Method for preparation of membrane electrode of water-keeping proton exchange film fuel cells

A technology of proton exchange membrane and fuel cell membrane, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., and can solve the problems of structural defects of inorganic oxide catalytic layer, influence of electronic conduction of catalytic layer, difficulty in uniform dispersion, etc. , to achieve good water retention capacity, high dispersion and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

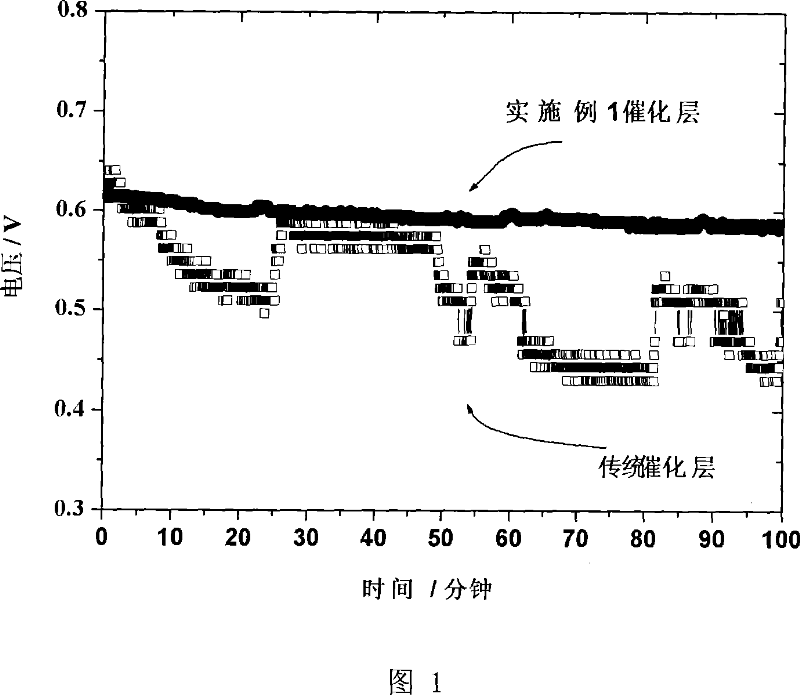

Embodiment 1

[0028] (1) Take 100 grams of perfluorosulfonic acid resin solution (Nafion DE 520) with a weight concentration of 5%, adjust the pH value to 7.5 with NaOH, then transfer to 100 grams of N-methylpyrrolidone, and stir it electromagnetically for 30 minutes to make The perfluorosulfonic acid resin was fully dissolved in N-methylpyrrolidone; the solution was distilled for 5 hours to remove moisture in the solution until the solution temperature reached 203°C, and at the end, the perfluorosulfonic acid resin (Nafion DE 520 solution) / N- Methylpyrrolidone solution.

[0029] (2) Weigh 1.7 grams of tetraethoxysilane (about 0.5 grams of silicon dioxide in total), dissolve in the perfluorosulfonic acid resin (Nafion DE 520 solution) / N-methylpyrrolidone solution prepared in step (1), Electromagnetic stirring was performed for 30 minutes to obtain an inorganic oxide precursor solution.

[0030] (3) In the inorganic oxide precursor solution, add an excessive amount of HCl solution (HCl cont...

Embodiment 2

[0035] (1) Take 80 grams of sulfonated polyether ether ketone resin solution with a weight concentration of 10%, adjust the pH value to 7 with NaOH, then transfer to 150 grams of ethylene glycol-methyl ether, and electromagnetically stir for 30 minutes to make the sulfonated polyether ether ketone resin solution Polyetheretherketone resin is fully soluble in ethylene glycol-methyl ether. The solution was distilled for 6 hours to remove water in the solution until the temperature of the solution reached 125° C., and ended; a sulfonated polyether ether ketone resin / ethylene glycol-methyl ether solution was obtained.

[0036] (2) Weigh 1.2 g of ethyl titanate, dissolve it in the sulfonated polyether ether ketone resin / ethylene glycol-methyl ether solution prepared in step (1), and stir it electromagnetically for 30 minutes to obtain an inorganic oxide precursor solution.

[0037] (3) Add an excess of HCl solution (the HCl content is 37wt.% and the water content is 63wt%) to the s...

Embodiment 3

[0041] (1) Take 500 grams of weight concentration and be 3% sulfonated trifluorostyrene resin, adjust the pH value to 6.5 with NaOH, then transfer to 900 grams of ethylene glycol-ether (making the sulfonated trifluorostyrene resin mixed The content in the solution reaches 1-9wt.%), and electromagnetic stirring is performed for 30 minutes to fully dissolve the sulfonated trifluorostyrene resin in ethylene glycol-ether. Distill to remove water in the solution until the temperature of the solution reaches 136°C, and end; a sulfonated trifluorostyrene resin / ethylene glycol-ether solution is obtained.

[0042] (2) Take 0.1 g of isopropyl titanate, dissolve it in the sulfonated trifluorostyrene resin / ethylene glycol-ether solution prepared in step (1), and stir it electromagnetically for 30 minutes to obtain an inorganic oxide precursor solution.

[0043] (3) In the inorganic oxide precursor solution, add an excess of HCl solution (HCl content is 37wt.%, water content is 63wt%) that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com