Ascending pipe waste heat insertion-type temperature control thermal expansion decoking heat pipe guiding-out method and device

A thermal expansion and plug-in technology, which is applied in the field of coke oven riser gas waste heat recovery, can solve the problems of large investment and pipe burst, and achieve the effects of stable system operation, large heat recovery and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

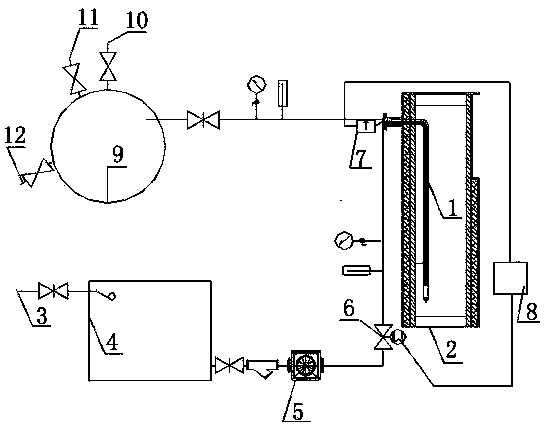

[0029] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

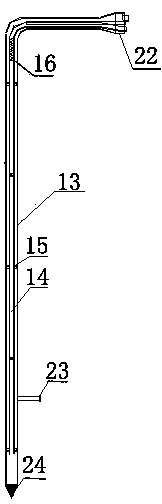

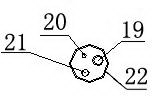

[0030]In the embodiment, the riser waste heat plug-in type temperature-controlled thermal expansion decoking heat pipe export device includes a steam outlet pipe 13, a water inlet pipe 14, a steam outlet 19, a water inlet 20, a detachable connector 22 and an anti-coking head 24; There is a water inlet pipe in the steam pipe, the lower end of the water inlet pipe is not closed, the lower end of the steam outlet pipe is closed, and the lower end of the steam outlet pipe is provided with an anti-coking head, which is a conical structure with the cone point downward; the upper ends of the steam outlet pipe and the water inlet pipe are It is connected with a detachable connector, and the detachable connector is provided with a steam outlet and a water inlet. The water inlet and the steam outlet are arranged independently and parallel on the detachable connector. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com