Heat regenerative system adopting jet-type heat pumps

A jet heat pump and heat recovery system technology, which is applied in preheating, feed water heaters, lighting and heating equipment, etc., can solve problems such as the limitation of heat recovery stages, achieve reduction of irreversible losses, obvious benefits of energy saving and emission reduction, and thermal efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

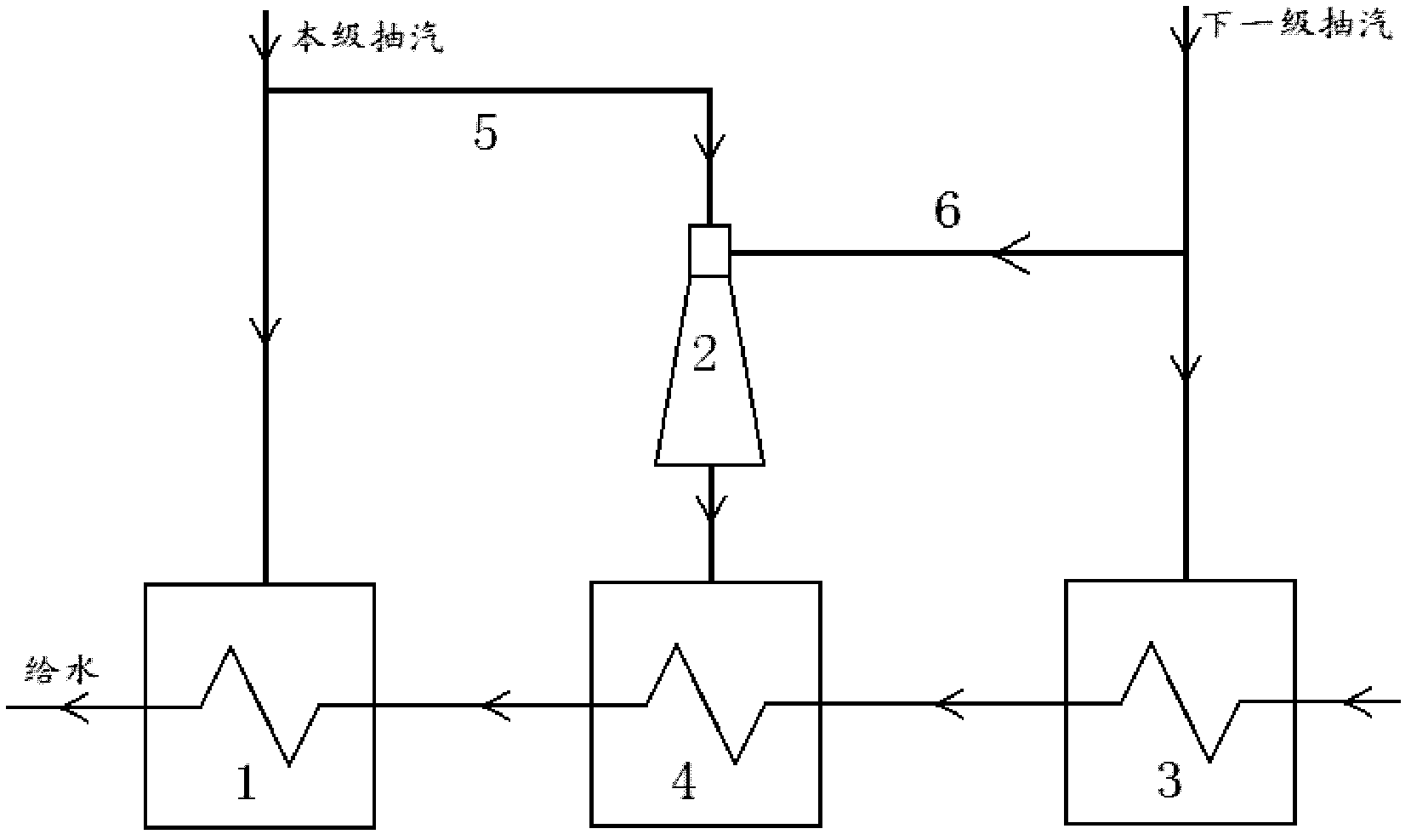

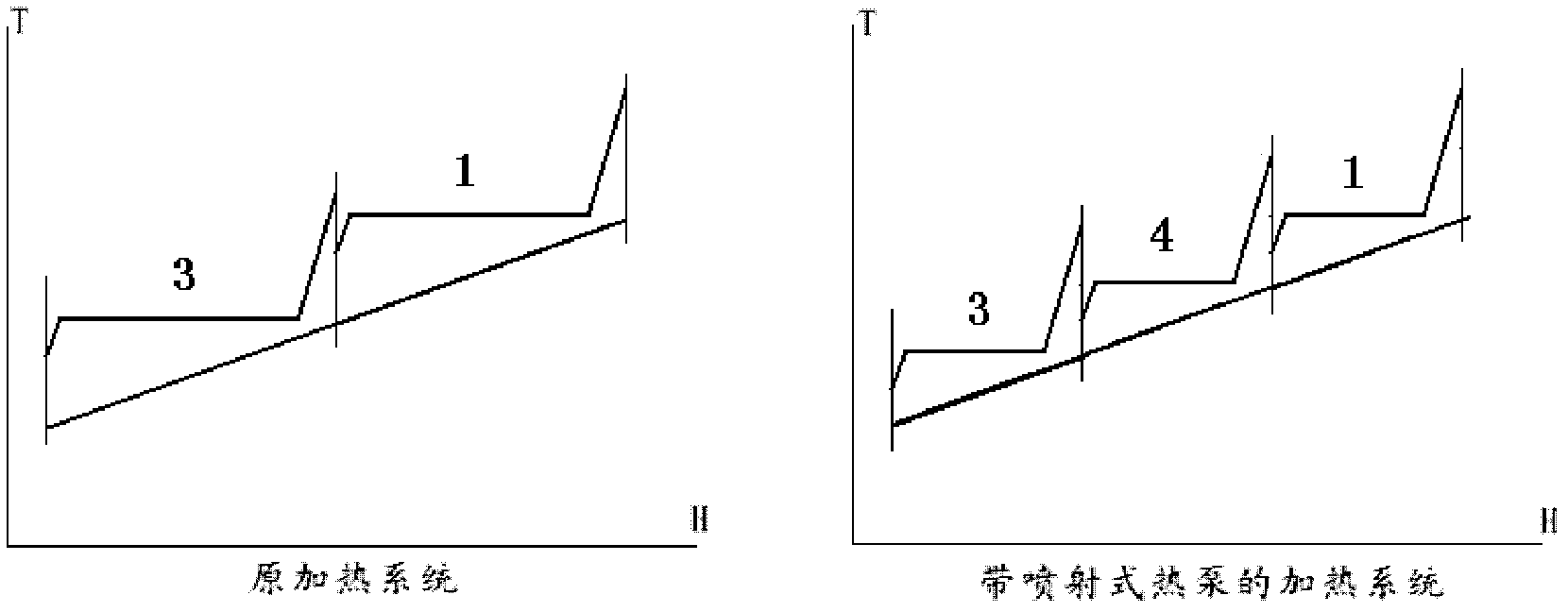

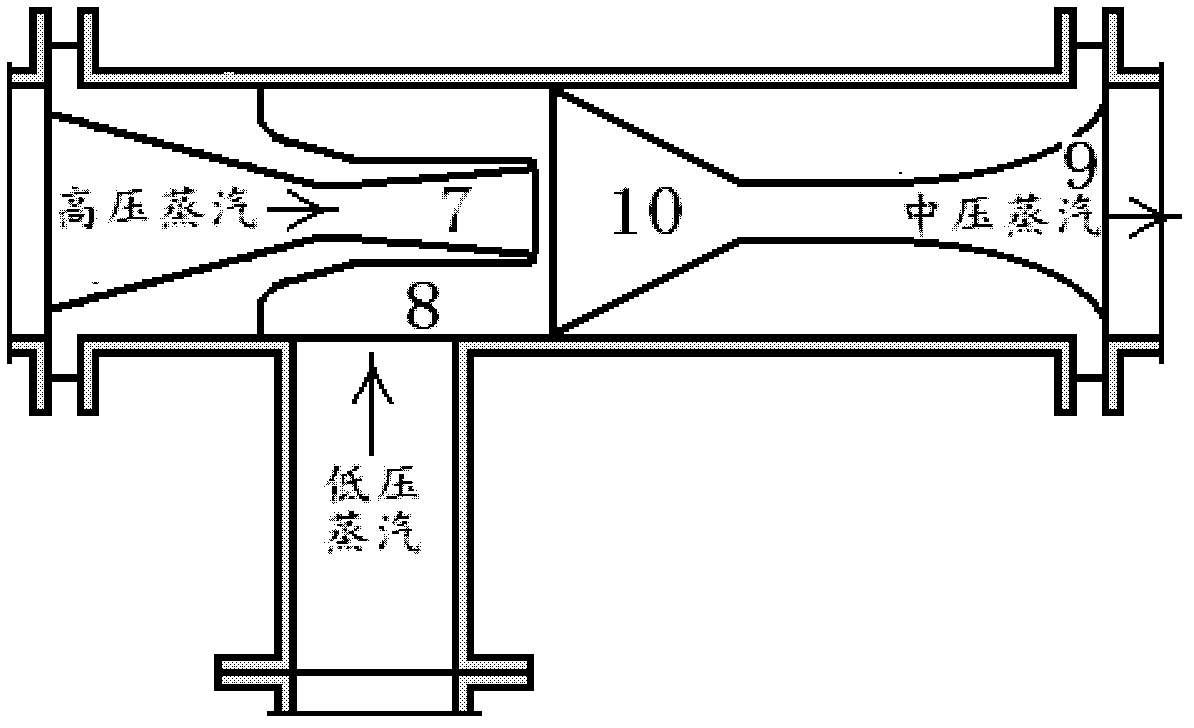

[0011] Since the regenerative heater of thermal power plant uses steam to heat the feed water, there is an irreversible loss due to the temperature difference between the steam and the feed water. The greater the temperature difference between steam and feed water, the greater its irreversible loss. figure 2 The temperature-enthalpy diagram of the regenerative heating process is given. It can be seen from the figure that increasing the number of regenerative stages can reduce the temperature difference in the regenerative process, thereby reducing the irreversibility of the regenerative process. loss. However, in reality, limited by factors such as the structure of the steam turbine, currently large coal-fired generating units generally use 7-9 stages of regenerative steam extraction, and the corresponding regenerative heater stages are also 7-9 stages. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com