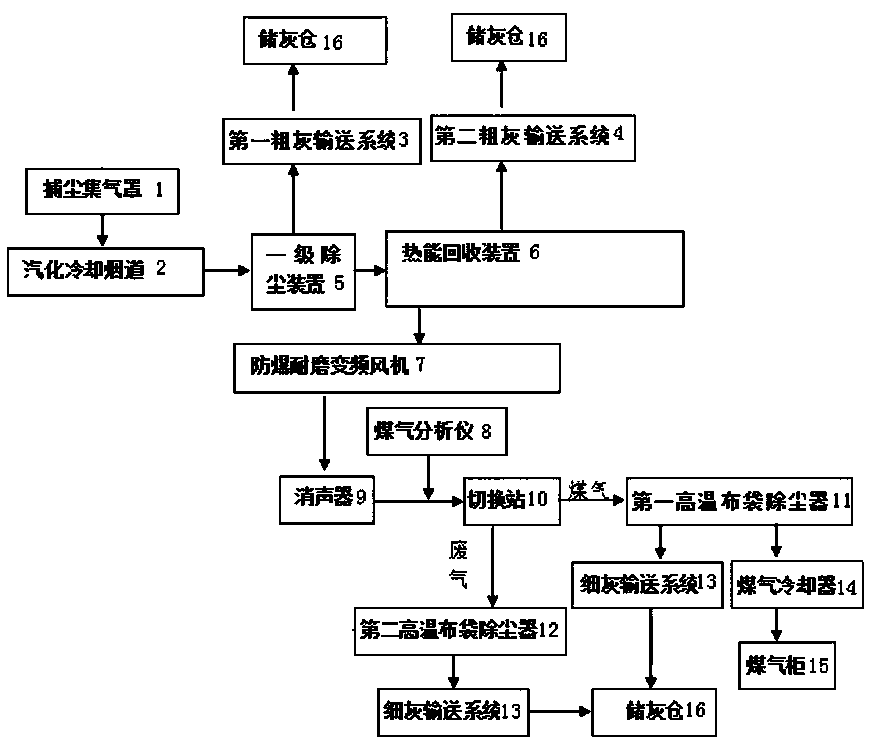

Fully dry process purification recovery method for converter gas heat energy and device

A converter gas recovery method technology, which is applied in the direction of manufacturing converters, improving energy efficiency, improving process efficiency, etc., can solve problems such as waste of energy, corrosion and disconnection of cathode wires, heavy maintenance and repair workload, etc., to ensure gas quality and emission requirements, to avoid explosion accidents, and to save the effect of complex links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: The 120-ton converter of Baotou Iron and Steel Group adopts the converter gas thermal energy all-dry purification and recovery process of the present invention, and the recovered heat increases 31kg of steam per ton of steel, and 11m of gas is collected more3 , has been in good condition since it was put into production in March 2016.

Embodiment 2

[0036] Example 2: The 50-ton converter of Hebei Jinxi Iron and Steel Group adopts the converter gas thermal energy all-dry purification and recovery process of the present invention, and the recovered heat increases 26kg of steam per ton of steel, and 7m of gas is collected more 3 , has been in good condition since it was put into operation in August 2015.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com