Converter on-line diagnosis energy-saving and consumption-reducing SADS system

A converter and converter gas technology, which is applied in the field of converter online diagnosis, energy saving and consumption reduction SADS system, can solve problems such as affecting the economic benefits of steel mills, unable to monitor accident status in real time, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

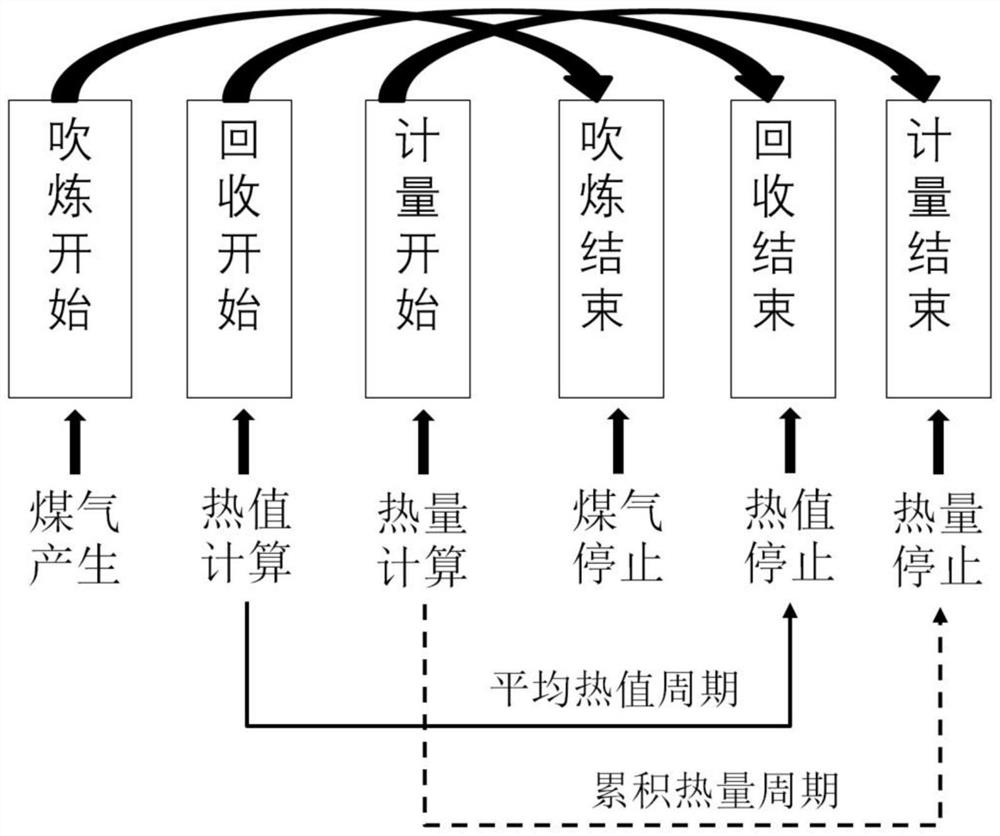

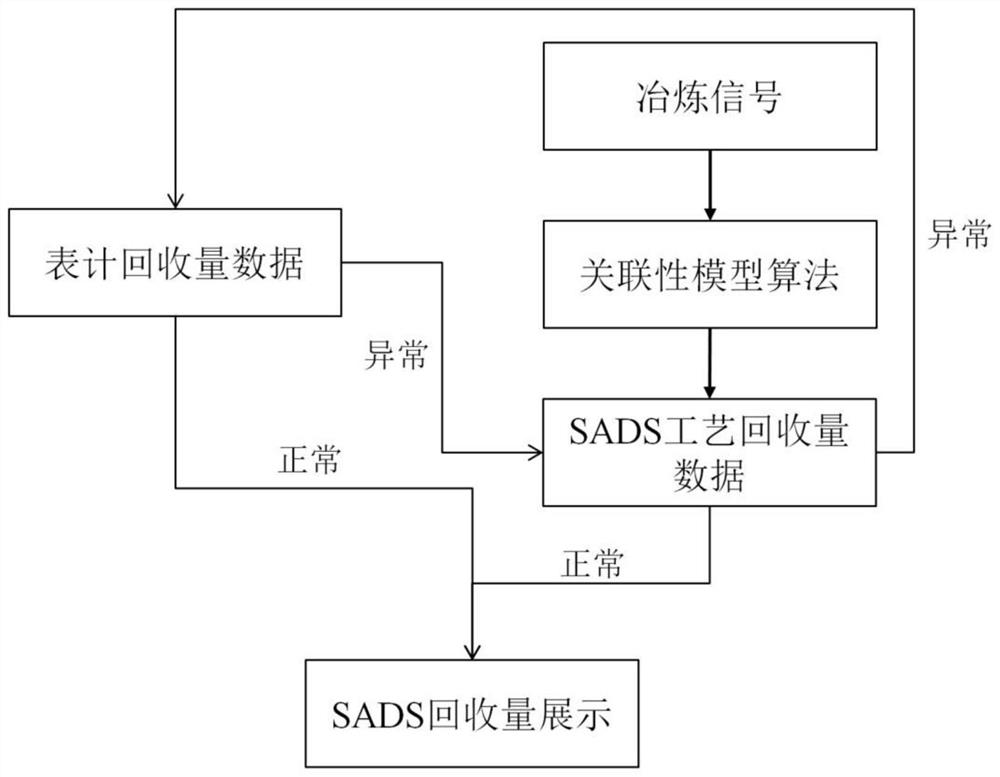

[0129] The specific steps of the present invention are described in detail. The SADS system for online diagnosis of energy saving and consumption reduction of the converter includes the following steps:

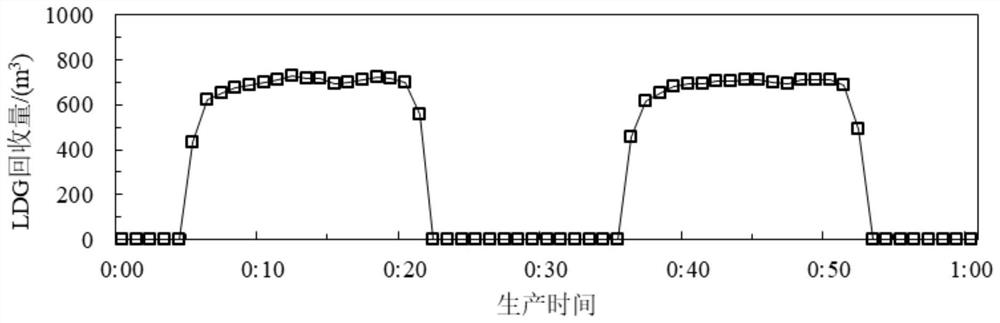

[0130] Step 1: Establish a signal correlation model of the converter smelting process, and realize the increase of converter gas recovery and recovered calorific value in the converter through the process signal and correlation algorithm related to the converter gas production in the converter smelting process.

[0131] The calculation method of the recovery amount of theoretical generation and actual generation amount of converter gas is as follows:

[0132] 1. Theoretical generation and recovery of converter gas

[0133] The formula for calculating the theoretical generation of converter gas is:

[0134]

[0135] In the formula, V L Recovered amount of converter gas per ton of steel, unit: Nm 3 / t; α is the air suction coefficient; C 铁水 and C 钢水 are the carbon cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com