Super strength silicate cement adhesive and preparation method thereof

A technology of cement adhesive and portland cement, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems that cannot satisfy the production of high-tonnage suspension porcelain insulators, and achieve good compactness, good durability, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A kind of super-strength Portland cement adhesive, the raw material composition of this adhesive and its weight content ratio are Portland cement 30.5%, quartz sand 35.2%, silicon fume 4.2%, slag 12.7%, powder Coal ash 4.2%, water reducing agent 0.9%, water 12.3%.

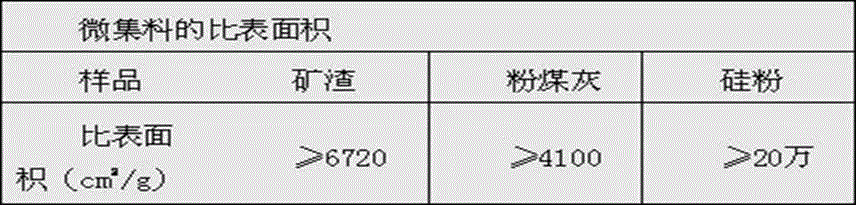

[0016] Among them, the cement first meets the requirements of GB175-1999, and the label is not less than 52.5 or 52.5R Portland cement; the particle size of the quartz sand is 80-120 mesh, which meets GB178-1977. The micro-aggregate is a mixture of silicon powder, slag and fly ash, and their average particle size is required to be less than 0.01 μm. The water reducer is a polycarboxylate water reducer. This experiment uses a polycarboxylate high-performance water reducer produced by Suzhou Xingbang Chemical Building Materials Co., Ltd., the model is SUNBO PC-1016, which conforms to JG / T 223-2007 .

[0017] The preparation method of the above-mentioned adhesive is as follows: first mix cement,...

Embodiment 2

[0018] Embodiment 2: basically the same as Embodiment 1, the difference is the raw material ratio of cement: Portland cement 31.4%, quartz sand 34.8%, silicon powder 4.1%, slag 12.2%, fly ash 4.1%, reducing Aqua 0.9%, water 12.5%.

Embodiment 3

[0019] Embodiment 3: basically the same as Embodiment 1, the difference is the raw material ratio of cement: Portland cement 40.0%, quartz sand 26.8%, silicon powder 3.8%, slag 11.6%, fly ash 3.8%, reducing Aqua 1.0%, water 13.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com