Coal mill grinding hot air pipe and power generation hot air pipe parallel device

A hot air duct and coal grinding technology, which is applied in steam engine installations, waste heat treatment, machines/engines, etc., can solve the problems of wear of hot air ducts and cyclone dust collectors, increased concentration of clinker dust, and accelerated wind speed of pipes, etc. The effect of reducing the chance of explosion, increasing the output of coal mill and reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail;

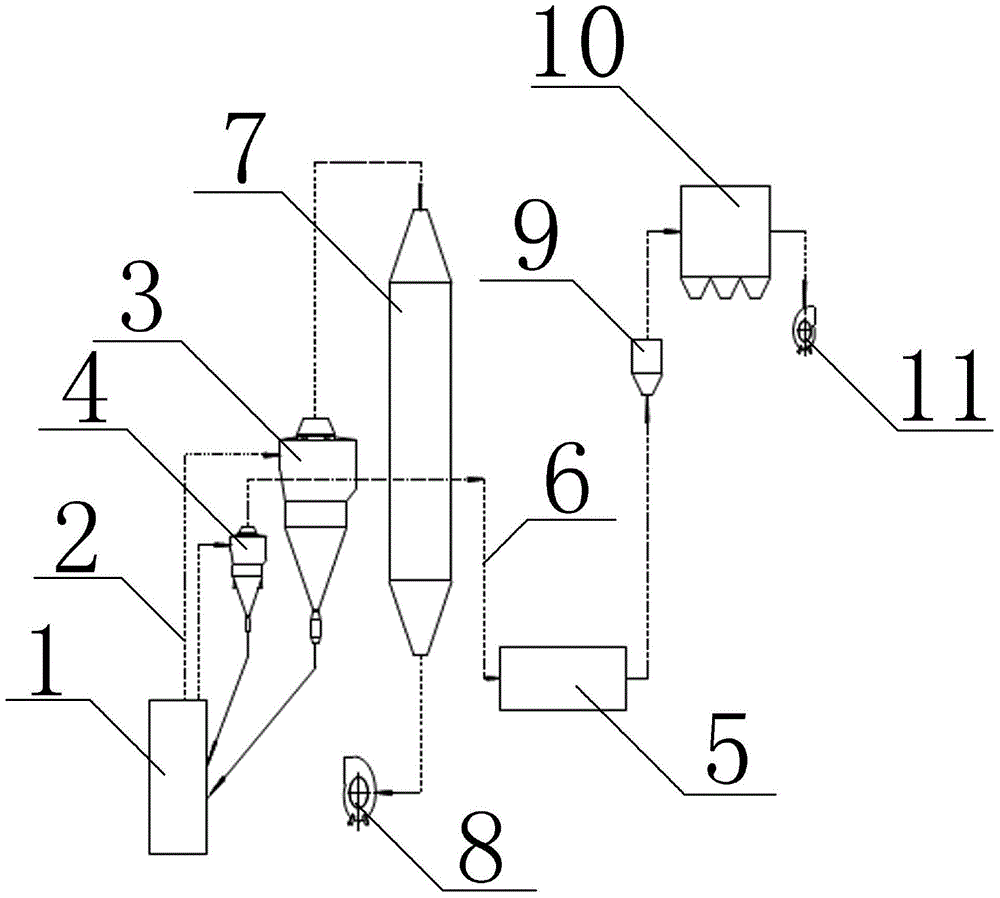

[0016] Such as figure 1 As shown, the grate cooler 1 is connected to the cyclone separator A3 and the cyclone separator B4 respectively through the hot blast pipeline A2 and the hot blast pipeline B6, and the cyclone separator B4 is connected to the coal mill 5 through the hot blast pipeline B6, and the cyclone separator A3 is connected to the cyclone separator A3 through the hot blast pipeline B6. The pipe A2 is connected to the kiln head 7, the kiln head 7 is connected to the kiln head waste gas fan 8 through the hot air pipe A2, the coal mill 5 is connected to the coal mill separator 9 through the hot air pipe A2, and the dust collecting device 10 is connected through the hot air pipe A2 They are respectively connected to the coal mill powder separator 9 and the fan 11 of the coal mill system.

[0017] The air intake of coal mill 5 is directly connected to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com