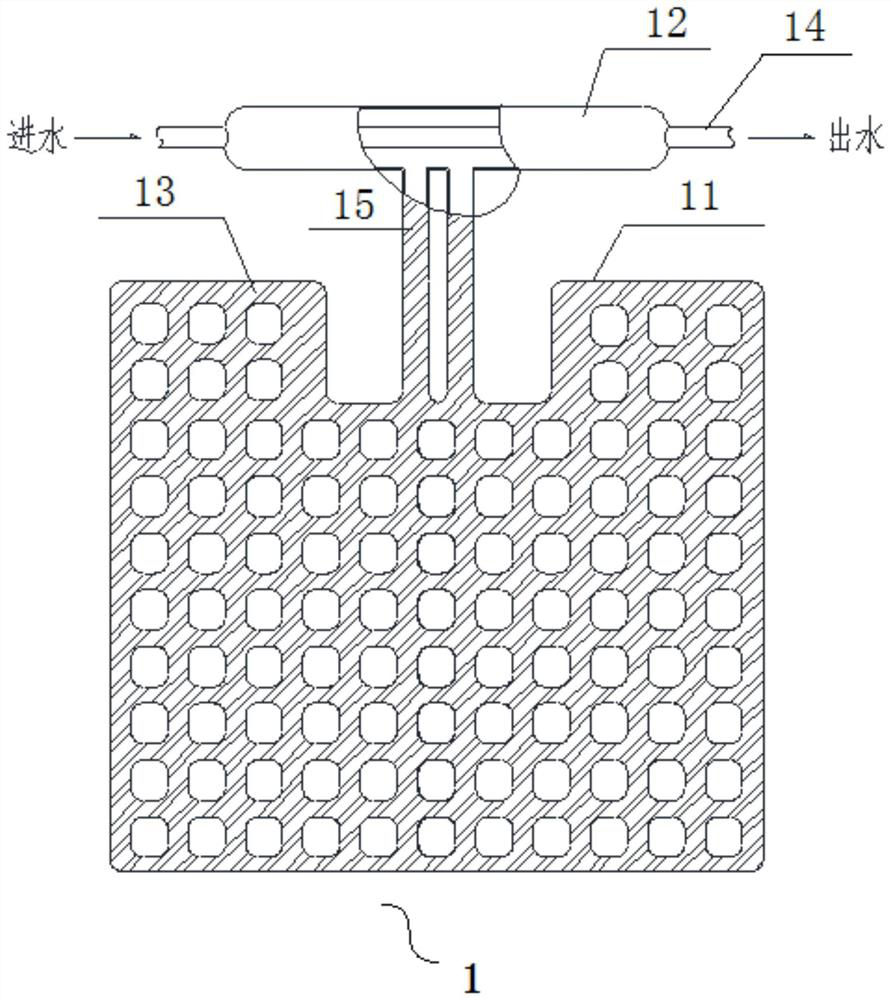

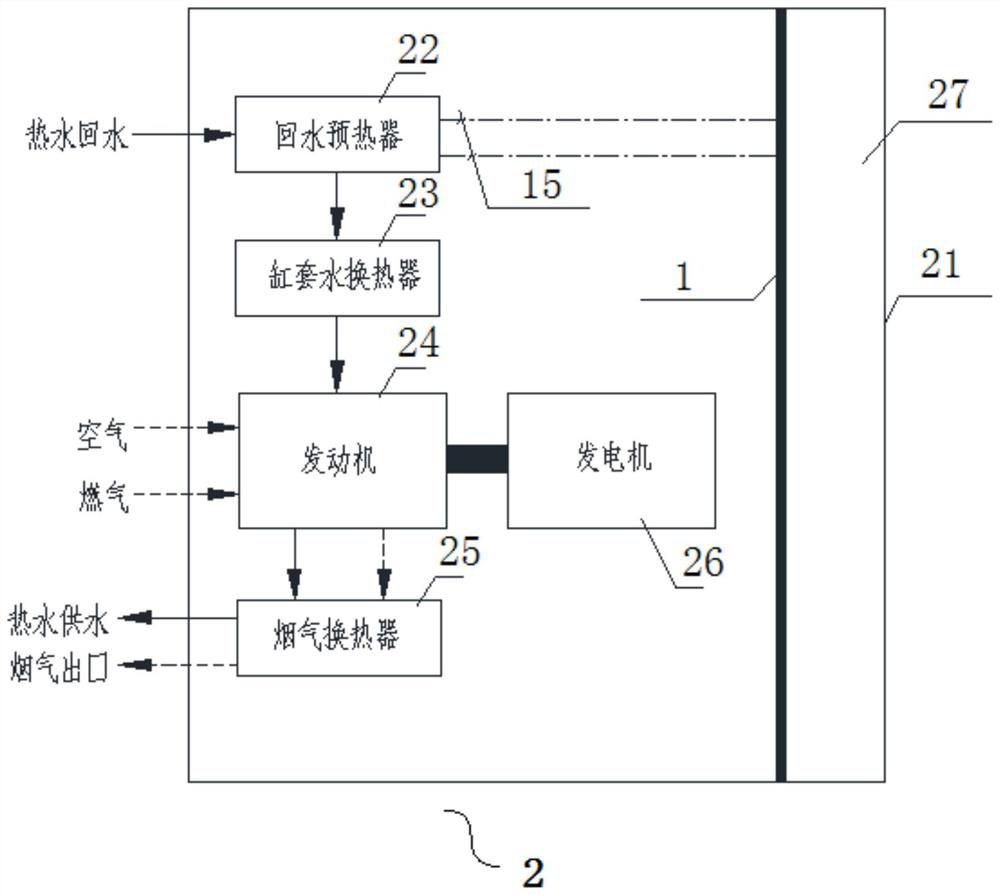

The evaporative heat exchanger that recovers heat from the surface of the component and the household miniature combined heat and power device

ActiveCN111878224BAvoid Energy Efficiency LossImproved heat recoveryInternal combustion piston enginesExhaust apparatusHome useCogeneration

The invention relates to an evaporative heat exchanger for recovering heat dissipation from the surface of components and a household miniature cogeneration device. The evaporation heat exchanger is used to recover heat dissipation from the surface of components in the household micro cogeneration device. In the closed box of the household miniature cogeneration device, the evaporating heat exchanger includes an evaporating section and a condensing section, and the evaporating section has interconnected fluid channels, and the fluid channels are filled with absorbing components For the working fluid that dissipates heat on the surface, the condensation section is set on the return water pipeline of the domestic micro cogeneration device, and the evaporation section and the condensation section are connected through a working fluid exchange pipeline. Compared with the prior art, the evaporative heat exchanger of the present invention is used to recover the surface heat dissipation of the components in the household micro cogeneration device, which not only increases the heat recovery, but also avoids the attenuation of power generation capacity and the decline of energy efficiency caused by the intake air of the prime mover as the cooling medium The problem.

Owner:TONGJI UNIV

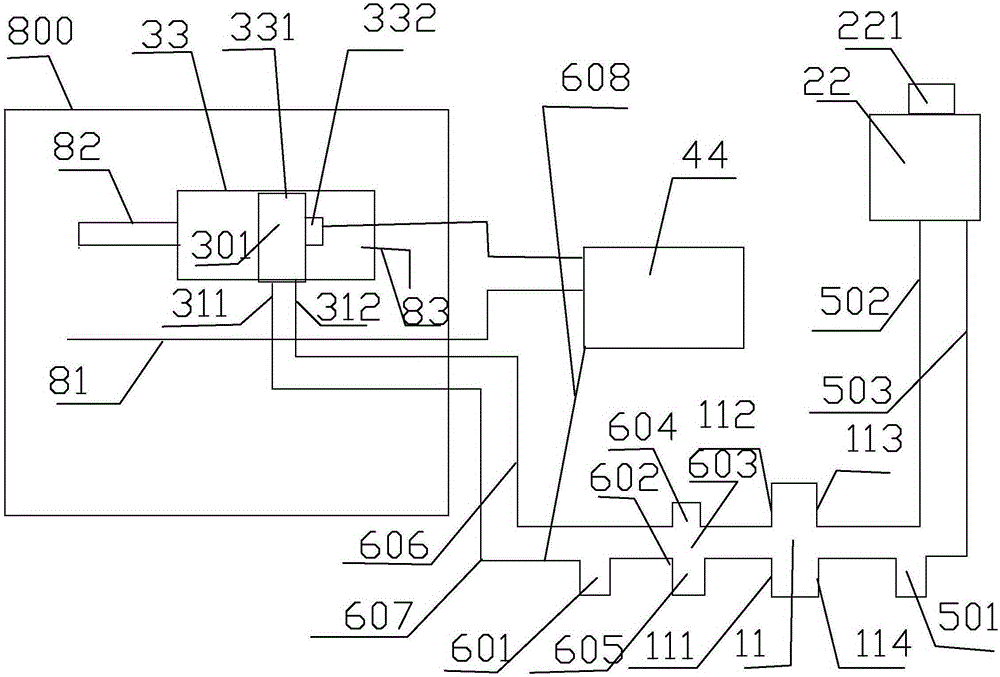

Riser waste heat plug-in temperature control thermal expansion decoking heat pipe export method and equipment

ActiveCN104059676BLess investmentTo achieve non-cokingEnergy inputBoiler cleaning apparatusTemperature controlCoke oven

The invention relates to an ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device, and belongs to the technical field of coking furnace ascending pipe raw gas waste heat recycling. According to the technical scheme, a steam outlet pipe (13) and a water inlet pipe (14) are bent together to be of an L-type structure (1), the end of the horizontal segment of the L-type structure is provided with a detachable connector (22), the end of the perpendicular segment is provided with an anti-coking head (24), the steam outlet pipe is connected with a steam pocket (9), the water inlet pipe is connected with a water inlet system, raw gas and the water inlet pipe are isolated through the steam outlet pipe, the temperature of the exterior of the steam outlet pipe is not lower than the coking temperature, and meanwhile steam ascends gradually to heat inflowing water, so that the inflowing water is completely gasified. According to the ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device, the temperature is detected through a high-temperature thermocouple in the heat exchange process, the water yield of the inflowing water is controlled, and therefore coking of the exterior of the device is avoided; raw gas waste heat can be recycled, completely independent installation is achieved, the problems that a heat exchange device inside an ascending pipe is prone to coking, the ascending pipe is prone to explosion, installation is difficult, and the replacement and maintenance cost is high are solved, and the heat exchange amount is large.

Owner:TANGSHAN BAOKAI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com