A distributed energy generation system and method for multi-stage utilization of waste heat

A distributed energy and waste heat technology, applied in machines/engines, steam engines, mechanical equipment, etc., can solve the problem of low thermal efficiency, and achieve the effects of improving thermal efficiency, increasing net output power, and cleaning emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0020] Example.

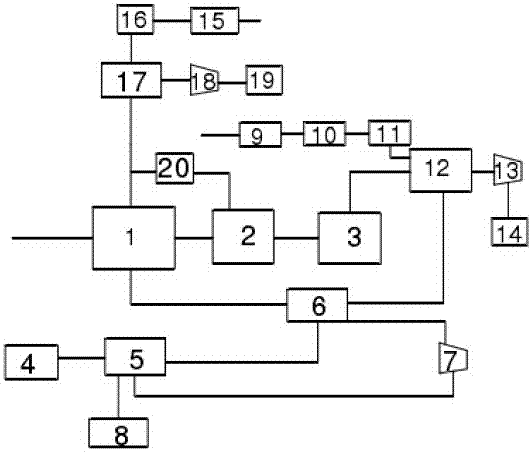

[0021] see figure 1 In this embodiment, the distributed energy generation system for multi-stage utilization of waste heat includes a gas-fired internal combustion engine generator set 1, a waste heat boiler 2, a steam-type lithium bromide set 3 and a multi-stage organic Rankine cycle system.

[0022] In this embodiment, the gas-fired internal combustion engine generator set 1, the waste heat boiler 2 and the steam-type lithium bromide unit 3 are connected in sequence, and the multi-stage organic Rankine cycle system includes No. 1 working fluid pump 4, No. 1 regenerator 5, and No. 1 evaporator 6 , No. 1 expander 7, No. 1 condenser 8, No. 2 working medium pump 9, No. 2 regenerator 10, preheater 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com