Coastal area cement production and seawater desalination combined implementation system and method

A cement and regional technology, applied in the joint realization system field of cement production and seawater desalination in coastal areas, can solve the problems of lack of energy utilization rate of fresh water, and achieve low waste heat recovery utilization rate, increase economic benefits, and high energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

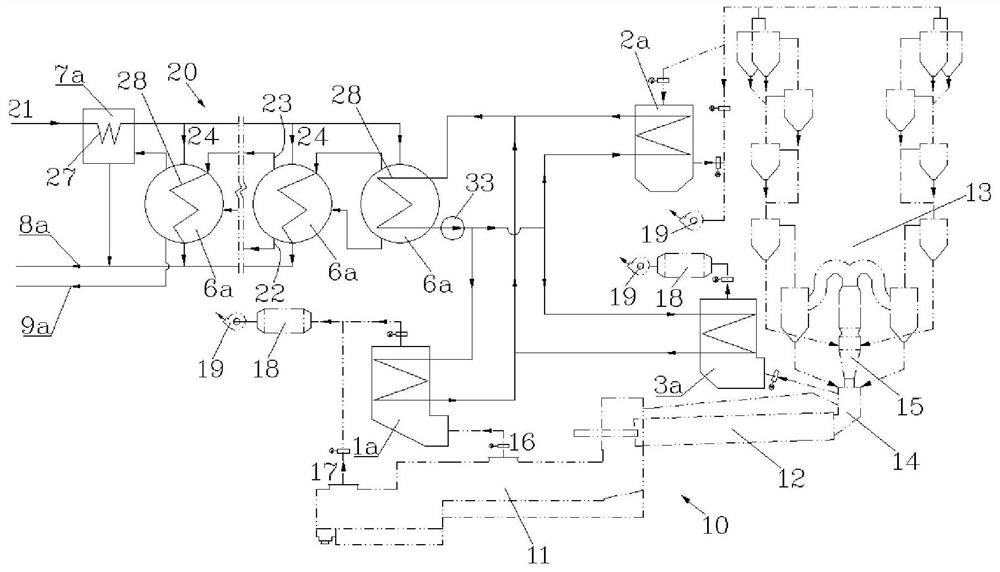

[0047] see figure 1 , the present embodiment provides a joint realization system of cement production and seawater desalination in coastal areas, which includes a cement system 10 and a seawater desalination system 20.

[0048] Wherein, the cement system 10 includes a grate cooler 11, a rotary kiln 12 and a preheater 13; wherein, the grate cooler 11 is connected to the rotary kiln 12, and the rotary kiln 12 is communicated with the calciner 15 of the preheater 13 through the smoke chamber 14 .

[0049] Grate cooler 11 middle part and afterbody are respectively provided with middle part air extraction port 16 and tail part air extraction port 17, and middle part air extraction port 16 is communicated into AQC boiler 1a, and AQC boiler 1a is communicated with blower fan 19 by dust collector 18.

[0050] The kiln tail flue gas outlet of the rotary kiln 12 communicates with the SP boiler 2a from the outlet of the preheater 13, and the SP boiler 2a communicates back to the cement ...

Embodiment 2

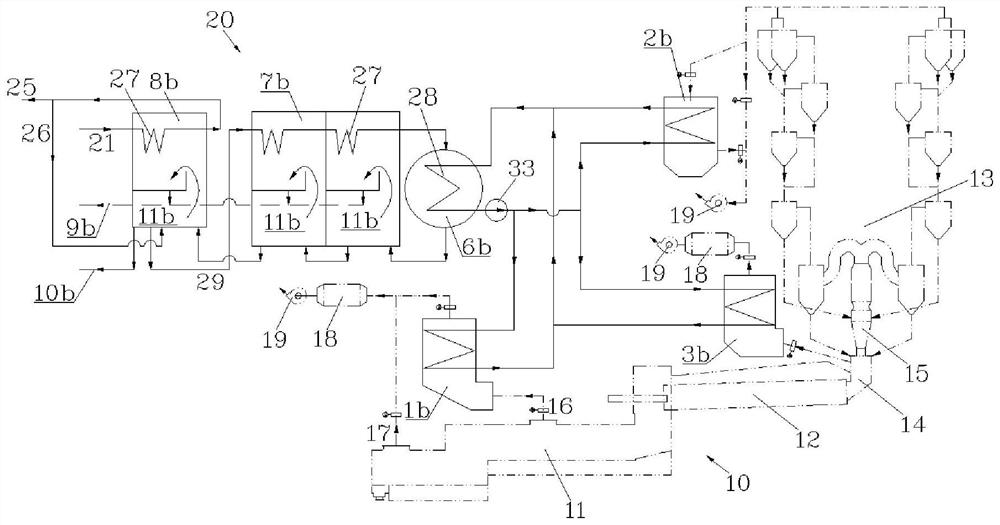

[0064] This embodiment provides a joint realization system of cement production and seawater desalination in the coastal area, which includes a cement system 10 and a seawater desalination system 20;

[0065] Described cement system 10 comprises grate cooler 11, rotary kiln 12 and preheater 13; Wherein, grate cooler 11 connects rotary kiln 12, rotary kiln 12 is communicated with the calciner 15 of preheater 13 by flue chamber 14;

[0066] Grate cooler 11 middle part and afterbody are respectively provided with middle part air extraction port 16 and afterbody air extraction port 17, and middle part air extraction port 16 is communicated into AQC boiler 1b, and AQC boiler 1b is communicated with blower fan 19 by deduster 18;

[0067] The kiln tail flue gas outlet of the rotary kiln 12 is connected to the SP boiler 2b from the outlet of the preheater 13, and the SP boiler 2b is connected to the cement system 10 through the fan 19; the smoke chamber 14 between the rotary kiln 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com