Direct-air-cooling power generation system with natural ventilation cooling tower

A technology of natural ventilation and cooling towers, applied in the direction of water shower coolers, direct contact heat exchangers, engine components, etc. Sensitivity to hot air backflow and other issues, to achieve the effects of reducing fan power consumption, reducing film condensation, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

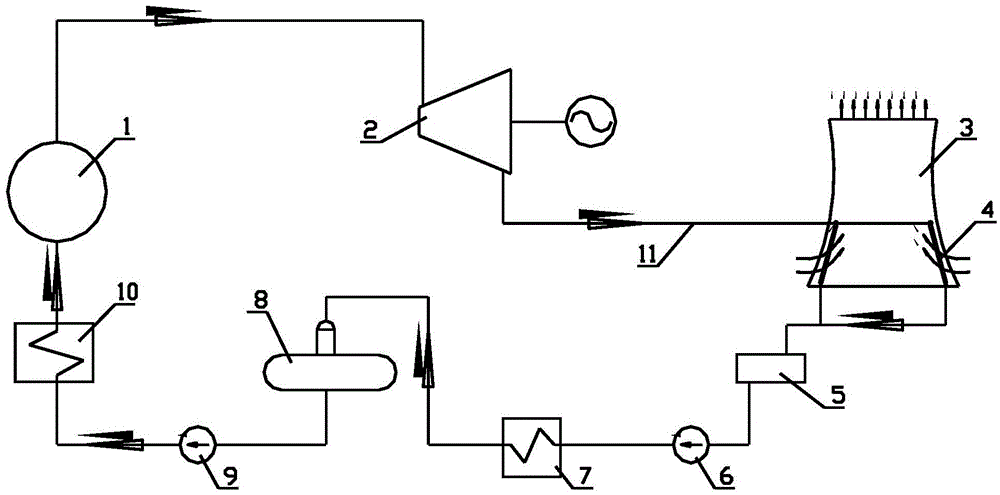

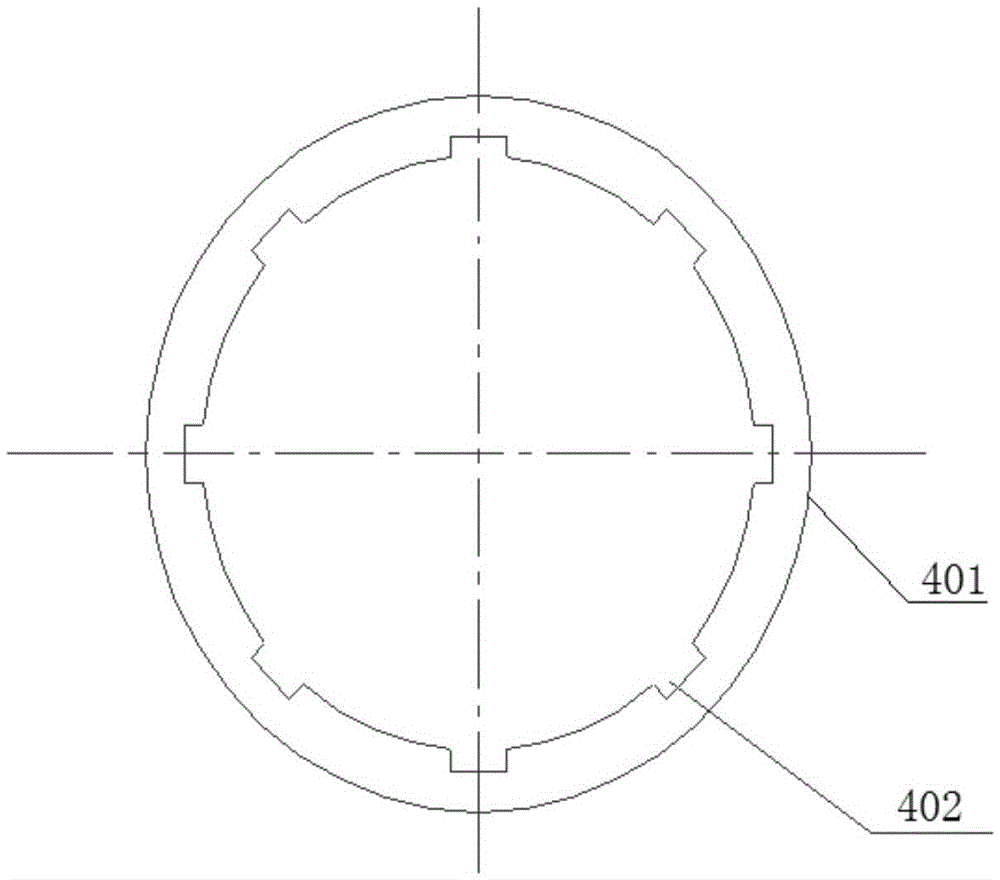

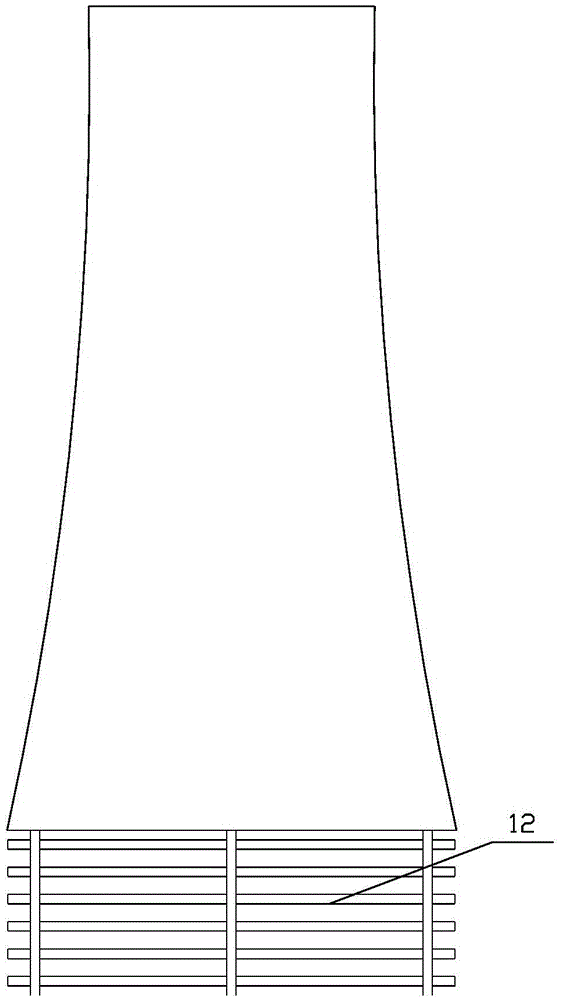

[0021] In a preferred embodiment of the present invention, as Figure 1-Figure 3 As shown, a direct air-cooled power generation system using a natural draft cooling tower, the system includes a boiler 1, a turbogenerator set 2, an air-cooled condenser 4, a condensate tank 5, a condensate pump 6, a low-pressure heater 7, and a deaerator 8. Feed water pump 9, high-pressure heater 10, and related connecting pipelines. The system also includes a natural draft cooling tower 3. The bottom of the natural draft cooling tower 3 is evenly opened with multiple air inlets along the circumference. The natural d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com