Carbon dioxide separating and collecting system and method of operating same

A technology for separation and recovery of carbon dioxide, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of reduced energy consumption and smaller effects of regeneration towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

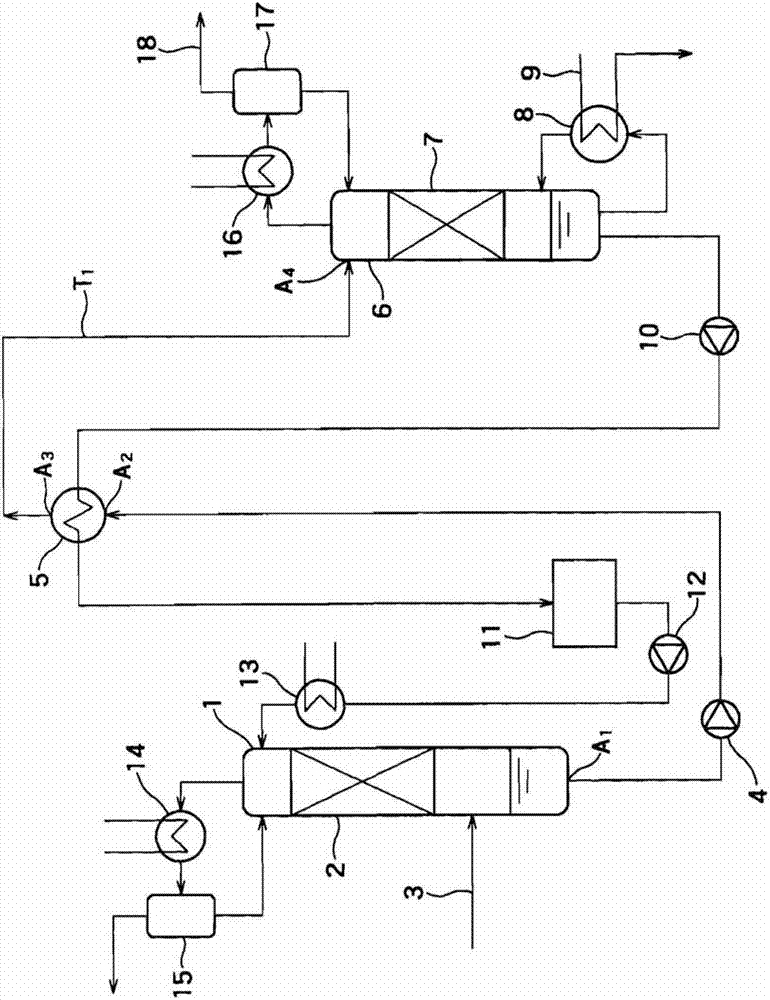

[0021] figure 1 It is a schematic diagram showing the structure of the carbon dioxide separation and recovery system of the first embodiment.

[0022] figure 1 The carbon dioxide separation and recovery system consists of absorption tower 1, absorption tower packing layer 2, combustion exhaust gas supply port 3, rich liquid transfer pump 4, regeneration heat exchanger 5, regeneration tower 6, regeneration tower packing layer 7, regeneration tower reboiler 8. Reboiler heating medium supply port 9, lean liquid transfer pump 10, lean liquid tank 11, lean liquid return pump 12, lean liquid cooler 13, absorption tower reflux cooler 14, absorption tower gas-liquid separator 15, Regeneration tower reflux cooler 16, gas-liquid separator 17 for regeneration tower, and recovery of CO 2 Drain line 18.

[0023] Combustion exhaust gas from a thermal power plant or the like is introduced into the lower part of the absorption tower 1 through the combustion exhaust gas supply port 3 . The...

no. 2 Embodiment approach )

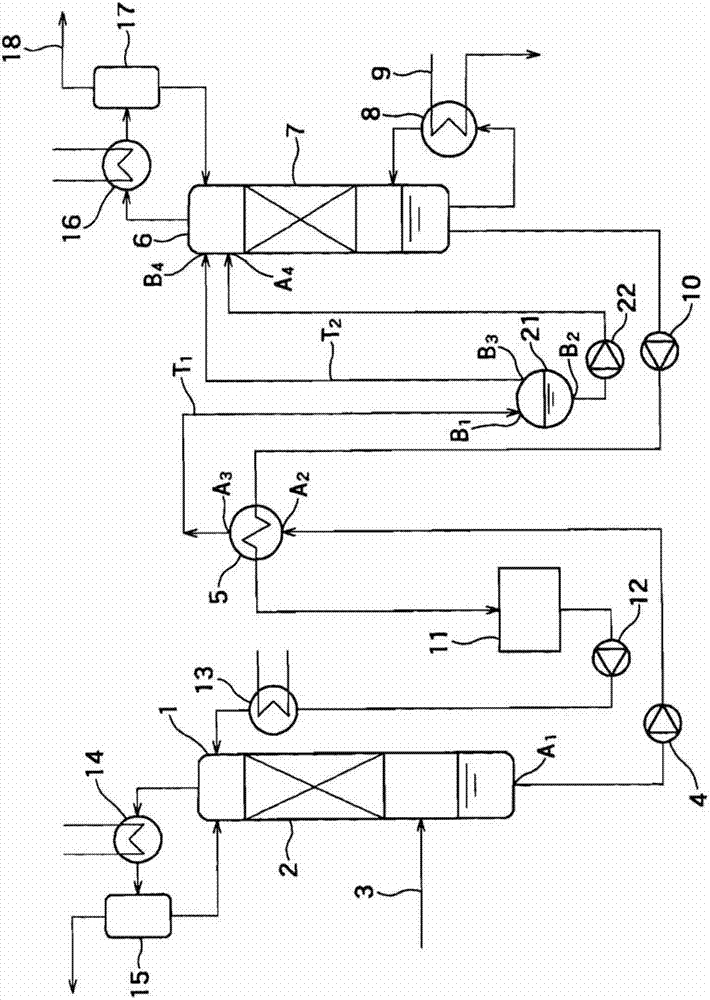

[0064] image 3 It is a schematic diagram showing the structure of the carbon dioxide separation and recovery system of the second embodiment.

[0065] image 3 The carbon dioxide separation and recovery system in addition to figure 1 In addition to the shown components, a first gas-liquid separator 21 and a first semi-lean liquid transfer pump 22 are further provided.

[0066] The first gas-liquid separator 21 is provided between the regeneration heat exchanger 5 and the regeneration tower 6, and separates the rich liquid discharged from the regeneration heat exchanger 5 into gas and liquid. Label B 1 , B 2 , B 3 A rich liquid supply port, a liquid discharge port, and a gas discharge port of the first gas-liquid separator 21 are respectively shown. from outlet B 2 , B 3 The discharged liquid and gas are respectively supplied from the supply port A 4 , B 4 It is supplied to the regeneration tower 6. In addition, this liquid (semi-poor liquid) is transferred to the r...

no. 3 Embodiment approach )

[0079] Figure 4 It is a schematic diagram showing the structure of the carbon dioxide separation and recovery system of the third embodiment.

[0080] Figure 4 The carbon dioxide separation and recovery system in addition to figure 1 In addition to the components shown, it also has a flow splitter 31, and CO 2 Ejector 32.

[0081] The splitter 31 is provided between the absorption tower 1 and the regenerative heat exchanger 5, and separates the rich liquid flowing therebetween into first and second rich liquids. And, the first rich liquid is supplied to the regenerative heat exchanger 5, and the second rich liquid is supplied to the CO 2 Ejector 32 supplies. The distribution ratio of the first and second rich solutions is, for example, 85 to 90% versus 10 to 15%.

[0082] CO 2 The discharger 32 is provided between the splitter 31 and the regeneration tower 6, and heats the second rich liquid with the heat of the exhaust gas discharged from the regeneration tower 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com