Flat-plate solar collector and manufacturing method thereof

A flat-panel solar energy and heat collector technology, which is applied to solar heat collectors, solar heat collectors using working fluids, solar thermal energy, etc. The equipment process is complex and other problems, so as to achieve the effect of good sealing performance and thermal insulation effect, improving heat exchange efficiency and increasing heat absorption area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

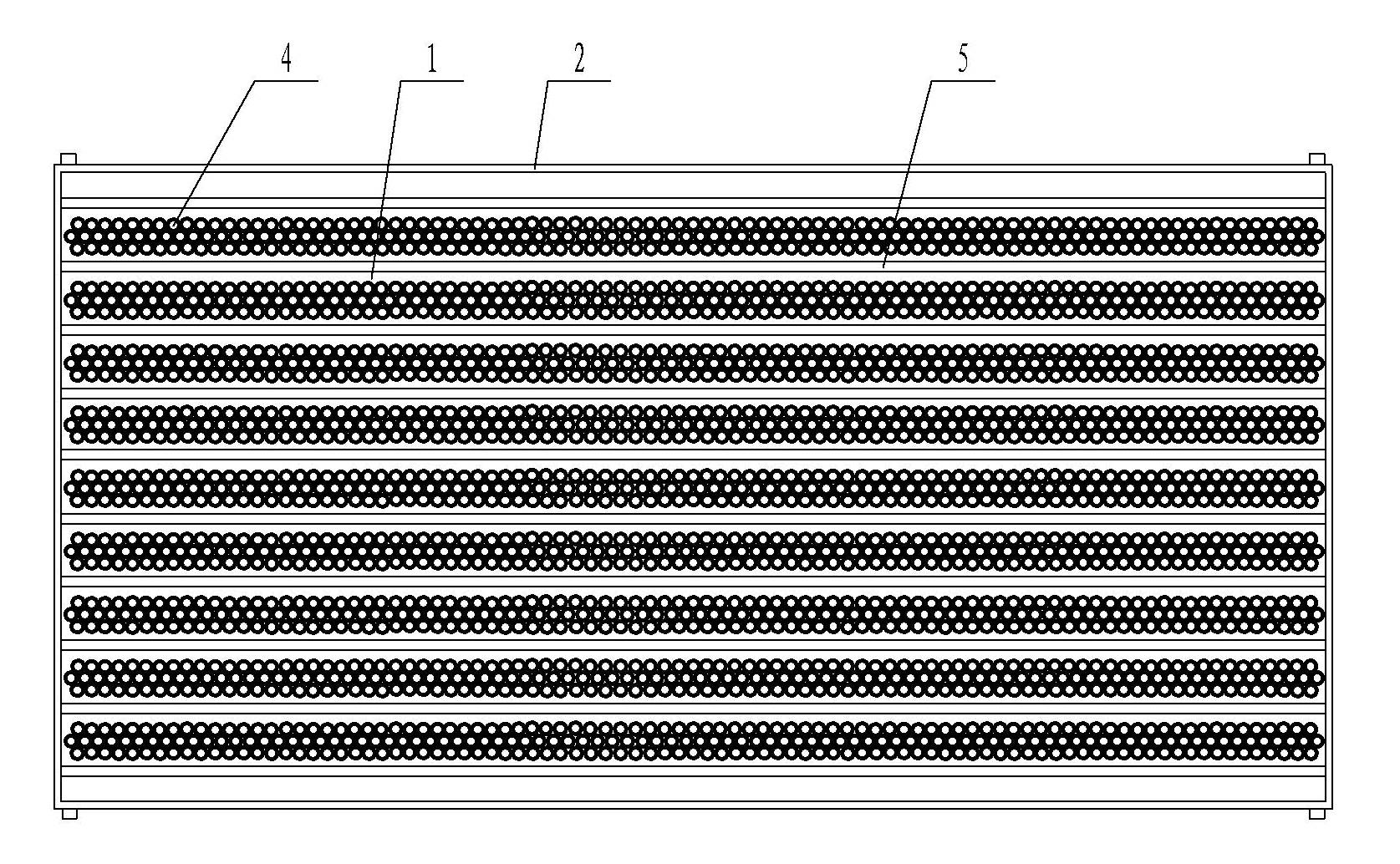

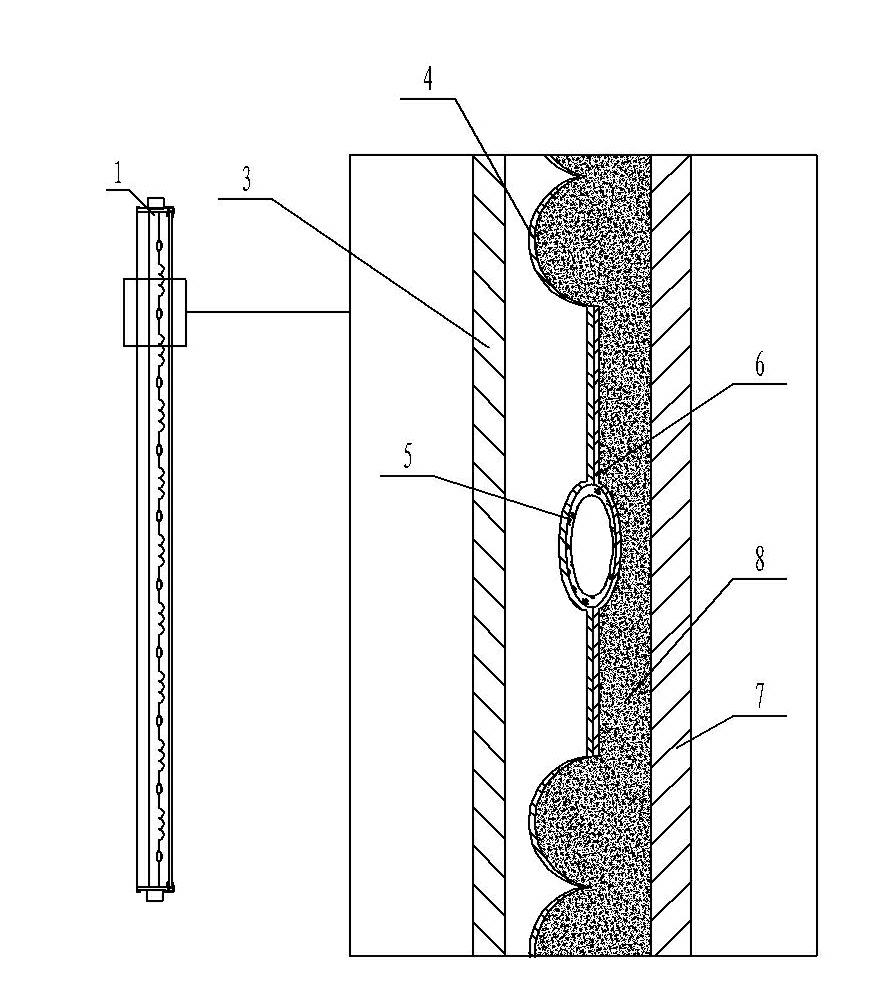

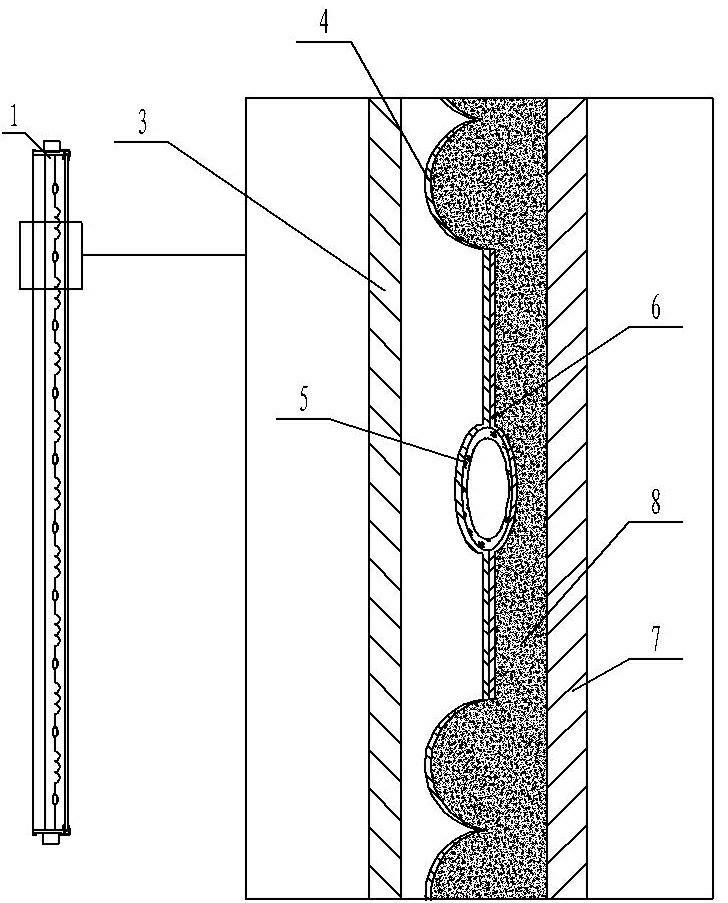

[0019] A flat solar heat collector includes a frame 2 and a heat collecting plate 1, and the heat collecting plate 1 includes a light-transmitting layer 3, a heat absorbing layer and an insulating layer. The frame 2 is located around the heat collecting plate 1, wherein the transparent layer 3 is located on the upper part of the heat absorbing layer, and the heat preservation layer is located on the lower part of the heat absorbing layer. The heat-absorbing layer is composed of a heat-absorbing plate 4, a bottom plate 6 and a branch pipe 5. There are spherical protrusions and strip-shaped protrusions on the heat-absorbing plate 4. The spherical protrusions are arranged in rows, and several rows of spherical protrusions form a group of spherical protrusions. The group of spherical protrusions and the bar-shaped protrusions are arranged at intervals. The bottom plate 6 is provided with strip-shaped grooves, the strip-shaped protrusions are arranged correspondingly to the strip-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com