Method and system for recycling waste heat of ammonia water

A waste heat recovery and ammonia water technology, applied in the coking field, can solve the problems of long pipeline laying distance, low reliability, large investment, etc., and achieve the effects of improving the utilization rate of waste heat recovery, avoiding waste, and operating safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

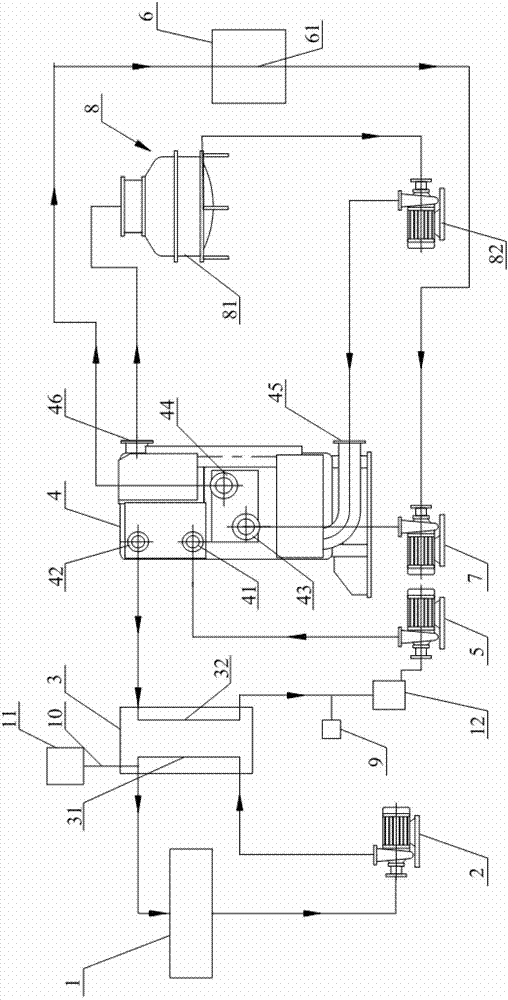

[0046] Such as figure 1As shown, the ammonia water waste heat recycling method provided in this embodiment is as follows: firstly, the circulating ammonia water is passed into the coke oven gas collecting pipe 1, the raw coal gas is cooled once, and the circulating ammonia water is heated, which also includes: sending the heated circulating ammonia water to into the heat exchange device 3, and the circulating water in the heat exchange device 3 is heated; the circulating water heated in the heat exchange device 3 is passed into the lithium bromide absorption refrigerator 4, and is passed into the lithium bromide absorption refrigerator 4 as a heat source The frozen water in 4 is refrigerated; the coolant is passed into the lithium bromide absorption refrigerator 4; the cooled circulating water is sent back to the heat exchange device 3 for reheating.

[0047] It recovers the heat in the heated circulating ammonia water through the heat exchange device 3, and is used to heat th...

Embodiment 2

[0053] Such as figure 1 As shown, the ammonia water waste heat recovery and utilization system provided in this embodiment includes a coke oven gas collecting pipe 1 and an ammonia water circulating pump 2. The water outlet of the coke oven gas collecting pipe 1 is connected with the water inlet of the coke oven gas collecting pipe 1, and forms a first Circulation loop, the first circulation loop is provided with a circulating ammonia water pump, and also includes at least one heat exchange device 3 and a lithium bromide absorption refrigerator 4; wherein, the heat exchange device 3 is provided with a first pipeline 31 and a second pipeline 32 , the water outlet of the coke oven gas collecting pipe 1 is connected with the inlet of the first pipeline 31, the water inlet of the coke oven gas collecting pipe 1 is connected with the outlet of the first pipeline 31; the outlet of the second pipeline 32 is connected with the lithium bromide absorption type The hot water inlet 41 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com