Desiccant composition for moisture-sensitive electronic devices

A desiccant and composition technology, applied in the direction of dispersion particle separation, other chemical processes, separation methods, etc., can solve problems such as unmentioned, difficult film, saturation reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

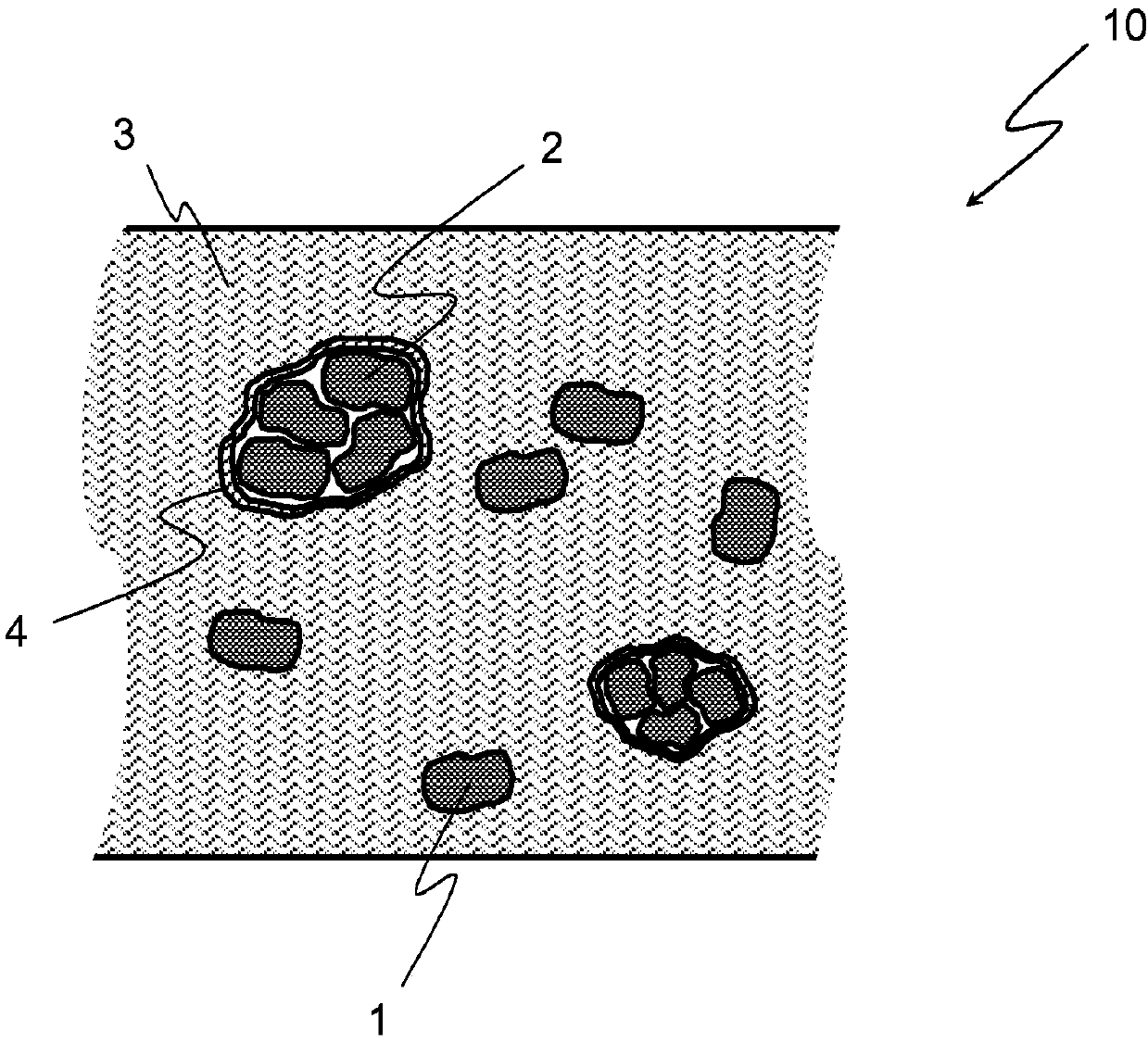

[0021] The polymer-encapsulated desiccant according to the present invention was produced by spray drying a stock solution comprising desiccant powder particles (CaO, 22.5 g) dispersed in a suitable suspending agent (toluene, 1425 g), The encapsulating polymer (PMMA, 52.5 g) was dissolved in the suspending agent. The solution was sprayed at high temperature to promote rapid volatilization of the suspending agent (toluene, 120°C).

[0022] The collected powder (5 grams) was added to a polymer matrix (epoxy resin, 27.5 grams) along with unencapsulated drying agent (CaO, 17.5 grams). The mixture was mechanically mixed and stored under a refrigerated, dry atmosphere.

[0023] Desiccant samples were obtained by leaf distribution on stainless steel substrates and final maturation at 150°C for 1 hour.

[0024] The adsorption characteristics of the desiccant samples at 22° C. and 55% relative humidity were tested by gravimetric test, and the results showed that 80% of the residual a...

Embodiment 2

[0026] The polymer-encapsulated desiccant according to the present invention was prepared by spray drying a stock solution comprising desiccant powder particles (CaO, 22.5 g) dispersed in a suitable suspending agent (toluene, 1425 g), The encapsulating polymer (polysulfone PSU, 52.5 g) was dissolved in the suspension. The solution was sprayed at high temperature to promote rapid volatilization of the suspending agent (toluene, 120°C).

[0027] The collected powder (7.5 g) was mixed with unencapsulated desiccant (Li 2 0, 17.5 g) into a polymer matrix (epoxy resin, 27.5 g). The mixture was mechanically mixed and kept under a refrigerated, dry atmosphere.

[0028] Desiccant samples were obtained by leaf distribution on stainless steel substrates and final maturation at 150°C for 1 hour.

[0029] The adsorption characteristics of the desiccant samples at 22° C. and 55% relative humidity were tested by gravimetric test, and the results showed that after exposure for 24 hours, 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com