Double-hearth circulating fluidized bed boiler

A circulating fluidized bed and double furnace technology, which is applied to fluidized bed combustion equipment, steam boilers, fuels burned in a molten state, etc., can solve the difficulties in arranging high-temperature heating surfaces, high pressure heads of primary air fans, and complex furnace structures, etc. problems, increased reliability and flexibility of regulation, avoidance of heat load differences, simple furnace design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

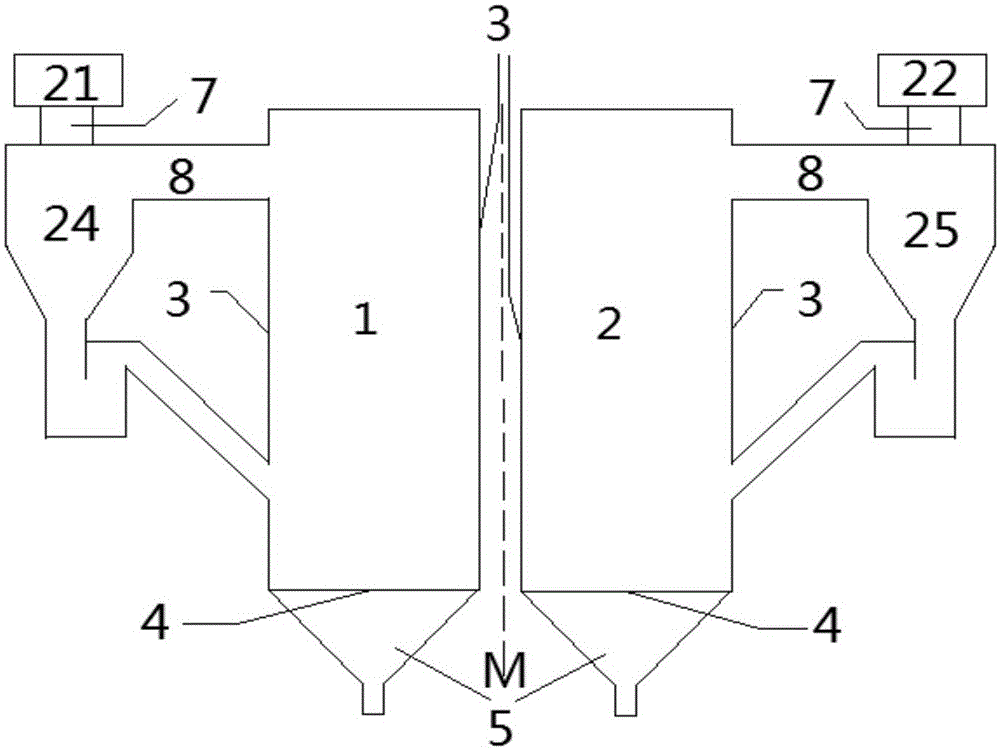

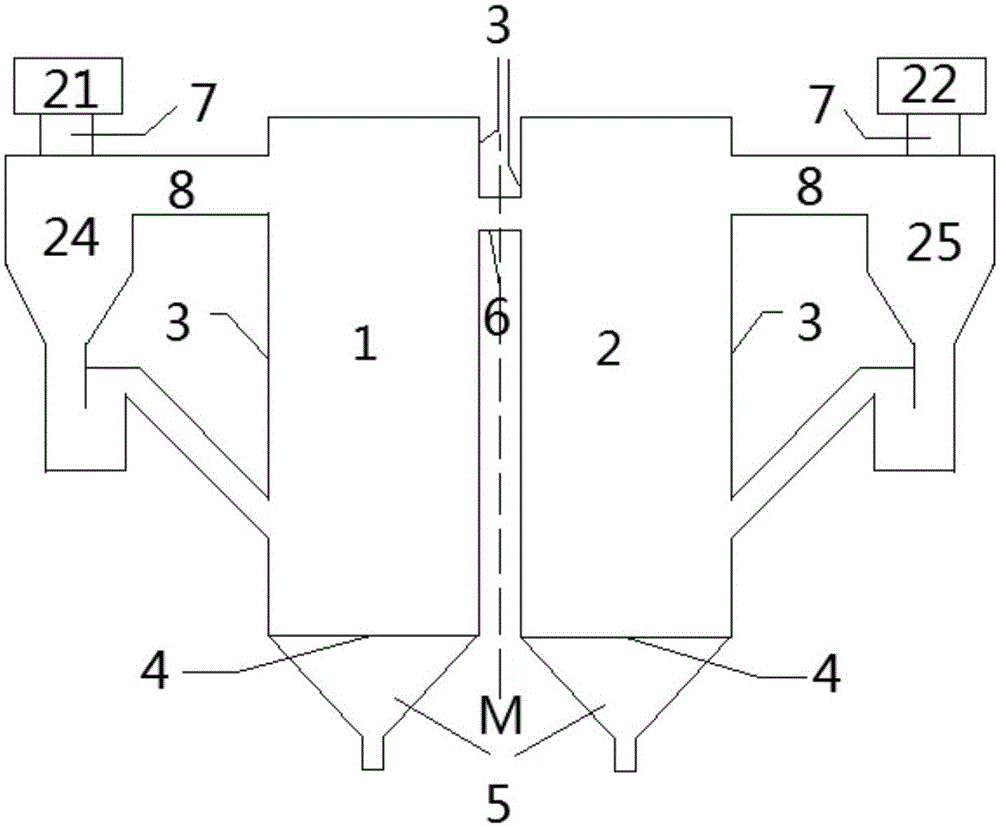

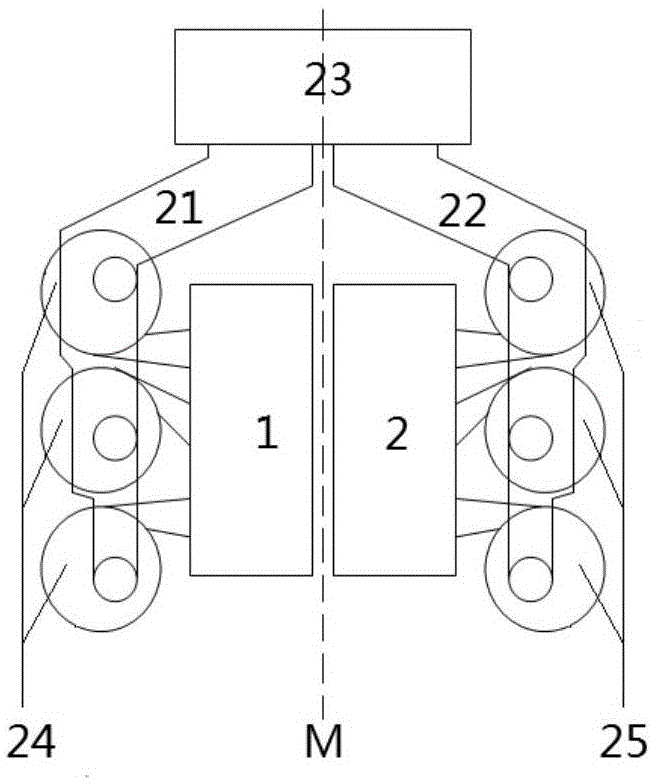

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0017] The main components of a circulating fluidized bed boiler generally include a furnace, a cyclone separator, a return valve and a tail convection flue, and may also include an external heat exchanger, etc.; a superheater, a reheater and a coal-saving The heating surface of the device.

[0018] The present invention provides a double furnace circulating fluidized bed boiler such as figure 1 As shown, it contains two completely independent first furnace 1, second furnace 2, two sets of cyclone separators and a tail convection flue 23; the first furnace and the second furnace are arranged side by side, and there is a gap between the two furnaces There is a certain gap, and there is an independent air distribution device 4 and an air chamber 5 under each furnace; the cross-sectional shape, size and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com