Aromatic hydrocarbon purification apparatus and process used in hydrofining of coking crude benzene

A technology for hydrofining and coking crude benzene, applied in organic chemistry, extraction purification/separation, distillation purification/separation, etc., to achieve the effects of reduced consumption, increased heat recovery, and reduced solvent ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

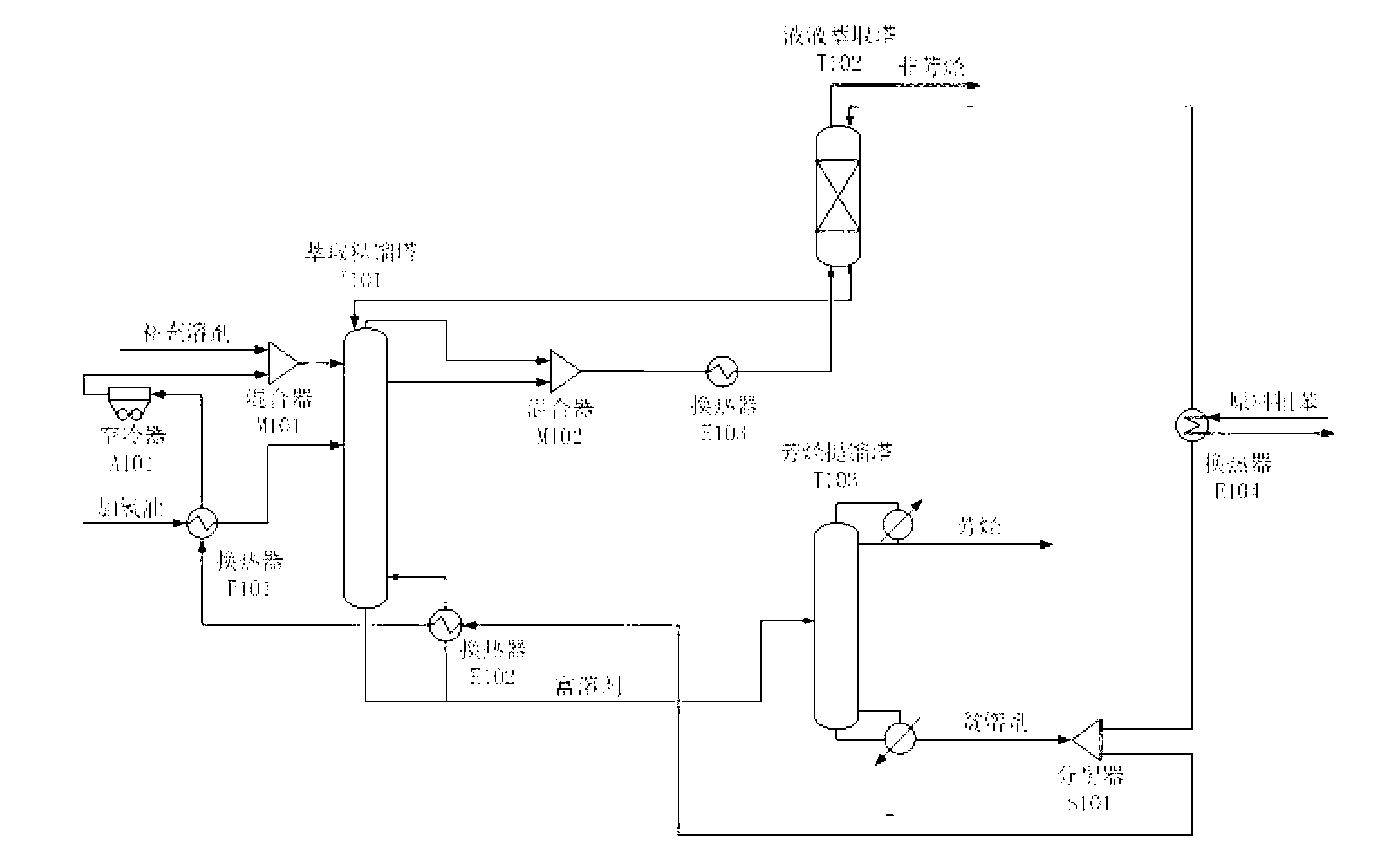

[0021] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

[0022] Such as figure 1 As shown, the raw material mixer 3 is connected to the side line of the extractive distillation tower 4, the top of the extractive distillation tower 4 and the discharge side line of the rectification section are connected to the discharge mixer 6, and a cooler 7 is arranged behind the discharge mixer 6 to cool The device 7 is connected to the feed port at the bottom of the liquid-liquid extraction tower 8, and the discharge port at the bottom of the liquid-liquid extraction tower 8 is connected to the top of the extractive distillation tower 4, and the bottom of the extractive distillation tower 4 is connected to the feed port of the aromatics stripping tower 9, and the aromatics The bottom of the stripping tower 9 is connected to the distributor 10, and the outlet of the distributor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com