High-temperature catalytic combustion device and method for liquid nitrogen washing tail gas

A high-temperature catalytic and combustion device technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of high furnace temperature, limited use range, heat waste, etc., and achieve low investment cost, simple structure, and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

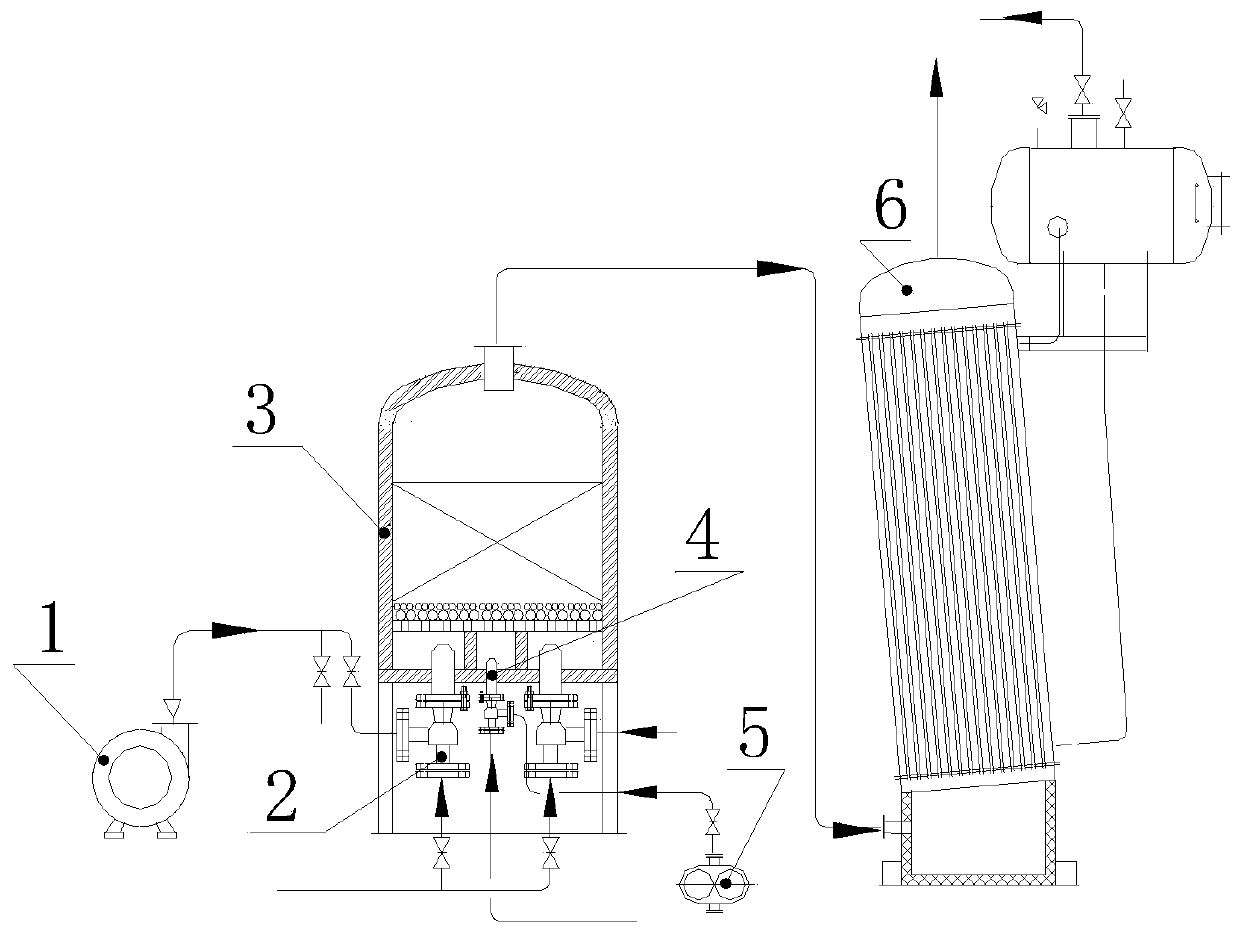

Image

Examples

preparation example Construction

[0036] In the present invention, the preparation method of the catalyst preferably comprises the following steps:

[0037]1) mixing lanthanum nitrate, manganese nitrate, a first metal nitrate compound, citric acid and water, and complexing the obtained first mixture to obtain a gel;

[0038] 2) performing a first calcination on the gel to obtain a first carrier product;

[0039] 3) mixing the first carrier product, aluminum nitrate, the second metal nitrate compound and water, and performing a precipitation reaction on the obtained second mixture under the action of a buffer to obtain a precipitate;

[0040] 4) Carrying out the second roasting of the precipitate to obtain the second carrier product;

[0041] 5) immersing the second carrier product in a palladium nitrate solution for impregnation, and then drying the obtained mixture in sequence and third roasting to obtain a catalyst;

[0042] The first metal nitrate compound is yttrium nitrate and / or strontium nitrate;

[...

Embodiment 1

[0064] Liquid nitrogen scrubbing tail gas component: H 2 1.98%, CO 8.44%, N 2 87.9%, CH 4 1.59%, control liquid nitrogen to wash tail gas: air=1:0.466 (volume ratio).

[0065] The combustible gas is sent to the auxiliary burner, and the air is sent to the auxiliary burner by the auxiliary blower to carry out combustible gas combustion. When the temperature reaches 400-450°C, the liquid nitrogen scrubbing tail gas is sent from the main pipe to the main burner, and the liquid nitrogen is controlled. The exhaust gas flow rate is 20000m 3 / h, the air is sent to the main burner by pressurizing the blower to 5kPa, and the air volume is controlled to be 9320Nm 3 / h, liquid nitrogen scrubbing tail gas and air are burned in the high-temperature catalytic combustion furnace, the combustion temperature is 790-800°C, hot flue gas is obtained from the outlet of the high-temperature catalytic combustion furnace, and O in the hot flue gas 2 3~4%, CO, CH 4 The concentration is less than ...

Embodiment 2

[0068] The difference between this embodiment and Example 1 is that the liquid nitrogen washing tail gas is controlled: air=1:0.5, and the liquid nitrogen washing tail gas flow rate is 30000m 3 / h, blast volume 15000Nm 3 / h, the combustion temperature is 720-750°C, the oxygen content in the outlet hot flue gas obtained is 8-10%, and the CO is burned out.

[0069] Sending the hot flue gas into the furnace of the boiler can reduce the amount of fuel in the original boiler and use it as supplementary heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com