Device and method of recovering heat energy in waste water anaerobic treatment process

A technology for anaerobic treatment and recovery of heat energy, applied in anaerobic digestion treatment, combustion methods, waste fuels, etc., and can solve problems such as low energy utilization rate, corrosion of cylinder walls, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An anaerobic biogas thermal energy recovery project for a paper company that treats 5,000 tons of papermaking wastewater per day.

[0047] The Paper Co., Ltd. currently has two wastewater treatment anaerobic reaction towers with a diameter of 10 meters and a height of 20 meters, which can process 5,000 tons of papermaking wastewater every day. The two anaerobic towers together produce about 1,500 cubic meters of biogas per day.

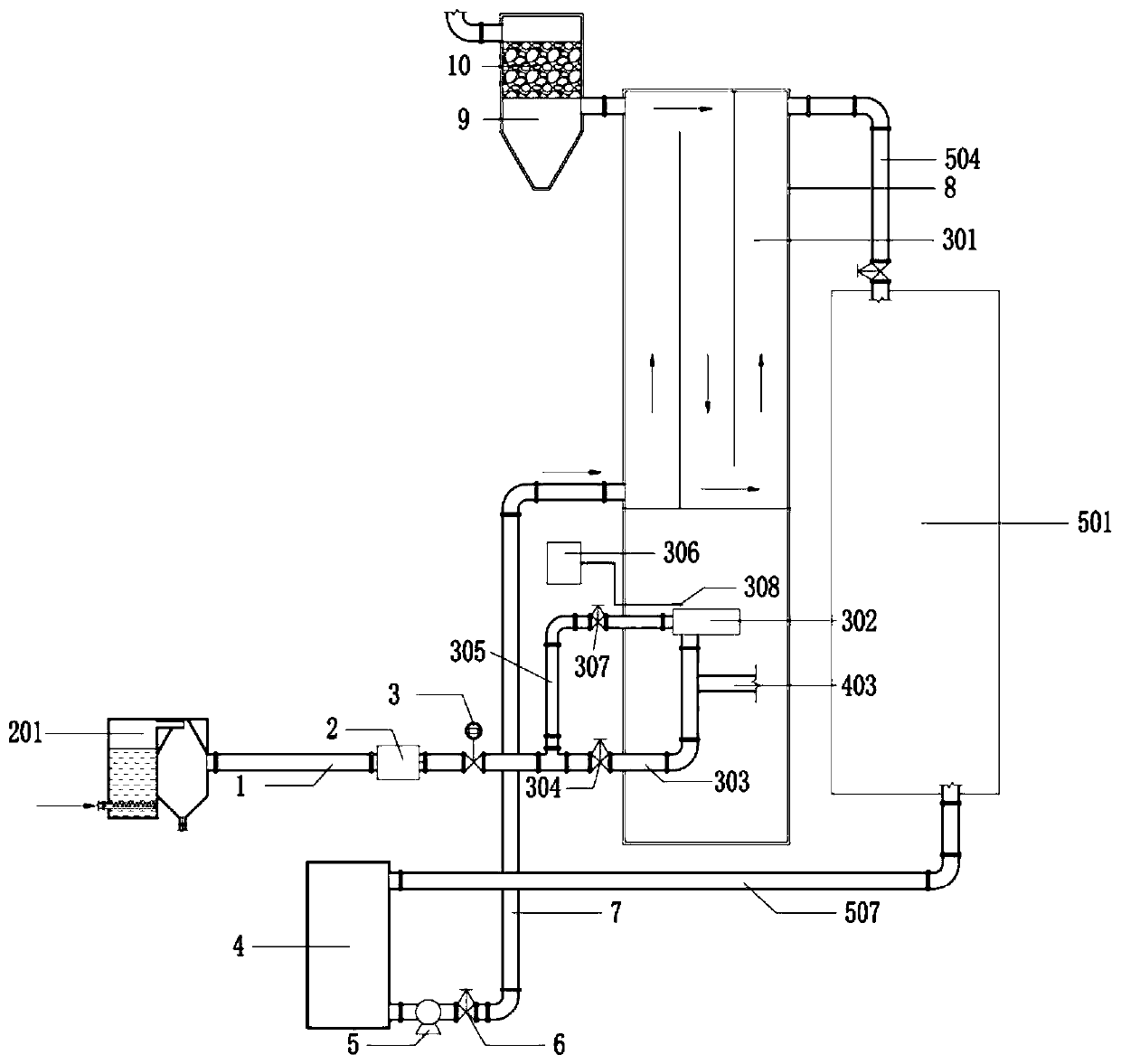

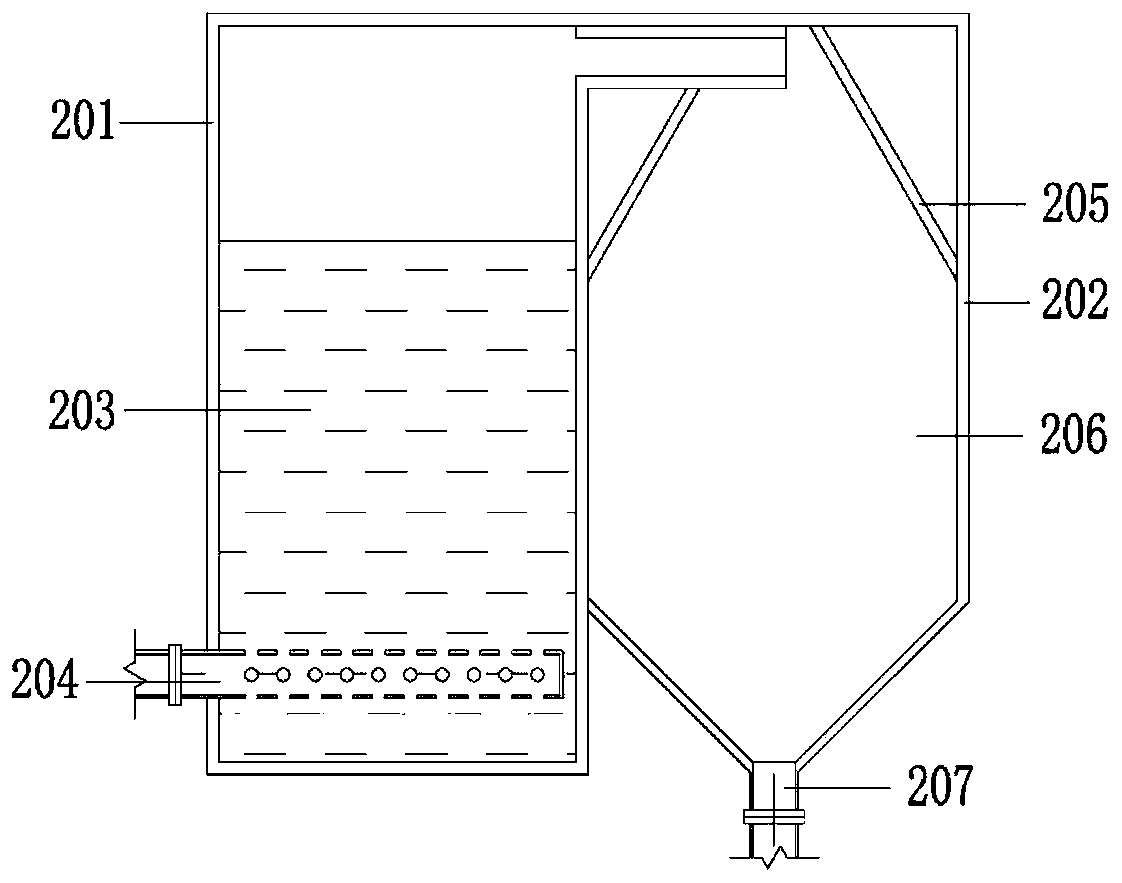

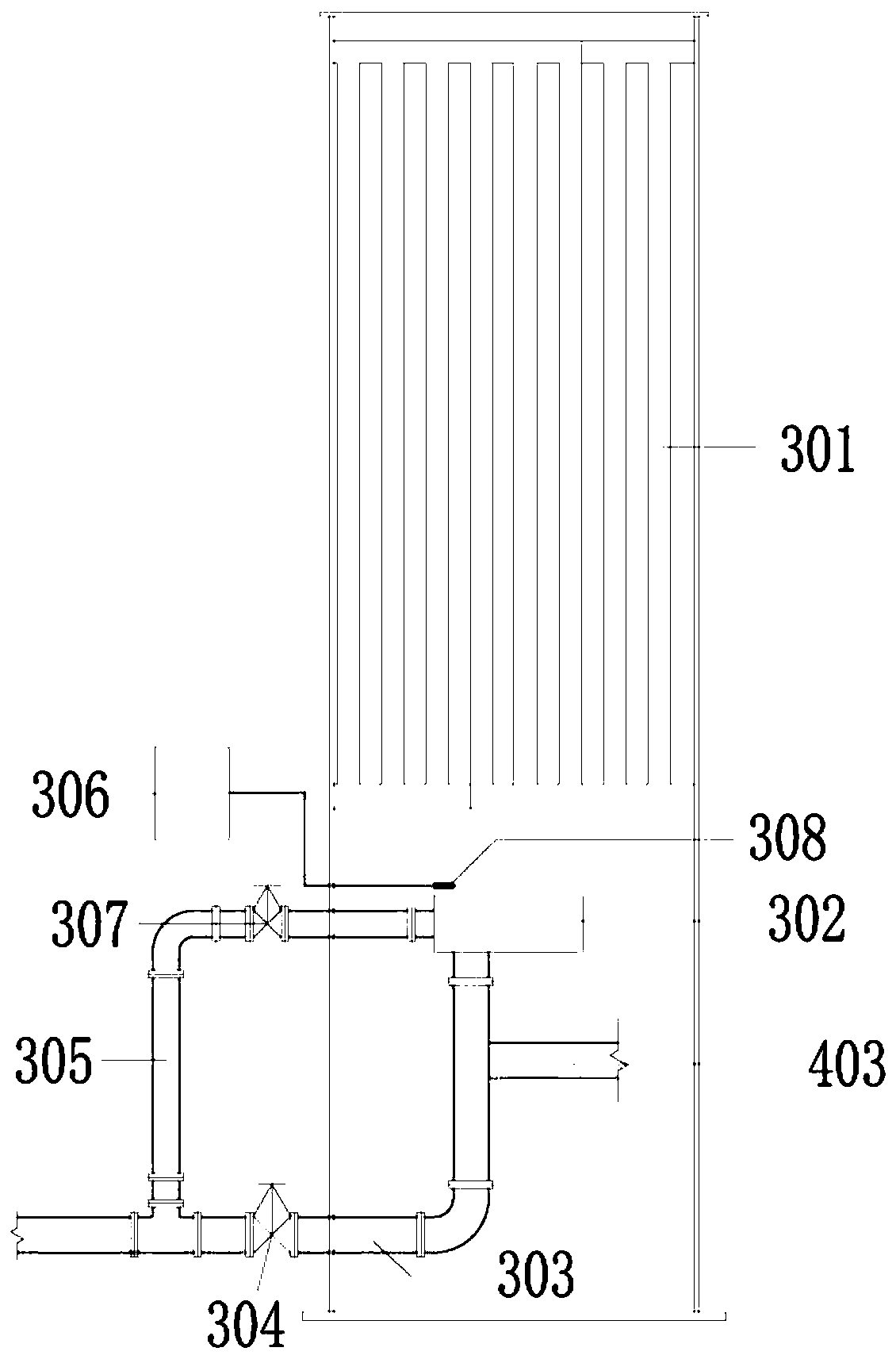

[0048] Such as figure 1 As shown, the heat recovery equipment used in this plant during the anaerobic treatment of wastewater includes a combustion heat exchanger body 8, a biogas purification system 201, a flame arrester 2, a gas pipeline 1, a heat transfer fluid storage tank 4, and a heat recovery utilization system 501. The combustion heat exchanger body 8 is a hollow cylinder structure with a height of 9 meters and a diameter of 2.5 meters. The combustion heat exchanger body 8 is provided with a gas delivery pipeline 303 and a control val...

Embodiment 2

[0058] A paper industry processes 3,000 tons of papermaking wastewater per day for an anaerobic biogas heat recovery project.

[0059] The difference between this embodiment and embodiment 1 is:

[0060] The combustion heat exchanger body 8 has an overall height of 10 meters and a diameter of 2.5 meters. The inner and upper thin-walled tubular heat exchanger system 301 adopts clustered thin-tube thin-walled heat exchange tubes with a diameter of 20 mm and a length of 5 meters. A total of 48; the surface of the stainless steel burner 302 is provided with 4 circles of circular pores according to concentric circles, and each circle has 8 circular pores with a diameter of 6 mm.

[0061] In this embodiment, the biogas generated by the anaerobic tower can increase the temperature of 10 tons of water by about 30°C per hour, and the heat production is equivalent to saving 0.6 tons of standard coal per day. The heated water enters the boiler to produce steam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com