Low-temperature fast-fired environmentally-friendly pottery clay plate prepared from iron ore tailings and preparation method thereof

A technology of iron ore tailings and clay panels, applied in the field of building decoration materials, can solve the problems of low drying pass rate, waste, long drying cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

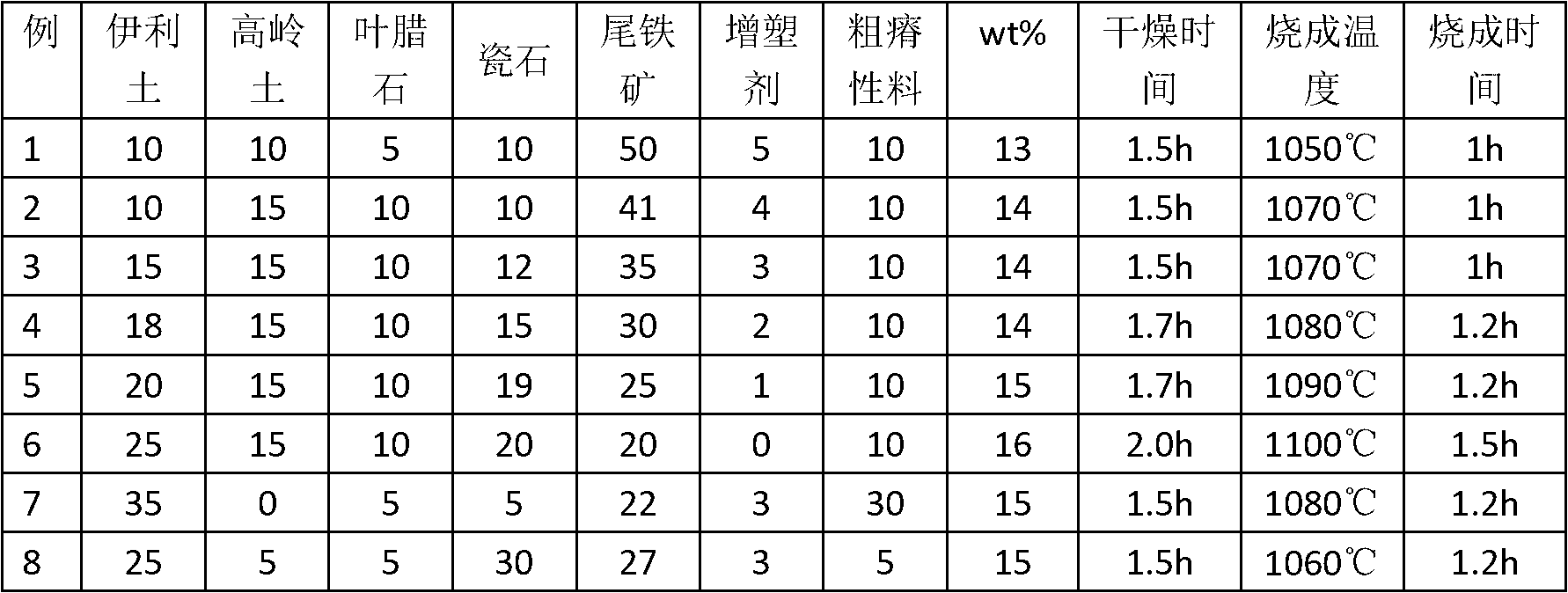

Examples

Embodiment Construction

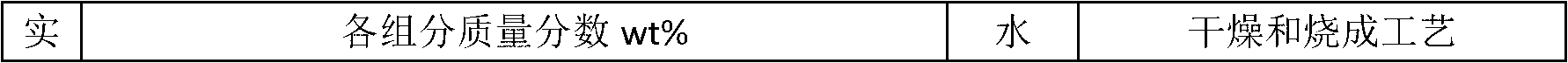

[0018] A low-temperature fast-burning environment-friendly clay board prepared by iron ore tailings. The formula of the clay board includes the following component raw materials in terms of mass percentage: 10-35% of illite, 0-15% of kaolin, and 5-15% of pyrophyllite , porcelain stone 5-30%, iron ore smelting tailings 20-50%, coarse material 5-30% and plasticizer 0-5%;

[0019] A clay mass made of a mixture of the above components and water, subjected to molding, drying and firing steps to obtain clay panels;

[0020] Among them, the coarse material is obtained by crushing quartz, pyrophyllite and / or waste clay plates.

[0021] Described plasticizer mainly adopts macromolecule binder, and existing plasticizer is optional more, and the selection of plasticizer should meet the following conditions:

[0022] 1) After adding the mud, the ceramic mud will not thicken, will not affect the fluidity of the mud, and is easy to transport the mud. It fundamentally solves the defects of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com