Patents

Literature

33results about How to "Reasonable gradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Limestone ultrafine powder concrete with strength grade not higher than C40

The invention relates to the technical field of concrete in building materials and discloses limestone ultrafine powder concrete with a strength grade not higher than C40. The limestone ultrafine powder concrete is prepared from coarse aggregate, fine aggregates, cementing materials, water and an additive, wherein the coarse aggregate is rubble; the fine aggregates comprise river sand and machine-made sand; the cementing materials comprises comprise cement, slag powder, fly ash and limestone ultrafine powder; and the additive is a water reducing agent. In the invention, the limestone ultrafine powder replaces certain amount of cement as part of the cementing materials; the prepared limestone ultrafine powder concrete is superior to traditional concrete in terms of working performance, compressive strength, elasticity modulus, durability and the like; and moreover, the cement is saved, the production cost of concrete is reduced, the energy consumption and CO2 discharge in the cement production process are reduced, and the combination of greenness, energy conservation and environmental protection can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

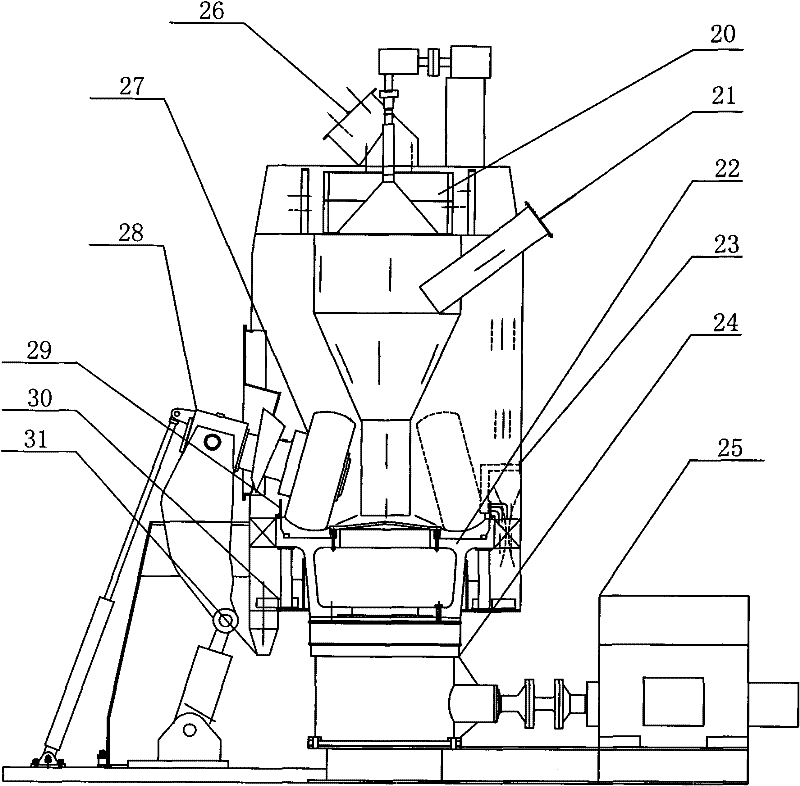

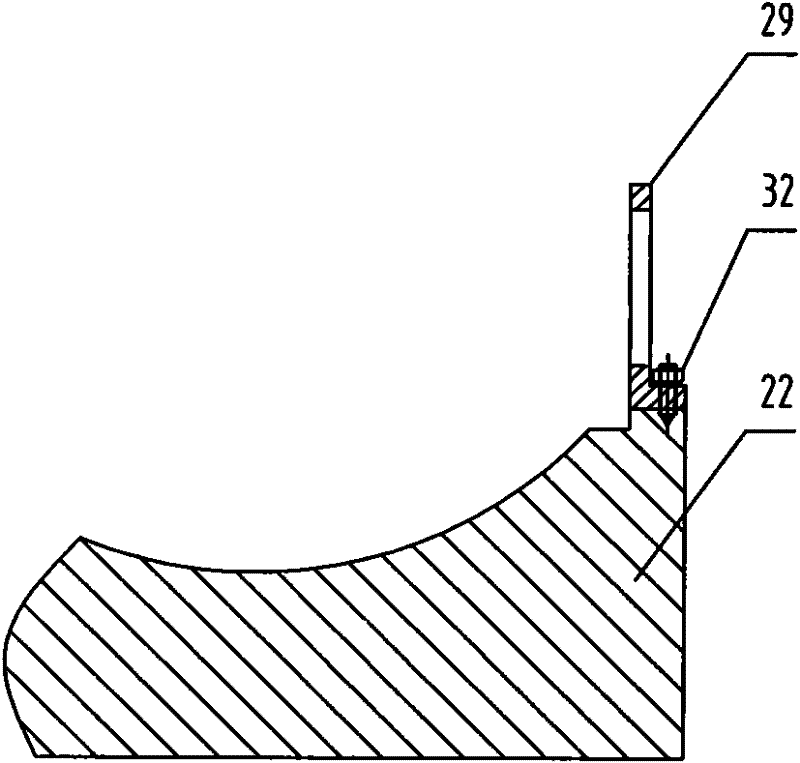

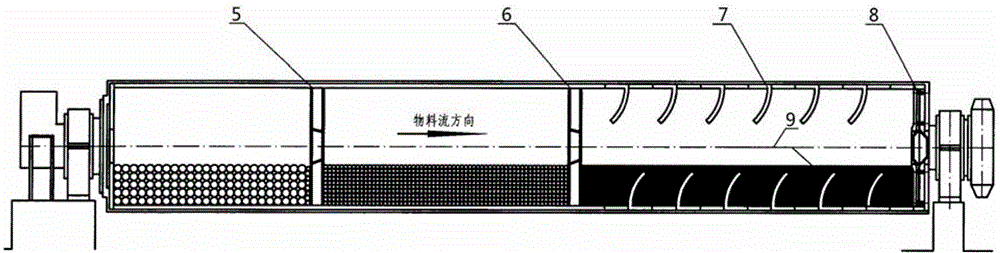

Semi-finished pre-grinding vertical-milling and ball-milling combined grinding device

InactiveCN101862699AGood lookingImprove grinding efficiencyCement productionGrain treatmentsEconomic benefitsCement grinding

The invention belongs to the technical field of cement grinding, in particular to a semi-finished pre-grinding vertical-milling and ball-milling combined grinding device which comprises a semi-finished pre-grinding vertical-milling machine and a ball milling machine, wherein the feeding end of the semi-finished pre-grinding vertical-milling machine is connected with the discharging end of a proportioning belt scale, a gas outlet is connected with a dust remover, and the discharging hole of the dust remover is connected with a finished product conveying machine; the discharging hole of the semi-finished pre-grinding vertical-milling machine is connected with a lifting machine through a vertical milling discharging belt, and the discharging hole of the lifting machine is connected with the feeding hole of the ball milling machine; the gas outlet of the ball milling machine is connected with the dust remover, the discharging hole of the dust remover is connected with the finished product conveying machine; and the discharging hole of the ball milling machine is connected with a powder concentrating machine through the lifting machine, the finished product fine powder discharging hole of the powder concentrating machine is connected with a third finished product conveying machine, and the crude powder discharging hole of the powder concentrating machine is connected with the feeding hole of the ball milling machine through a feed back conveying machine. The invention combines high yield and energy saving of the vertical milling machine with cement grading advantages of the ball milling machine, and has lower investment, lower electricity consumption, more reasonable grading of cement particles, very convenient maintenance and remarkable economic benefit.

Owner:南京旋立重型机械有限公司

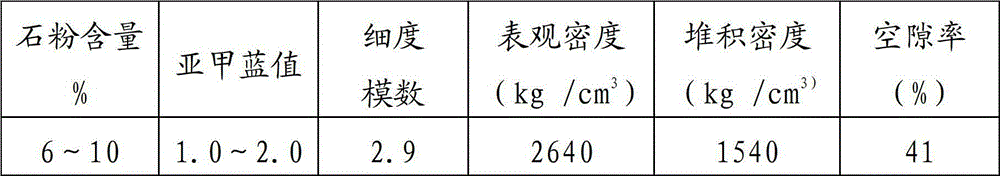

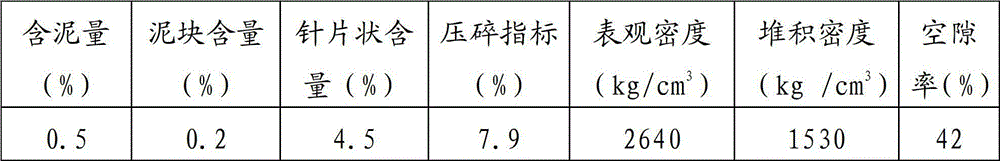

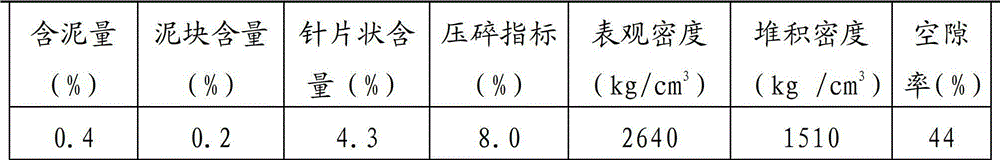

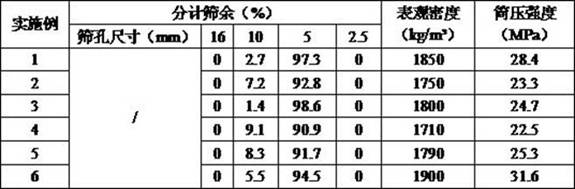

Production process of machine-made sand

InactiveCN109351446AHigh degree of automationLow running costGrain treatmentsGranularityCrushed stone

The invention provides a production process of machine-made sand. The process comprises the following steps of 1, carrying out first-time screening on raw materials to remove impurities and debris inthe raw materials so as to obtain block stones; 2, coarsely crushing the block stones to obtain the crushed stones, carrying out second-time screening on the crushed stones, wherein the crushed stoneswith the sizes larger than 400 mm are coarsely crushed again till the sizes are smaller than 400 mm, intermediately crushing is carried out on the crushed stones with the sizes smaller than 400 mm toobtain products I; 3, carrying out three-time screening on the products I, wherein re-intermediate-crushing is carried out on the crushed stones with the sizes larger than 10 mm till the sizes are smaller than 10 mm, and finely crushing is carried out on the crushed stones with the sizes less than 10 mm to obtain products II; 4, carry out four-time screening on the products II, wherein sand withthe sizes smaller than 3 mm enters a sand washing machine, and the sand with the sizes of 3-10 mm is finely crushed again into the sand with the sizes smaller than 3 mm, and then the sand enters the sand washing machine; and 5, obtaining the finished sand. The sand obtained through the production process has strong firmness and durability, and the granularity of the sand is more uniform.

Owner:徐州金盟新型建材有限公司

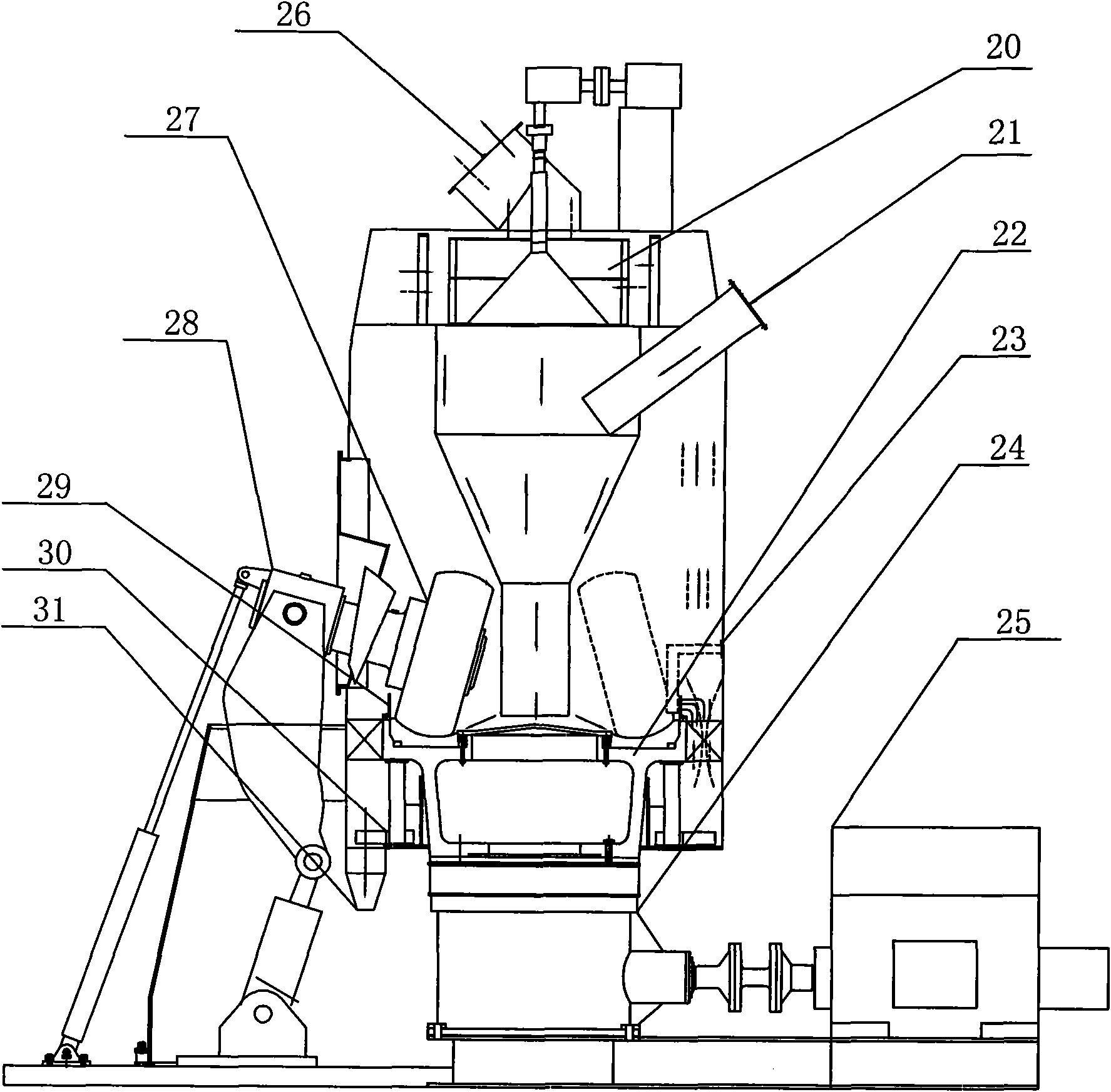

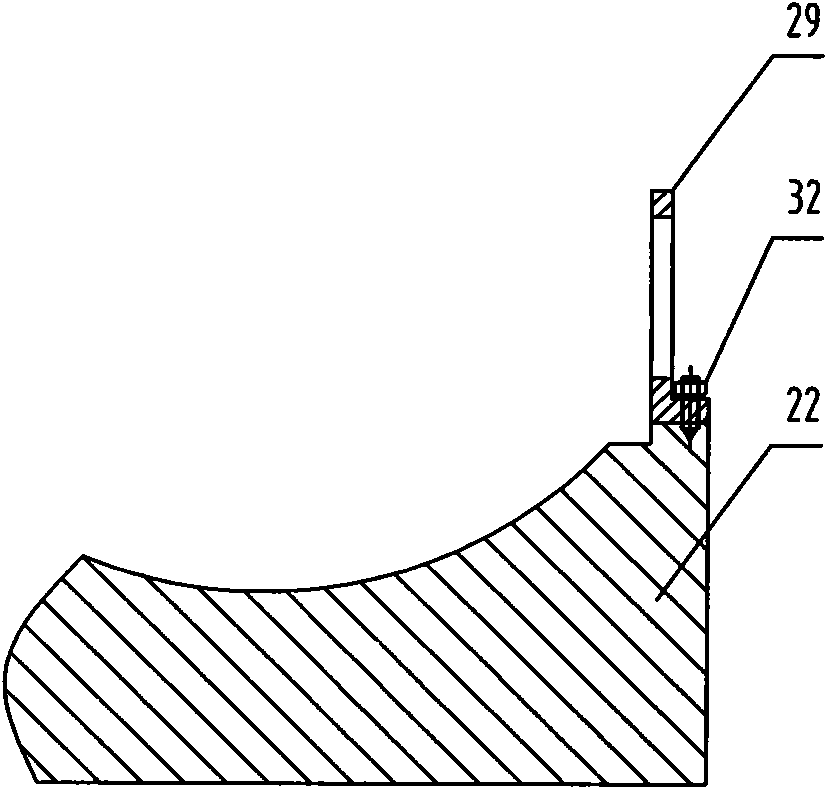

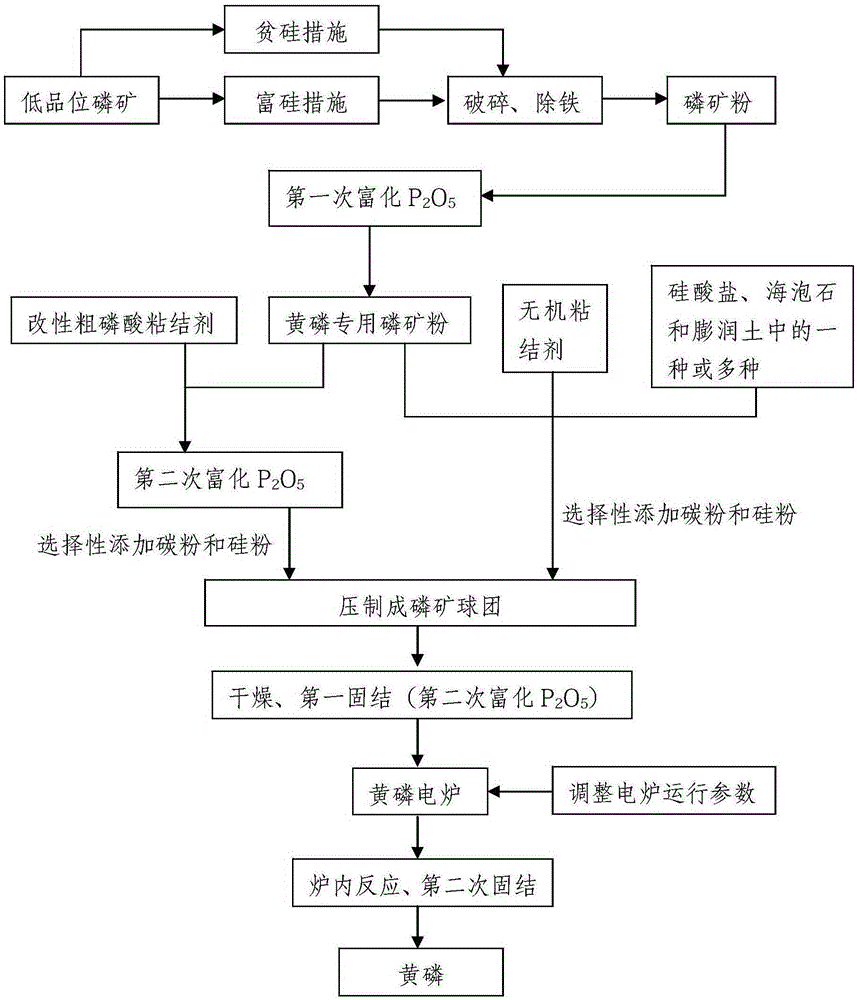

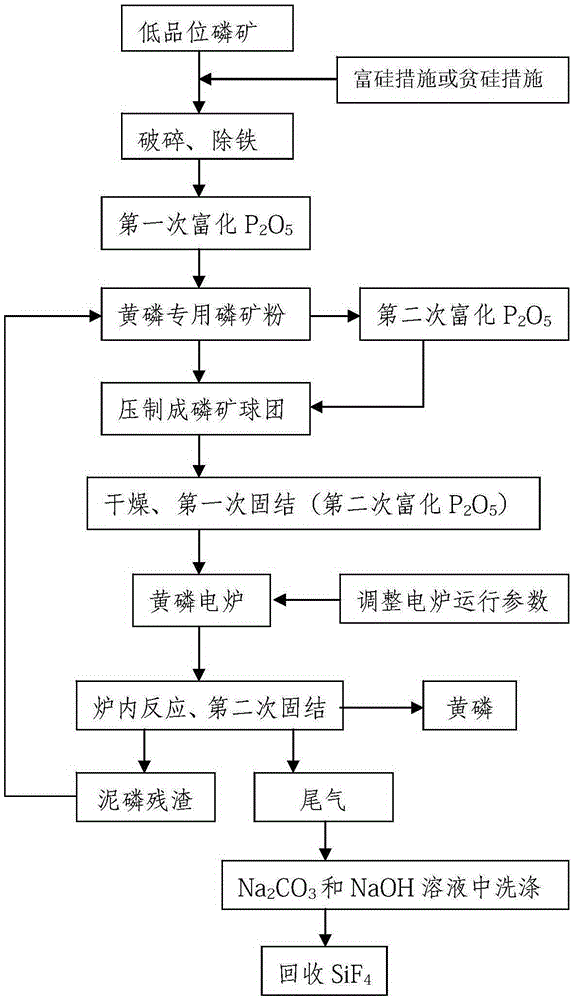

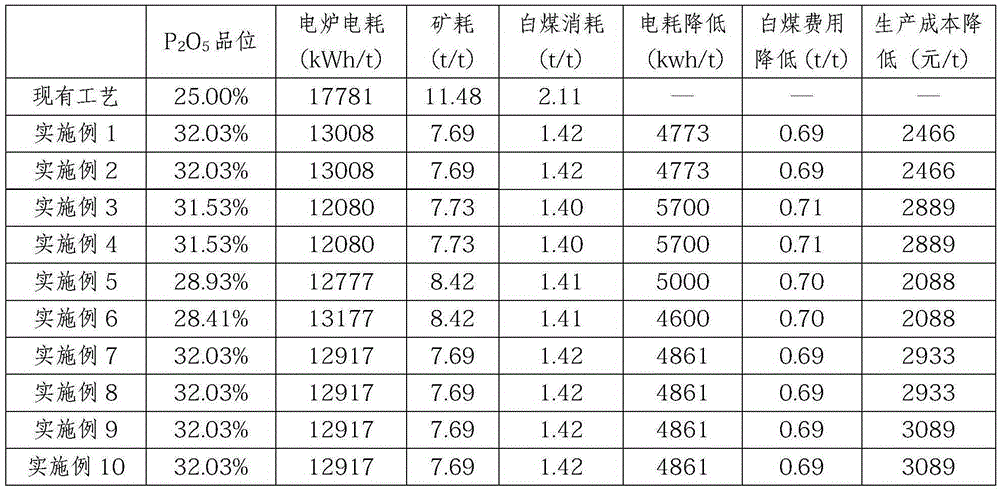

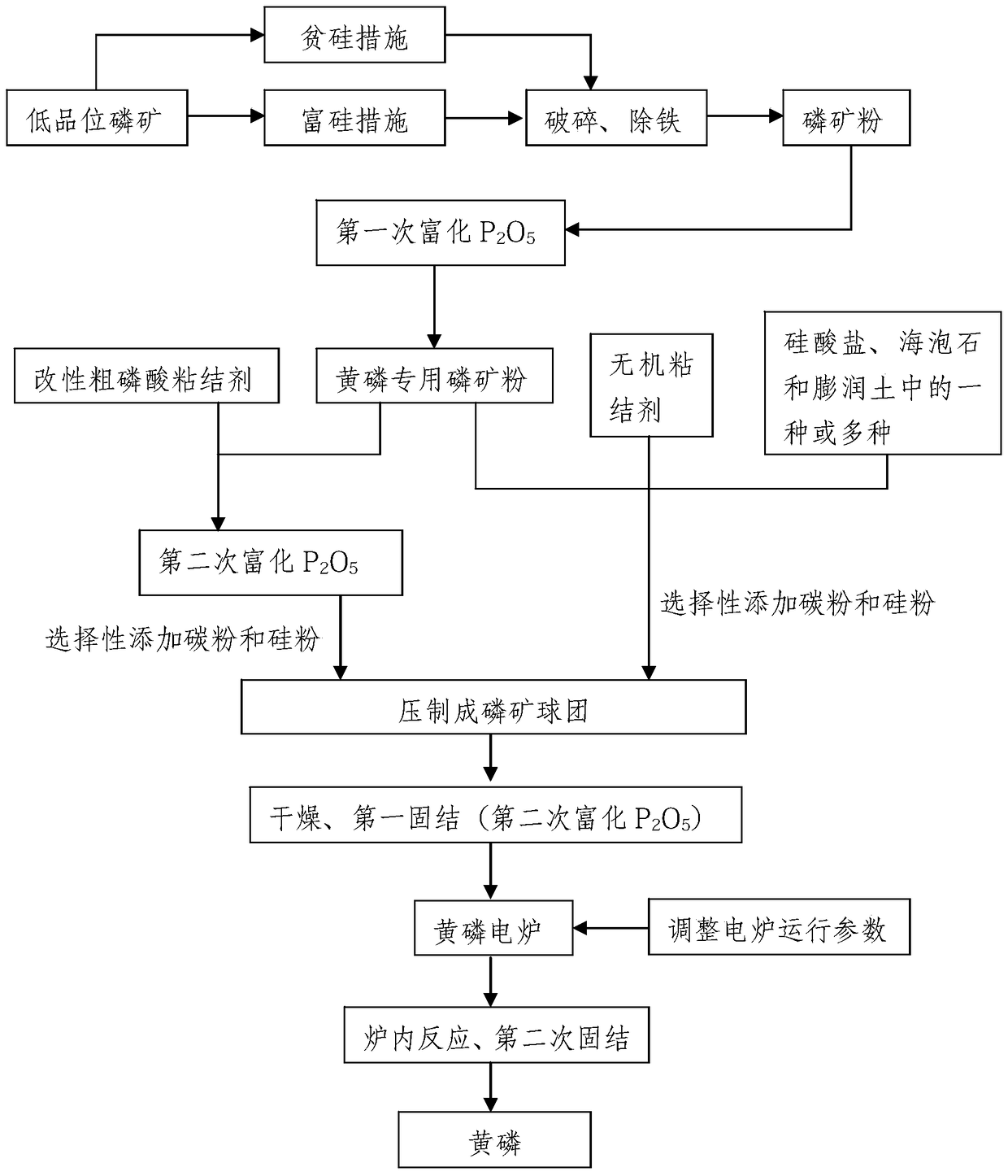

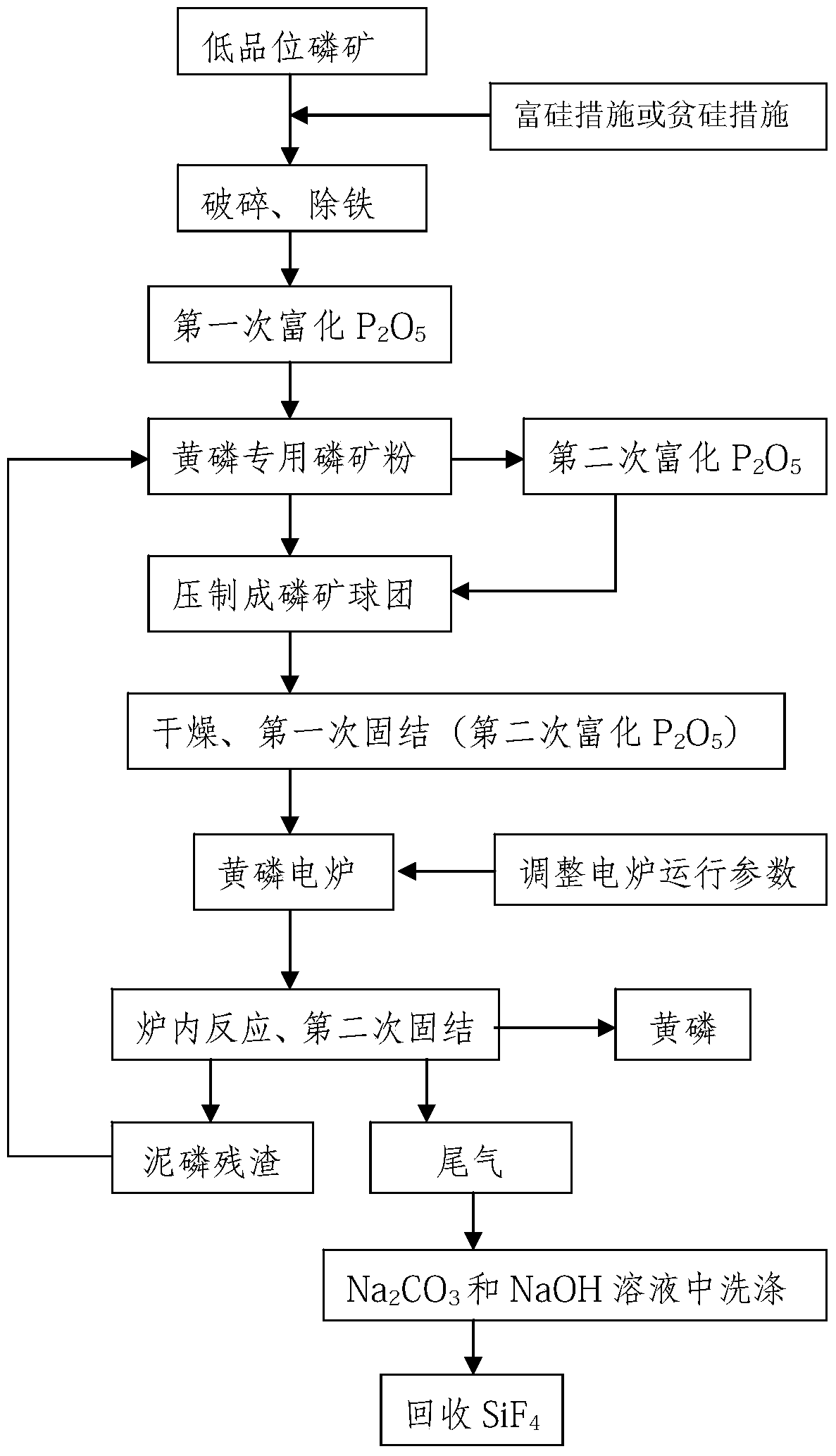

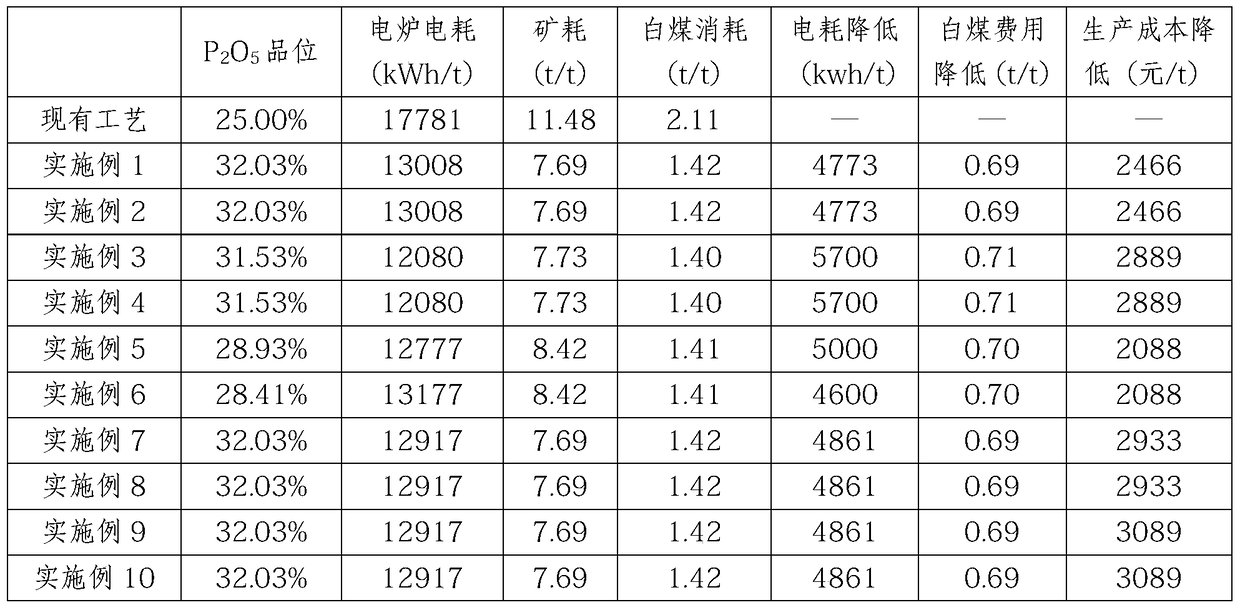

Method and preparation technology used for producing yellow phosphorus from low-grade phosphate ore

ActiveCN105329865AReduce wasteAvoid wastingRaw phosphate material treatmentHalogenated silanesEnvironmental resistanceLower grade

The invention relates to a method used for producing yellow phosphorus from low-grade phosphate ore. According to the method, phosphate ore powder with appropriate silicon content and low iron content is obtained via selectively adapting silicon concentrating or removing technology and removing iron-containing compounds in smashing period based on the difference of phosphate ores in mining period; a first time P2O5 enrichment and a second time P2O5 enrichment are carried out respectively via drying, roasting, or obverse flotation, or reverse flotation, drying,, curing, and obtaining of phosphate ore balls. The method is low in cost, high in efficiency, is friendly to the environment, is capable of improving yellow phosphorus quality, avoiding accidents or faults such as arch structure formation, material collapse, and electrode broken, and ensuring safe, stable, and high efficiency operation of electric furnaces.

Owner:成都天屿新磷科技有限公司

Dry-mixed mortar prepared from industrial solid waste

The invention provides dry-mixed mortar prepared from industrial solid waste. The dry-mixed mortar is characterized by being prepared from materials in parts by weight as follows: 100 parts of cement, 300-400 parts of river sand, 50-100 parts of steel slag, 0-50 parts of iron mine tailings, 0-50 parts of glass powder, 1-2 parts of an interface reinforcing agent, 1-2 parts of an exciting agent, 0.1-0.5 parts of a water retaining agent, 1-2 parts of a water reducing agent and 0.1-0.3 parts of reinforcing fibers. According to the dry-mixed mortar, the industrial solid waste is fully utilized as aggregate to replace natural river sand, environmental protection is facilitated, resource recycling is realized, and meanwhile, performance such as the freezing resistance, the permeability resistance and the like of the dry-mixed mortar is improved through addition of the industrial solid waste.

Owner:四川震强建筑材料有限责任公司

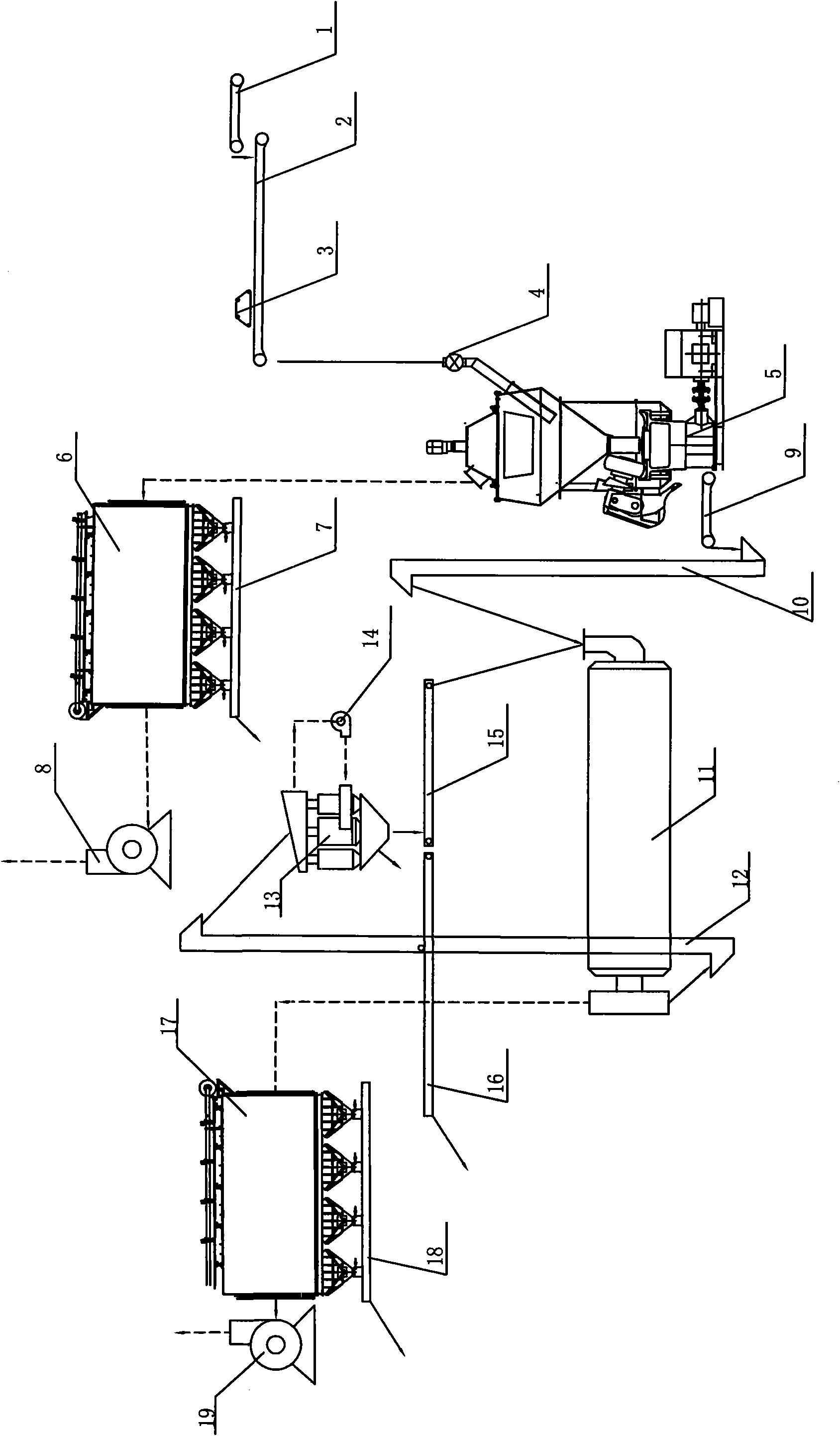

Rubble production line

InactiveCN104069926AGood particle shapeReasonable gradationGrain treatmentsFineness modulusElectric control

The invention discloses a rubble production line. The rubble production line is composed of a vibration feeder, a jaw breaker, a cone breaker I, a vibration screen I, a cone breaker II, a vibration screen II, an impact breaker and an assorted belt conveyor and an electric control system, wherein the jaw breaker is used for primary breaking, the cone breaker I is used for secondary breaking, and the cone breaker II is used for the third-level breaking. According to the rubble production line provided by the invention, the particle shape is good; the gradation is reasonable, and the fineness modulus is adjustable; the indicators for the rubble product meet the national standard, and the rubble product is concrete aggregate of high quality; the production cost is low, and the benefit is good.

Owner:WUXI WEIHAIDA MACHINERY MFG

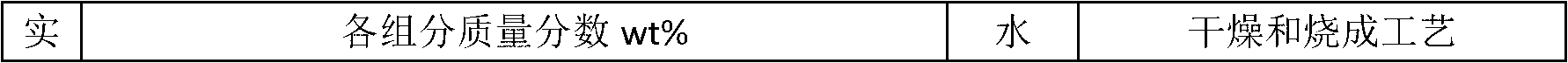

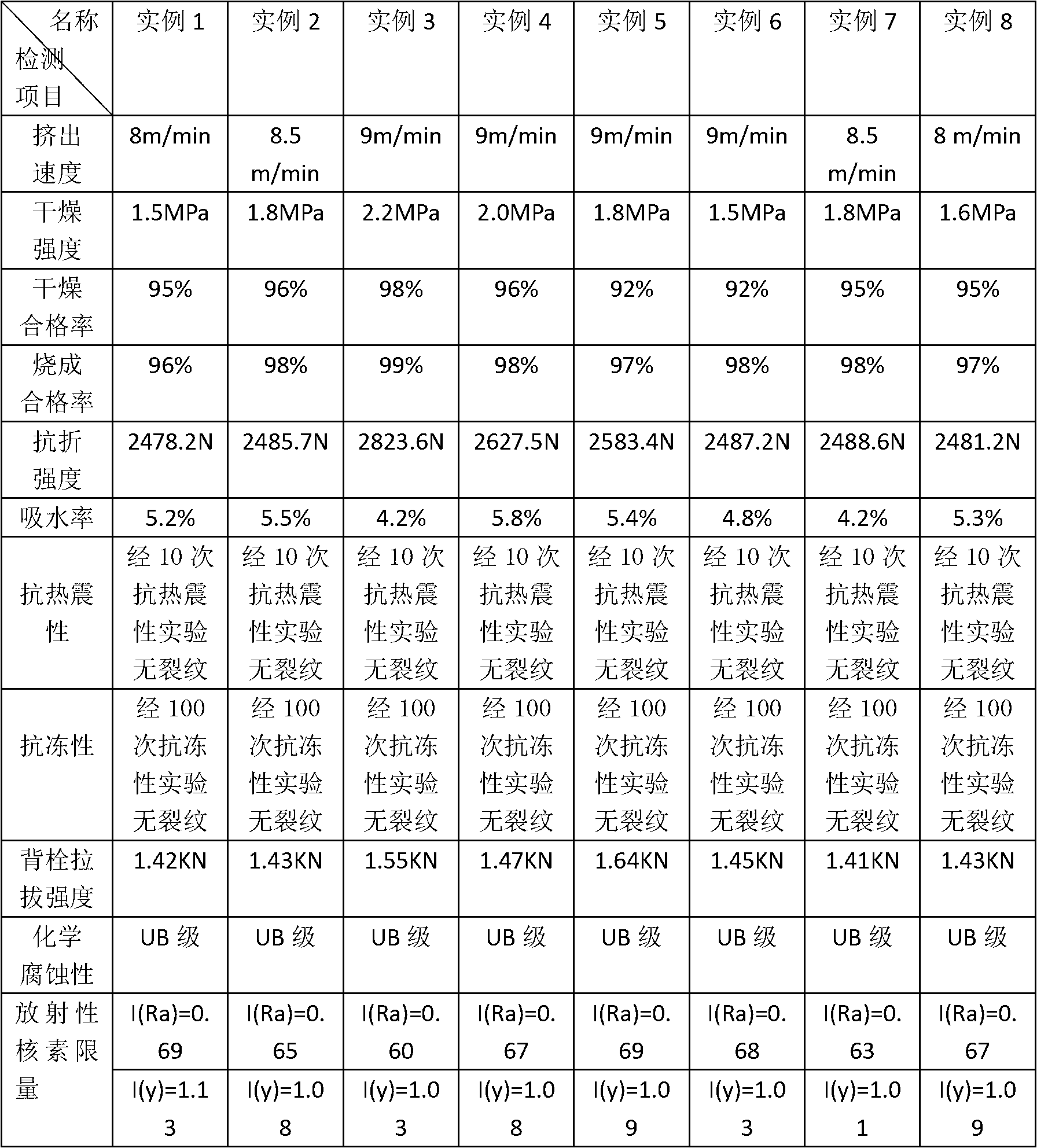

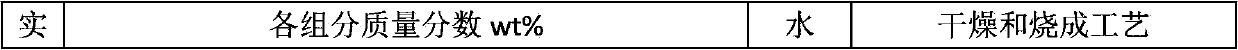

Low-temperature fast-fired environmentally-friendly pottery clay plate prepared from iron ore tailings and preparation method thereof

ActiveCN102795838AReasonable gradationHigh porosityCeramic materials productionClaywaresSolventEnvironmental resistance

The invention relates to a low-temperature fast-fired environmentally-friendly pottery clay plate prepared from iron ore tailings and a preparation method thereof. Iron ore tailings obtained by iron ore enterprise production is used as a main solvent raw material and is adopted by a formula of the low-temperature fast-fired environmentally-friendly pottery clay plate. The low-temperature fast-fired environmentally-friendly pottery clay plate comprises a superfine plastic material, a fine lean material, fine iron ore tailings, a coarse lean material, a plasticizer and water. The formula of the low-temperature fast-fired environmentally-friendly pottery clay plate comprises illite, kaolin, chinastone, pyrophyllite, iron ore tailings, the coarse lean material, the plasticizer and water. The preparation method comprises the following steps of uniformly mixing 15 to 35% by mass of the superfine plastic material, 10 to 45% by mass of the fine lean material and the coarse lean material, 20 to 50% by mass of iron ore tailings and 0 to 5% of by mass of the plasticizer, adding 10 to 28% by mass of water into the mixture, carrying out extrusion molding by a screw-type extruder, drying, and carrying out sintering in a roller kiln having the length of 280 meters at a temperature of 1000 to 1100 DEG C, wherein a sintering period is in a range of 1 to 1.5 hours. The mixed raw materials adopted by the preparation method have good extrusion performances and good drying and sintering performances. The low-temperature fast-fired environmentally-friendly pottery clay plate sintered by the preparation method has high strength and small contractility, cracks and deforms difficultly, can be sintered fast and has high environmental protection benefits and economic benefits.

Owner:江苏金久科技新材料有限公司

Prestress concrete tubular pile free of steaming and pressing

Provided is a prestress concrete tubular pile free of steaming and pressing. Each cubic meter of concrete contains 420-480 kg of gel materials, the water-binder ratio is 0.24-0.26, and the sand ratio is 30-33%. Crushed stone is broken cobblestone, and each cubic meter of concrete contains 1250-1350 kg of the cobblestone. Doped water reducers account for 1.5%-2.0% of the gel materials. The gel materials are prepared from, by mass, 20-30% of superfine slag powder, 5-7% of carbide slag, 5-10% of micro silicon powder, 5-7% of gypsum powder and the balance cement. The comprehensive performance of the tubular pile is fully improved while the quality of the PHC tubular pile is guaranteed; meanwhile, the technology process is simplified, steam consumption in the pile making process is reduced; use of hoisting equipment required when the pile enters and gets out of an autoclave is reduced, and electric energy consumption is correspondingly reduced.

Owner:河南双建科技发展股份有限公司

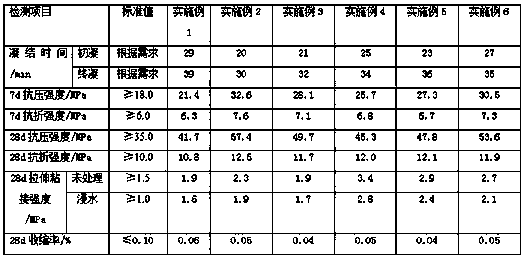

Repair mortar for tap water pipeline PCCP (Prestressed Concrete Cylinder Pipe)

The invention discloses repair mortar for a tap water pipeline PCCP (Prestressed Concrete Cylinder Pipe), and belongs to the technical field of polymer cement mortar. The repair mortar is prepared from raw materials including gelling materials, fine aggregate, heavy calcium carbonate, hydroxyethyl cellulose, water reducing agents, redispersible adhesive powder, lithium carbonate and boracic acid,wherein the initial setting time of the repair mortar is 20 to 30min; the final setting time is 30 to 40min; the 28d intensity is 35 to 50MPa; the processless boding intensity is greater than 1.5MPa.The repair mortar has excellent performance; the prepared repair material has the advantages of safety, high intensity, strong bonding force, excellent cracking resistant performance, corrosion resistance and the like.

Owner:JIAHUA SPECIAL CEMENT

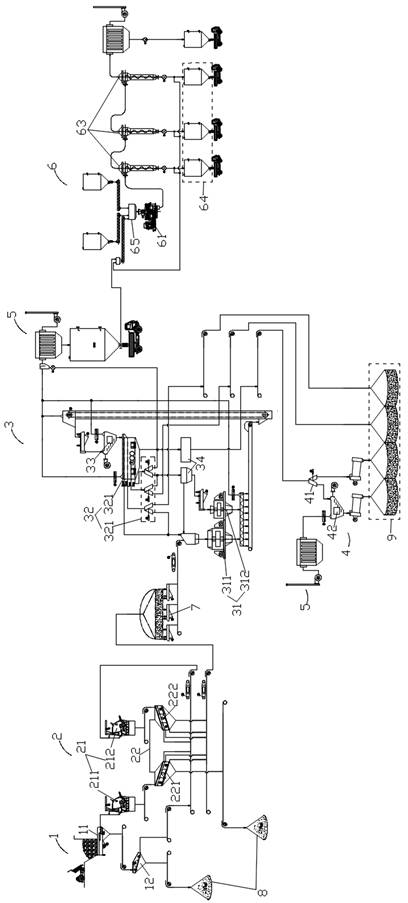

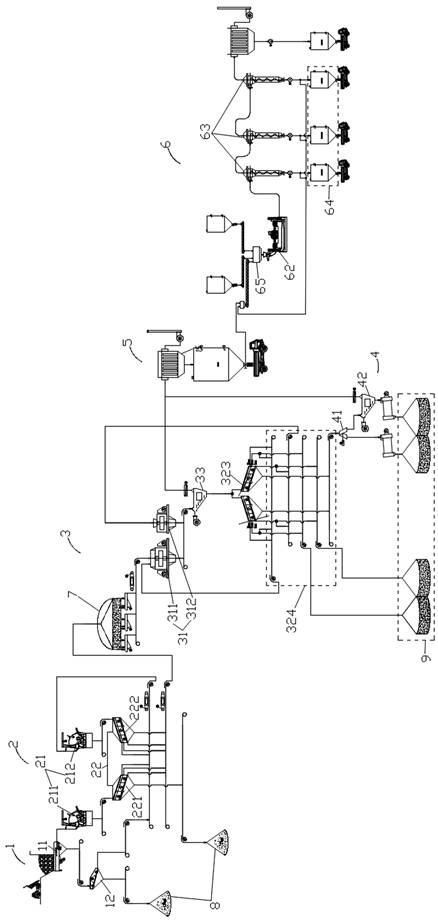

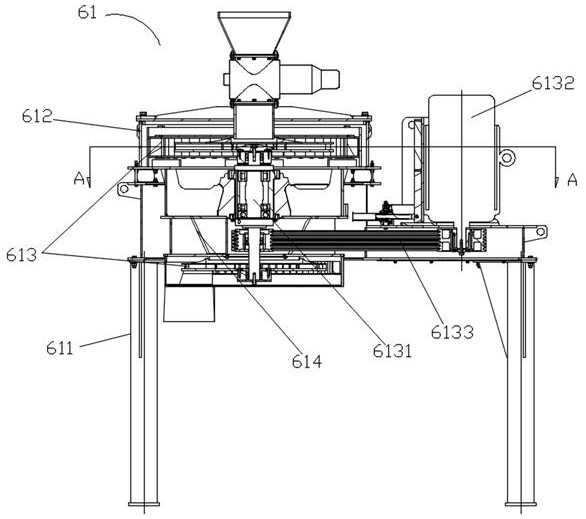

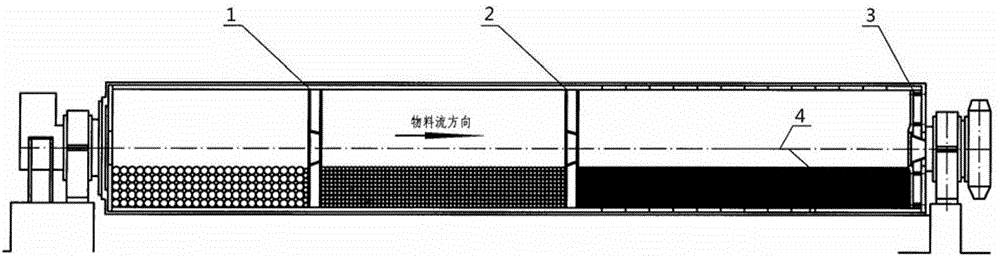

Thick-thin micro aggregate 6S processing process for concrete and production line

The invention discloses a thick-thin micro aggregate 6S processing process for concrete and a production line. The thick-thin micro aggregate 6S processing process comprises the following steps: pretreating materials; performing circulatory multi-stage rough crushing and multi-stage desliming; performing circulatory multi-stage fine crushing and multi-stage powder concentrating, and preparing finesand and aggregates of different specifications and different limestone powder contents in proportion; and performing crushing and processing, and multistage winnowing, sorting and collecting on recycled dust materials. The whole sand-making production line is perfected, so that the system yield can be effectively increased, and finished product gravel aggregate quality can be effectively improved, and therefore, various grading and optimal grading of finished product gravel aggregates are realized; moreover, recycled powder waste is effectively recycled, treatment ability is strong, mountainflour grading can be precisely controlled, and mountain flour of various specifications is prepared; and the thick-thin micro aggregate 6S processing process is used for effectively improving durability and mechanical property of concrete, is low in production cost, and is efficient and energy-saving.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

Real stone paint

InactiveCN104513038AIncrease authenticityGood construction performanceAcrylic resinCellulose compounds

A real stone paint includes, by weight, 30-40 parts of artificial color fine sand with the fineness of 80-120 meshes, 20-30 parts of artificial color medium sand with the fineness of 40-80 meshes, 5-10 parts of artificial big sand with the fineness of 10-20 meshes, 80-100 parts of acrylic resin, 0.1-0.3 parts of a cellulose compound, 30-60 parts of a master batch and 0.05-0.25 parts by weight of the antifoaming agent. The master batch used in the invention greatly improves the workability of a slurry in order to make the big sand in the real stone paint not settle. The grading of color sand particles is reasonable, and the addition of the big sand greatly enhances the real effect of the real stone paint. The cellulose compound obviously reduces the sand dropping phenomenon during spraying for a water retention thickening agent, and improves the workability of the real stone paint. The above artificial color sands have diversified and brilliant colors, and can be mixed to obtain colors cannot be realized by natural color sands.

Owner:QINGDAO XINGGUO PAINT CHEM

Mixture of concrete roadbase

The invention belongs to the technical field of solid waste resource utilization, and particularly relates to a mixture of a concrete roadbase. The mixture is prepared from the following components inparts by weight: 496-513 parts of thiourea waste residues, 350-469 parts of thermoelectric furnace slag, 75-84 parts of cement, 246-265 parts of fly ash, 96-113 parts of cyanamide residues and 398-423 parts of stones or building crushed materials. By the adoption of the method, thiourea can be comprehensively utilized for producing waste residues, meanwhile, soil filling smashing and compacting are facilitated, the strength of the roadbase can be improved, influences of compression deformation and shrinkage deformation are reduced, the water stability and durability of the roadbase are improved, the resource utilization level is improved, and the production cost is reduced.

Owner:山东京博环保材料有限公司

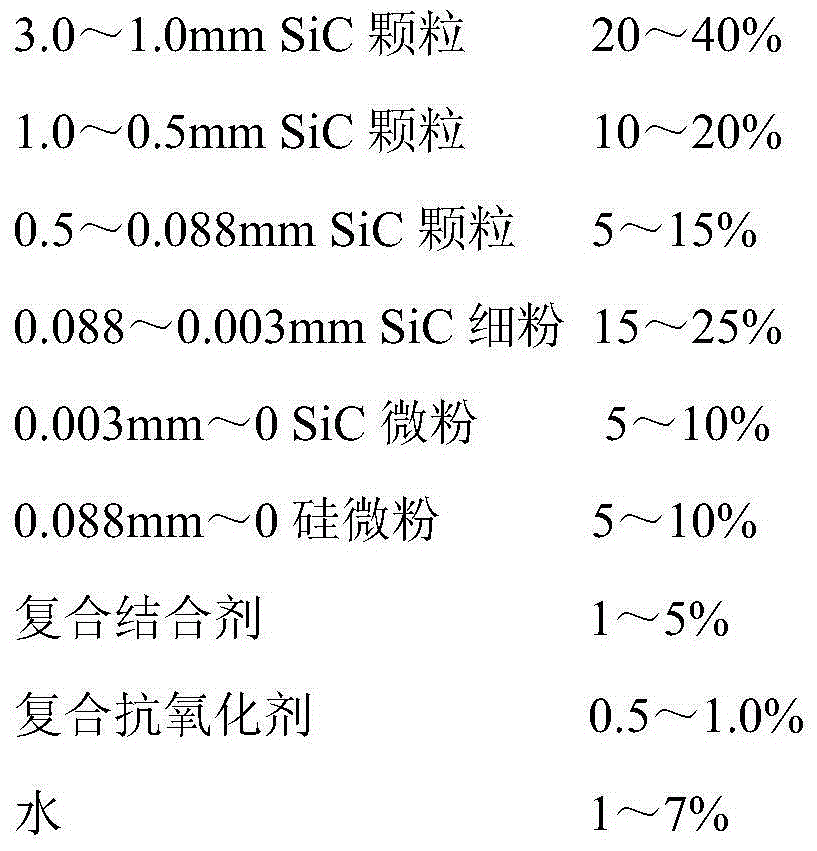

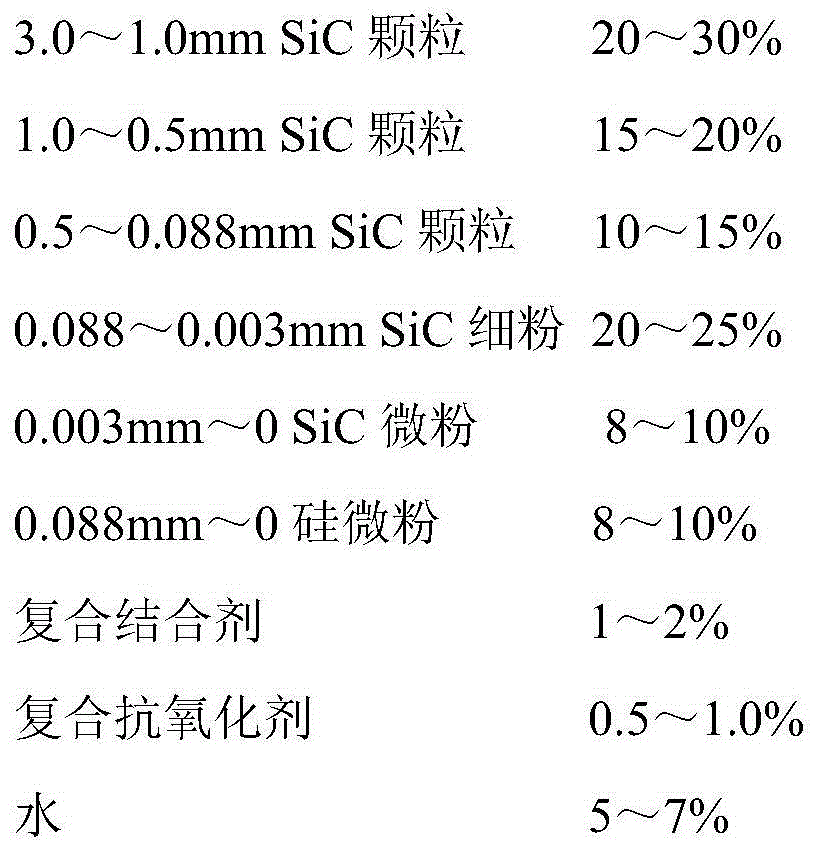

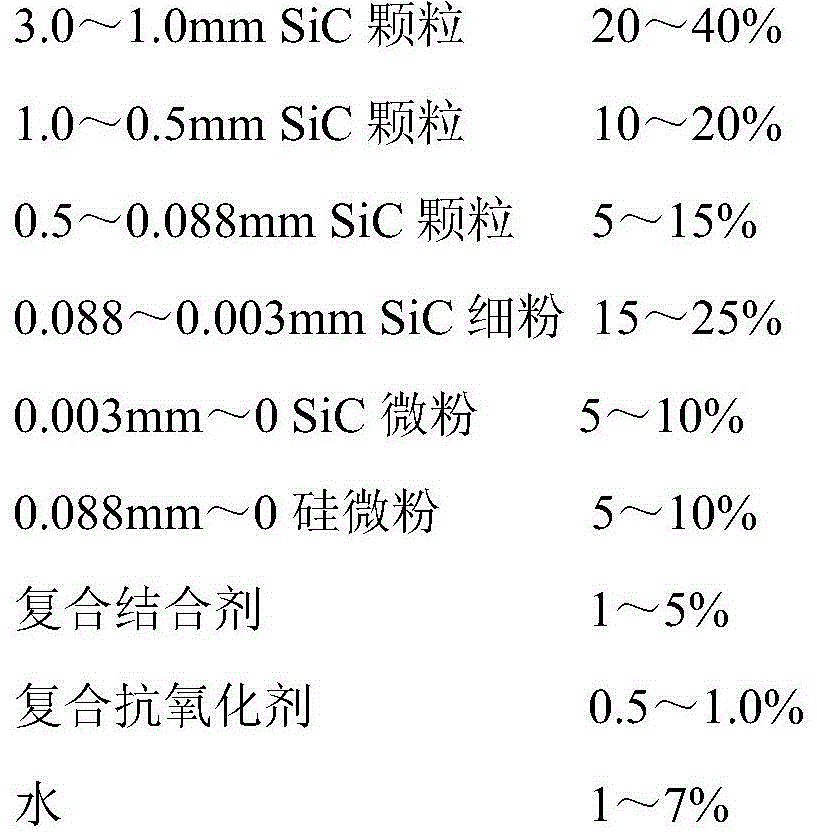

High-temperature-resistant energy-saving silicon carbide plate and preparation method thereof

The invention discloses a high-temperature-resistant energy-saving silicon carbide plate and a preparation method thereof, belonging to the technical field of ceramic materials. The high-temperature-resistant energy-saving silicon carbide plate is prepared from the following components in percentage by weight: 20-40% of 3.0-1.0mm SiC particle, 10-205 of 1.0-0.5mm SiC particle, 5-15% of 0.5-0.088mm SiC particle, 15-25% of 0.088-0.003mm SiC fine powder, 5-10% of 0.003-0mm SiC micropowder, 5-10% of 0.088-0mm silicon micropowder, 1-5% of composite binder, 0.5-1.0% of composite antioxidant and 1-7% of water. The preparation method comprises the following steps: proportionally mixing the materials, forming, drying, firing, and spraying a high-temperature oxidation-resistant paint on the surface. The high-temperature-resistant silicon carbide plate has the advantages of high density, high compressive strength and folding strength, consumption reduction, energy saving, lower waste gas emission and waste reutilization.

Owner:YIXING ZHONGCUN KILN PRODS

Adhesive tape matched with polymeric prelaid waterproofing membrane, and construction application thereof

InactiveCN110408341AHigh strengthGood bonding propertiesNon-macromolecular adhesive additivesFilm/foil adhesivesComposite filmEngineering

The invention discloses an adhesive tape matched with a polymeric prelaid waterproofing membrane. The adhesive tape matched with the polymeric prelaid waterproofing membrane comprises a PE release film, a polymeric self-adhesive film, a strong cross Laminated PE composite film, a polymeric self-adhesive film and a special surface particle layer which are sequentially arranged from bottom to top. The invention also provides a construction application of the adhesive tape matched with the polymeric prelaid waterproofing membrane. The adhesive tape matched with the polymeric prelaid waterproofingmembrane has the characteristics of good bonding property, high strength, softness, lightness and thinness, so the adhesive tape can be used to solve many problems occurring in onsite construction ofthe polymeric prelaid waterproofing membrane.

Owner:JIANGSU CANLON BUILDING MATERIALS

Mineralized material used in cement grinding process

The invention is suitable for the technical field of cement grinding aids, and provides a mineralized material used in a cement grinding process, the mineralized material is composed of the following substances by mass: 2-5% of sodium sulfate, 4-7% of sodium thiosulfate, 0-3% of sodium sulfite, 1-3% of maleic anhydride dimer acid triethanolamine ester, 1-3% of ethylene glycol, and 79-92% of fly ash. By determining proper substances and content, promoting early hydration of cement and greatly improving the early hydration rate of cement particles, the early strength is improved, the hydration durability is considered, the later hydration of the cement is promoted through sodium thiosulfate, maleic anhydride dimer acid triethanolamine ester and ethylene glycol, the strength of cement paste is improved, and the cement paste can also wrap the surface of cement particles to form a protective film to eliminate bonding and adsorption agglomeration, the maleic anhydride dimer acid triethanolamine ester can form an oxidation protection film on the metal surface to retard the corrosion of steel bars so that the machine-hour yield of a mill is increased, the comprehensive performance of the product is improved, the power consumption of cement grinding is reduced, and the damage to the cement concrete caused by excessive chloride ions is avoided.

Owner:山西天润恒德新材料有限公司

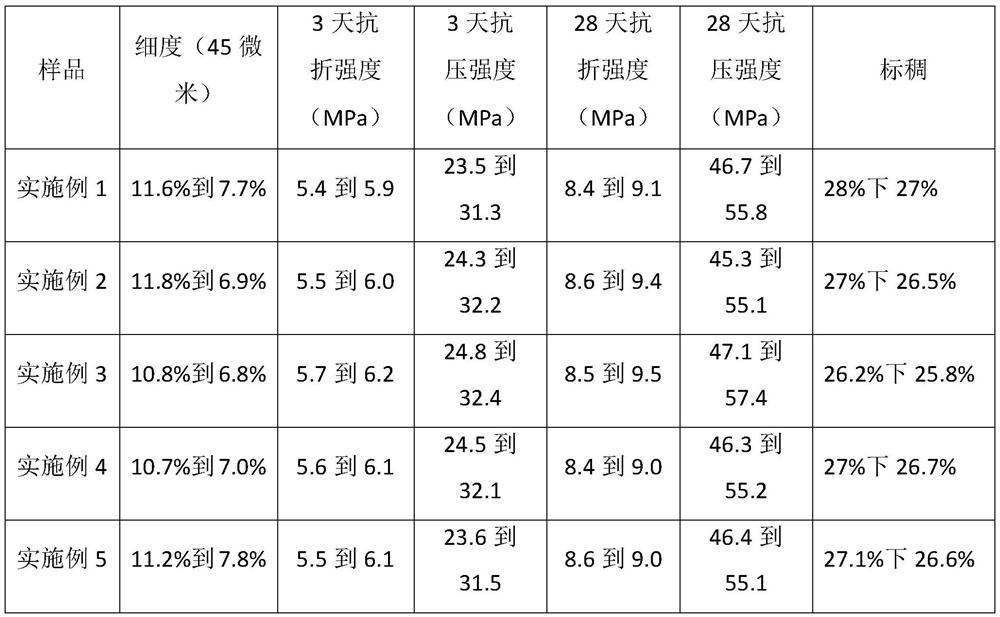

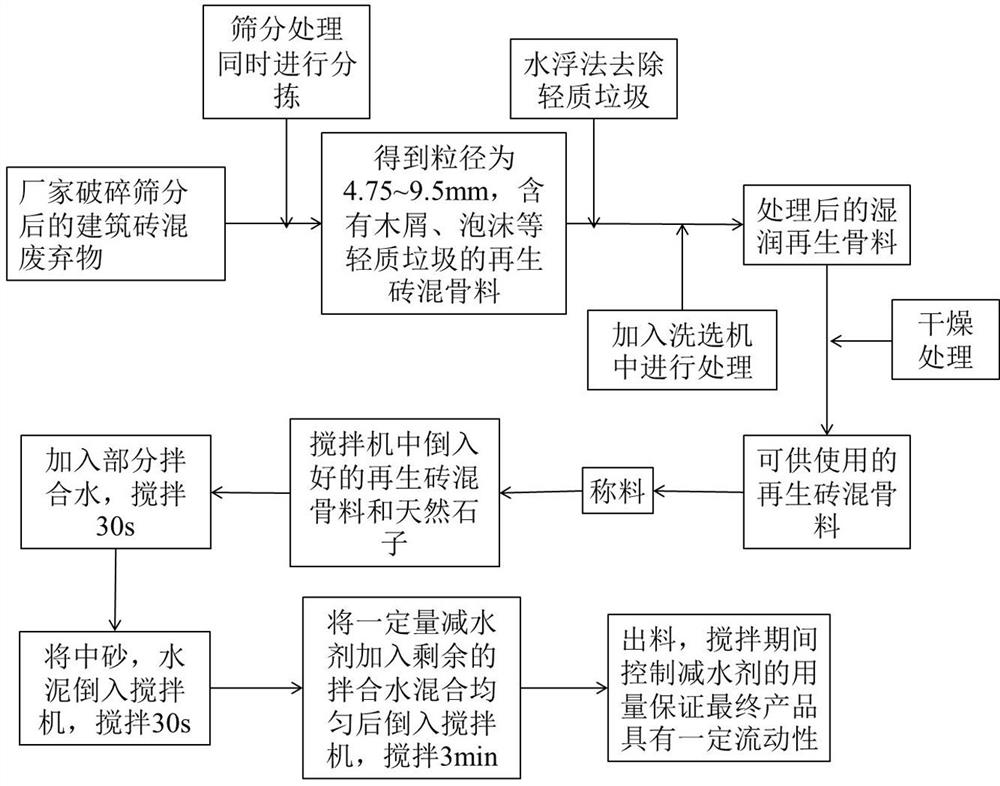

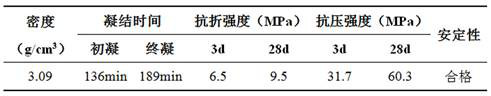

Preparation method of recycled brick-concrete aggregate pervious concrete

Owner:ZHEJIANG UNIV

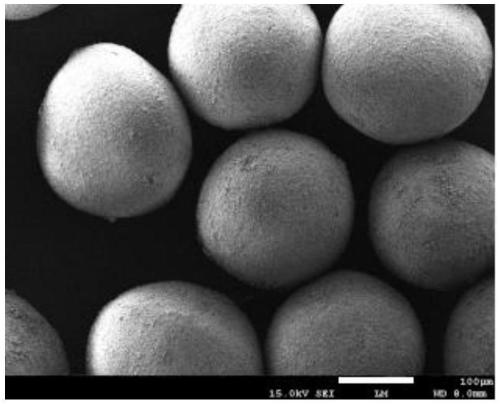

Method for preparing medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using surplus materials

The invention relates to the field of preparation of micro-beads, in particular to a method for preparing a medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using surplus materials. The formula comprises the raw materials in mass percentage: 48%-88% of zirconium silicate micro-powder surplus material having D50 of smaller than 7 microns discarded in the process of preparing zirconium silicate polishing micro-powder, 9%-49% of aluminum sesquioxide micro-powder surplus material having D50 of smaller than 7 microns discarded in the process of preparing aluminum sesquioxide polishing micro-powder and 3% of lignin. The method comprises the preparation steps of proportioning materials, drily mixing the materials, wetly mixing the materials, ageing the mixture, tightly compacting the mixture, crushing the mixture, screening the mixture, pelletizing the mixture, tightly molding the pelletized balls, selecting balls, drying the balls, screening the balls, sintering the balls, carefully selecting the sintered balls, polishing the balls, cleaning the balls and drying the balls. The prepared micro-bead has a particle size of 63-600 microns and a density of 3.8-4.0 g / cm3 and a sphericity of more than 95%. According to the method for preparing the medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using the surplus materials, the industrial residual materials are utilized, the cost is low, the product application is wide, the process is simple, and the method is an innovation in the preparation method of the zirconium silicate composite microbead.

Owner:郑州可塑金新材料有限公司

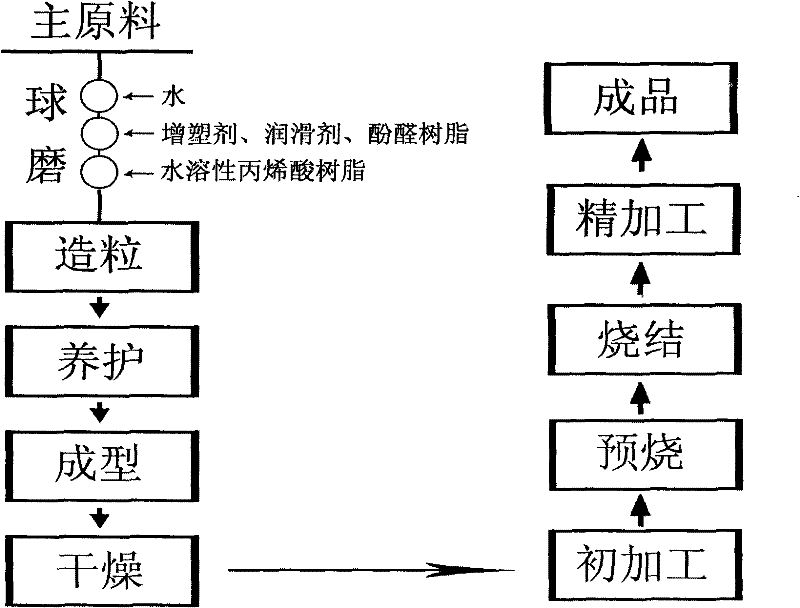

Preparation method of normal pressure-sintered silicon carbide ceramics

The invention discloses a preparation method of normal pressure-sintered silicon carbide ceramics, which adopts a solid normal pressure sintering method and takes submicro silicon carbide powder, graphite powder and boron carbide powder as main materials. The method comprises the following steps: 1) material grinding is carried out by adopting a staged ball milling mode, firstly, the main raw materials are ball-milled by adding water under the environment of the pH value being 10-12 to lead the agglomerated silicon carbide micro powder and other main raw materials to be evenly dispersed; thena plasticiser, a lubricant and water soluble phenol resin are added and ball-milled for a period of time; and finally a caking agent is added for ball milling; 2) spray granulation technology is adopted for carrying out granulation on the silicon carbide slurry; (3) the materials after granulation are maintained under constant temperature and humidity; (4) double-sided compression moulding is carried out on the maintained materials; (5) a staged drying mechanism is adopted for drying the molded body; and (6) the silicon carbide body is put in a vacuum firing furnace for being subjected to twotimes of sintering by taking the argon as protective gas. The silicon carbide ceramics prepared by the method have superior performance, corrosion resistance and long service life, and are applicableto commercial process.

Owner:宁波欧翔精细陶瓷技术有限公司

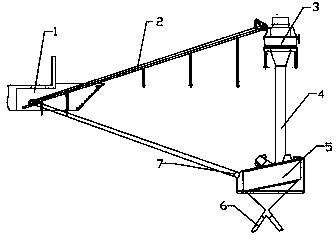

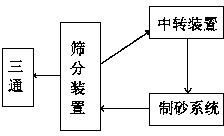

Construction waste sand-making equipment

The invention discloses construction waste sand-making equipment, which is mainly used for solving a problem that the existing construction waste cannot be reasonably utilized. The construction waste sand-making equipment structurally comprises a transfer device, a sand-making system, a screening device and a tee joint, wherein the transfer device and the sand-making system are connected by a belt conveyor; the sand-making system and the screening device are connected by a conveying device; a discharging hole of the screening device is connected with the tee joint; a material return hole is formed in one side of the screening device; the material return hole is connected with the transfer device by a returning belt conveyor. The equipment disclosed by the invention is convenient to use, cost-saving, suitable for a production line of construction waste and common stone sand making, capable of realizing comprehensive utilization of construction waste, environmental friendly and energy-saving.

Owner:SHANTUI JANEOO MACHINERY

Preparation method of high-performance recycled aggregate concrete

A preparation method of high-performance recycled aggregate concrete is characterized in that waste concrete is broken to obtain large stones with granularity of 20 to 25mm, small stones with granularity of 5 to 20mm and sand with granularity of smaller than 5mm, and dust produced in the breaking process is pneumatically collected; and then the large stones, the small stones and sand are mixed with polycarboxylic acid water reducing agent, cement and appropriate water to further obtain the high-performance recycled aggregate concrete. Against for the special situation of the waste concrete, the waste concrete is smashed and screened on purpose, so that a new concept for treating the waste concrete is provided, the problems such as worsening of engineering disasters, resource waste and environmental pollution can be avoided, and the performance of the recycled concrete is excellent.

Owner:SHANDONG DAYUAN IND

A method and preparation process for preparing yellow phosphorus from low-grade phosphate rock

ActiveCN105329865BSimple ingredientsReduce consumptionRaw phosphate material treatmentHalogenated silanesPhosphateYellow phosphorus

The invention relates to a method used for producing yellow phosphorus from low-grade phosphate ore. According to the method, phosphate ore powder with appropriate silicon content and low iron content is obtained via selectively adapting silicon concentrating or removing technology and removing iron-containing compounds in smashing period based on the difference of phosphate ores in mining period; a first time P2O5 enrichment and a second time P2O5 enrichment are carried out respectively via drying, roasting, or obverse flotation, or reverse flotation, drying,, curing, and obtaining of phosphate ore balls. The method is low in cost, high in efficiency, is friendly to the environment, is capable of improving yellow phosphorus quality, avoiding accidents or faults such as arch structure formation, material collapse, and electrode broken, and ensuring safe, stable, and high efficiency operation of electric furnaces.

Owner:成都天屿新磷科技有限公司

Synthesized compound sillimanite products and preparation method thereof

The invented synthetic composite sillimanite product is a composte body formed from mullite crystal phase as main material and corundom phase and high silica glass as auxiliary material, and its composition includes (wt%) 28-32% of alpha-alumina powder, 8-12% of plate corundom granules, 7-10% of silicon dioxide powder, 38-42% of mullite aggregate, 8-14% of mullite powder, and 0.2-0.8% of fused magnesite powder. Its preparation adopts gel forming method including the following steps: firstly, preparing monomer premixed liquor, adding micropowder materials, ball-grinding to make slurry, adding aggregate, initiator and defoaming agent, stirring and mixing them uniformly to obtain suspension body, finally, pouring it into mould and forming so as to obtain the invented sillimanite product.

Owner:殷若博

Grading method of ore ball mill

InactiveCN112934380AIncrease contact areaImprove crushing effectGrain treatmentsEngineeringBall mill

The invention relates to a grading method of an ore ball mill. The purposes of improving the collision probability of grinding balls and increasing the contact surface of the grinding balls and a lining plate are achieved. The proportion of the total convex surface area and concave surface area of the grinding balls and the lining plate is used as a grading basis, the proportion number of each grinding ball can be accurately calculated by solving an equation set, the total convex surface area and the total concave surface area of the lining plate and the grinding ball participating in ore grinding work are approximately equal, and the probability of convex-concave matching collision between the lining plate and the grinding balls is improved to the greatest extent, so that the comprehensive ore grinding efficiency of the ball mill is greatly improved. The grading method of the ore ball mill is suitable for grading of two-stage grinding balls, and is suitable for grading of multi-stage grinding balls. Besides, the crushing performance and the grinding performance of the ball mill are balanced, the ball mill does not need to be provided with a multi-bin structure, a through bin structure with a simple structure is adopted, so that the swelling caused by non-uniform capacity of each bin is avoided, the grading of the grinding balls is more reasonable, and the operation is easier.

Owner:栾川县金鼎矿业有限公司

Low-temperature fast-fired environmentally-friendly pottery clay plate prepared from iron ore tailings and preparation method thereof

ActiveCN102795838BReasonable gradationHigh porosityCeramic materials productionClaywaresPyrophyllitePlasticizer

The invention relates to a low-temperature fast-fired environmentally-friendly pottery clay plate prepared from iron ore tailings and a preparation method thereof. Iron ore tailings obtained by iron ore enterprise production is used as a main solvent raw material and is adopted by a formula of the low-temperature fast-fired environmentally-friendly pottery clay plate. The low-temperature fast-fired environmentally-friendly pottery clay plate comprises a superfine plastic material, a fine lean material, fine iron ore tailings, a coarse lean material, a plasticizer and water. The formula of the low-temperature fast-fired environmentally-friendly pottery clay plate comprises illite, kaolin, chinastone, pyrophyllite, iron ore tailings, the coarse lean material, the plasticizer and water. The preparation method comprises the following steps of uniformly mixing 15 to 35% by mass of the superfine plastic material, 10 to 45% by mass of the fine lean material and the coarse lean material, 20 to 50% by mass of iron ore tailings and 0 to 5% of by mass of the plasticizer, adding 10 to 28% by mass of water into the mixture, carrying out extrusion molding by a screw-type extruder, drying, and carrying out sintering in a roller kiln having the length of 280 meters at a temperature of 1000 to 1100 DEG C, wherein a sintering period is in a range of 1 to 1.5 hours. The mixed raw materials adopted by the preparation method have good extrusion performances and good drying and sintering performances. The low-temperature fast-fired environmentally-friendly pottery clay plate sintered by the preparation method has high strength and small contractility, cracks and deforms difficultly, can be sintered fast and has high environmental protection benefits and economic benefits.

Owner:江苏金久科技新材料有限公司

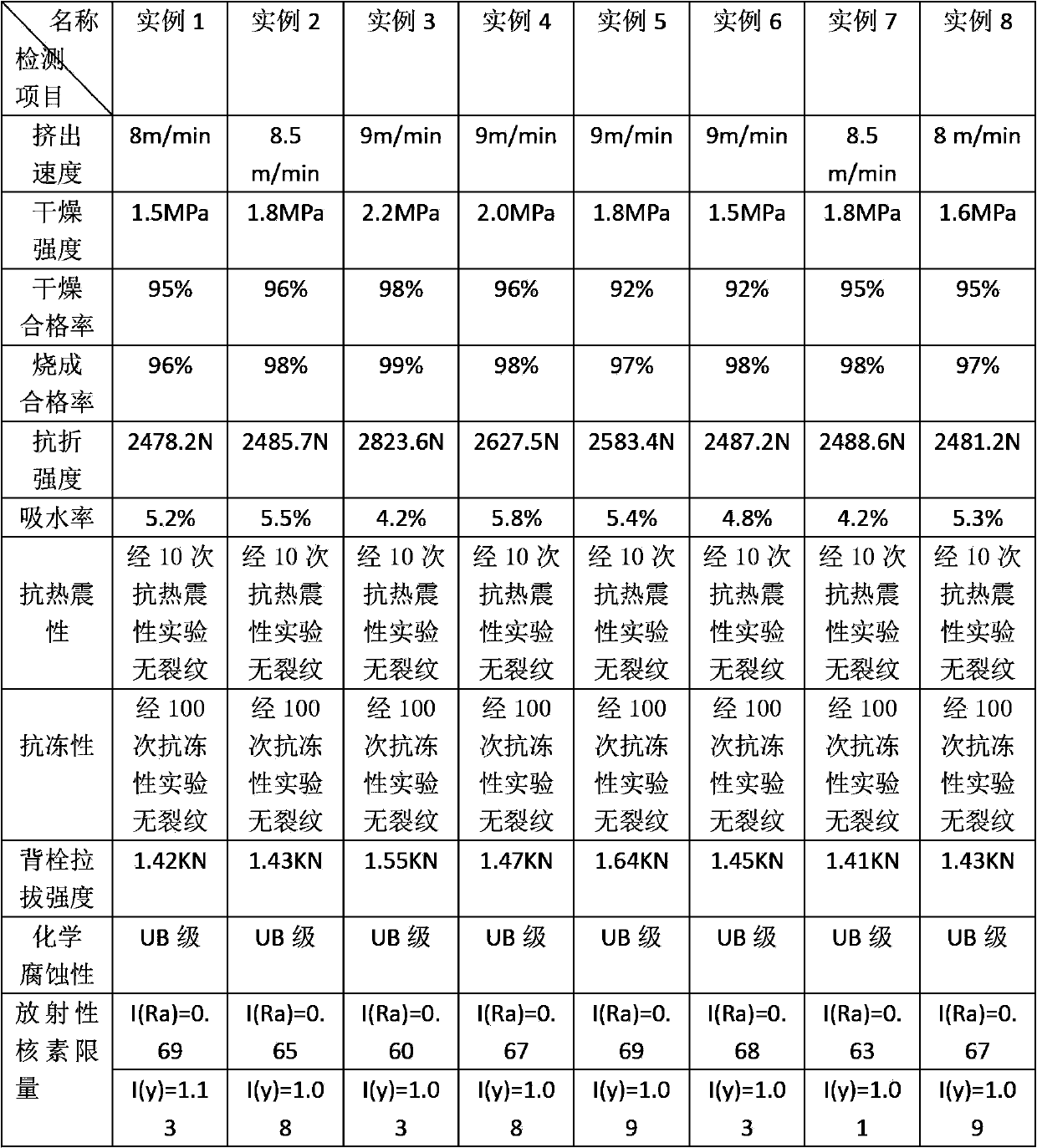

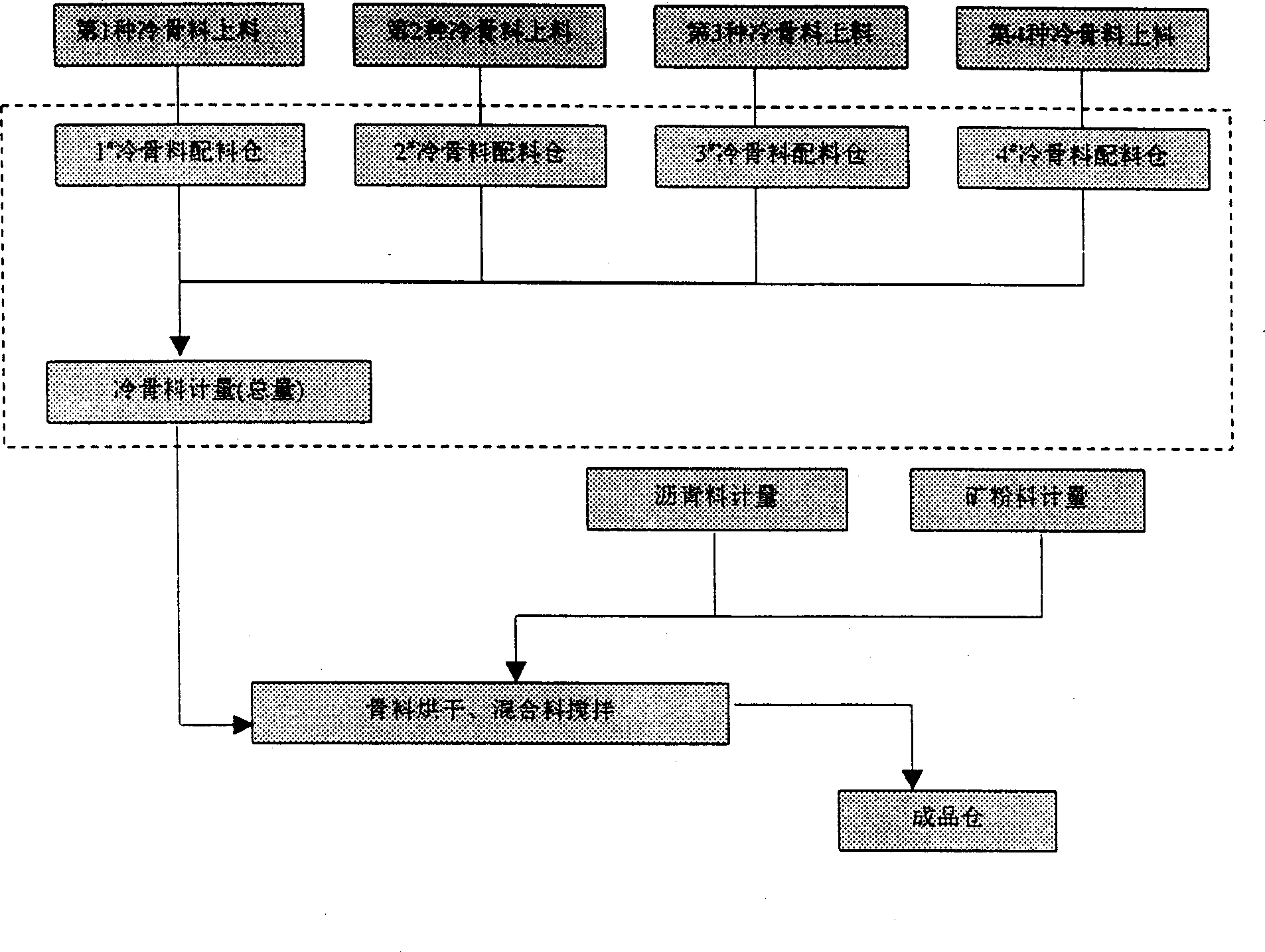

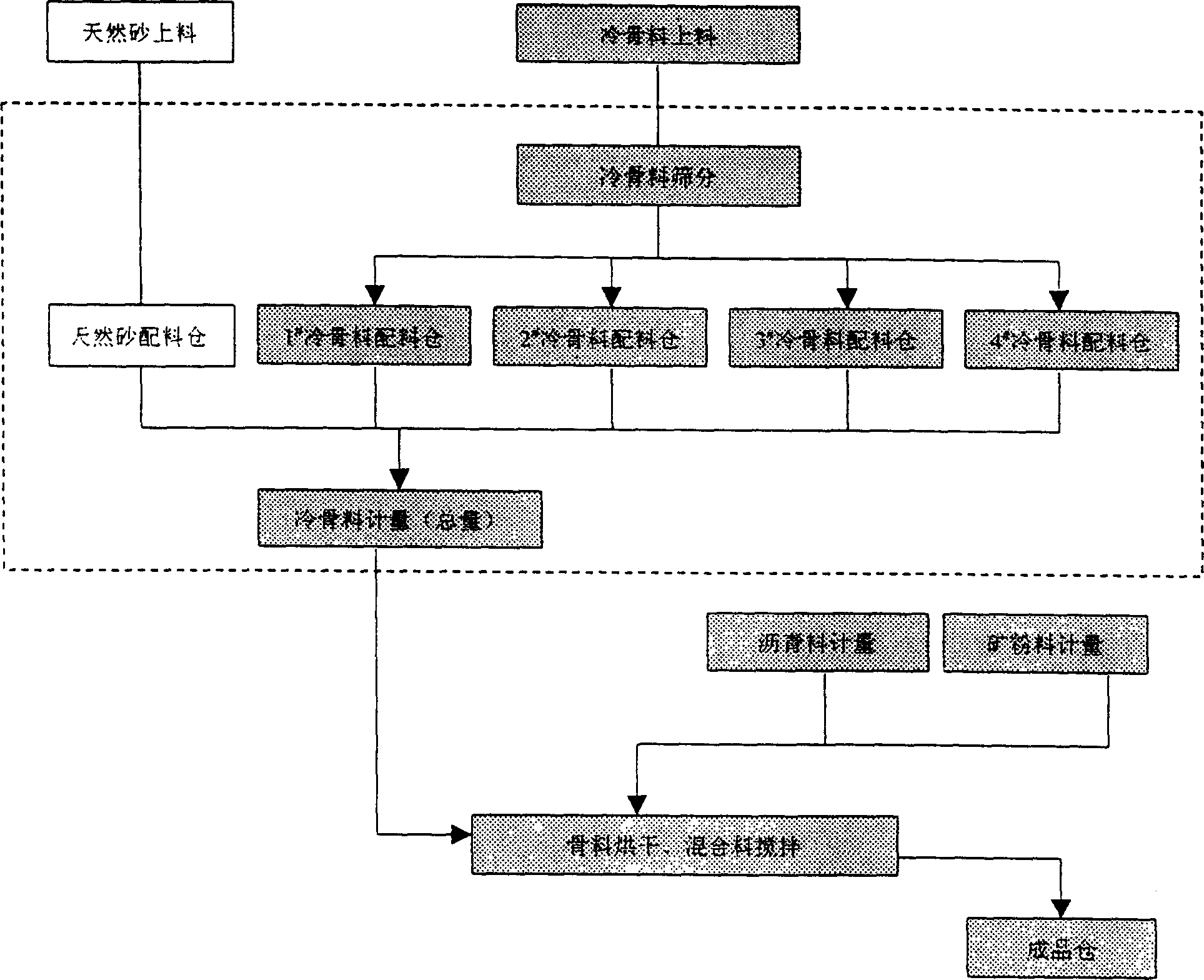

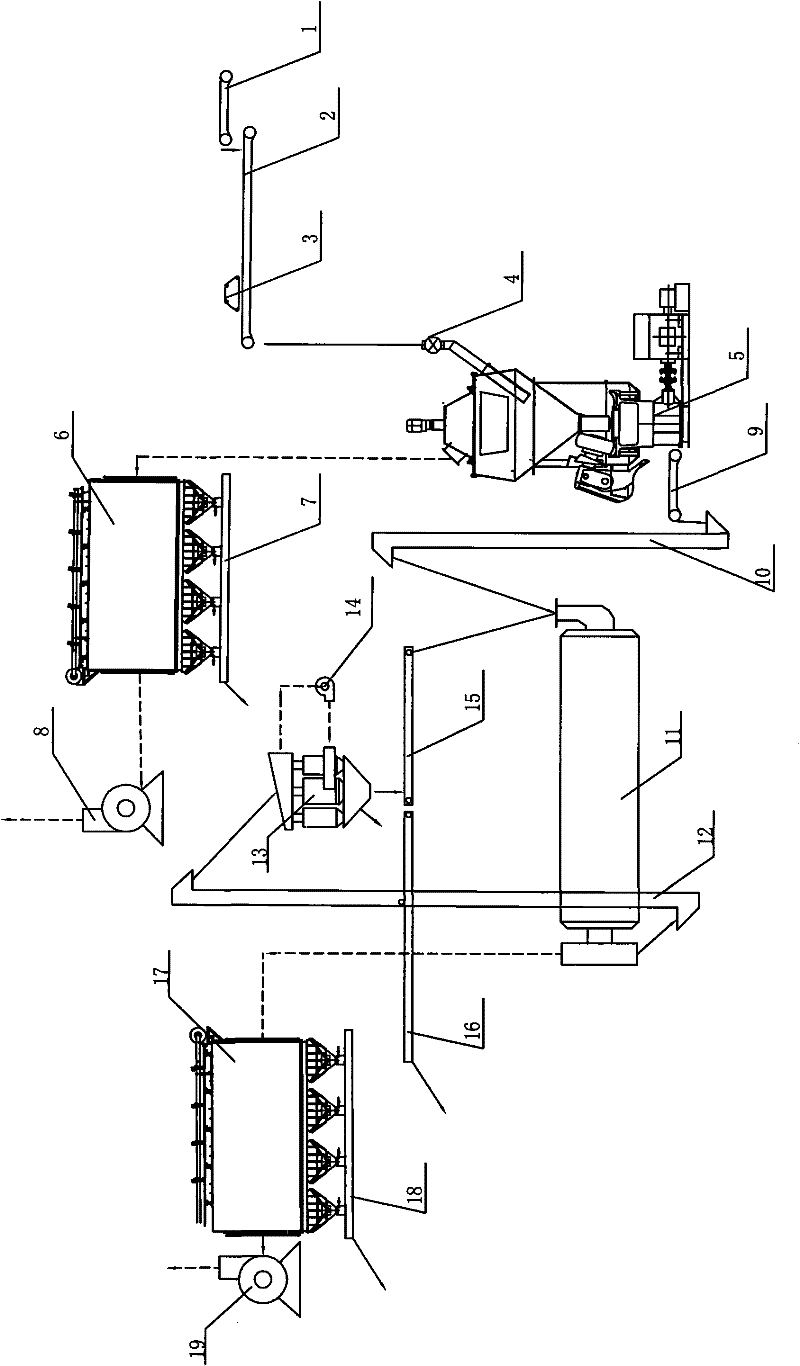

Cold aggregate batching treatment method and device for continuous bituminous concrete mixing equipment

InactiveCN1173813CQuality improvementReasonable gradationSievingScreeningSurface constructionRoad surface

The present invention relates to a cold aggregate batching treatment method for continuous-stirring equipment of bituminous concrete for highroad surface construction and asphalt parement regeneration engineering, and is characterized by that before the cold aggregate is continuously metered, firstly, said cold aggregate is passed through sieving machine to implement pregradation, then continuously metered by means of metering device then fed into continuous bituminous concrete stirring equipment and its next stoving procedure.

Owner:袁国琴

Semi-finished pre-grinding vertical-milling and ball-milling combined grinding device

InactiveCN101862699BReasonable gradationLess investmentCement productionGrain treatmentsEconomic benefitsCement grinding

The invention belongs to the technical field of cement grinding, in particular to a semi-finished pre-grinding vertical-milling and ball-milling combined grinding device which comprises a semi-finished pre-grinding vertical-milling machine and a ball milling machine, wherein the feeding end of the semi-finished pre-grinding vertical-milling machine is connected with the discharging end of a proportioning belt scale, a gas outlet is connected with a dust remover, and the discharging hole of the dust remover is connected with a finished product conveying machine; the discharging hole of the semi-finished pre-grinding vertical-milling machine is connected with a lifting machine through a vertical milling discharging belt, and the discharging hole of the lifting machine is connected with the feeding hole of the ball milling machine; the gas outlet of the ball milling machine is connected with the dust remover, the discharging hole of the dust remover is connected with the finished productconveying machine; and the discharging hole of the ball milling machine is connected with a powder concentrating machine through the lifting machine, the finished product fine powder discharging holeof the powder concentrating machine is connected with a third finished product conveying machine, and the crude powder discharging hole of the powder concentrating machine is connected with the feeding hole of the ball milling machine through a feed back conveying machine. The invention combines high yield and energy saving of the vertical milling machine with cement grading advantages of the ball milling machine, and has lower investment, lower electricity consumption, more reasonable grading of cement particles, very convenient maintenance and remarkable economic benefit.

Owner:南京旋立重型机械有限公司

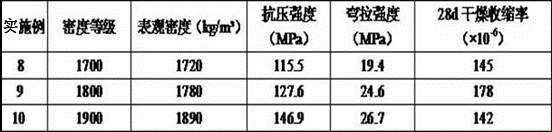

A self-made low-defect ultra-high-strength lightweight aggregate and its preparation method and application

The invention relates to the technical field of building materials, in particular to a self-made low-defect ultra-high-strength lightweight aggregate, which is made of the following raw materials in parts by weight: 700-770 parts of cement, 90-110 parts of fly ash, and 210-230 parts of silica fume 90-135 parts of hollow glass beads, 4-8 parts of polyvinyl alcohol fiber, 360-520 parts of quartz sand, 1.8-2.2 parts of active activator, 28-35 parts of water reducing agent, 0.06-0.08 parts of defoamer , 135-155 parts of water; the self-made low-defect ultra-high-strength lightweight aggregate adopting the technical solution of the present invention has very obvious advantages when preparing lightweight high-strength concrete, and has broken through the strength bottleneck of lightweight concrete represented by ceramsite concrete , and at the same time solve the problem of poor coordination between aggregate and matrix in concrete, with good feasibility and broad application prospects.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

Mill capable of improving mixing amount of road cement mineral powder

InactiveCN104475196AOvercome unreasonable mill gradationReasonable gradationGrain treatmentsCurrent limitingMulti element

The invention discloses a mill capable of improving the mixing amount of road cement mineral powder. The mill comprises a first sorting sub system, a second sorting sub system, an activated arc current-limiting ring and a special discharge system for a sorting mill, which are connected sequentially; the special discharge system for the sorting mill is internally provided with abrasion-resistant multi-element alloy micro forged pieces. The mill capable of improving the mixing amount of the road cement mineral powder can overcome the defects of unreasonable mill grading, poor metering accuracy, low clinker intensity and the like in the prior art so as to achieve the advantages of reasonable mill grading, good metering accuracy and high clinker intensity.

Owner:GUANGXI YUFENG CEMENT

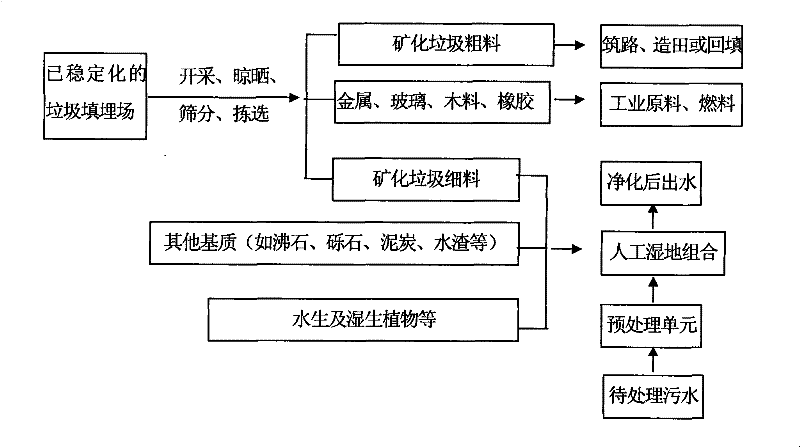

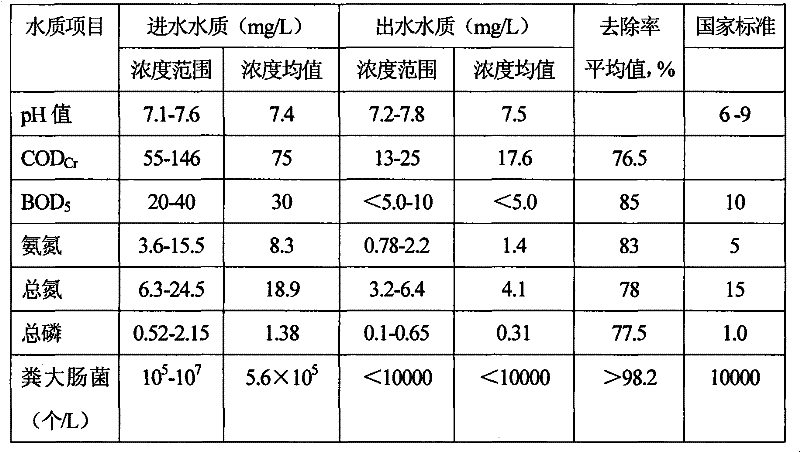

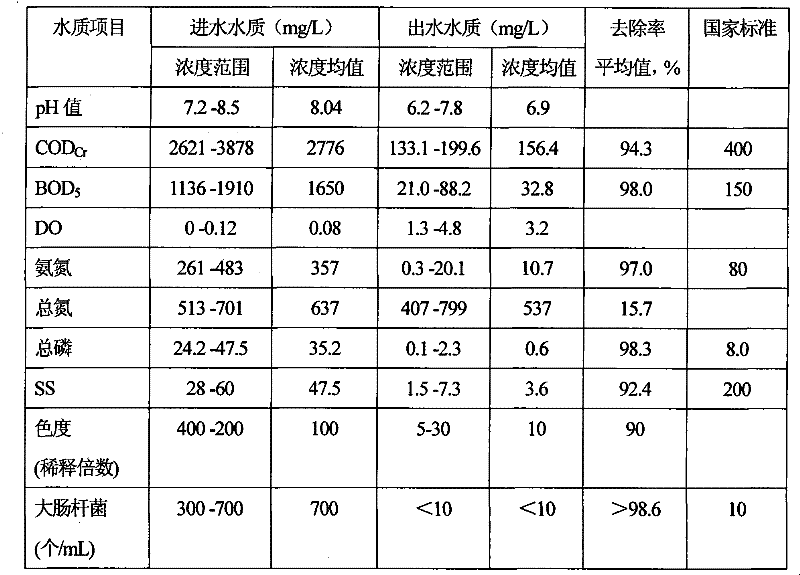

Method for constructing artificial wetland through aged refuse for processing sewage

ActiveCN101838053BAchieve recyclingEasy to handleSolid waste disposalSustainable biological treatmentConstructed wetlandLitter

The method provides a method for constructing artificial wetland through aged refuse for processing sewage, which includes the following steps: extracting, airing, sieving and sorting the aged refuse to obtain granular loose fine material; constructing an artificial wetland substrate bed by taking the aged refuge fine material as the base substrate together with other substrates; and growing hygrophytes on the bed. The method not only provides a new option for substrate for processing various types of sewage through wetlands and provides an approach for improving the additional value of the aged refuge.

Owner:BAOSHAN IRON & STEEL CO LTD

Process or preparing microcrystal wear-resisting alumina ceramic

The invention belongs to the field of ceramic processes, and in particular relates to a process for preparing a microcrystal wear-resisting alumina ceramic. The process comprises the following steps: ball-milling raw materials into small particles of 1.8 micrometers; detecting the particle size of slurry; drying and milling the slurry, and then grading the particles; performing pressure forming on blanks; and finally sintering the ceramics. The process has the following advantages: in the process of milling, a servo system is used when conveying the materials from a stock tank to a spray drying tower to ensure that the flowing slurry is even and the moisture in the prepared powder is even; and the adoption of mesh screens with different diameters to perform particle gradation is more reasonable and the particle distribution is controlled precisely.

Owner:JINGANG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com