Preparation method of normal pressure-sintered silicon carbide ceramics

A silicon carbide ceramic and atmospheric sintering technology, applied in the field of preparation, can solve the problems of insufficient service life, limited application, insufficient corrosion resistance, etc., and achieve the effects of uniform moisture content, reasonable gradation and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

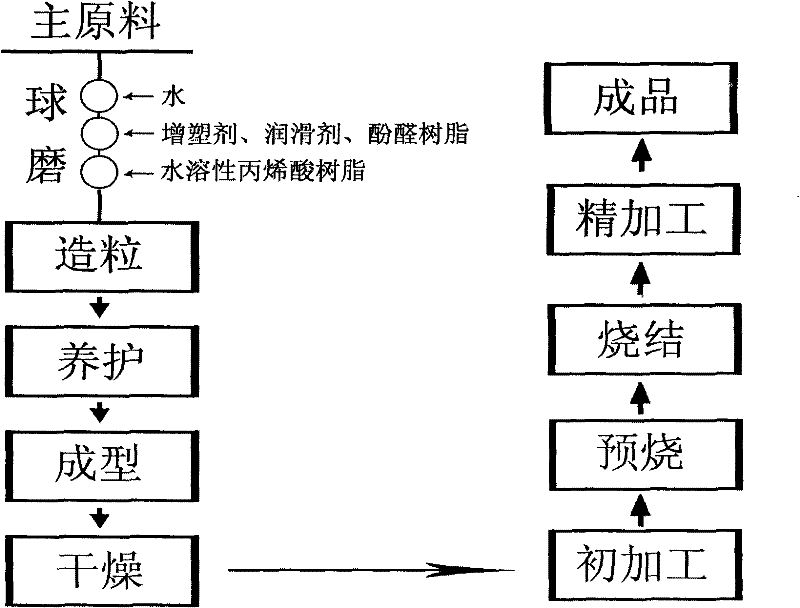

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of solid-phase atmospheric pressure sintered silicon carbide ceramics, the main raw materials are 98.9% by weight of submicron silicon carbide powder, 0.6% of graphite powder, and 0.5% of boron carbide powder, and the weight of the main raw materials is 100%, including the following steps:

[0030] 1) Put the main raw material and water with a weight of 122% of the main raw material into a ball mill and mill for 6 hours to form a silicon carbide slurry with a solid content of 45%, and the pH of the system is 11;

[0031] 2), adding 0.5% polyethylene glycol and 0.6% oleic acid as the main raw materials to the silicon carbide slurry, and then adding 0.8% water-soluble phenolic resin to ball mill for 5 hours;

[0032] 3), adding water-soluble acrylic resin of 1.5% by weight as the main raw material, and then ball milling for 4 hours;

[0033] 4) Using a spray drying process to granulate the silicon carbide slurry after ball milling to obtain silicon c...

Embodiment 2

[0043] A preparation method of solid-phase atmospheric pressure sintered silicon carbide ceramics, the main raw materials are 99% by weight of submicron silicon carbide powder, 0.5% of graphite powder, and 0.5% of boron carbide powder, and the weight of the main raw materials is 100%, including the following steps:

[0044] 1) Add the main raw material and water with 100% weight of the main raw material into a ball mill and mill for 8 hours to form a silicon carbide slurry with a solid content of 50%, and the pH of the system is 11;

[0045]2), adding 0.4% sucrose lipid and 0.5% stearic acid as the main raw materials to the silicon carbide slurry, and then adding 1% water-soluble phenolic resin for ball milling for 6 hours;

[0046] 3), adding water-soluble acrylic resin of 1% by weight as the main raw material, and then ball milling for 4 hours;

[0047] 4) Using a spray drying process to granulate the silicon carbide slurry after ball milling to obtain silicon carbide granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com