Repair mortar for tap water pipeline PCCP (Prestressed Concrete Cylinder Pipe)

A tap water pipeline repairing mortar technology, applied in the field of polymer cement mortar, to achieve the effects of improving cohesion and water retention, improving overall flexibility, and improving rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

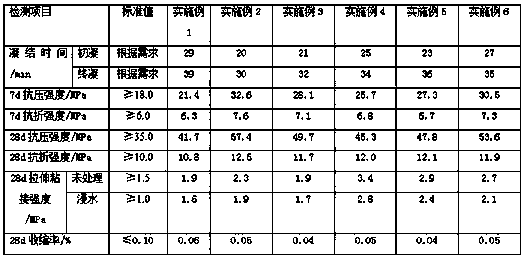

Examples

Embodiment 1

[0031] A repairing mortar for PCCP pipes for tap water pipelines, comprising the following raw materials in parts by weight: 30 parts of Portland cement; 20 parts of sulphoaluminate cement; 7 parts of heavy calcium powder; 40 parts of fine aggregate; redispersible rubber powder 3 parts; lithium carbonate 0.005 part; boric acid 0.1 part; hydroxyethyl cellulose ether 0.05 part; water reducer 0.01 part.

Embodiment 2

[0033] A repairing mortar for PCCP pipes for tap water pipelines, comprising the following raw materials in parts by weight: 50 parts of Portland cement; 10 parts of sulphoaluminate cement; 5 parts of heavy calcium powder; 30 parts of fine aggregate; redispersible rubber powder 5 parts; 0.1 part of lithium carbonate; 0.08 part of boric acid; 0.2 part of hydroxyethyl cellulose ether; 0.1 part of water reducer.

[0034] In this embodiment, Portland cement is ordinary salt cement with a strength grade of 42.5; and sulphoaluminate cement is a sulphoaluminate cement with a strength grade of 42.5.

Embodiment 3

[0036]A repairing mortar for PCCP pipes for tap water pipelines, comprising the following raw materials in parts by weight: 40 parts of Portland cement; 15 parts of sulphoaluminate cement; 10 parts of heavy calcium powder; 32 parts of fine aggregate; redispersible rubber powder 3; 0.03 parts of lithium carbonate; 0.06 parts of boric acid; 0.15 parts of hydroxyethyl cellulose ether; 0.05 parts of water reducing agent.

[0037] In this example, Portland cement is ordinary salt cement with a strength grade of 42.5; sulphoaluminate cement is a sulphoaluminate cement with a strength grade of 52.5; the gradation ratio of fine aggregate is 20 to 40 mesh: 40-70 mesh: 70-140 mesh = 1:4:3, fine aggregate mud content <2%; redispersible rubber powder is vinyl acetate-tertiary carbonic acid ethylene copolymer;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com