Patents

Literature

70 results about "Micro aggregates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

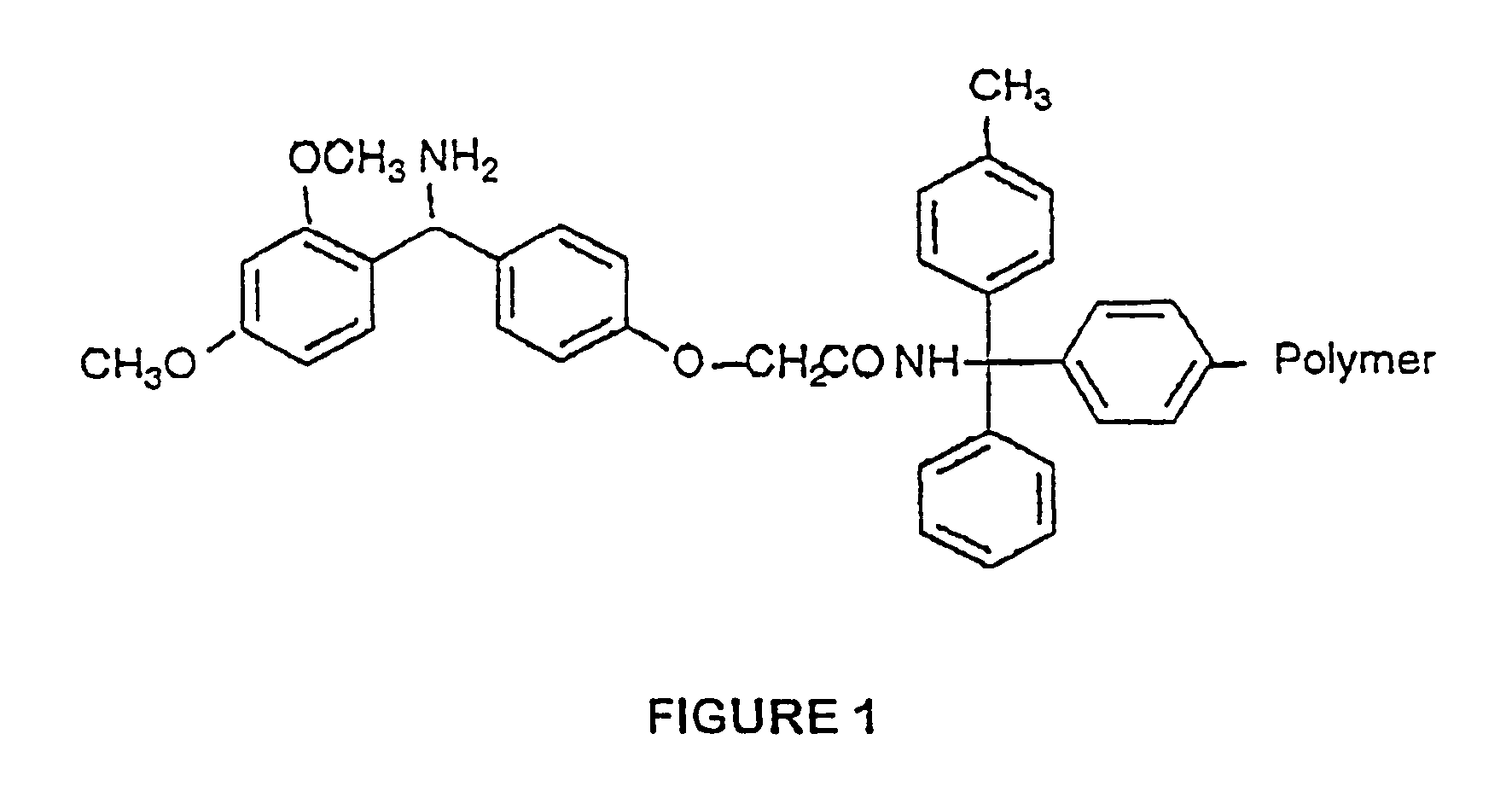

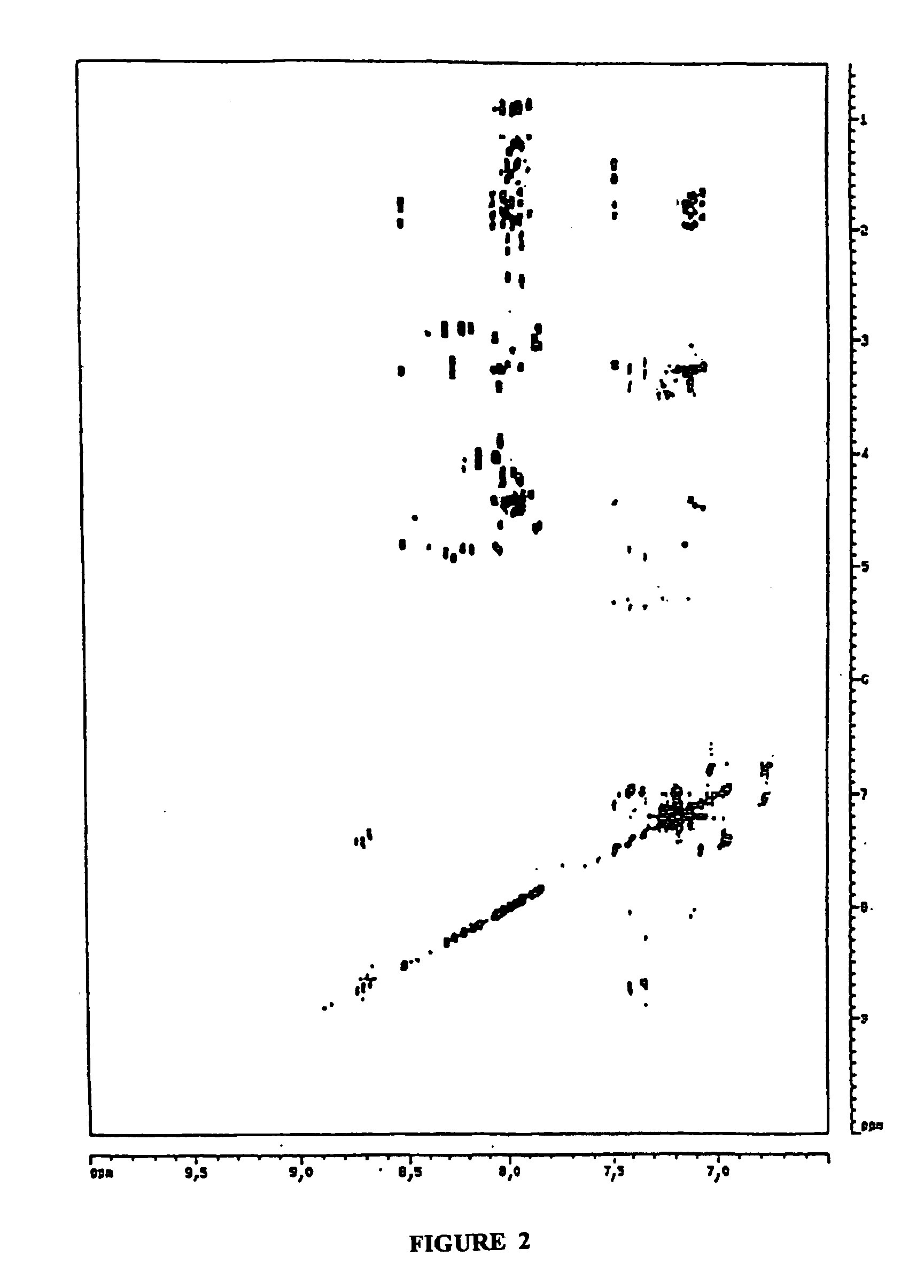

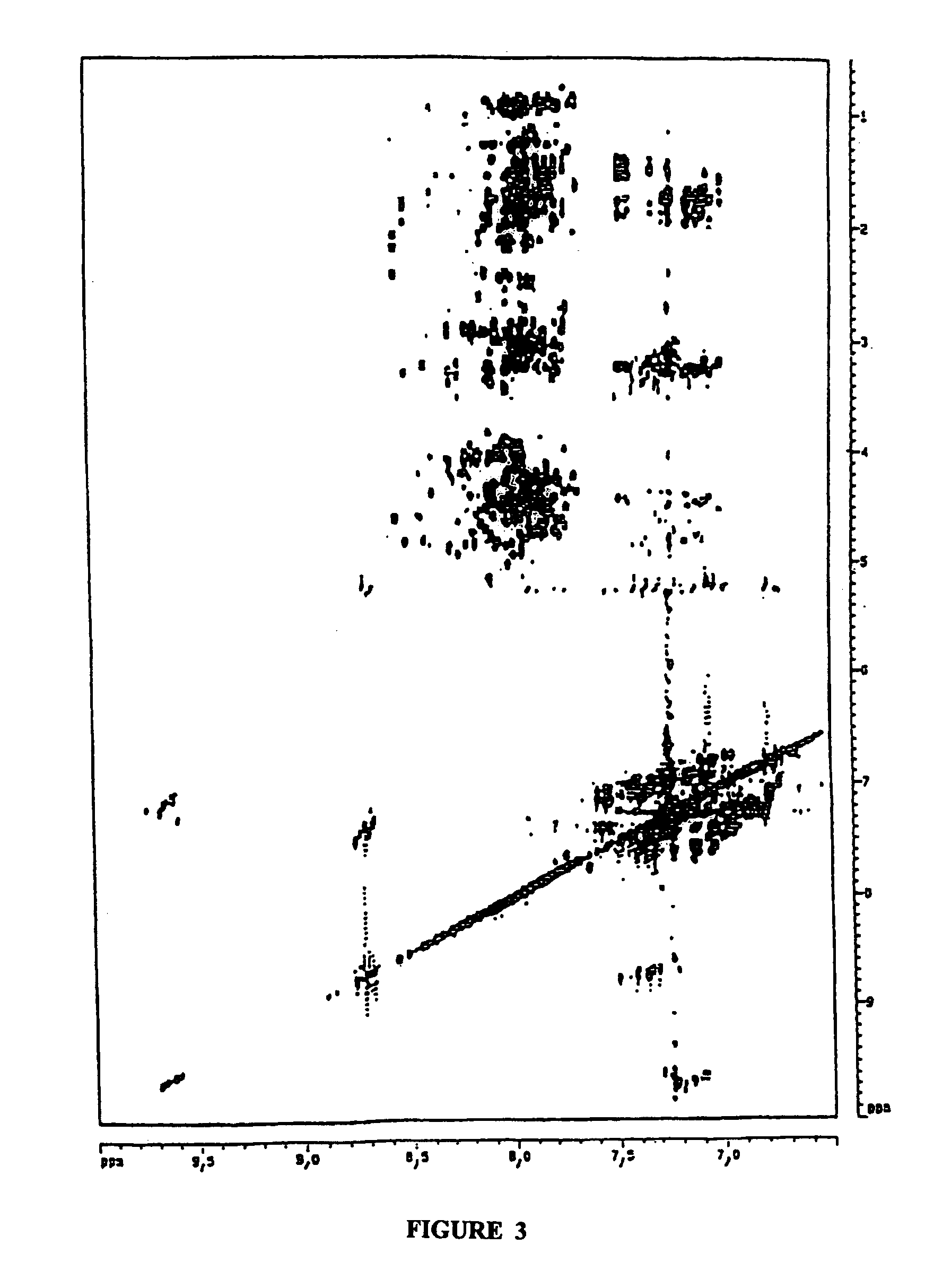

Mixed lipopeptide micelles for inducing an immune response

The invention concerns mixed micelles or micro-aggregates for inducing an immune response containing at least a first lipopeptide comprising a CTL epitope and at least a first lipid motif; and a second lipopeptide comprising at least an auxiliary T epitope and at least a lipid motif, whereof the type can be different from the first lipopeptide motif. Said micelles can be used as medicines and vaccines.

Owner:INSTITUT PASTEUR DE LILLE +2

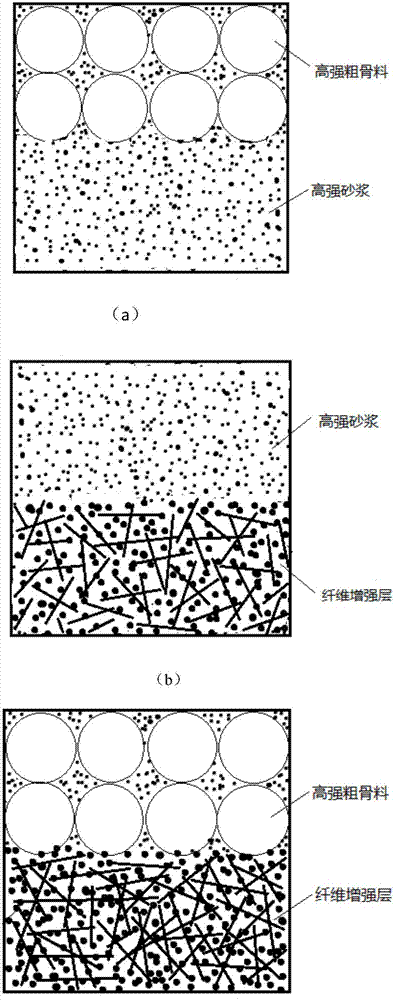

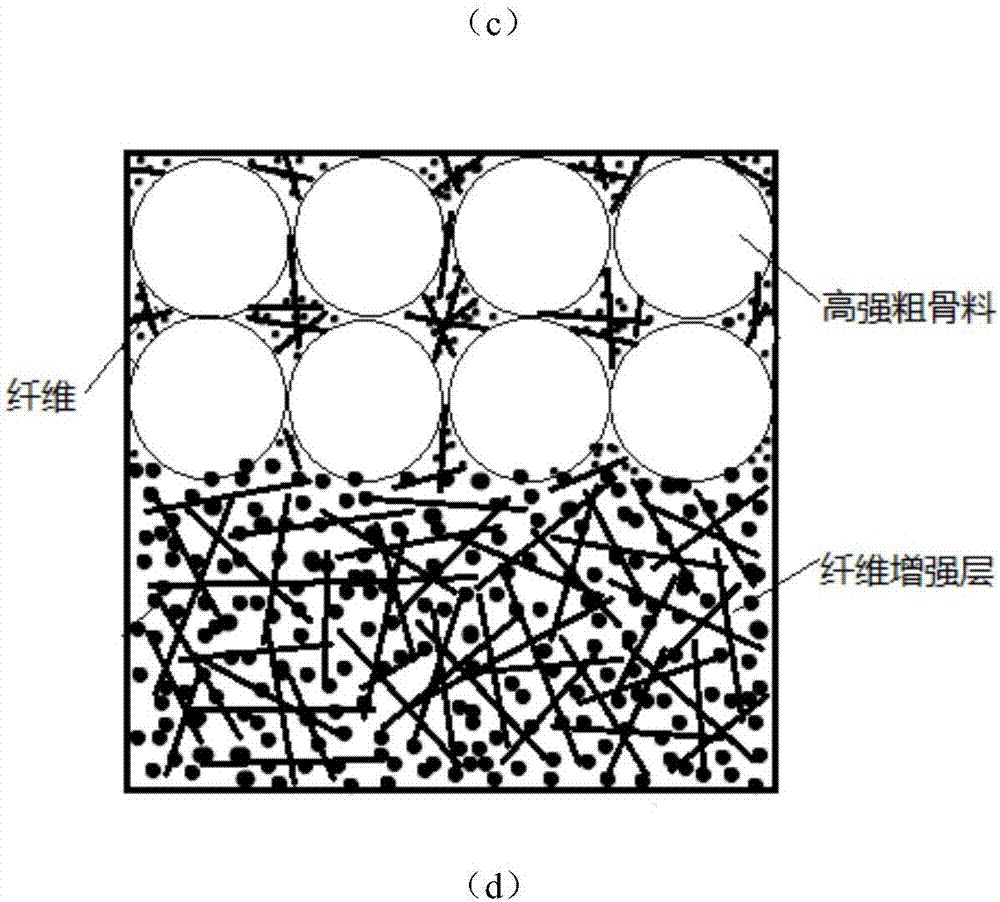

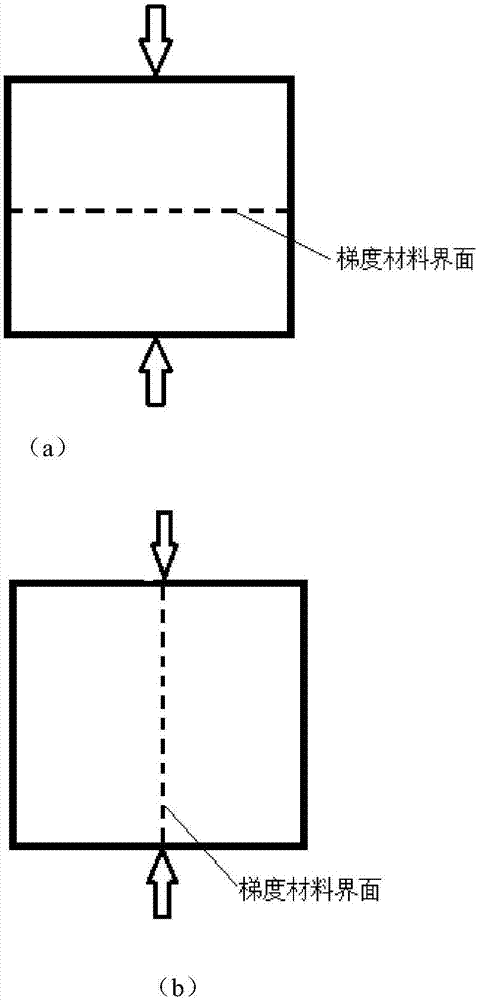

Functional gradient cement-based composite material enhanced by nano material and preparation method thereof

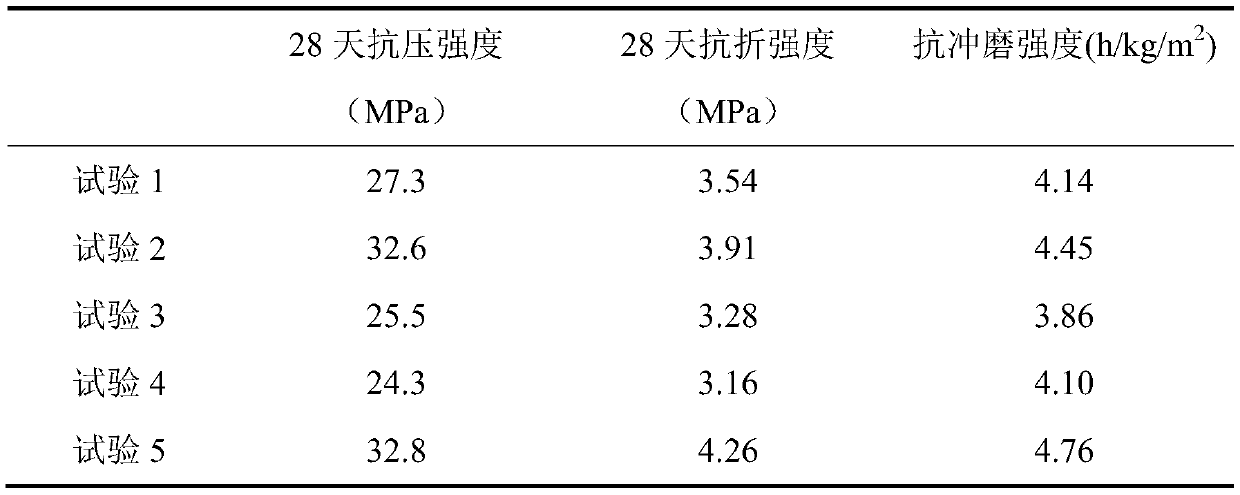

ActiveCN107098657AWide variety of sourcesConducive to ecological sustainable developmentCement pasteUltimate tensile strength

The invention discloses a functional gradient cement-based composite material enhanced by a nano material and a preparation method thereof. The composite material is composed of two or more of high-strength mortar, high-strength crude aggregate concrete, the fiber-enhanced super-high performance concrete, and the fiber-enhanced crude aggregate concrete according to isopyknic ratio. The nano material is doped into the composite material, an aperture and a gap of a gelling system can be filled with the material taken as a micro aggregate, the hydration rate at an early stage of cement paste is increased; at the same time, the gradient design is employed, by aiming at out-phase in the composite material and an interface in a functional zone, the performance of the cement-based composite material is effectively improved, and the functional gradient cement-based composite material is prepared, and the performances of intensity, toughness, impact resistance, penetration resistance, and blast resistance are greatly increased.

Owner:NANJING UNIV OF SCI & TECH

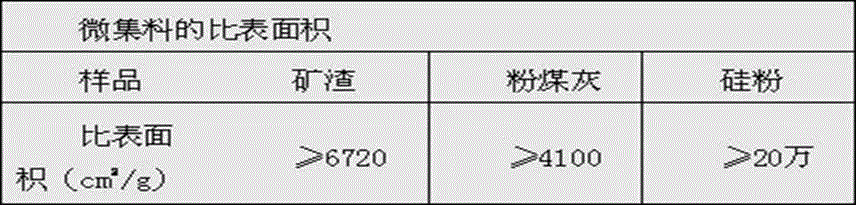

Low-carbon high-performance concrete supplementary cementitious material

The invention discloses a low-carbon high-performance concrete supplementary cementitious material which is prepared from 20-70 parts of slag, 20-70 parts of coal ash, 5-10 parts of silica fume, 3-10 parts of desulfurized gypsum and 1-3 parts of water reducing agent by weight to form an admixture, wherein the slag, the coal ash, the silica fume and the desulfurized gypsum are micro aggregates of 100 nanometers to 100 microns; and the materials are sequentially placed in a mixer and stirred for 60-120 minutes at a speed of 60-120 rpm at normal temperature under normal pressure to obtain the supplementary cementitious material. The low-carbon high-performance concrete supplementary cementitious material disclosed by the invention can replace 70% of cement in concrete when applied to concrete; and even if the 70% of cement is replaced, the strength of the prepared concrete also can reach C15-C60. The low-carbon high-performance concrete supplementary cementitious material is suitable to be used as a building material and also has special purposes of back-fill grouting, toxic waste solidification and the like.

Owner:宁夏新丰益节能科技有限公司

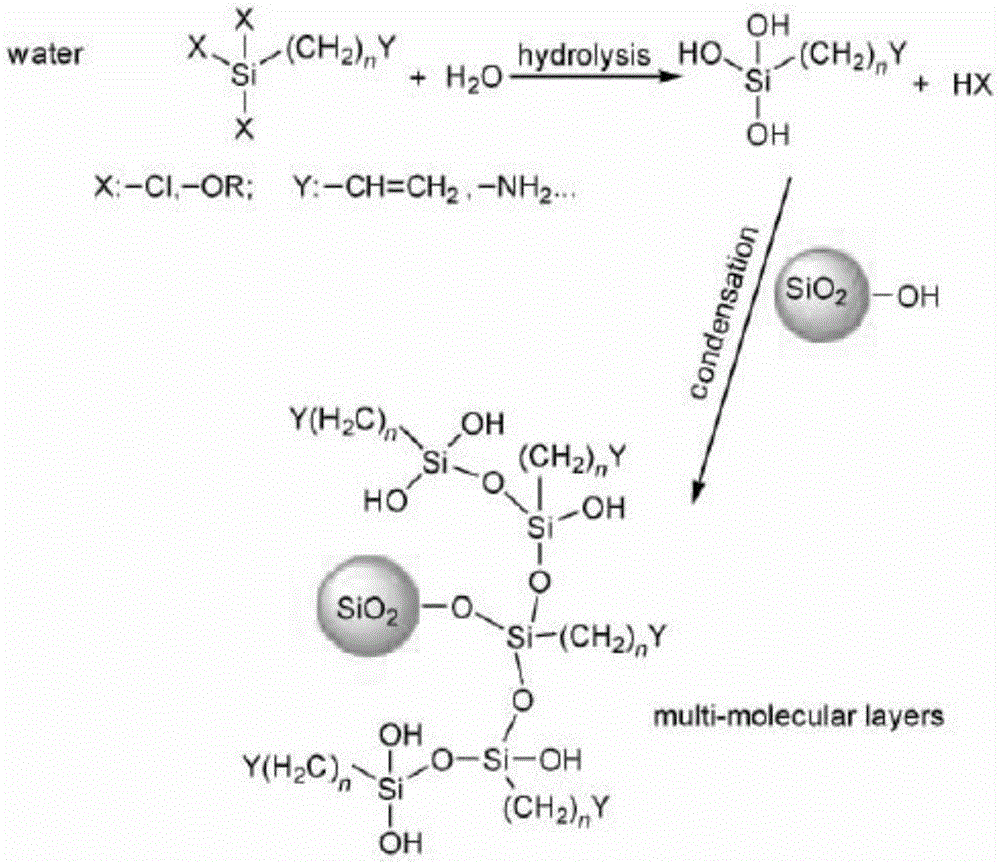

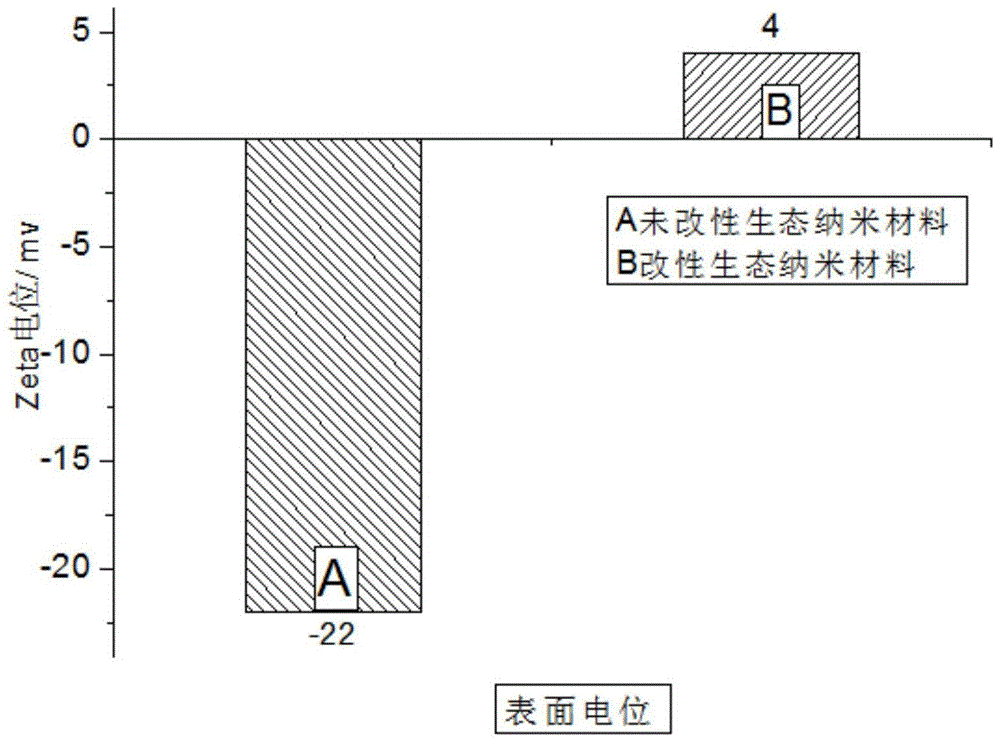

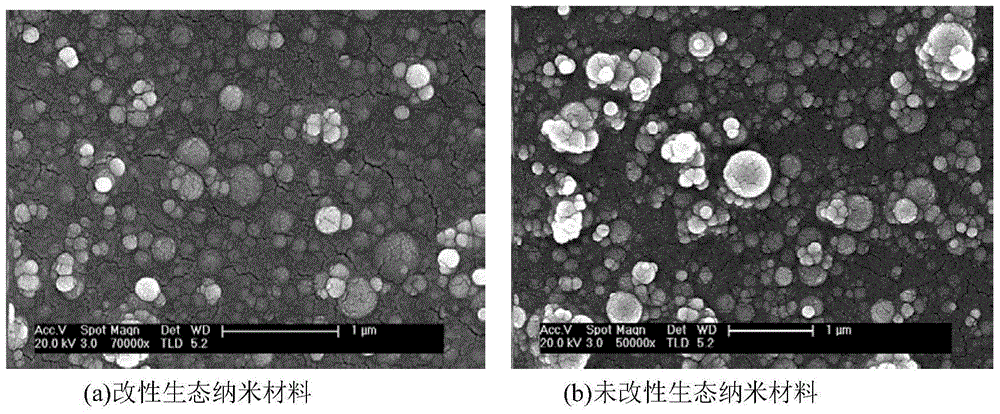

Aminosilane-modified ecological nano cementing material and preparation method thereof

ActiveCN105693164AImprove microstructureImprove mechanical propertiesWater reducerMechanical property

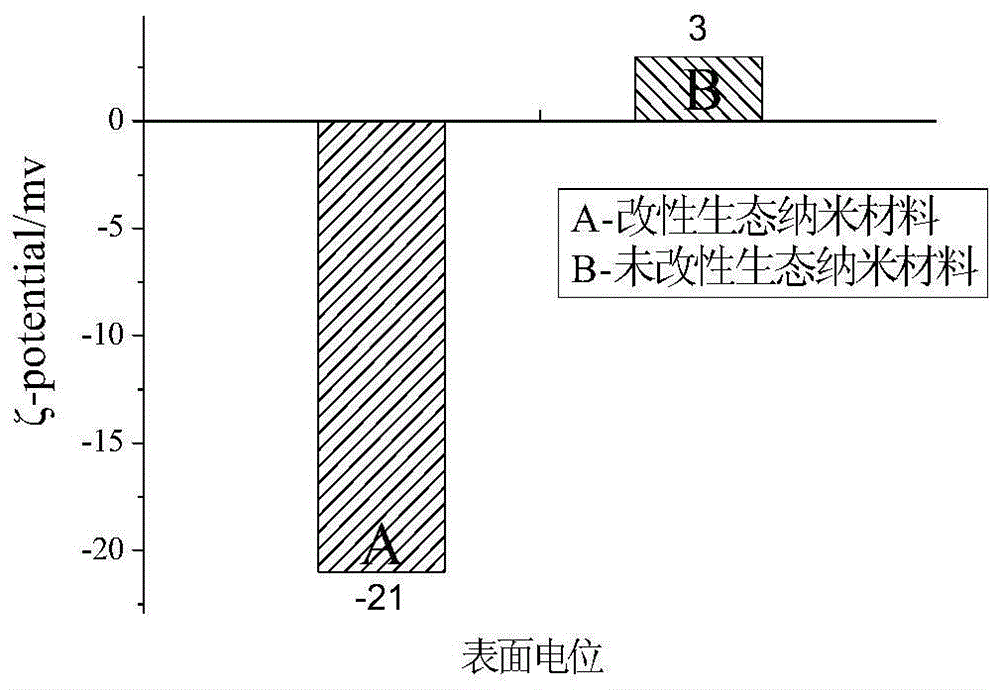

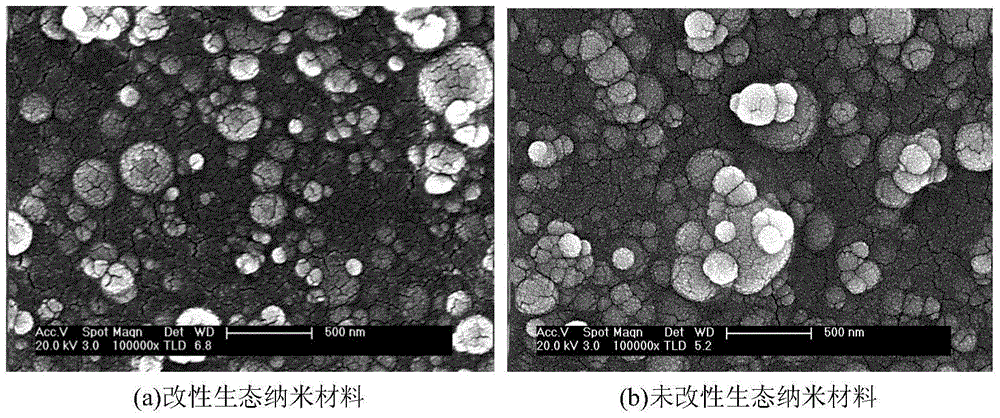

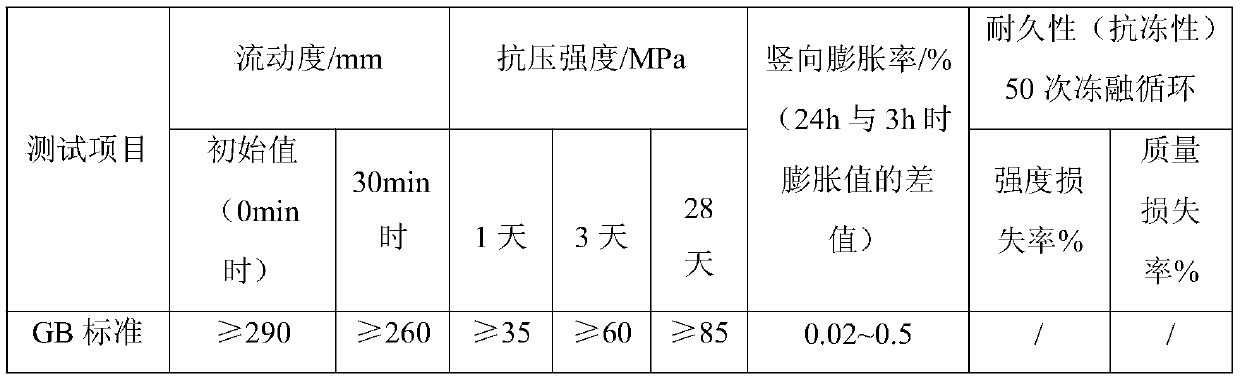

The invention discloses an aminosilane-modified ecological nano cementing material and a preparation method thereof. According to the aminosilane-modified ecological nano cementing material, the ratio of water to ash is 0.15-0.35; except the water, the cementing material is prepared from the following raw materials in percentage by mass: 35%-55% of cement, 3%-11% of an ecological nano material, 10%-20% of limestone powder, 30%-40% of flyash, 0.013%-0.024% of an aminosilane modification agent and 0.2%-2% of a water reducer. The ecological nano material silicon powder is pre-dispersed, so that the dispersibility of the ecological nano material in a cement-based material is greatly improved; the micro-aggregate effect, the filling effect and the volcanic ash effect of the ecological nano material are more fully exerted; the properties such as microstructure, the physical and mechanical properties and the durability and the like of the cementing material are more effectively improved.

Owner:SOUTHEAST UNIV

Super strength silicate cement adhesive and preparation method thereof

The invention discloses a super strength silicate cement adhesive and a preparation method thereof. The adhesive is mainly prepared from the following raw materials in percentage by weight: 30 to 40 percent of cement, 25 to 43 percent of quartz sand, 9 to 24 percent of micro aggregates, 0.9 to 2 percent of water reducing agent and 11 to 14 percent of water. The preparation method comprises the following steps of firstly, uniformly mixing the cement, the micro aggregates, the water reducing agent and the quartz sand, then continuously stirring for 4 minutes and immediately forming after taking out the mixture; after the obtained product is formed, placing the obtained product into a curing box at the temperature of 35 DEG C to carry out steaming-curing under the humidity of not lower than 95 percent, demoulding after 4 to 12 hours, and placing a demoulding specimen into hot water at the temperature of 45 to 80 DEG C to carry out curing for 48 to 96 hours; and finally, testing the qualification of the product to obtain the cement adhesive. The cement adhesive disclosed by the invention has the excellent performances of excellent compaction, high strength, excellent durability and the like, is suitable for electrotechnical porcelain products such as a high-tonnage suspension type porcelain insulator and the like and has low cost.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

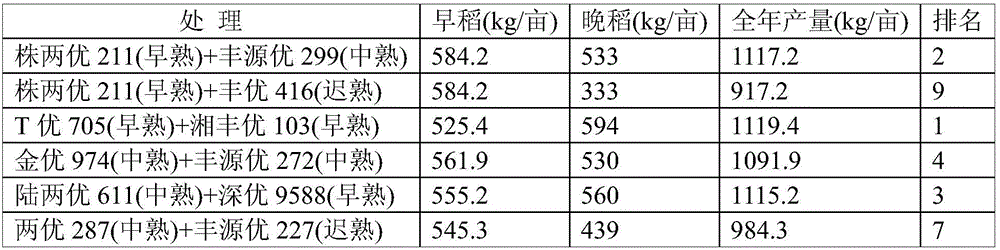

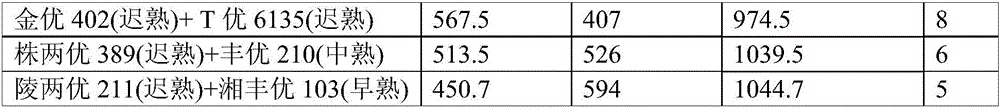

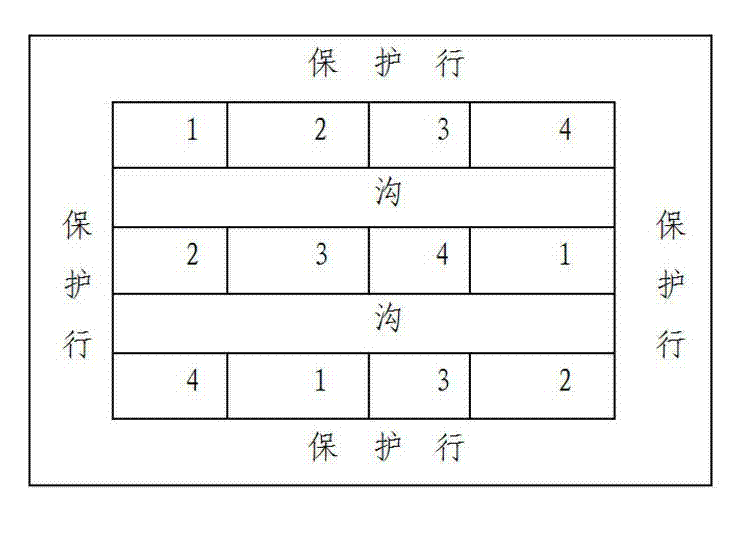

Solanum tuberosum and double cropping rice rotation crop rotation culture method for improving south double cropping rice paddy soil micro-aggregate structure

InactiveCN106069031AIncrease resourcesReduce non-point source pollutionCultivating equipmentsRice cultivationInsect diseaseEconomic benefits

The invention provides a solanum tuberosum and double cropping rice rotation crop rotation culture method for improving a south double cropping rice paddy soil micro-aggregate structure, and belongs to the field of agricultural production. The method mainly comprises the first step of solanum tuberosum high-yield cultivation and the second step of early rice and late rice high-yield cultivation, wherein the first step comprises the substeps of preparation before seeding, variety selection, cutting of seed solanum tuberosum, seeding at suitable time and coverage of straw and a mulching film, field management comprising timely film breaking, topdressing, drainage and insect disease prevention, timely harvesting, and field returning of solanum tuberosum stem leaves and straw for coverage, and the second step comprises the substeps of variety selection, seedling transplanting, filed management comprising scientific fertilization, weeding, irrigation and insect disease prevention, timely harvesting and field returning of straw. By means of the method, south double cropping rice paddy winter agriculture can be reasonably developed, the rice paddy soil micro-aggregate structure is effectively improved, soil is fertilized, economic benefits of solanum tuberosum in one season are increased on the basis of ensuring the double cropping rice yield, the purposes of improving the rice paddy soil structure and obtaining high-yield year-round crops are achieved, and the popularization value is high.

Owner:HUNAN SOIL & FERTILIZER INST

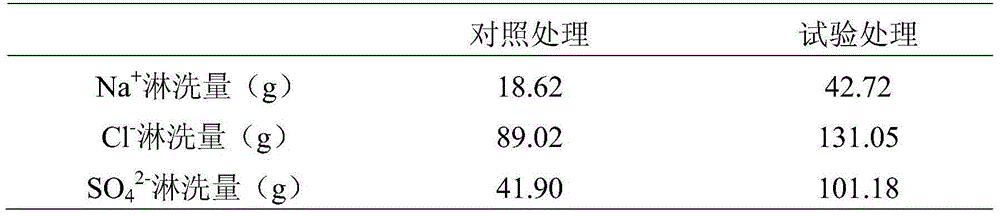

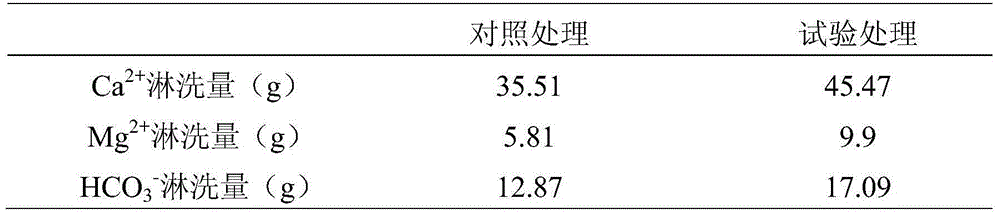

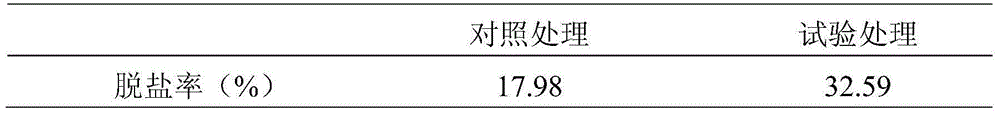

Water-soluble soil salinization improver and preparation method and application of improver

ActiveCN104449756ALight weightHigh porosityAgriculture tools and machinesOther chemical processesPorosityPhosphate

The invention discloses a water-soluble soil salinization improver and a preparation method and an application of the improver. The water-soluble soil salinization improver is prepared from guar gum, nonionic polyacrylamide, potassium polyacrylate, potassium polysilicate, citric acid and monoammonium phosphate according to a mass ratio of (5-8) to (10-16) to (10-16) to (8-18) to (30-50) to (10-20). The preparation method of the water-soluble soil salinization improver comprises the following steps: mixing guar gum, nonionic polyacrylamide, potassium polyacrylate, potassium polysilicate, citric acid and monoammonium phosphate according to a ratio, and prilling to prepare the water-soluble soil salinization improver. The application of the water-soluble soil salinization improver is characterized by spraying or irrigating the soil salinization improver to the salinization soil. The water-soluble soil salinization improver has the advantages that micro-aggregates are formed by the soil after the improver is applied to the salinization soil, the volume weight of the soil can be reduced, the total porosity of the soil is increased, the air permeability and water permeability are improved, the rate of gathering the salt of the deep soil to the earth surface is reduced, the rate of washing the salt is increased, the base exchange capacity is increased, the pH value is regulated, and the utilization value of the soil is increased.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Method for high-impermeability concrete material by wet grinding process

Owner:湖北大工防水科技有限公司

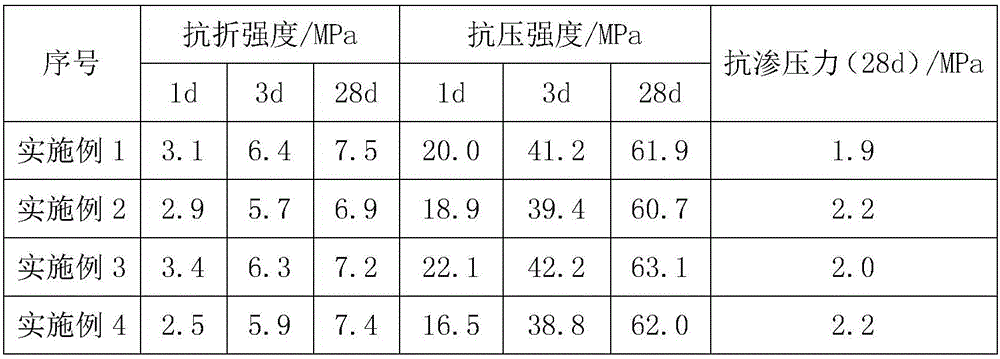

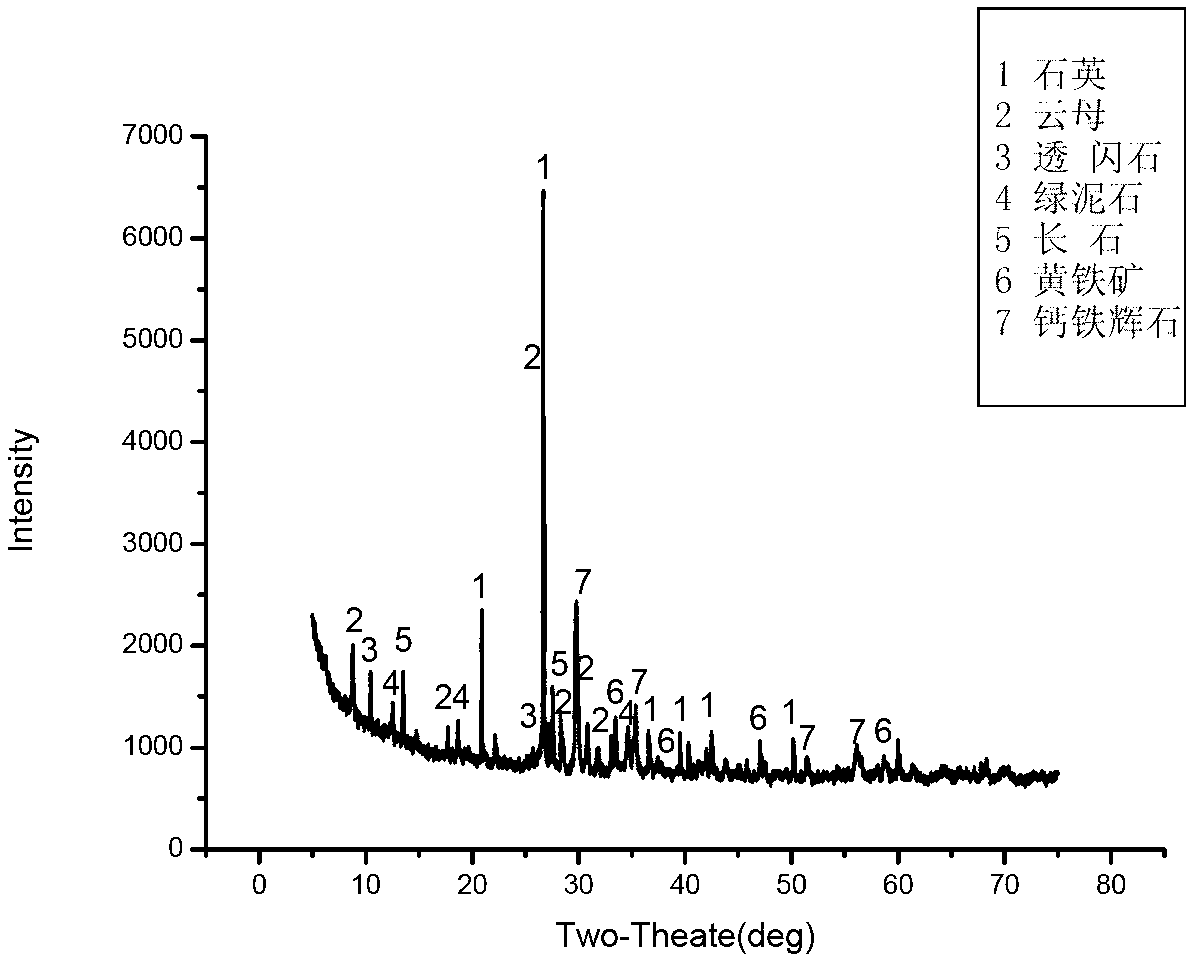

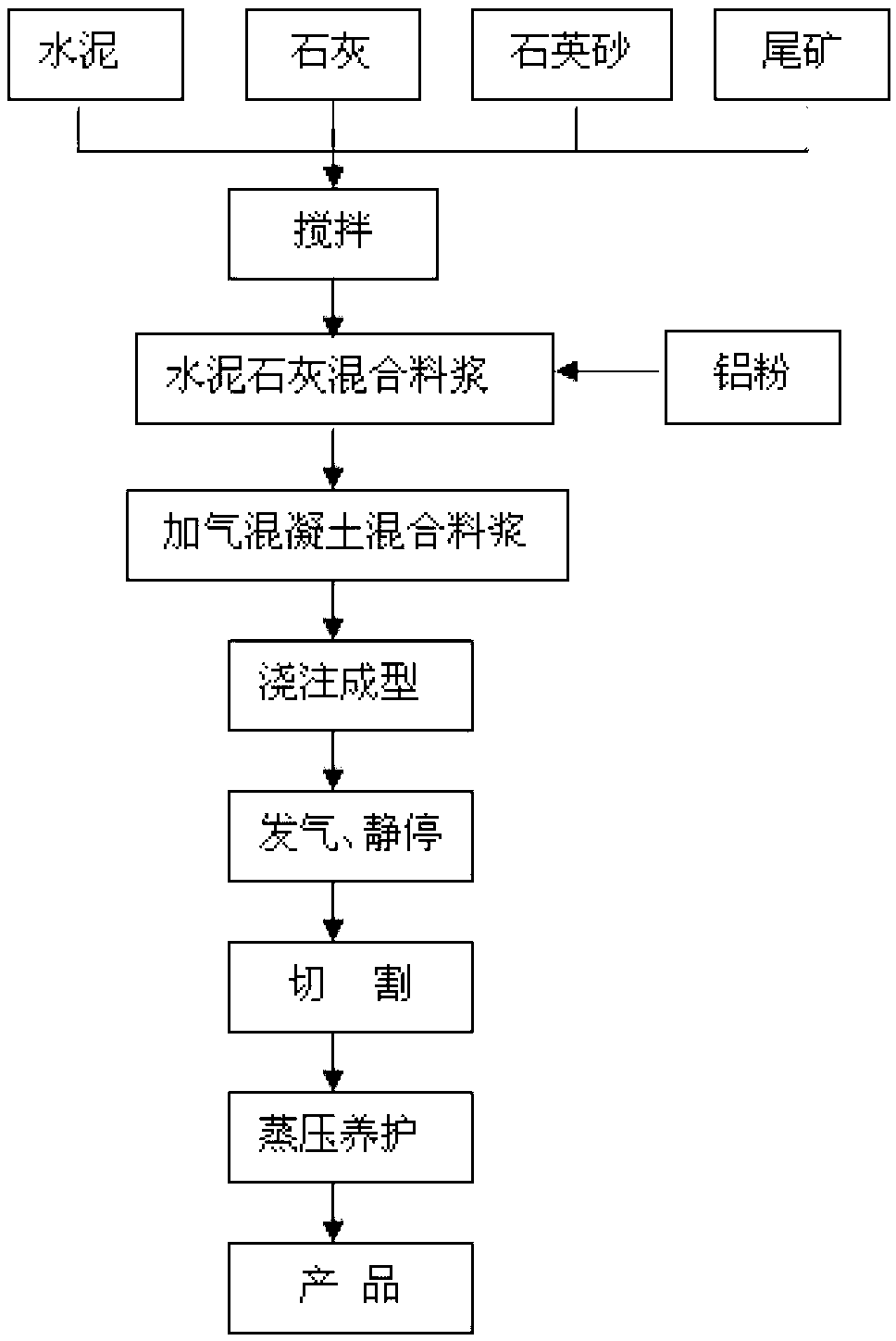

Method for preparing aerated concrete by utilizing lead zinc tailings

The invention discloses a method for preparing aerated concrete by utilizing lead zinc tailings. A part of quartz contained in the lead zinc tailings is utilized; silica in the part and calcium hydroxide can be subjected to hydro-thermal synthesis; a part of ultra-fine silicate minerals are taken as the lead zinc tailings of micro aggregates to be well combined with hydrated calcium silicate, so that the strength of silicate aerated concrete is enhanced. A part of fine quartz sand is doped, so that the defects that the quartz content namely the silica content is not enough in the lead zinc tailings are compensated; the content of the hydrated calcium silicate in hydro-thermal synthesis can be improved; the physical properties of the silicate product of the lead zinc tailings are improved. The density of the lead zinc tailings is high; the formed slurry is fast in sedimentation velocity, and isolated, so that the aeration stability of the aerated concrete of the lead zinc tailings is affected; the viscosity and the fluidity of the slurry are adjusted by adding polyvinyl alcohol (PVA) and milling diatomite; the sedimentation velocity is reduced; the aeration is smooth, so as to reduce the density of the product. By using a novel water reducer and a foam stabilizer, the pore structure is improved; the compressive strength of the product is also improved.

Owner:JIANGSU EAST CHINA MINE TAILINGS MANAGEMENT ENG +1

Pervious concrete

The invention discloses pervious concrete which is characterized in that the pervious concrete is prepared from the following components in parts by mass: 1500-1600 parts of coarse aggregate, 320-420parts of a cementing material, 105-114 parts of water and 4.5-5.9 parts of a water reducing agent. An anti-corrosion material in the formula has remarkable plasticizing effect, micro-aggregate effect,morphological effect and temperature peak reduction effect, and the mechanical property, abrasion resistance and denudation resistance of the pervious concrete can be improved through the excellent characteristics of the anti-corrosion material itself and the improvement of the continuous grading of the microstructure of the cementing material, so that the durability of the pervious concrete is improved, and the service lifetime of the pervious concrete is prolonged.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

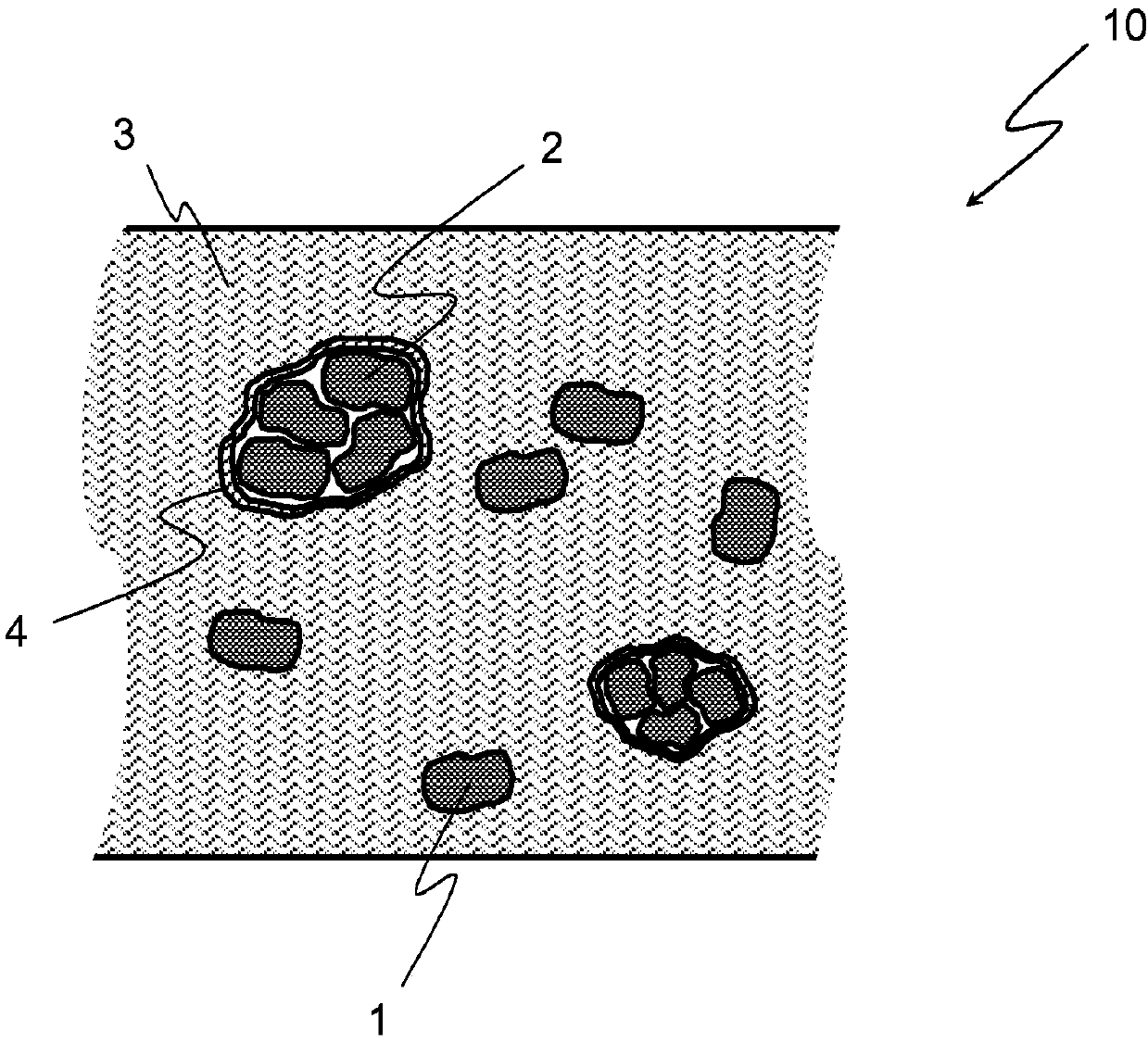

Desiccant composition for moisture-sensitive electronic devices

A desiccant composition containing a polymeric binder (3) and a dispersion of powders of desiccant materials (1, 2), in which the desiccant powders (1, 2) are dispersed at least in part in the form of micro aggregates of desiccant particles (2) surrounded by a polymeric encapsulating material (4) having a different composition with respect to the polymeric binder (3).

Owner:SAES GETTERS SPA

Mineral admixture for high durable concrete

InactiveCN102452805AImprove compactnessIncreased durabilityCalcium hydroxideUltimate tensile strength

A mineral admixture for high durable concrete. Two materials of siliceous dust and calcium hydrate are mixed according to a proportion, wherein the siliceous dust accounts for 20-50 weight parts and the balance is calcium hydrate. The fineness of the siliceous dust: its specific surface area is 18000m<2> / Kg. The content of silica is greater than 85%. The fineness of calcium hydrate is 0.045. The screen over-size is not greater than 4g. The purity is 90%. The fine siliceous dust and calcium hydrate are mixed according to a certain proportion to form the novel mineral admixture based on secondary hydration effect and micro-aggregate effect. The addition of the mineral admixture in cement contributes to cement strength and performance mainly in three aspects as follows: pozzolanic effect, particle filling effect and interface effect can greatly raise density of high-performance concrete and enhance durability and strength of high-performance concrete.

Owner:XINJIANG YANKE ENERGY SAVING TECH

Energy storage thermal insulation building material

ActiveCN102877553AHigh compressive strengthLarge energy storage capacityClimate change adaptationPassive housesBrickMass ratio

The invention relates to an energy storage thermal insulation building material which has the main characteristics that a pasty inorganic phase change energy storage material PCM is coated into a hollow high heat conductivity carbon-based functional material to form an energy storage coating body; oil shale residue powder, water glass, sodium hydroxide solution and cement are stirred and uniformly mixed into a slurry material according to the mass ratio; the energy storage coating body is added into the slurry material and the mixture is cast into a shape of a common brick body or other shapes; and the volume ratio of the slurry material to the energy storage coating body is 1:1 to 1:4. The energy storage thermal insulation building material has the advantages that the PCM has large energy storage capability and a low phase transformation point, so that the solid-liquid separation is avoided and the undercooling problem is solved; the carbon-based functional material is used as a coating material, so that the leakage of a liquid phase is prevented and the corrosion problem of the inorganic phase change material is solved; and the application of the oil shale residue powder which is used as a main body building material utilizes the activity effect, the morphological effect and the micro aggregate effect of the oil shale residue powder and aims to increase the absorption rate of the building material for the light as further as possible on the basis of not influencing the compression strength of the building material, achieve the effects of high efficiency, energy saving, heat preservation and energy consumption reducing and ensure the energy storage thermal insulation building material to have high practicality.

Owner:扬州欧拉工业设计有限公司

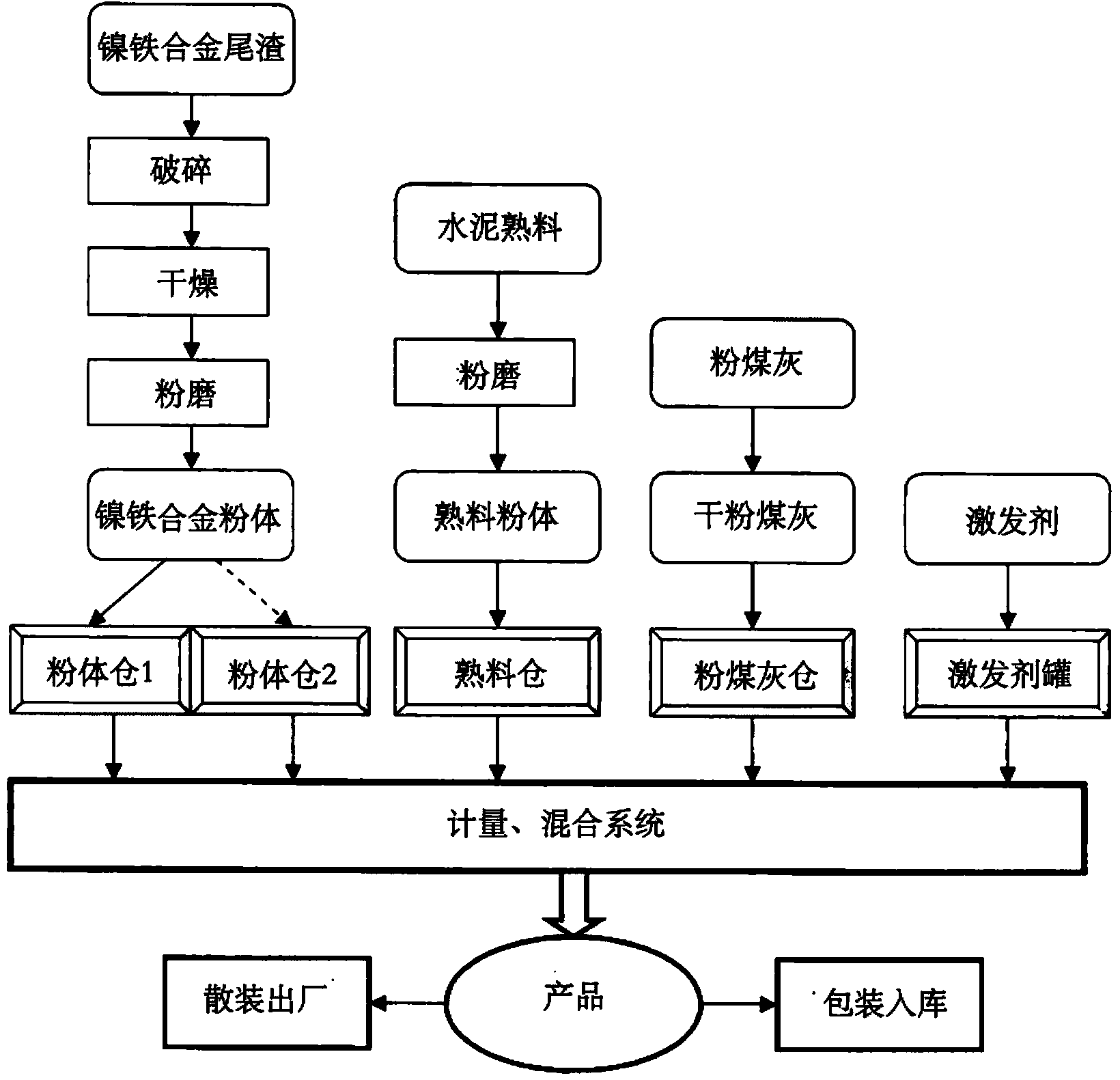

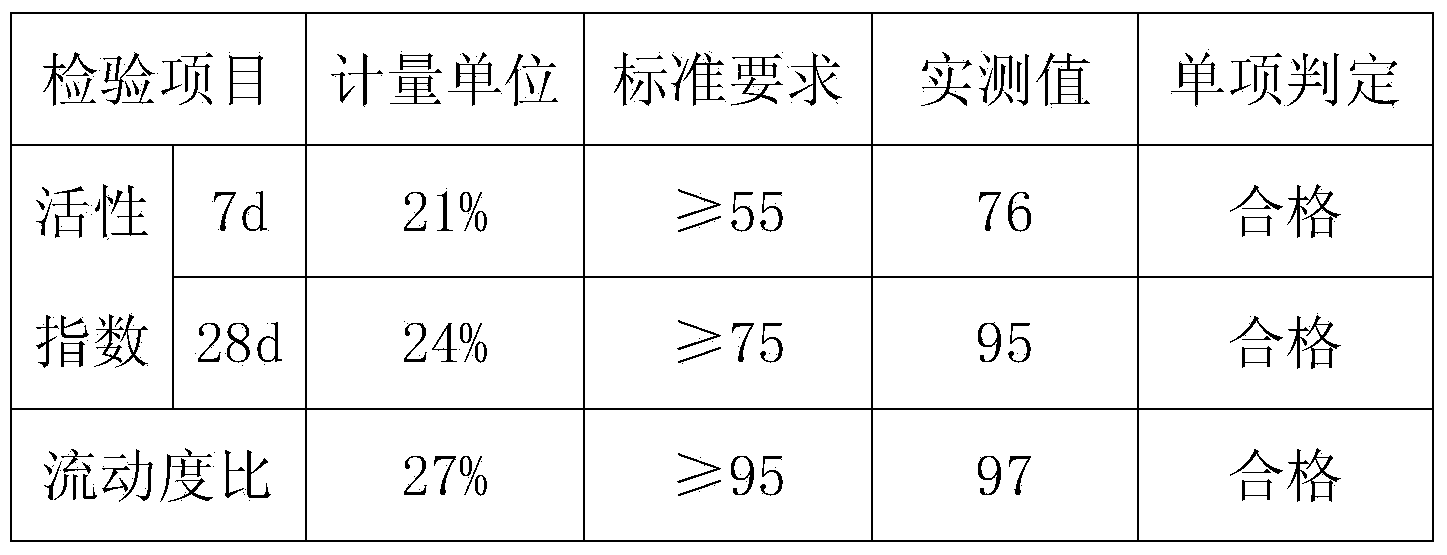

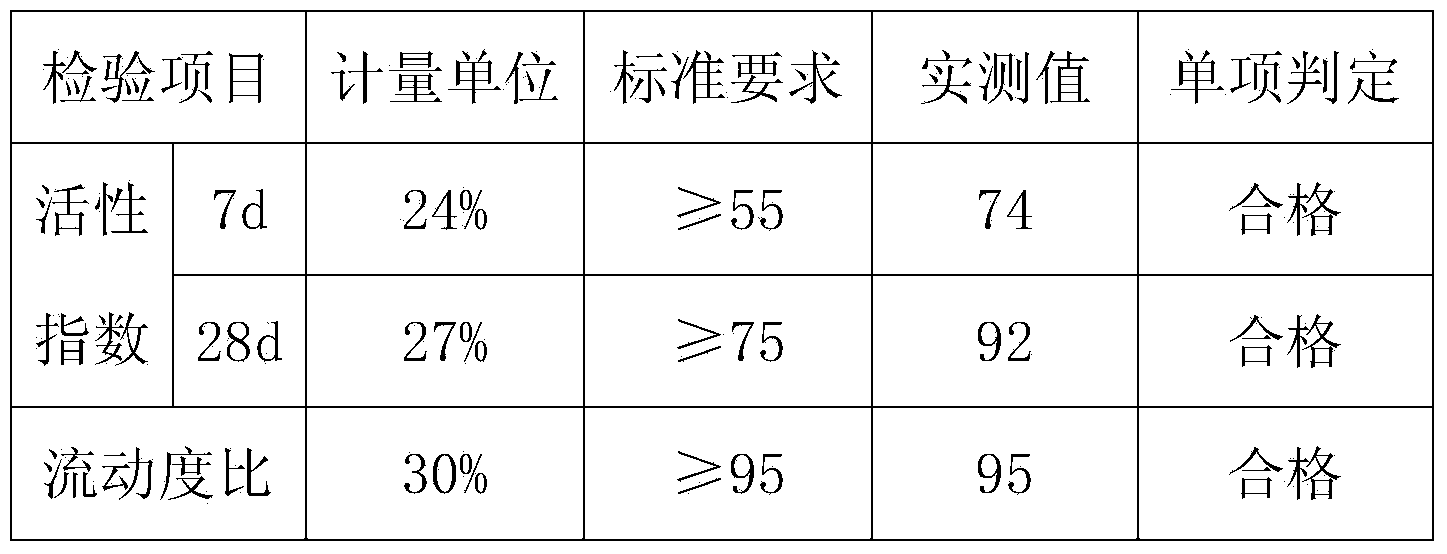

Method of producing environmental friendly active cement-based composite material by utilization of iron-nickel alloy tailings

InactiveCN104163583AImprove mechanical propertiesHas a volcanic effectClinker productionBiological activationMechanical property

The invention discloses a method of producing an environmental friendly active cement-based composite material by utilization of iron-nickel alloy tailings. The method is characterized in that: the composite material is prepared by mixing 3-5% of iron-nickel alloy powder, 3-5% of clinker powder, 3-5% of dry coal ash and 3-5% of an activator. The beneficial effects of the method are that: addition of the iron-nickel alloy tailings into the cement clinker after the iron-nickel alloy tailings are modified by processing and activation is simple and easy to operate; the method plays a positive role for recycling of industrial solid waste, improvement of the comprehensive utilization rate of resources, and saving and reasonable effective utilization of the resources; and the obtained cement-based composite material is capable of 1) enhancing mechanical properties of concrete, 2) reducing the engineering cost of cement and concrete, 3) significantly reducing heat of hydration of concrete, improving concrete workability, reducing segregation and water bleeding, reducing temperature changes and internal pressure of large-volume concrete, and inhibiting cracks generated by temperature differences, 4) inhibiting concrete alkali-aggregate reactions, and 5) having a micro-aggregate effect.

Owner:把正春

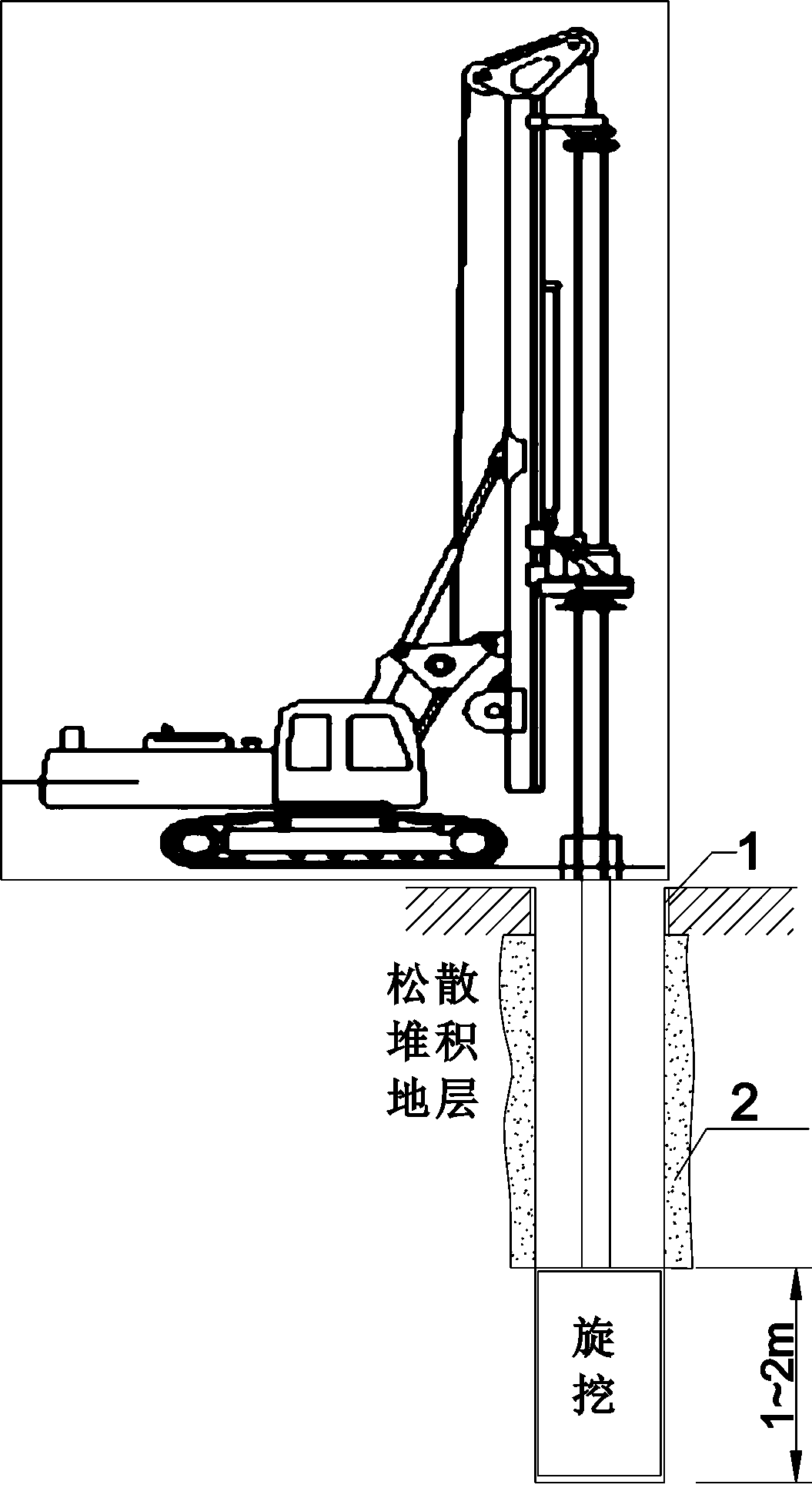

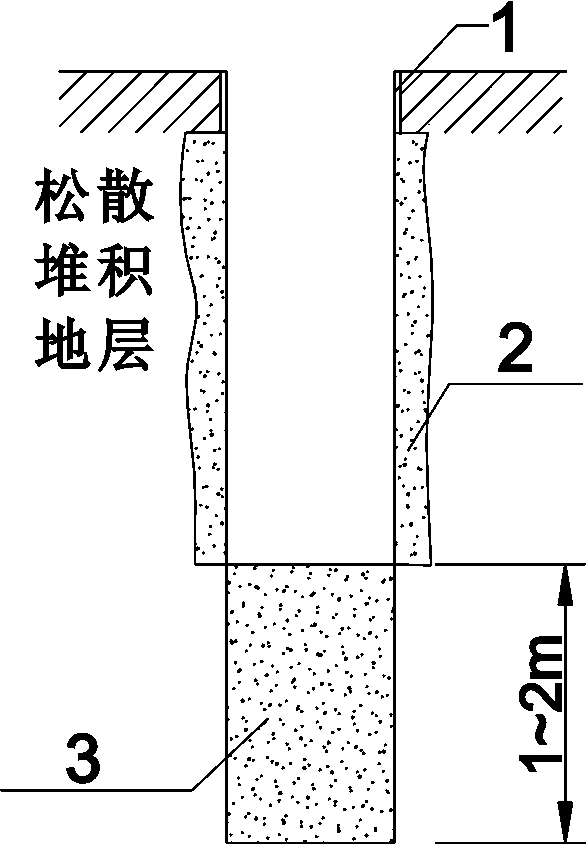

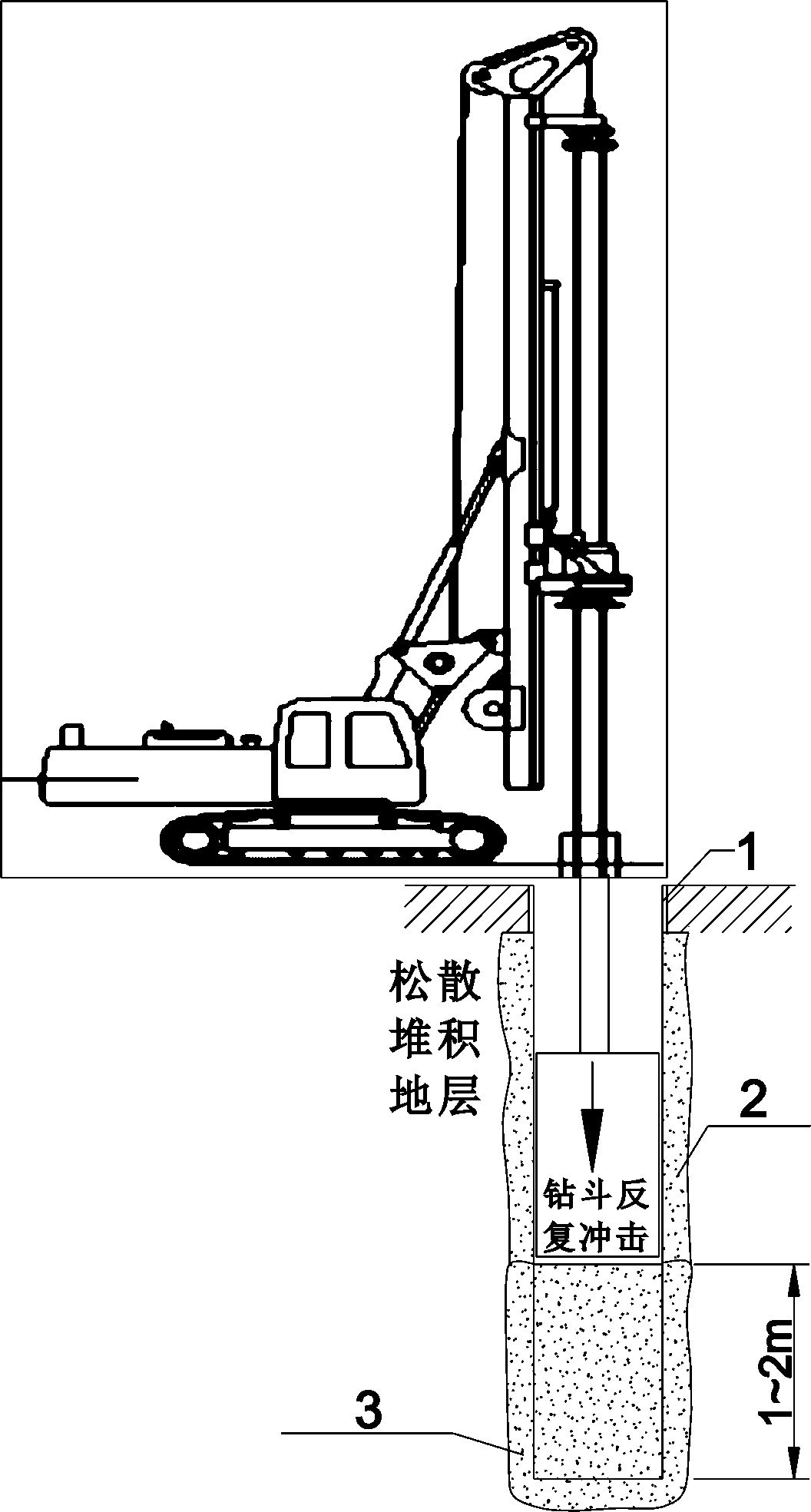

Loose accumulation body stratum concrete protection wall rotary excavating quick pore forming method

InactiveCN110185386ASimple structureEasy to operateBulkheads/pilesDrilling machines and methodsSlurrySoil horizon

The invention discloses a loose accumulation body stratum concrete protection wall rotary excavating quick hole forming method. The method mainly comprises the following construction steps of conducting measurement lofting, burying a steel retaining cylinder at a hole opening, conducting construction through a rotary drill rig to drill into a loose soil layer by the pile hole depth of about 2 m and lifting up the rotary drill rig; filling micro-aggregate concrete into a pile hole and descending a drill of the rotary drill rig to repeatedly impact and squeeze concrete downwards to press the micro-aggregate concrete or grout into a surrounding loose accumulation body under the action of a certain impact pressure; conducting initial setting for 1-2 days, conducting construction through the rotary drill rig again after the micro-aggregate concrete or the grout reaches a certain strength, conducting rotary drilling on the solidified concrete in the drilled hole previously, and squeezing thesolidified concrete into the surrounding loose accumulation body and adhering the solidified concrete to the hole wall to form a circle of concrete solidified body protective wall. Through the looseaccumulation body stratum concrete protection wall rotary excavating quick hole forming method, the rotary drilling rig can conduct effective drilling in a loose rock-soil accumulation body stratum, the construction progress is accelerated, the phenomena of hole collapse, drill jamming and the like are avoided, and the hole forming quality is improved.

Owner:SICHUAN ROAD & BRIDGE GRP

Ecological self-compact concrete

The invention discloses ecological self-compact concrete. The ecological self-compact concrete is prepared from the following components: a volume fraction of coarse aggregates is 0.35 to 0.38, a volume fraction of fine aggregates is 0.34 to 0.43, a volume fraction of micro aggregates is 0.01 to 0.10, the consumption of cement is 180 to 380 kg / m<3>, the consumption of mineral admixtures is 120 to300 kg / m<3>, the consumption of a water reduction agent is 0.5 to 2.0 percent of the consumption of gel materials, a doping amount of macromolecular rheology modifier is 0.001 to 0.05 percent of the weight of the gel materials, and the doping amount of the mineral rheology modifier is 1 to 5 percent of the weight of the gel materials. The fine and micro aggregates are adopted to compensate a grading gap between the gel material and the fine aggregate, the inclusion force of slurry for the aggregates can be increased by virtue of the macromolecular rheology modifier or the mineral rheology modifier, and the high mobility and separation resistance of the concrete can be maintained under the condition of little slurry. Due to the excellent workability of the self-compact concrete, the cost ofthe ecological self-compact concrete provided by the invention is significantly decreased, and a valuable way for promoting the self-compact popularization and application can be provided.

Owner:WUHAN UNIV OF TECH

Paste filling material for mine and preparation method of paste filling material

The invention relates to a paste filling material for a mine and a preparation method of the paste filling material, and belongs to the technical field of coal mining. By taking building wastes as rawmaterials, the cohesiveness of recycled aggregates and fresh mortar is enhanced; meanwhile, particles with relatively small particle size and a cementing material form a grading system microscopically; filling water originally filling pores are replaced to become free water, so that the flowability of slurry is improved; a large number of pores formed in a hydration process are filled with the slurry through a micro-aggregate effect, so that the structure of a mortar hardened body is compacted, and the strength and the impermeability of mortar are substantially improved; meanwhile, by addingof additives such as polyaluminum and calcium chloride, erosion by the cementing material to reinforced recycled aggregates is accelerated, synergistic hydration of the cementing material and the reinforced recycled aggregates is promoted, the porosity of slurry is reduced, and the compactness of the slurry is improved; furthermore, a hydrated product with high intensity and high stability can beproduced, and a filling material with high overall intensity is formed; moreover, the initial setting time and the final setting time are short; waste resources are comprehensively used.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

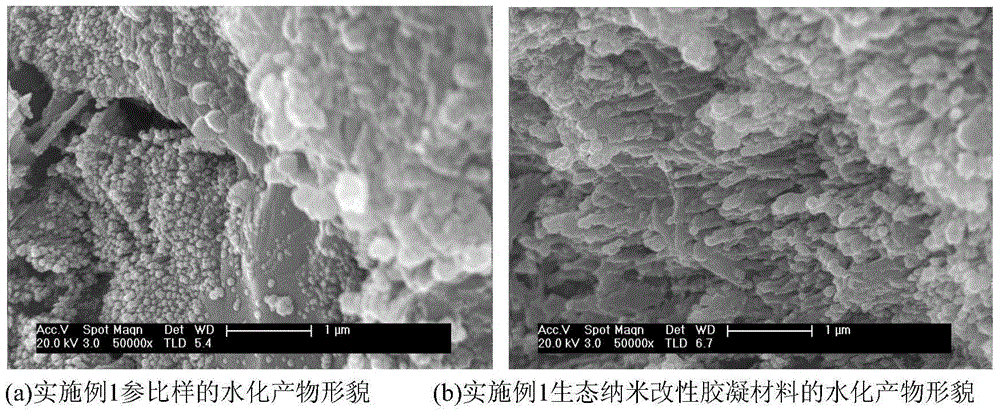

Modified ecological cementing nano-material and preparation method therefor

The invention relates to a modified ecological cementing nano-material and a preparation method therefor. According to the modified ecological cementing nano-material, the water cement ratio is 0.15 to 0.35; and the modified ecological cementing nano-material contains other ingredients in percentage by mass: 35% to 55% of cement, 3% to 11% of modified silica fume, 10% to 20% of limestone flour, 30% to 40% of high-quality I-class low-calcium fly ash and 0.2% to 2% of efficient water reducing agent. Through carrying out predispersing treatment on the silica fume of the ecological nano-material, the dispersity of the ecological nano-material in a cement-based material is greatly improved, so that the micro-aggregate effect, filler effect and volcanic ash effect of the ecological nano-material are more sufficiently exerted. By adding the high-quality limestone flour, the grain size distribution is further optimized, the cohesiveness of cementing material blended slurry is effectively improved, the compactness of a hardened cementing material is improved, and the microstructure of the cementing material is improved. Meanwhile, by adding the fly ash, the fluidity and later strength of cement slurry are improved, and the microstructure of the cementing material is improved.

Owner:SOUTHEAST UNIV

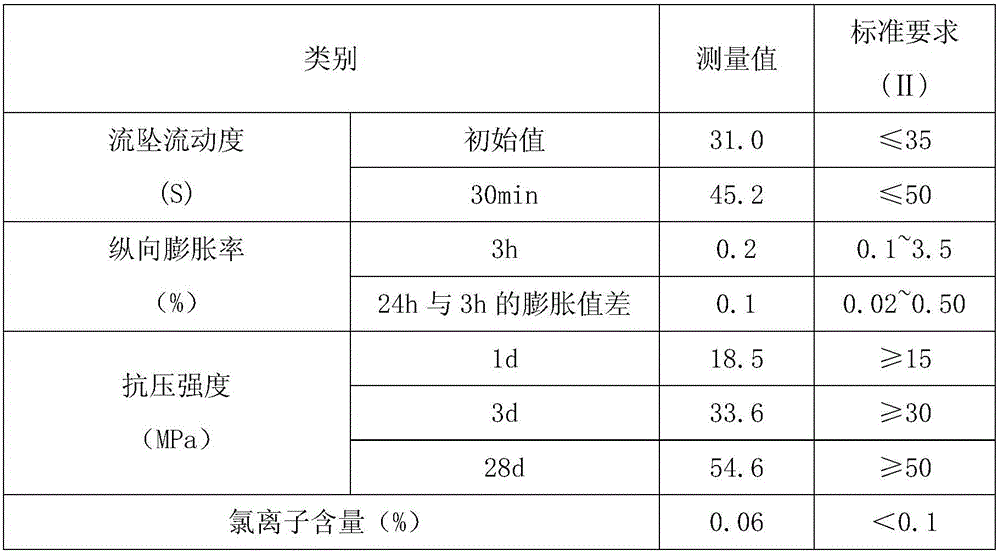

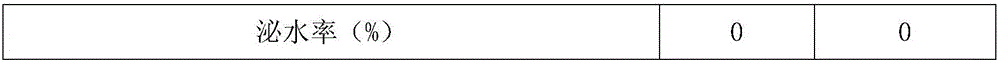

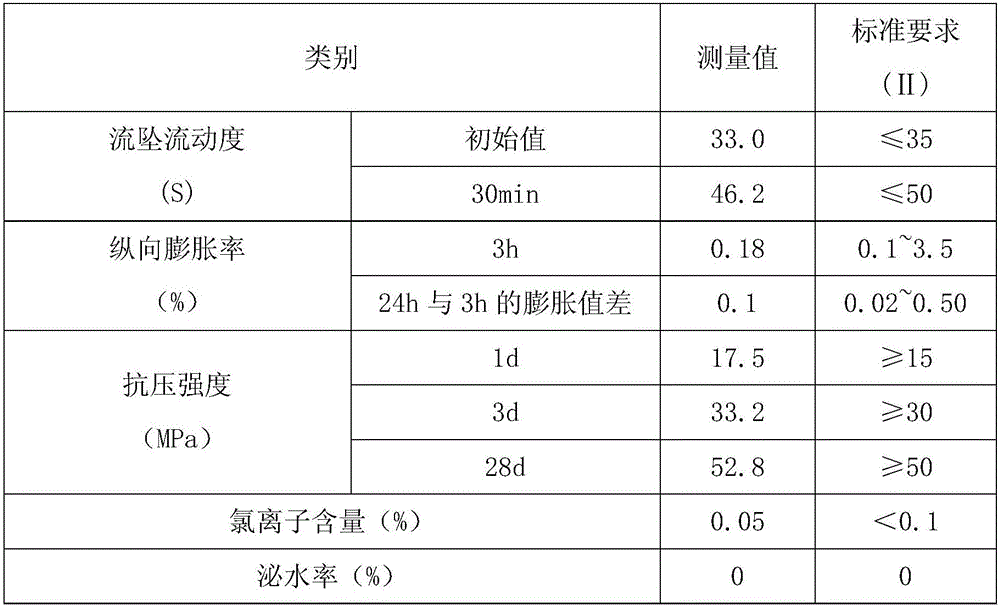

Self-repairing grouting material and preparation method thereof

The invention provides a self-repairing grouting material and a preparation method thereof. The self-repairing grouting material is prepared by mixing grouting material powder with water, wherein thegrouting material powder is prepared from, by mass, 40%-50% of a cementing material, 5%-15% of micro aggregate, 40%-50% of fine aggregate, 0.01%-1% of an admixture and 1%-5% of a self-repairing agent.The preparation method comprises the steps that step 1, sulphoaluminate clinker is prepared; step 2, the raw materials are uniformly mixed separately as required; step 3, a chemical repair agent anda catalyst which cooperate with each other are selected; step 4, the raw material components are mixed uniformly according to the mass percentage to prepare the grouting material powder; step 5, the grouting material powder is mixed with the water to prepare the self-repairing grouting material. The self-repairing grouting material can repair cracks, the preparation steps ares simple, the operation is convenient, and the prepared self-repairing grouting material has high strength, high fluidity and durability.

Owner:中建科技湖南有限公司

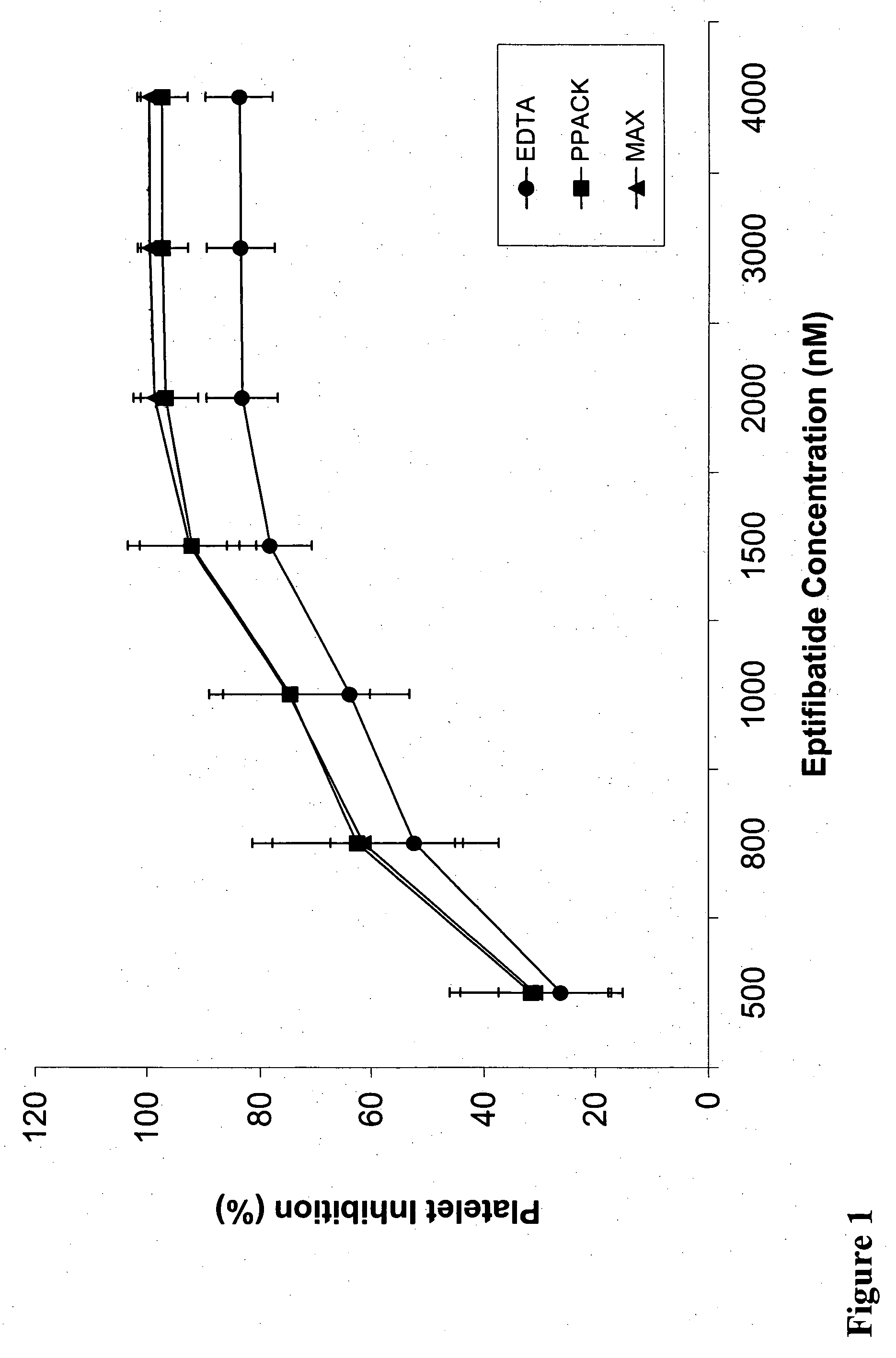

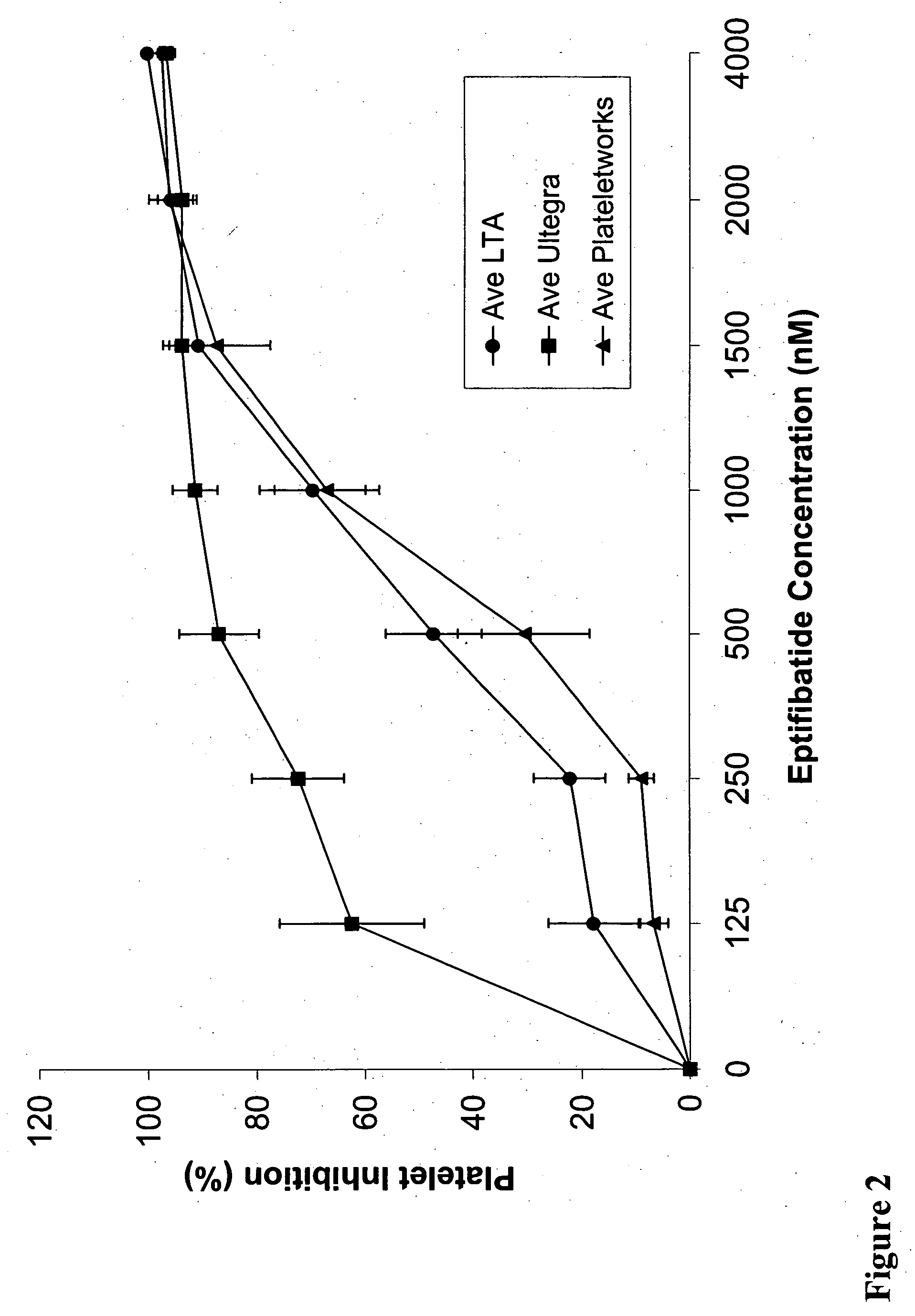

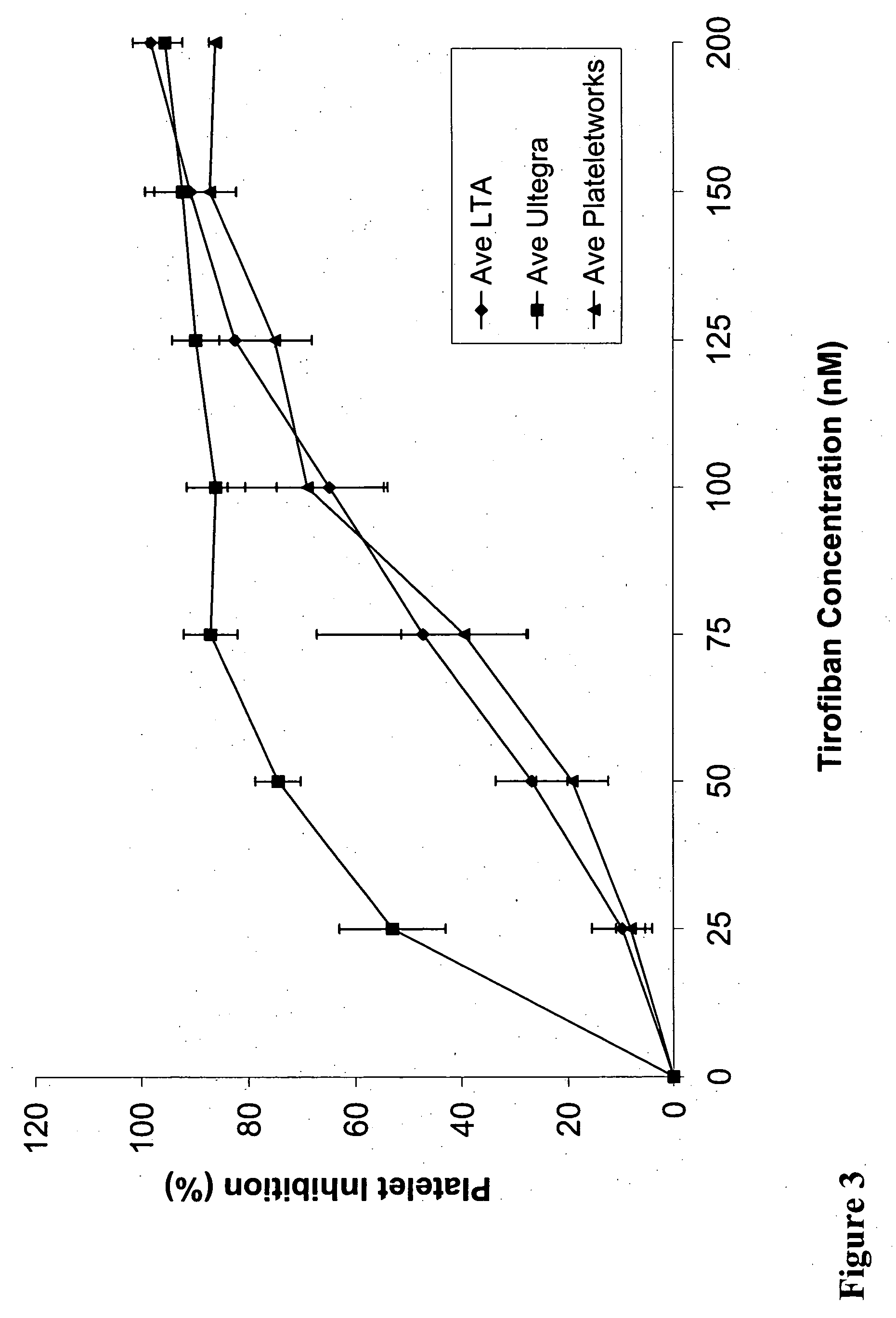

Methods for assessment of platelet aggregation

InactiveUS20050019742A1Easy to manageImprove accuracyDead animal preservationMonitoring particle agglomerationPoint of careHematology analyzer

Methods for measuring platelet aggregation in a blood sample, for measuring the efficacy of anti-platelet therapies at the point of care, and for detecting the presence of platelet micro-aggregates in a blood sample. Several differences between the methods of the present invention and previously disclosed procedures for practicing such methods while using a hematology analyzer will allow for achieving about 0.98 correlation relative to light transmission aggregometry. These differences allow the methods of the present invention to be used at the point of care for assessing, e.g., the efficacy of anti-platelet therapy, particularly GPIIb-IIIa antagonists.

Owner:UNIV OF TENNESSEE RES FOUND

Method for preparing cement-based grouting material from phosphorus solid wastes through wet grinding technology

ActiveCN105819811APotential active energy consumption is lowReduce manufacturing costSolid waste managementPhosphogypsumCrusher

The invention discloses a method for preparing a cement-based grouting material from phosphorus solid wastes through a wet grinding technology. The method comprises the following steps: carrying out grading crushing on 50-150 parts of phosphorus tailings, and sieving the crushed phosphorus tailings to obtain phosphorus tailing powder; crushing 50-90 parts of phosphorus residues through a crusher to form phosphorus residue powder; adding 6-12 parts of phosphogypsum, 0.5-0.8 parts of a grinding aid, 5-10 parts of an alkali activator and 50-65 parts of water to the phosphorus residue powder, placing the obtained mixture in a ball mill, carrying out ball milling, and ageing the ball-milled mixture for 2-5h to obtain a slurry; and taking 100 parts of cement, 0.8-1.5 parts of a water reducer, 5-8 parts of an expanding agent and 1.0-1.8 parts of an antifoaming agent, adding the phosphorus tailing powder and the slurry, and uniformly stirring all above materials in a stirrer to obtain the cement-based grouting material. The phosphorus solid wastes are adopted as a main raw material, wet grinding is adopted to substitute dry grinding, and the phosphorus tailings are adopted as aggregates, so the close packing and micro-aggregate effects are realized through particle size control, the potential activity of raw materials is fully displayed, and the cement-based grouting material has the advantages of good compactness, low energy consumption and low production cost, and can be applied to industries and building engineering.

Owner:HUBEI UNIV OF TECH

Gelling foamed concrete and preparation method thereof

The invention discloses gelling foamed concrete which contains cement, a fine aggregate, a coarse aggregate and an active micro aggregate. The foamed concrete is characterized by containing resin andan auxiliary agent. The resin contains modified unsaturated polyester resin which is rubber modified unsaturated polyester resin. The rubber modified unsaturated polyester resin is rubber modified epoxy vinyl ester resin. The invention also provides a preparation method of the gelling foamed concrete. The preparation method comprises the following steps: (1) carrying out a polymerization reactionon a preparation raw material of rubber and epoxy vinyl ester resin under the action of an initiator to prepare the rubber modified unsaturated polyester resin; (2) preparing an accelerator; (3) preparing foam and gel slurry; and (4) stirring and mixing the foam, gel slurry and an auxiliary agent to prepare the gelling foamed concrete.

Owner:刘沛灵

Conditioner for steppe soil of mud flat saline-alkaline land, and preparation method thereof

InactiveCN110156537AImprove the ecological environmentAltered salinization statusFertilizer mixturesAlkali soilMicrobial agent

The invention discloses a conditioner for steppe soil of mud flat saline-alkaline land, and a preparation method thereof. The conditioner for grassland comprises a blocking agent, an acid regulator, an organic fertilizer and a microbial agent. Aspergillus hyphae are used to wrap soil particles with a network structure in order to form a biologically-active soil aggregate structure, and Aspergillusflora and the blocking agent act together to promote the formation of soil micro-aggregates in order to improve the physical properties of soil, such as the structure and the permeability; and an inert material and organic metabolites are organically integrated to improve the soil texture and accelerate the ripening of a tillage layer, spontaneously form a saline-alkaline isolation layer at the plow ground layer, inhibit saline-alkaline recovery and prevent the salinization of repaired soil, so the purpose of fundamental control of the saline-alkaline land is achieved.

Owner:北京中农煦丰生态科技有限公司

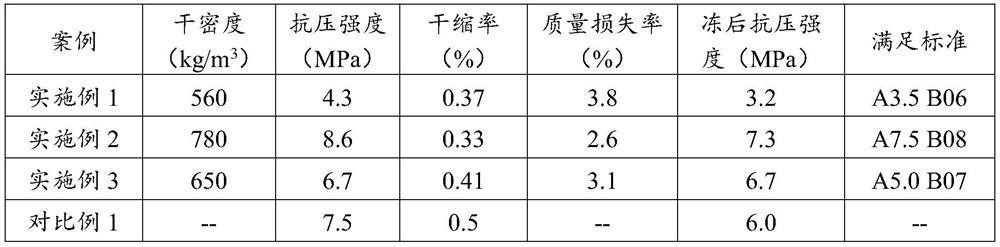

Autoclaved aerated concrete block and preparation method thereof

Owner:HUNAN UNIV OF SCI & TECH

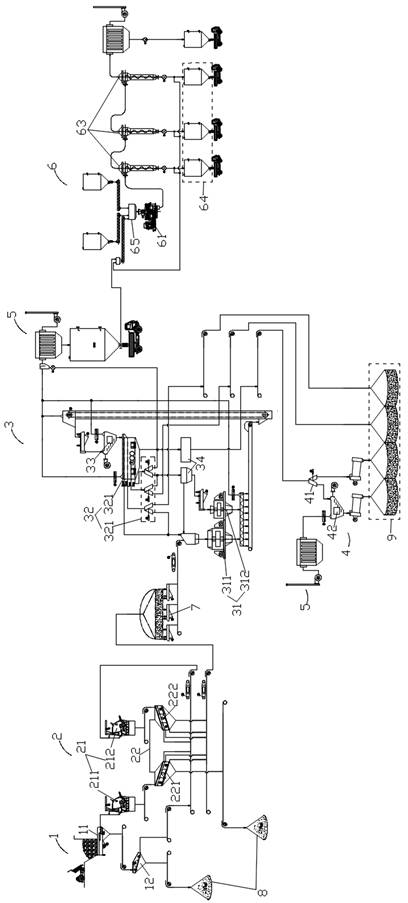

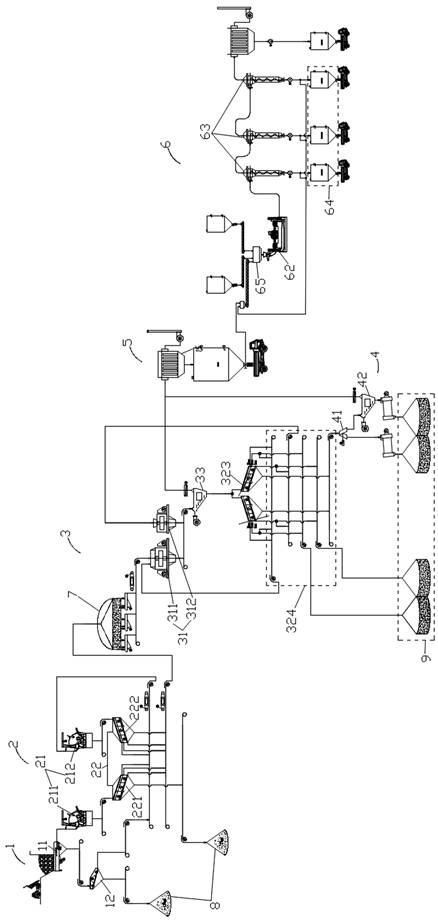

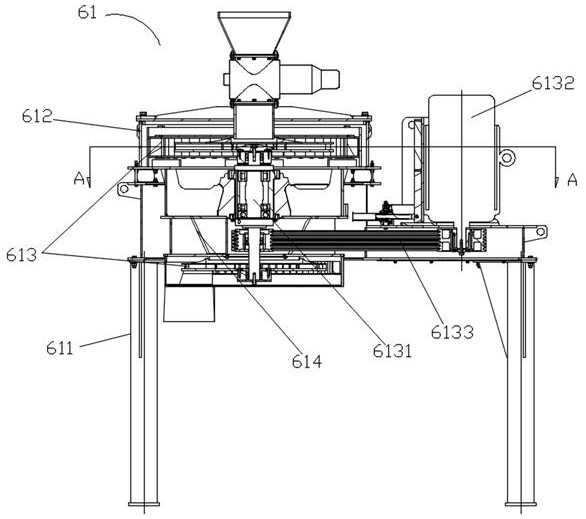

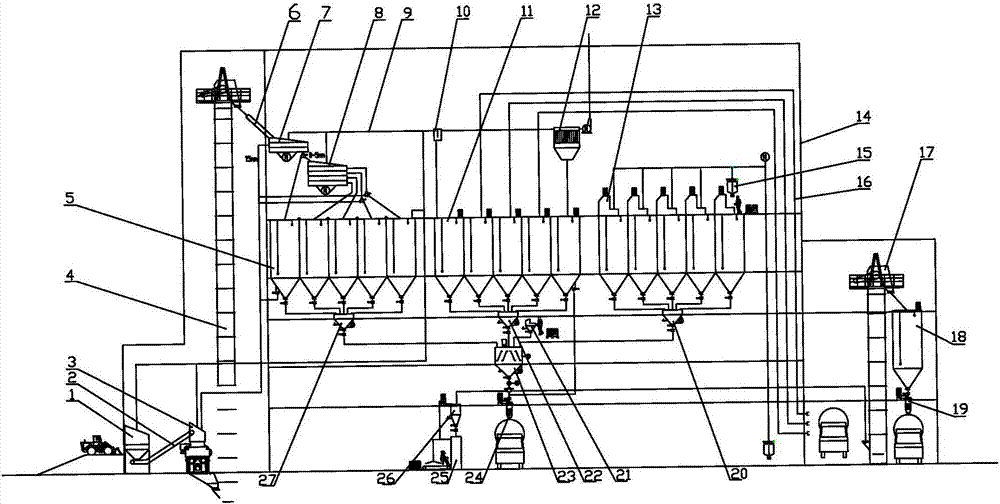

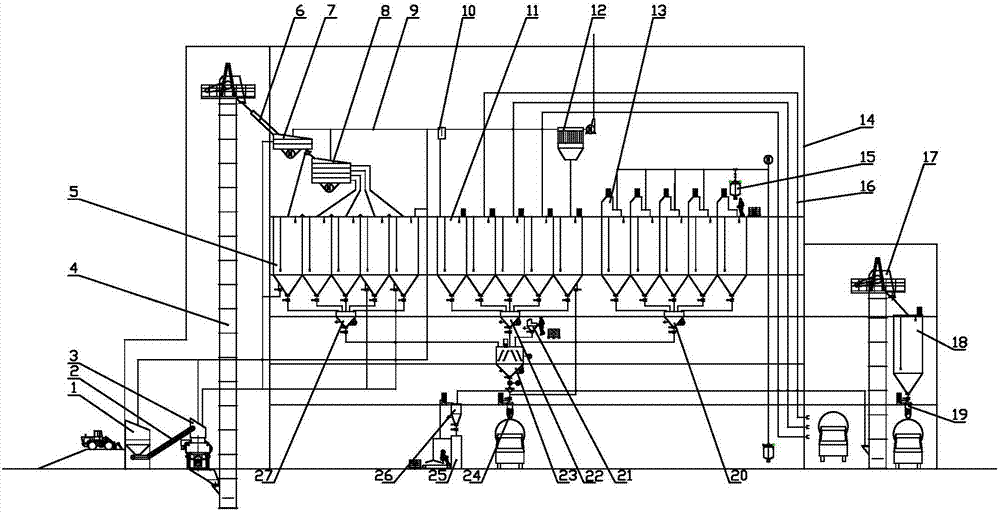

Thick-thin micro aggregate 6S processing process for concrete and production line

The invention discloses a thick-thin micro aggregate 6S processing process for concrete and a production line. The thick-thin micro aggregate 6S processing process comprises the following steps: pretreating materials; performing circulatory multi-stage rough crushing and multi-stage desliming; performing circulatory multi-stage fine crushing and multi-stage powder concentrating, and preparing finesand and aggregates of different specifications and different limestone powder contents in proportion; and performing crushing and processing, and multistage winnowing, sorting and collecting on recycled dust materials. The whole sand-making production line is perfected, so that the system yield can be effectively increased, and finished product gravel aggregate quality can be effectively improved, and therefore, various grading and optimal grading of finished product gravel aggregates are realized; moreover, recycled powder waste is effectively recycled, treatment ability is strong, mountainflour grading can be precisely controlled, and mountain flour of various specifications is prepared; and the thick-thin micro aggregate 6S processing process is used for effectively improving durability and mechanical property of concrete, is low in production cost, and is efficient and energy-saving.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

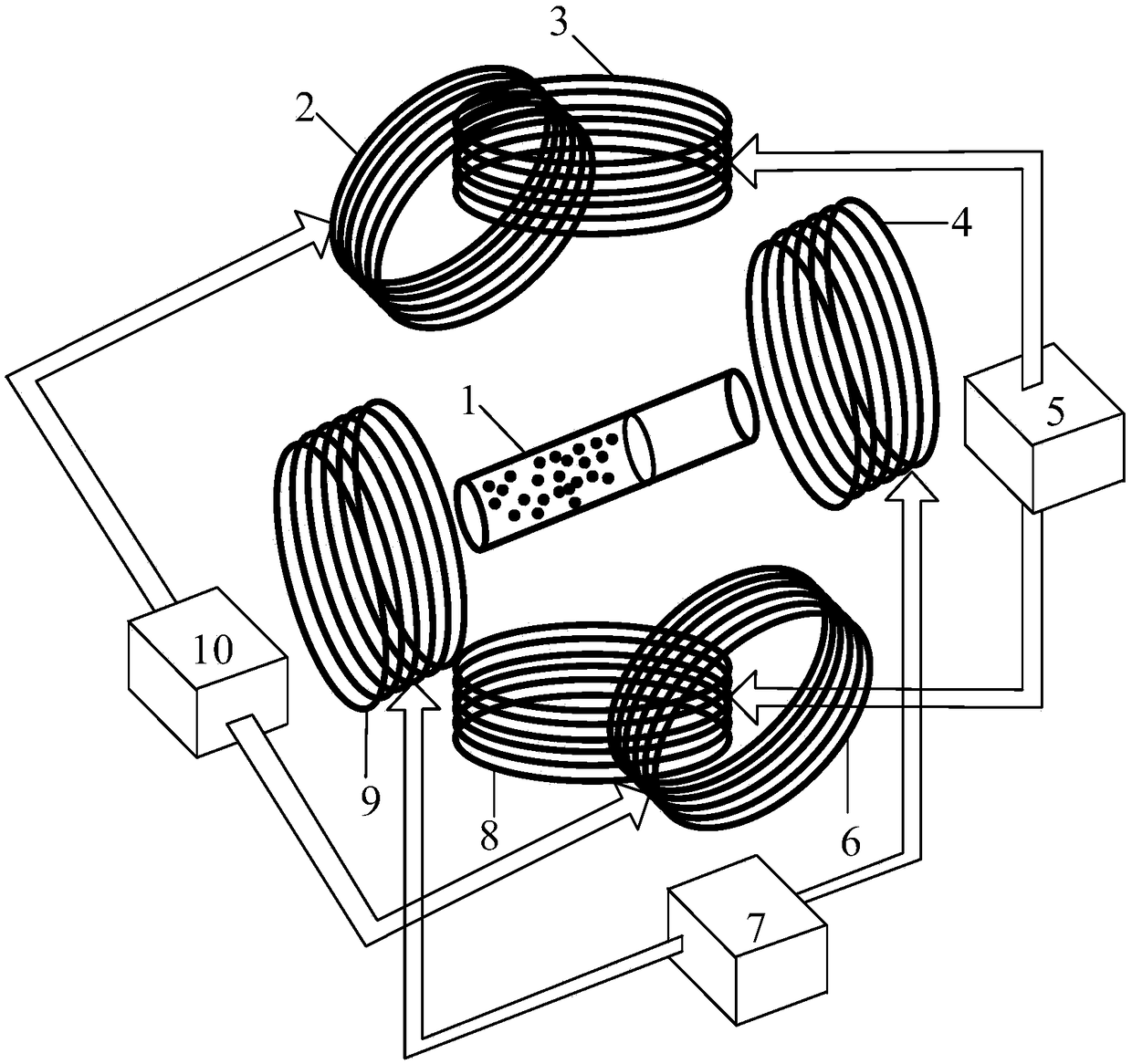

Device for improving efficiency of thrombolysis in veins by controlling magnetic nanometer material

InactiveCN108888313AFacilitated DiffusionImprove thrombolytic efficiencySurgeryCoilsEddy currentDissolution

The invention discloses a device for improving the efficiency of thrombolysis in veins by controlling a magnetic nanometer material, and belongs to the technical field of magnetic nanometer materials.By mixing magnetic nanometer particles with a urokinase solution, the magnetic nanometer particles is made to form micro-aggregate lines under the action of a magnetostatic field, and then under thecontrol of a spatial rotation field, the micro-aggregate lines do rotation movement, and the rotation movement causes the surrounding flow field to form eddy current, so that urokinase is helped to bediffused into the surfaces of thrombi, and dissolution of the thrombi is accelerated. The device has the advantages that the structure is simple, and the operation is convenient, and the efficiency of thrombolysis in the veins is helped to be quickly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for improving tobacco rhizosphere environment

InactiveCN103202124ASimple structureImprove soil qualityOrganic fertilisersSoil conditioning compositionsSoil propertiesSoil moisture storage

The invention relates to a method for improving a tobacco rhizosphere environment, and belongs to the technical field of soil improvement. The method is characterized by including the steps of ash soil dust manufacture and distributing application. By popularizing the technology for improving the tobacco rhizosphere environment by the aid of tobacco field ash soil dust, soil nutrient content can be improved, growth and development of microorganisms in soil are promoted, physical characteristics of the soil are improved, the soil is loosened, formation of soil micro-aggregates is promoted, accordingly, a soil structure is improved, and permeability and soil moisture storage capacity of the soil are enhanced. Besides, land hardened due to long-term chemical fertilizer application is effectively improved, and soil property is greatly improved.

Owner:HUNAN TOBACCO CHENZHOU +1

System for resource utilization and disposal of building wastes

InactiveCN107344820AImprove qualitySolve low value problemsSolid waste managementResource utilizationHigh water content

The invention relates to a system for resource utilization and disposal of building wastes. The system can also be used for the resource utilization and disposal of solid wastes such as mineral waste residues, tailings and the like. The system comprises a material bin, a belt conveyor, a sand making machine, a lifting machine, a sand bin assembly, a material spreading machine, a vibration sieve I, a vibration sieve II, a dust removal pipeline, a primary air separator, a powder bin assembly, a dust remover, an additive bin assembly, a sealed main building, a container bag lifting machine, a powder feeding pipeline, a finished product lifting machine, a finished product bin assembly, a finished product bulk machine, an additive scale, a micro-material additive feeding hopper, a powder scale, a mixing machine, a building bulk machine, a packing machine, a packing hopper and a sand scale, wherein dust suction hoods are arranged at the upper parts of the vibration sieves; a gradation-adjustable device is arranged between the vibration sieve II, the material bin and the sand making machine; a micro-aggregate collecting and recycling device is also arranged at the upper part of a cylinder bin. Through the system for the resource utilization and disposal of the building wastes, the problems of low utilization rate and low addition value of the wastes such as the building wastes and the like can be solved; the problems of low performance quality, high water content, poor grain shape and water pollution of the regenerated machine-made sand material caused by a wet process or a simple extensive type dry process can be solved.

Owner:北京百旺环境科技股份有限公司

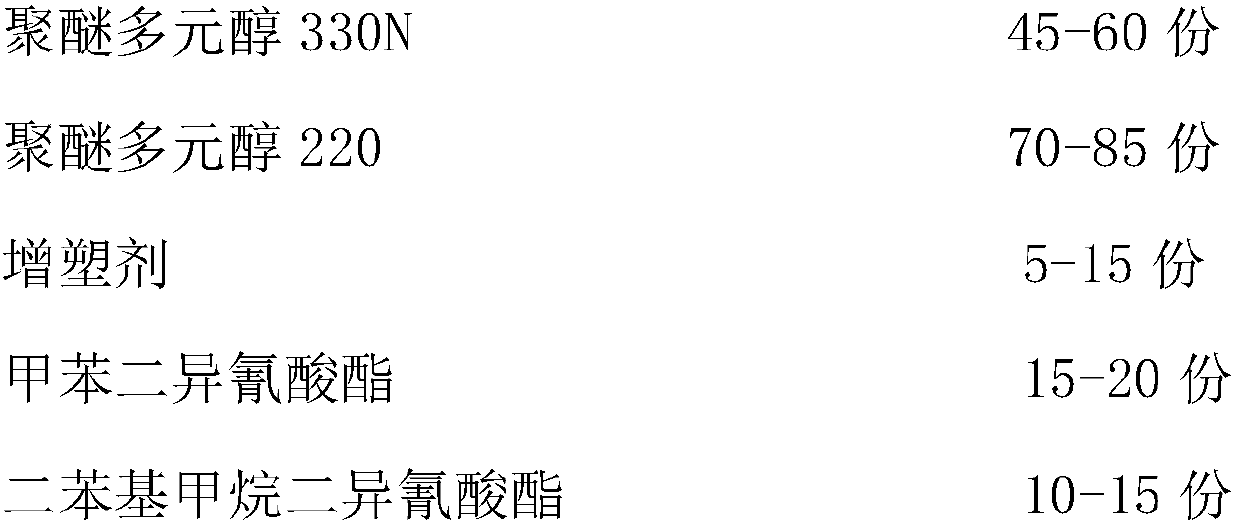

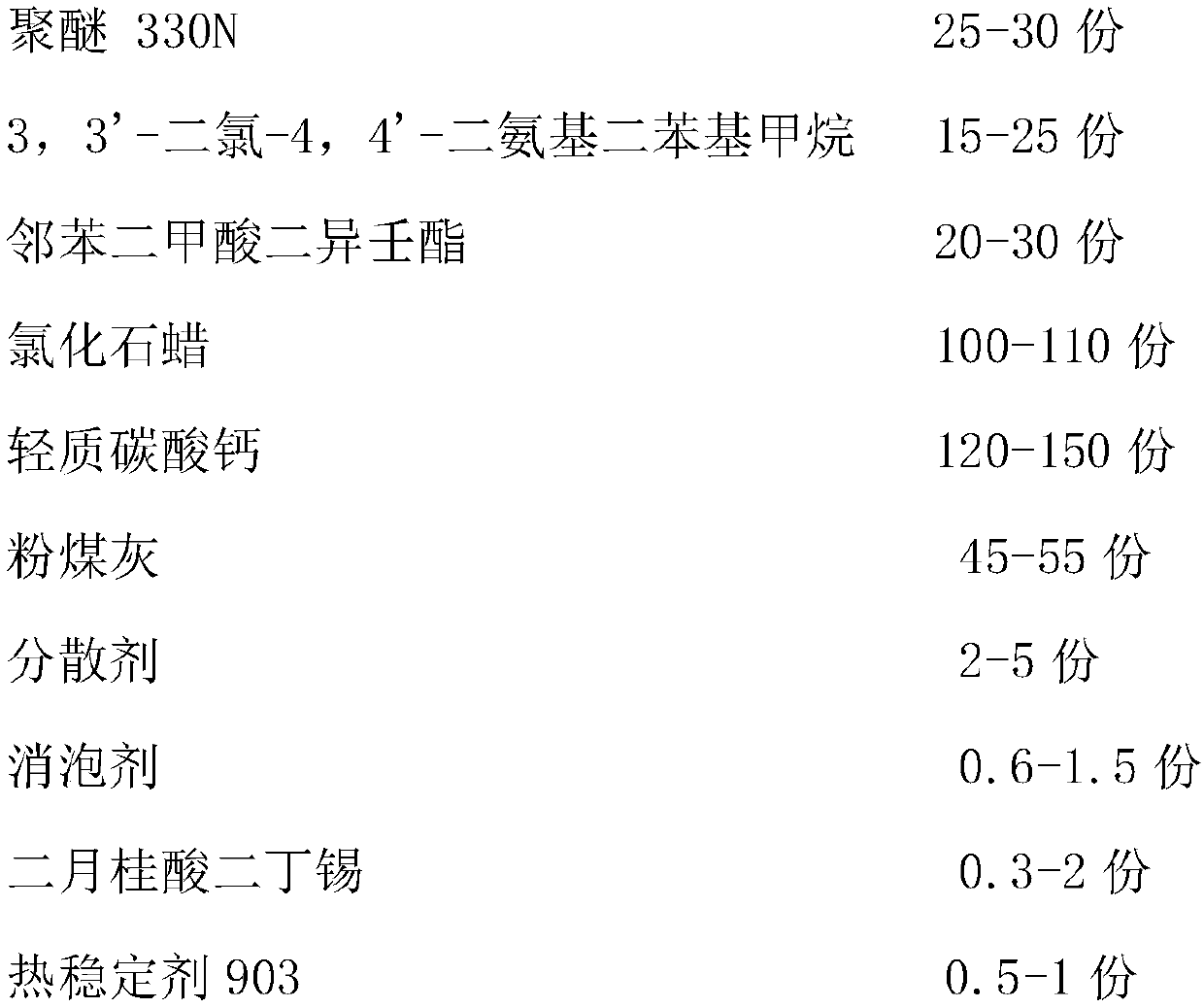

Two-component polyurethane waterproof coating and preparation method thereof

InactiveCN108047919ALow costLow pricePolyurea/polyurethane coatingsToluene diisocyanateChlorinated paraffins

The invention provides a two-component polyurethane waterproof coating. The two-component polyurethane waterproof coating comprises a component A and a component B, wherein the component A comprises 45 to 60 parts of polyether polyol 330N, 70 to 85 parts of polyether polyol 220, 5 to 15 parts of a plasticizer, 15 to 20 parts of toluene diisocyanate and 10 to 15 parts of diphenylmethane diisocyanate; and the component B comprises 25 to 30 parts of polyether 330N, 15 to 25 parts of 3,3'-dichloro-4,4'-diamino diphenyl methane, 20 to 30 parts of diisononyl ortho-phthalate, 100 to 110 parts of chlorinated paraffin, 120 to 150 parts of light calcium carbonate, 45 to 55 parts of fly ash, 2 to 5 parts of a dispersant, 0.6 to 1.5 parts of an antifoaming agent, 0.3 to 2 parts of dibutyltin dilaurateand 0.5 to 1 part of a heat stabilizer 903. The invention provides the two-component polyurethane waterproof coating and the preparation method thereof. According to the invention, through physical activities like particle effect and micro-aggregate effect of the fly ash, cementitious activities of a product can be promoted, and performances of the product are improved; meanwhile, by utilizationof a composite cross-linking agent, the proportion of rigid chain segments in a molecular chain is increased, so tensile strength and hardness are enlarged.

Owner:安徽中能众诚新能源科技有限公司

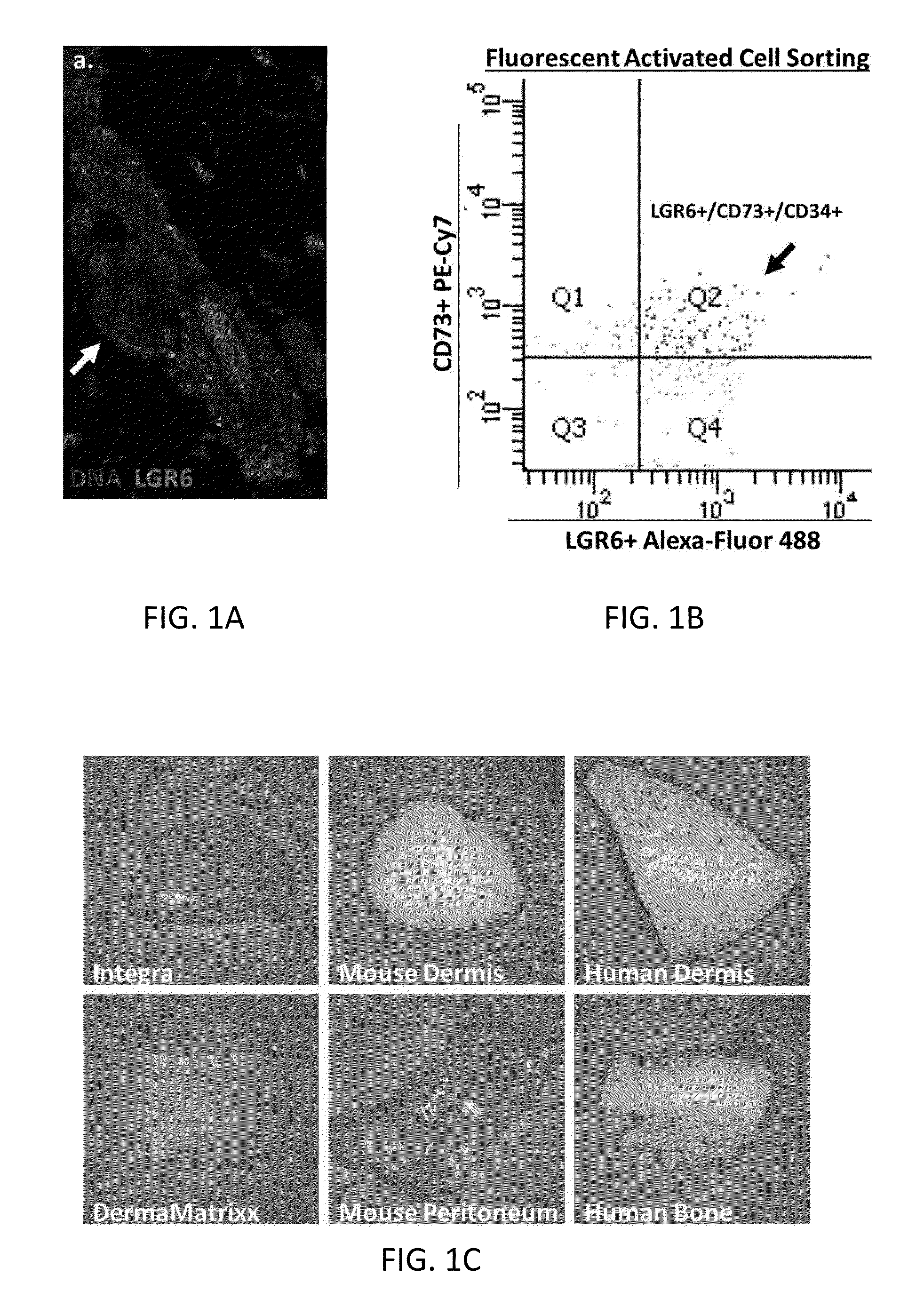

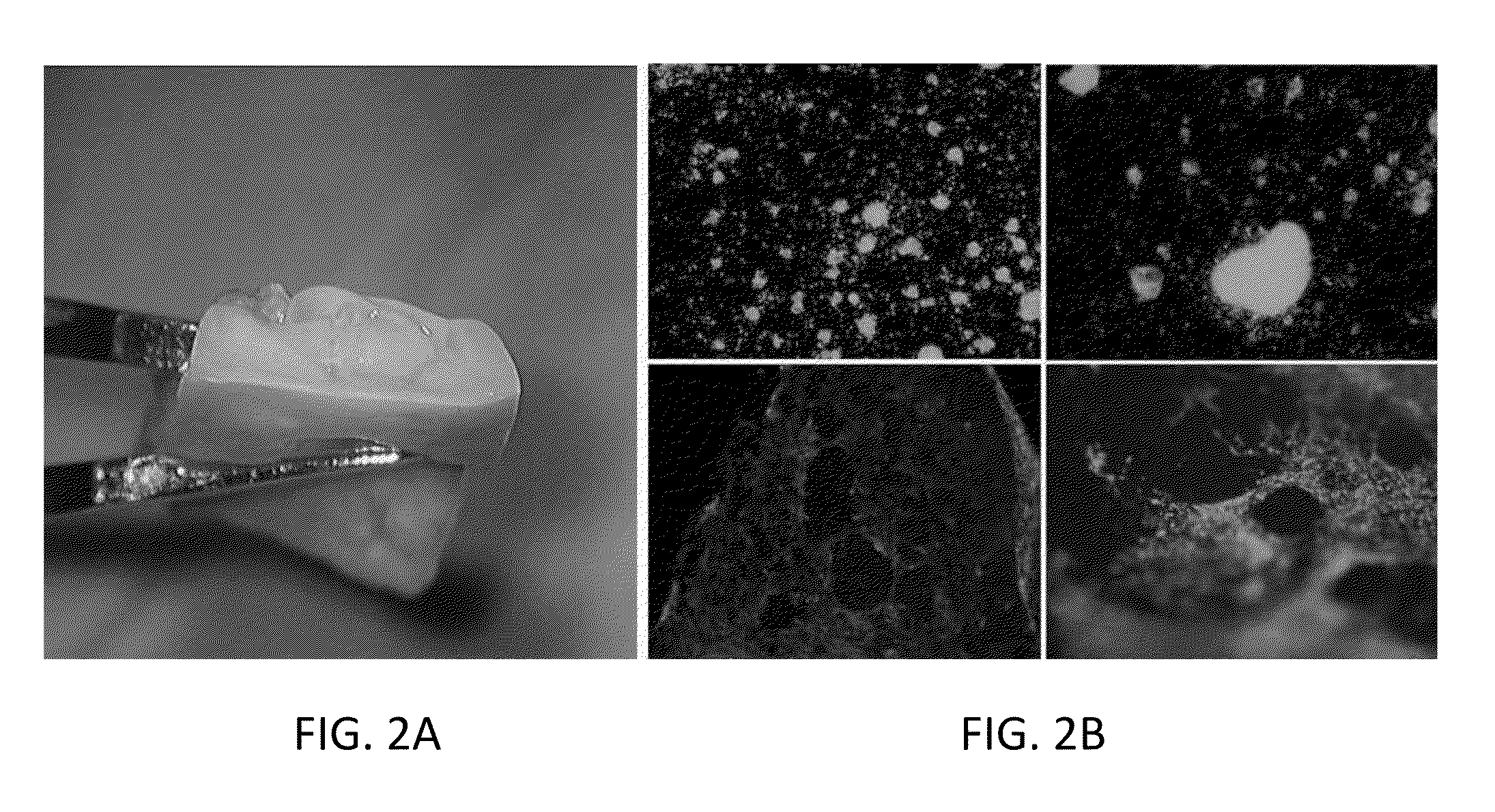

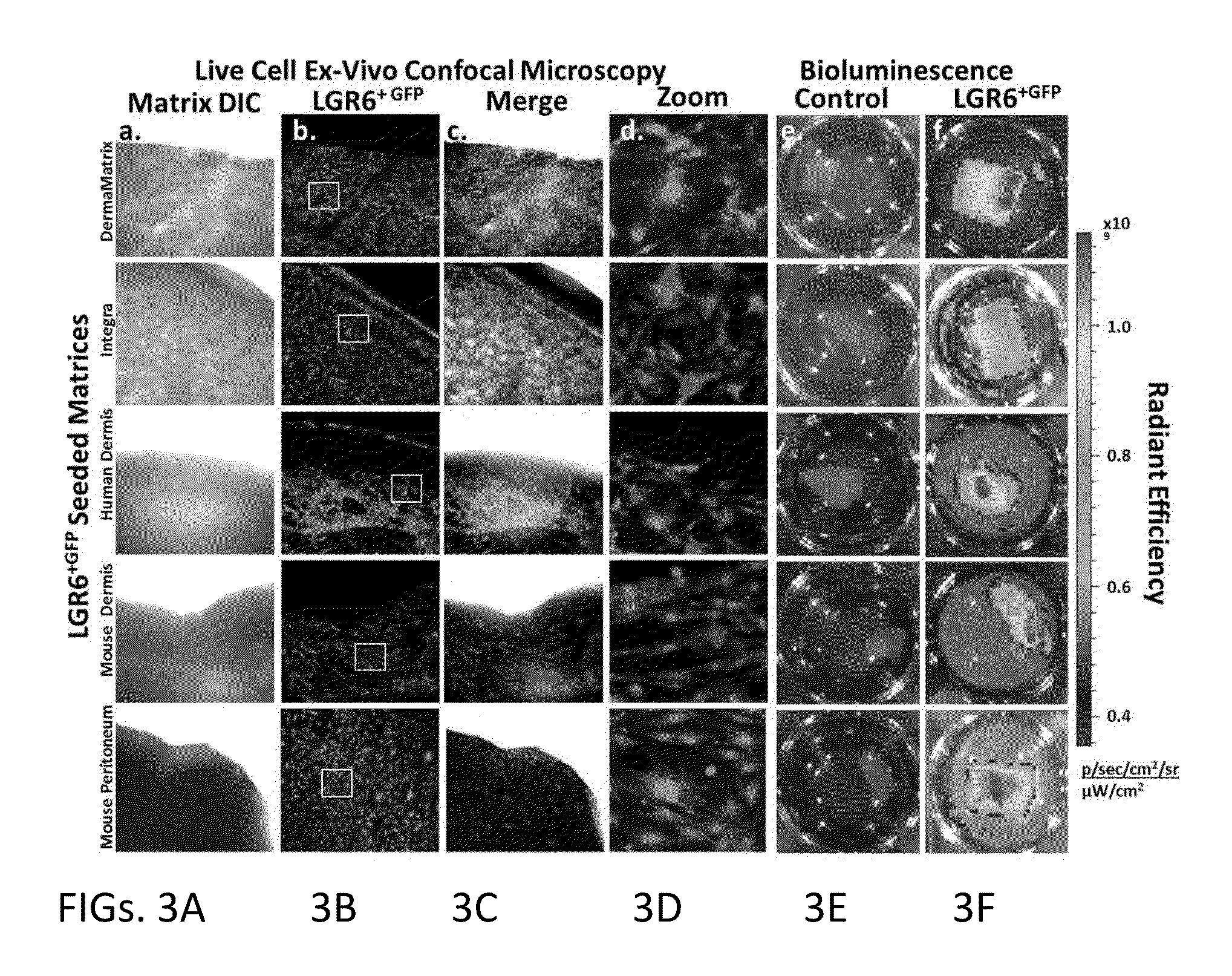

Methods for Development and Use of Minimally Polarized Function Cell Micro-Aggregate Units in Tissue Applications Using LGR4, LGR5 and LGR6 Expressing Epithelial Stem Cells

ActiveUS20160151540A1Process stabilityReduced viabilityBiocideEpidermal cells/skin cellsWound therapyImmune therapy

Provided herein are constructs of micro-aggregate multicellular, minimally polarized grafts containing Leucine-rich repeat-containing G-protein coupled Receptor (LGR) expressing cells for wound therapy applications, tissue engineering, cell therapy applications, regenerative medicine applications, medical / therapeutic applications, tissue healing applications, immune therapy applications, and tissue transplant therapy applications which preferably are associated with a delivery vector / substrate / support / scaffold for direct application.

Owner:GRANDER ACQUISITION LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com