Garbage incineration equipment and garbage incineration process

A waste incineration and equipment technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of insufficient heat utilization of exhaust gas, high intake of cold air, insufficient waste combustion, etc., and achieve heat recovery and recycling High utilization rate, reduced combustion furnace corrosion, and reduced processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

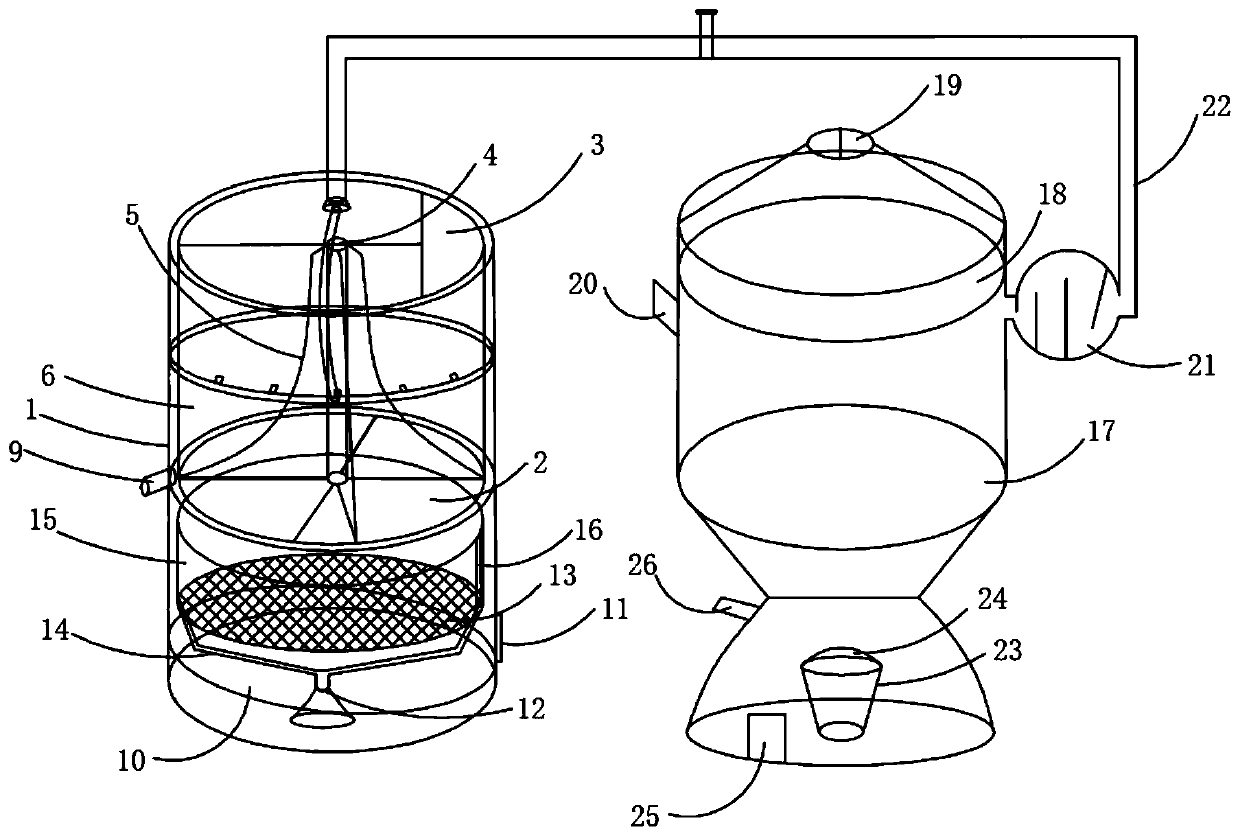

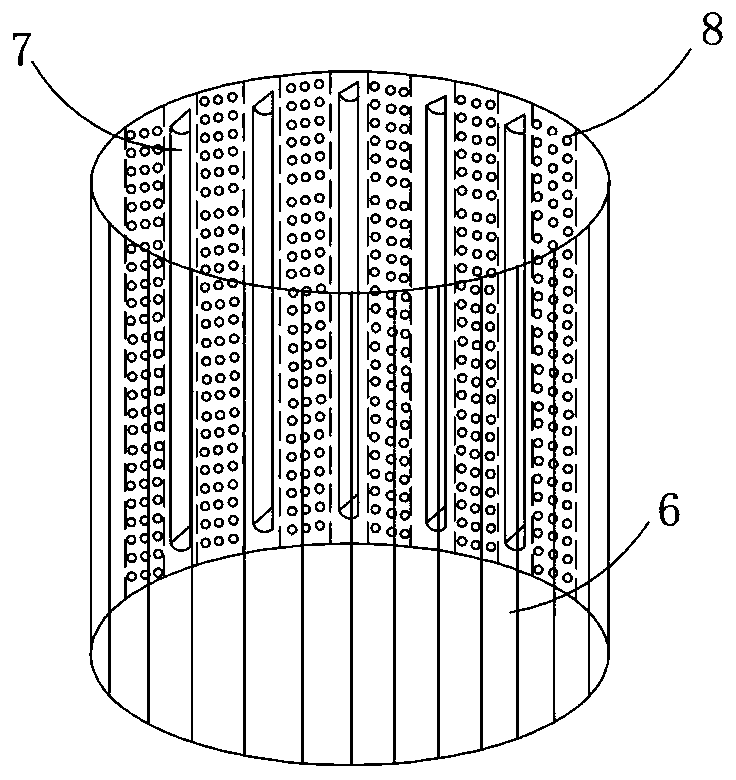

[0025] like figure 1 As shown, a kind of waste incineration equipment includes a pretreatment device and an incinerator. The pretreatment device includes a first casing 1, and a controllable door 2 that can be opened and closed is arranged inside the first casing 1, and the controllable door 2 can be controlled The door 2 divides the inner space of the first housing 1 into a drying section located at the upper part of the controllable door 2 and a screening section located at the lower part of the controllable door 2. The top of the first housing 1 is provided with a first feeding port 3, The inside of the drying part is provided with a rotating part that drives the material to rotate. The rotating part includes a first rotating shaft 4 extending in the vertical direction and a plurality of rotating blades 5 fixedly installed on the first rotating shaft 4. The first rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com