Thick-thin micro aggregate 6S processing process for concrete and production line

A processing technology and production line technology, which is applied in the field of 6S processing technology and production line of coarse and fine aggregates for concrete, and can solve the problems of lack of diversification of products, restriction of concrete development, low processing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

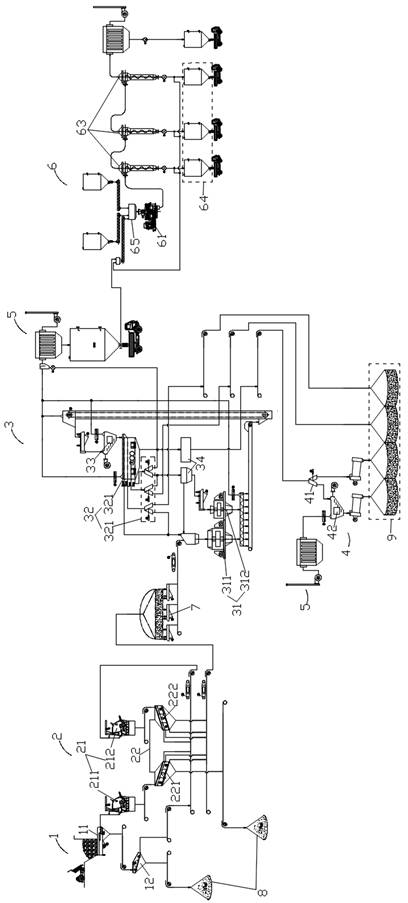

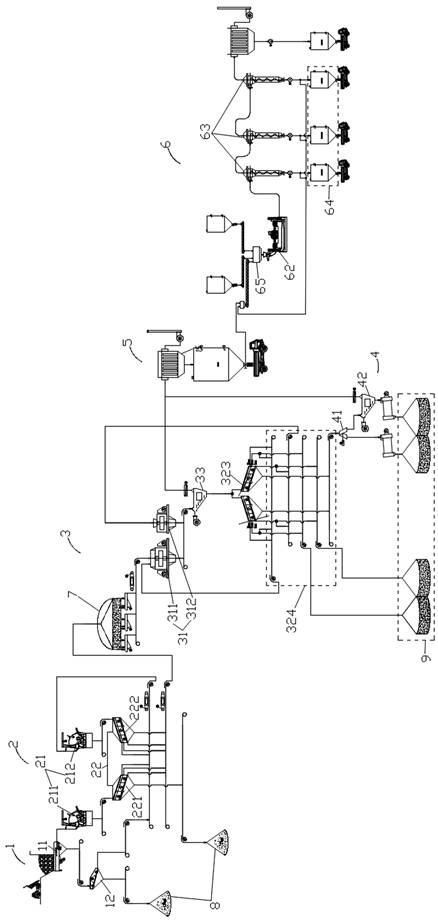

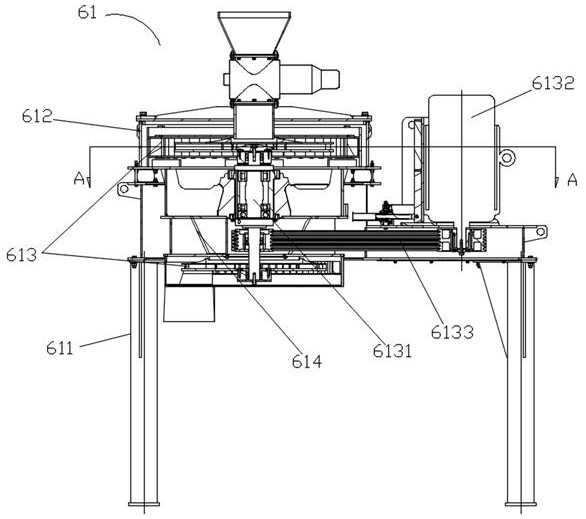

[0047] like Figure 1-Figure 7 as shown,

[0048] A 6S processing technology for medium and fine aggregates for concrete, which comprises the following steps:

[0049] s1. Carry out material pretreatment, vibrate and disperse the material, primary desliming, and quantitative feeding;

[0050] s2. Carry out coarse crushing of materials, circular crushing of materials, and multi-stage desliming;

[0051] s3. Carry out fine crushing of materials, multi-stage crushing of materials circulation, screening and classification, and produce high-quality sand and aggregates of different specifications in proportion;

[0052] s4. Carry out multi-stage powder selection for high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com