Energy recovery and reusing device

An energy recovery and potential energy technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of high cost, large hydraulic energy, poor system coordination, etc., and achieve high recovery and regeneration efficiency , the effect of reducing load and power, energy saving and emission reduction benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

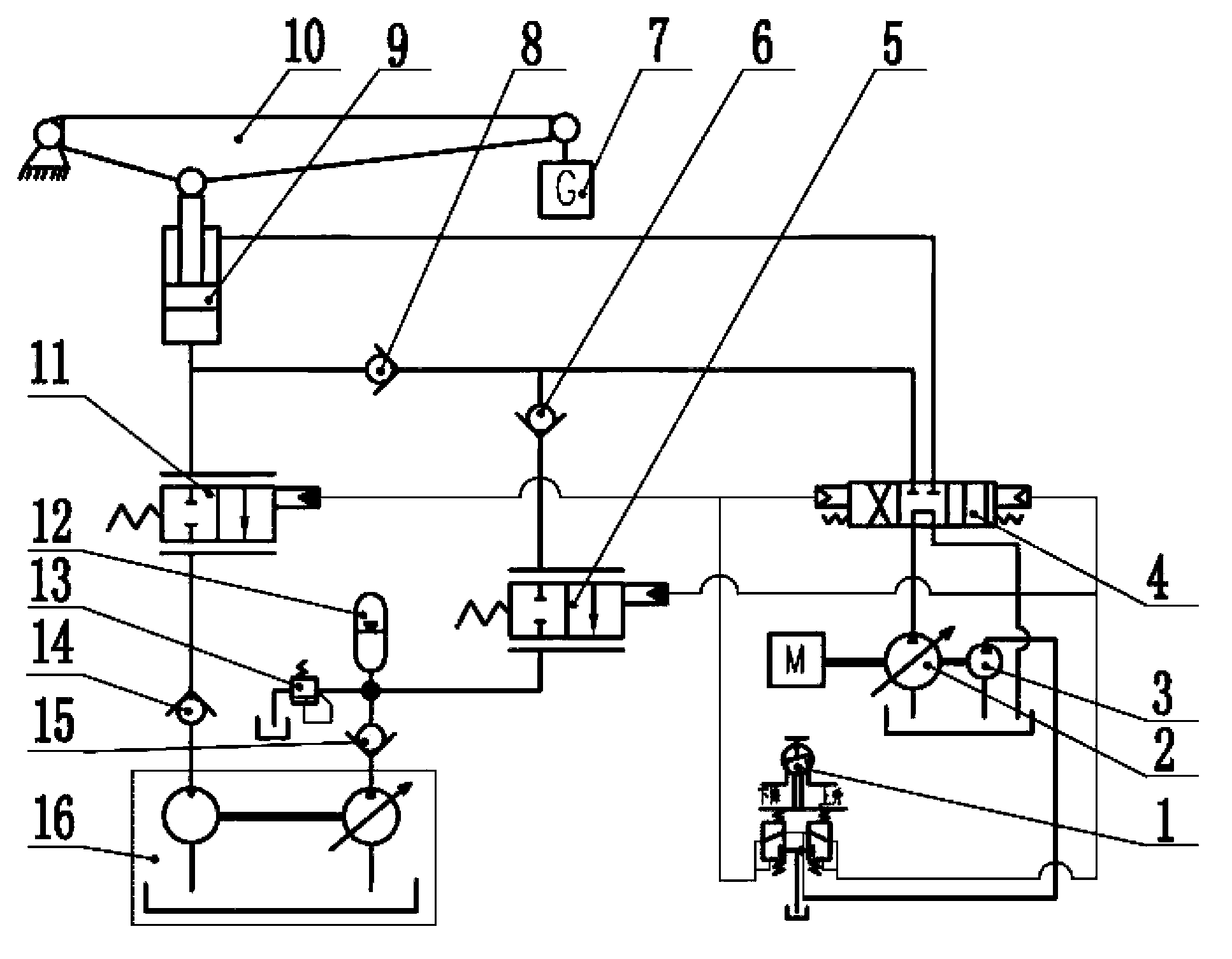

[0012] The invention discloses an energy recovery and reuse device for self-weight potential energy of a boom. The energy recovery and reuse device includes: a boom assembly and a hydraulic system; the boom assembly includes a boom 10 and a heavy Object 7; the hydraulic system includes: a hydraulic main pump system, the hydraulic main pump system includes a hydraulic main pump 2, a pilot pump 3 and a motor that drives the hydraulic main pump 2 and the pilot pump 3; the oil cylinder 9 connected to the boom 10 , the oil cylinder includes a cylinder, a piston and a piston rod, one end of the piston rod is connected with the piston, and the other end is connected with the boom, and the extension and retraction of the piston rod drive the boom to rise or fall; the hydraulic main valve 4, the The hydraulic main valve is located between the hydraulic main pump 2 and the oil cylinder 9, and controls the flow direction of the oil in the oil cylinder; it is characterized in that: the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com