Waste heat and pressure utilization-based fuel cell air supply system

A fuel cell and air supply technology, which is applied in the direction of fuel cells, fuel cell additives, electrical components, etc., can solve problems such as low exhaust temperature, energy that cannot meet the power demand of air compressors, and system net output power reduction. Achieve the effect of increasing net output power, compact structure and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

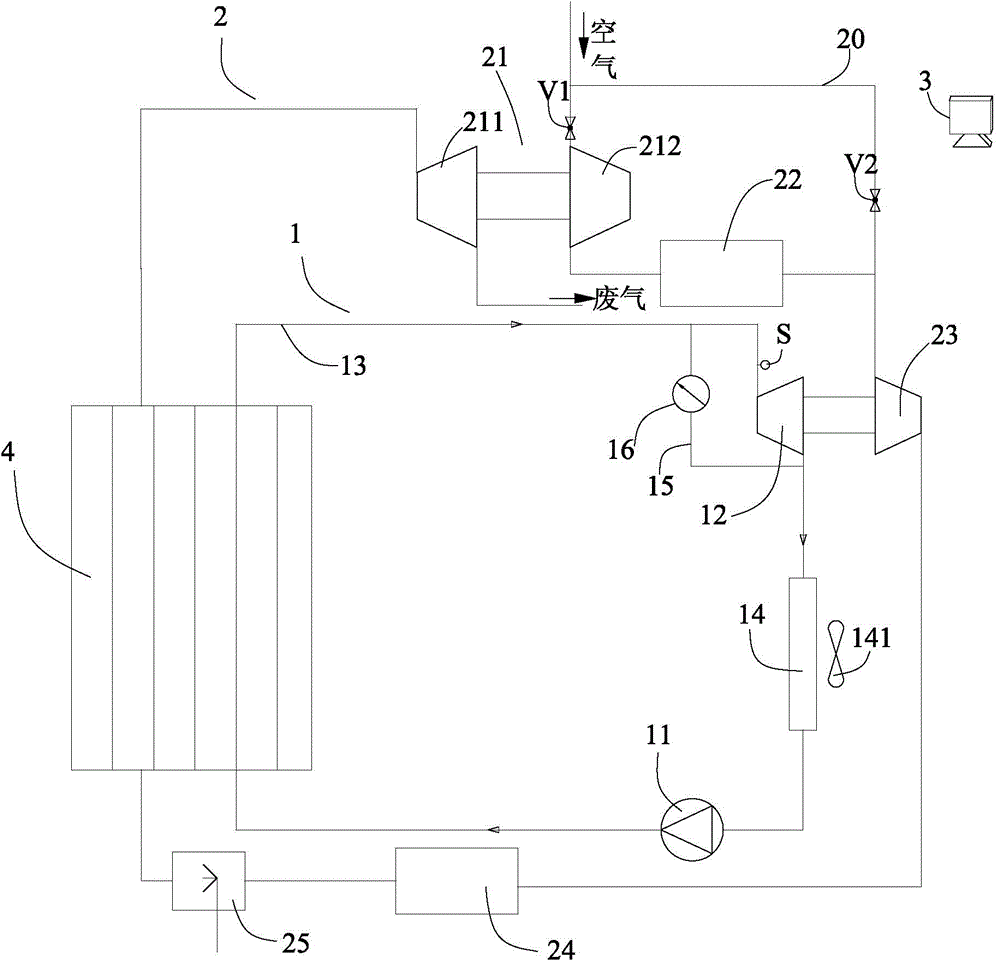

[0022] The fuel cell air supply system based on utilization of waste heat and pressure according to the present invention will be described in detail below with reference to the accompanying drawings.

[0023] refer to figure 1 According to the present invention, the fuel cell air supply system based on waste heat and pressure utilization includes: a waste heat recovery loop 1 based on an organic Rankine cycle, and a pressurized air supply system 2 . The waste heat recovery loop 1 based on the Organic Rankine cycle comprises: an organic working medium pump 11, connected to an external organic working medium liquid storage tank (not shown); an expander 12, arranged downstream of the organic working medium pump 11 and controlled Connected to the organic working medium pump 11; the organic working medium pipeline 13, one end communicates with the organic working medium pump 11 and the other end communicates with the expander 12 and passes through the fuel cell 4, the liquid organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com