Preparation method of recycled brick-concrete aggregate pervious concrete

A technology for permeable concrete and recycled bricks, applied in the field of building materials, can solve the problems of many edges and corners of recycled aggregate particles, low strength of recycled aggregates, uneven surface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

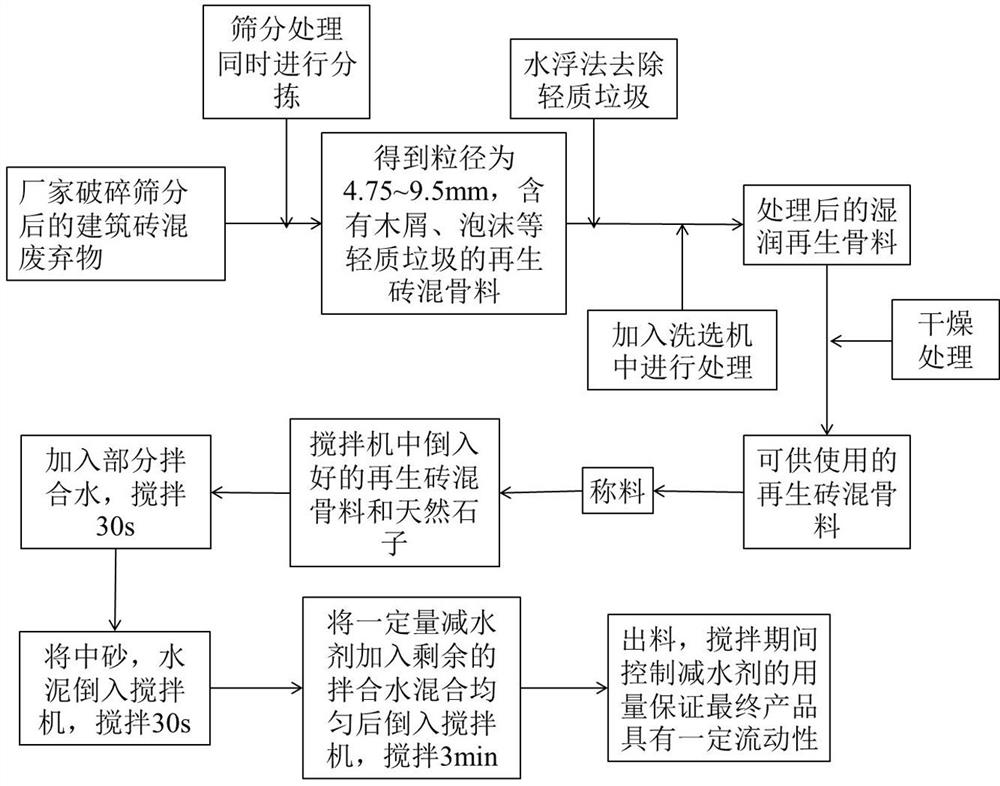

[0027] figure 1 Schematic diagram of the process for preparing pervious concrete from recycled brick-concrete aggregates. Such as figure 1 Shown, a kind of preparation method of recycled brick-concrete aggregate permeable concrete comprises steps:

[0028] The replacement rate of recycled aggregate in the recycled brick-concrete aggregate permeable concrete prepared in this example is 20%.

[0029] S1: Use a vibrating screen to re-screen the recycled brick-concrete aggregate raw materials that have been primarily crushed and screened to obtain recycled brick-concrete aggregates with a particle size of 4.75-9.5mm; While the raw materials are screened again, they are sorted to remove the large iron nails, glass fragments and wood doped in the recycled brick-concrete aggregate.

[0030] S2: Use the water flotation method to remove the light waste mixed in the recycled brick-concrete aggregate, and then place the recycled brick-concrete aggregate in a washing machine for proces...

Embodiment 2

[0041] A preparation method of recycled brick-concrete aggregate permeable concrete, wherein the replacement rate of recycled aggregate is 60%. Compared with Example 1, the difference of this example is that the amount of various materials used in the whole process of this example Recycled brick-concrete aggregate 633kg / m3, natural aggregate 422kg / m3, medium sand 264kg / m3 3 , cement 395kg / m3 , water 590kg / m 3 , the amount of water reducer depends on the concrete mixing state; finally the concrete mixture is formed into a test block. The compressive strength test method of the obtained sample is the same as that of Example 1, and the compressive strength of the final obtained sample is 16.43MPa.

Embodiment 3

[0043] A preparation method of recycled brick-concrete aggregate permeable concrete, wherein the replacement rate of recycled aggregate is 100%. Compared with Example 1, the difference of this example is that the amount of various materials used in the whole process of this example Recycled brick-concrete aggregate 1054kg / m 3 , medium sand 264kg / m 3 , cement 395kg / m 3 , water 590kg / m3, the amount of water reducer depends on the concrete mixing state; finally the concrete mixture is formed into a test block. The compressive strength test method of the obtained sample is the same as that of Example 1, and the compressive strength of the final obtained sample is 8.18MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com