Patents

Literature

36results about How to "Good shape effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling finishing elongation rate of strip steel by utilizing second flow

ActiveCN102407240AHigh yieldStable productionElongation control deviceHuman–machine interfaceLoop control

The invention provides a method for controlling a finishing elongation rate of strip steel by utilizing second flow, comprising the following steps of: respectively measuring an actual speed value and an actual tension value by using an encoder and a tension meter for measuring the speeds of an inlet and an outlet of a finishing machine; additionally arranging a second flow closed loop control system module in a programmable controller of the finishing machine, i.e., a PLC (Programmable Logic Controller); additionally arranging a second flow function option button in a human-computer interface; adopting a speed control mode for a main motor as well as a front tension roller and a back tension roller of the finishing machine; introducing an outlet tension deviation matching coefficient to a rolling force controller; and carrying out gain processing on a system function according to an input time interval. By using the method, the set value of the rolling force as well as parameters such as speed, tension and the like before and after finishing are not needed to be changed according to the material of the strip steel, the speed and the tension before and after the finishing are in astable state, the elongation rate is controlled more precisely, the steel plate pattern and the elongation rate index before and after the specification changes are effectively improved, a favorable surface quality of a product is obtained, and the yield of the strip steel is increased.

Owner:ANGANG STEEL CO LTD

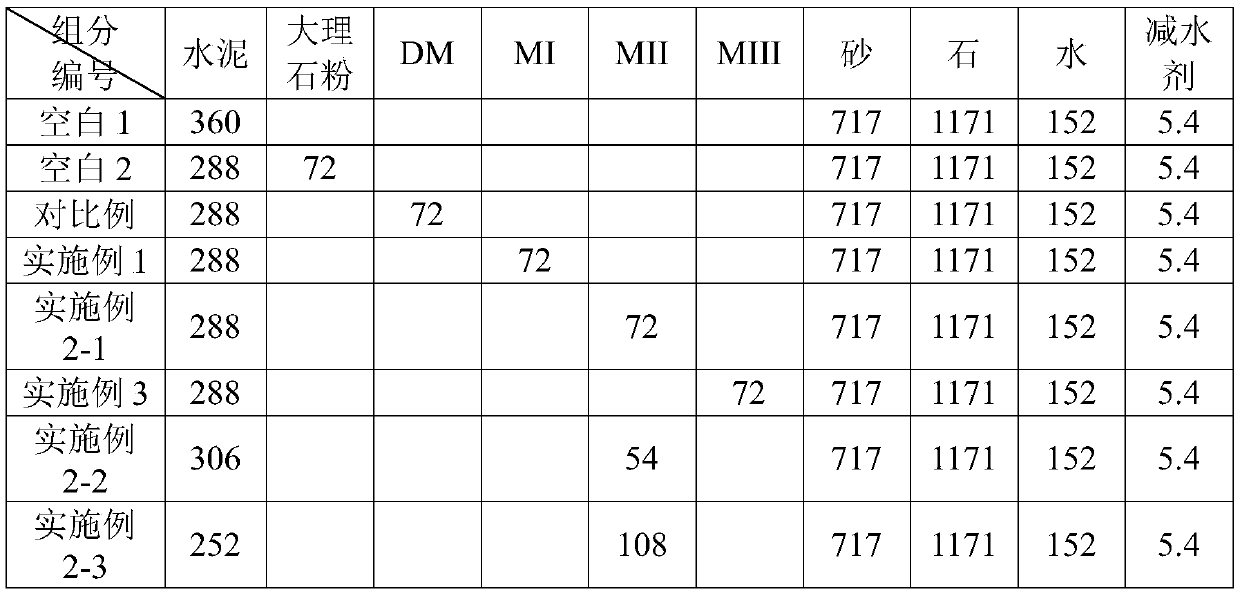

Limestone ultrafine powder concrete with strength grade not higher than C40

The invention relates to the technical field of concrete in building materials and discloses limestone ultrafine powder concrete with a strength grade not higher than C40. The limestone ultrafine powder concrete is prepared from coarse aggregate, fine aggregates, cementing materials, water and an additive, wherein the coarse aggregate is rubble; the fine aggregates comprise river sand and machine-made sand; the cementing materials comprises comprise cement, slag powder, fly ash and limestone ultrafine powder; and the additive is a water reducing agent. In the invention, the limestone ultrafine powder replaces certain amount of cement as part of the cementing materials; the prepared limestone ultrafine powder concrete is superior to traditional concrete in terms of working performance, compressive strength, elasticity modulus, durability and the like; and moreover, the cement is saved, the production cost of concrete is reduced, the energy consumption and CO2 discharge in the cement production process are reduced, and the combination of greenness, energy conservation and environmental protection can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

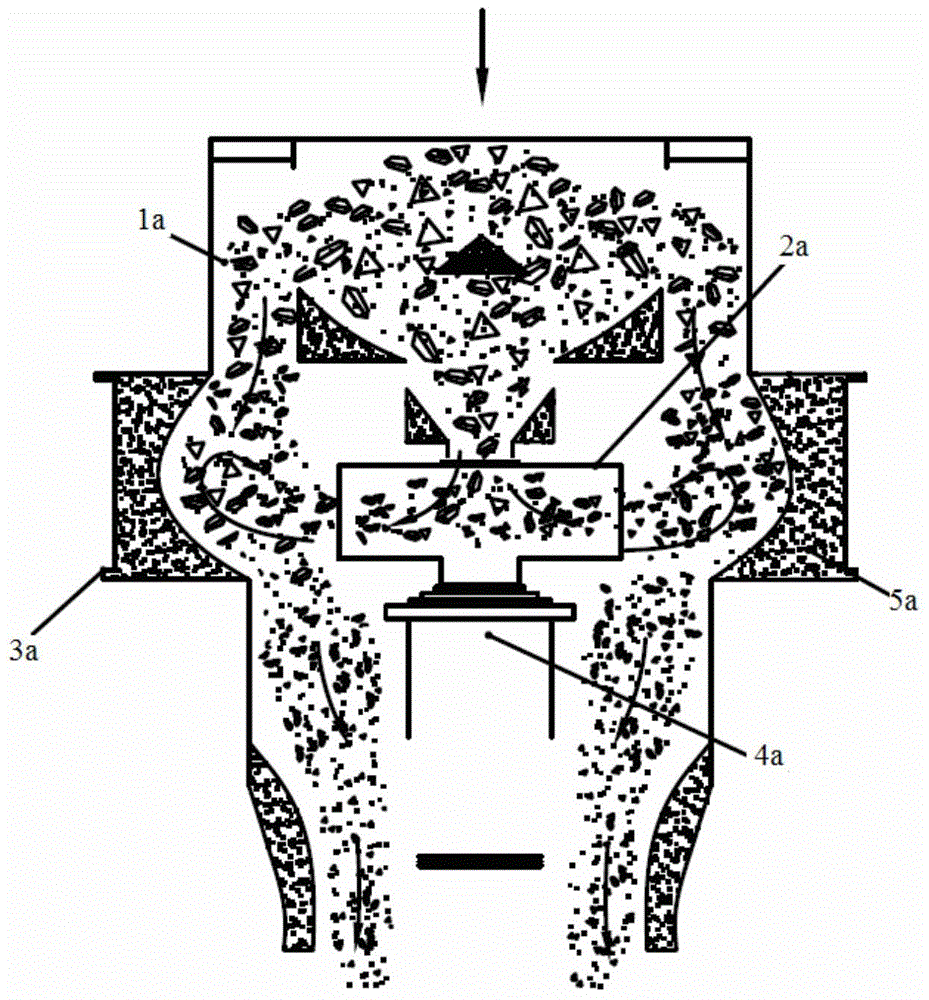

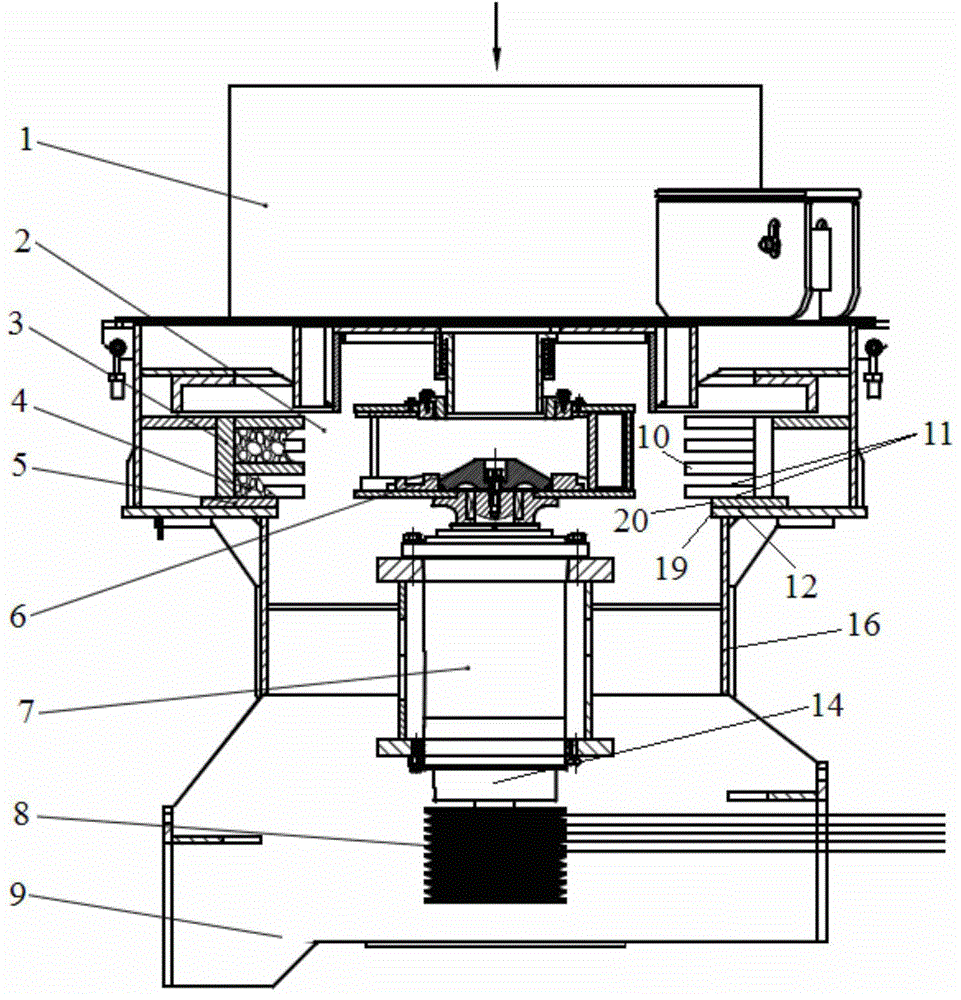

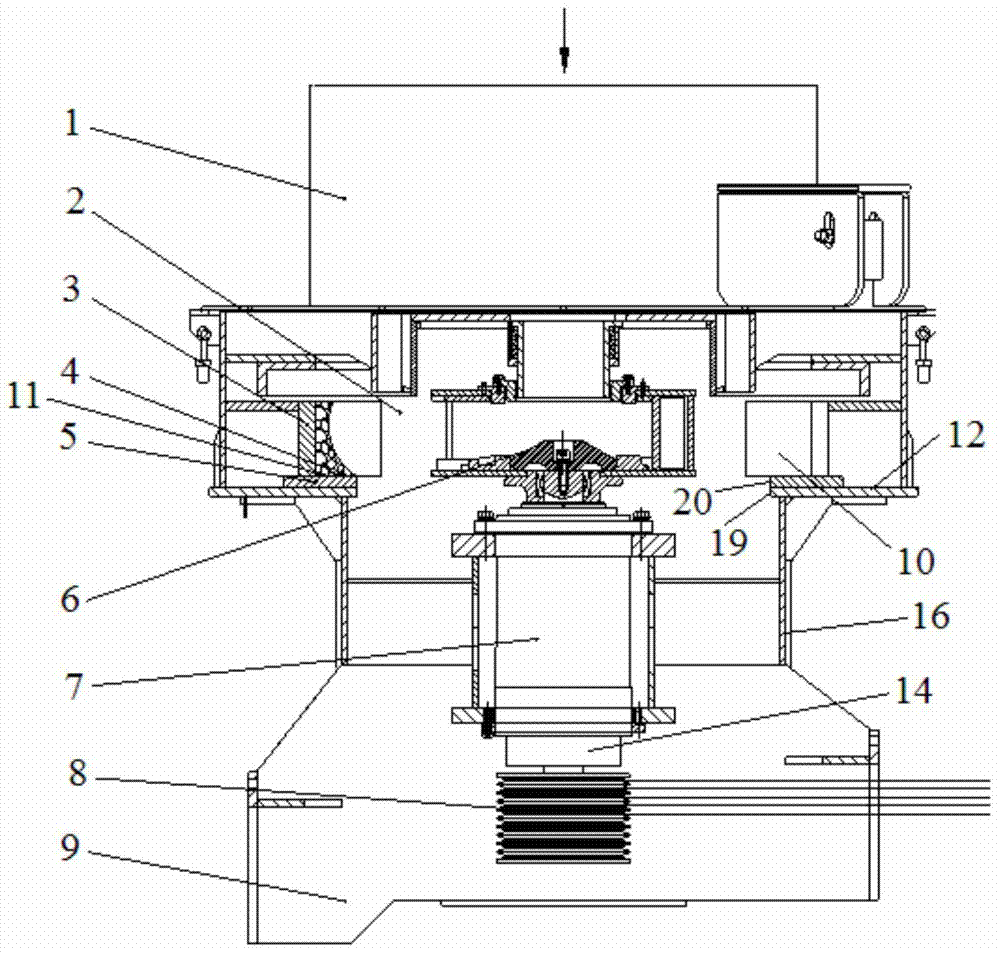

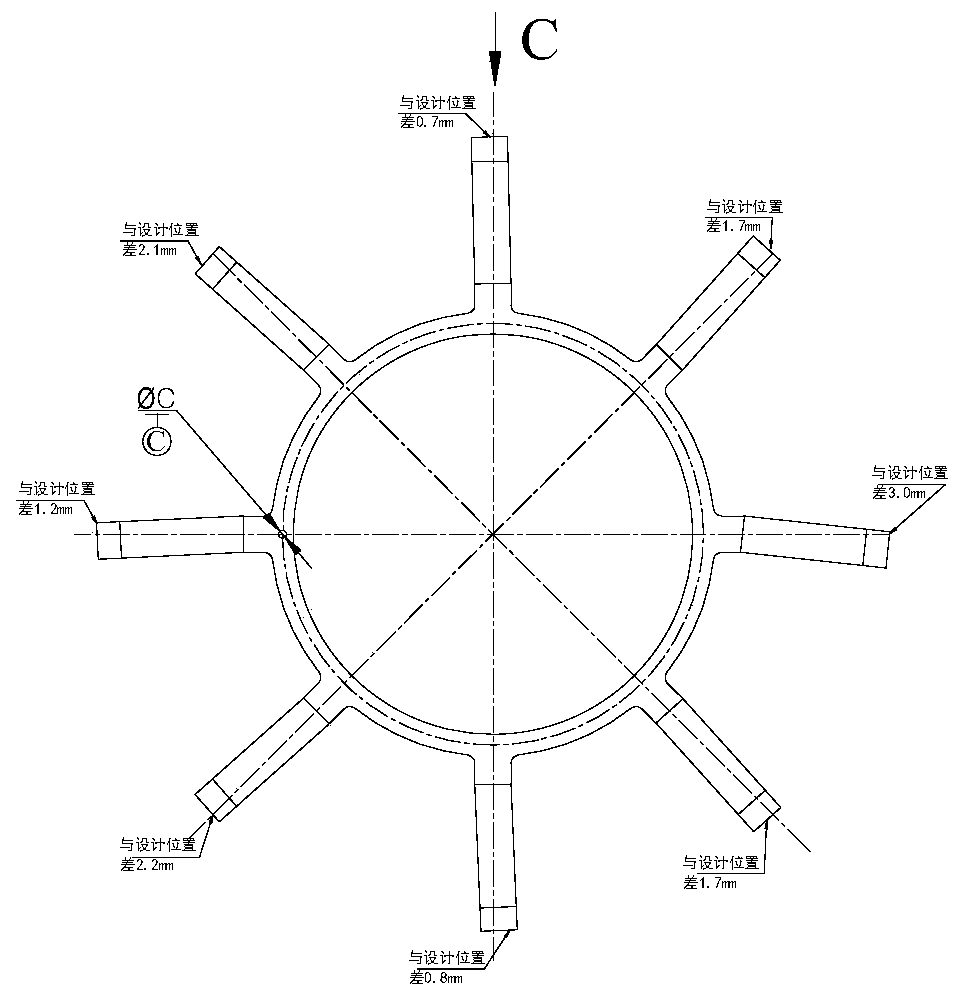

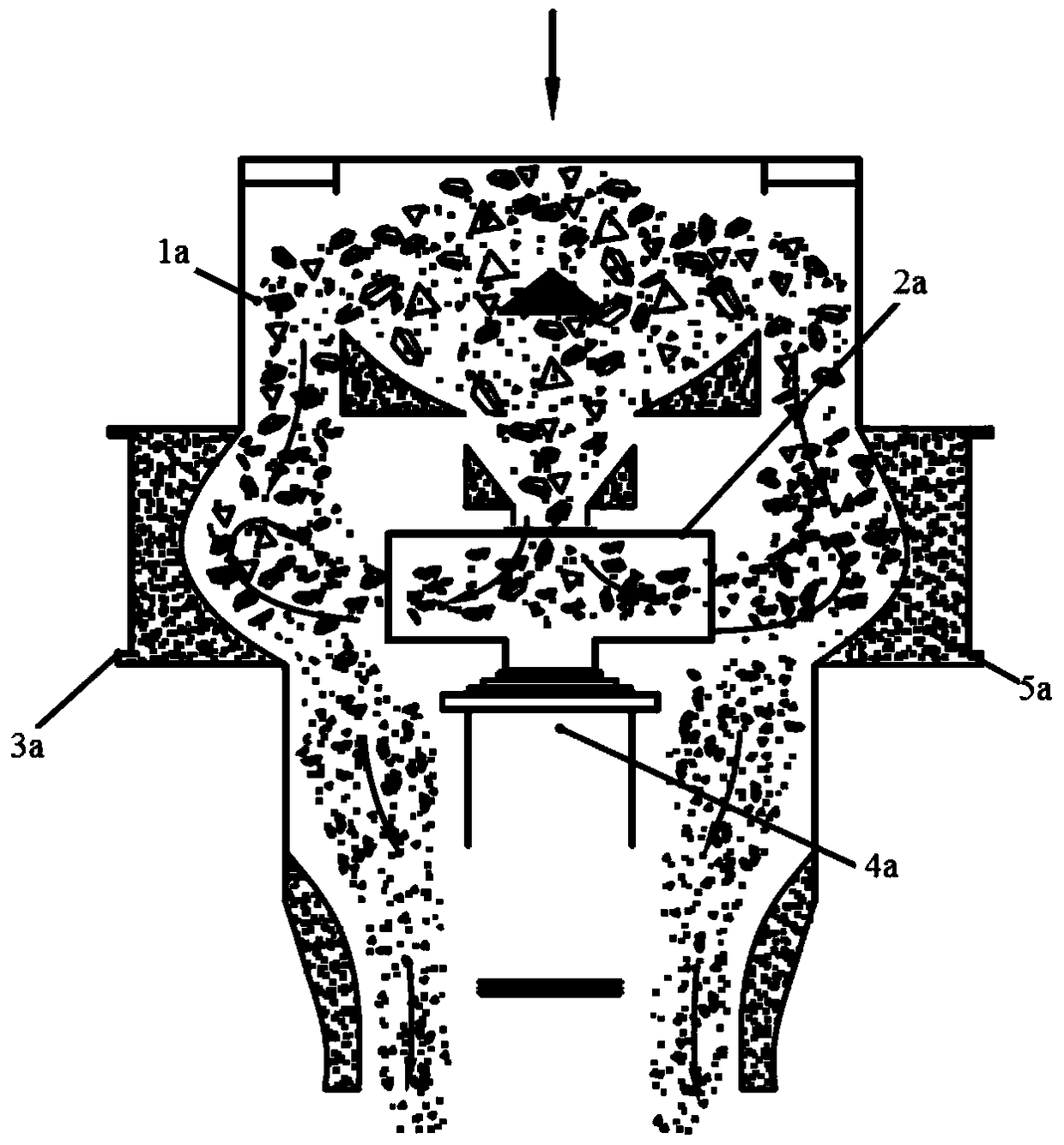

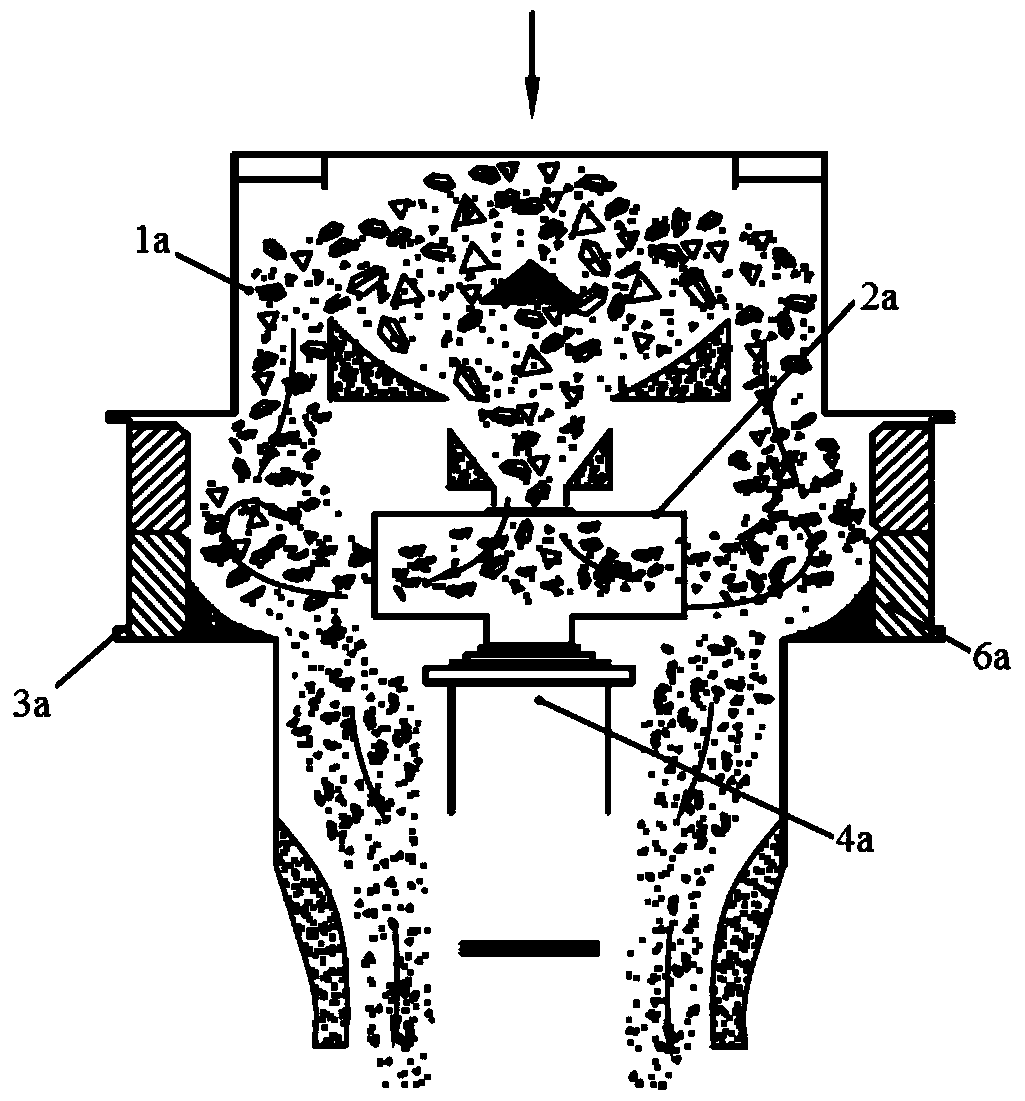

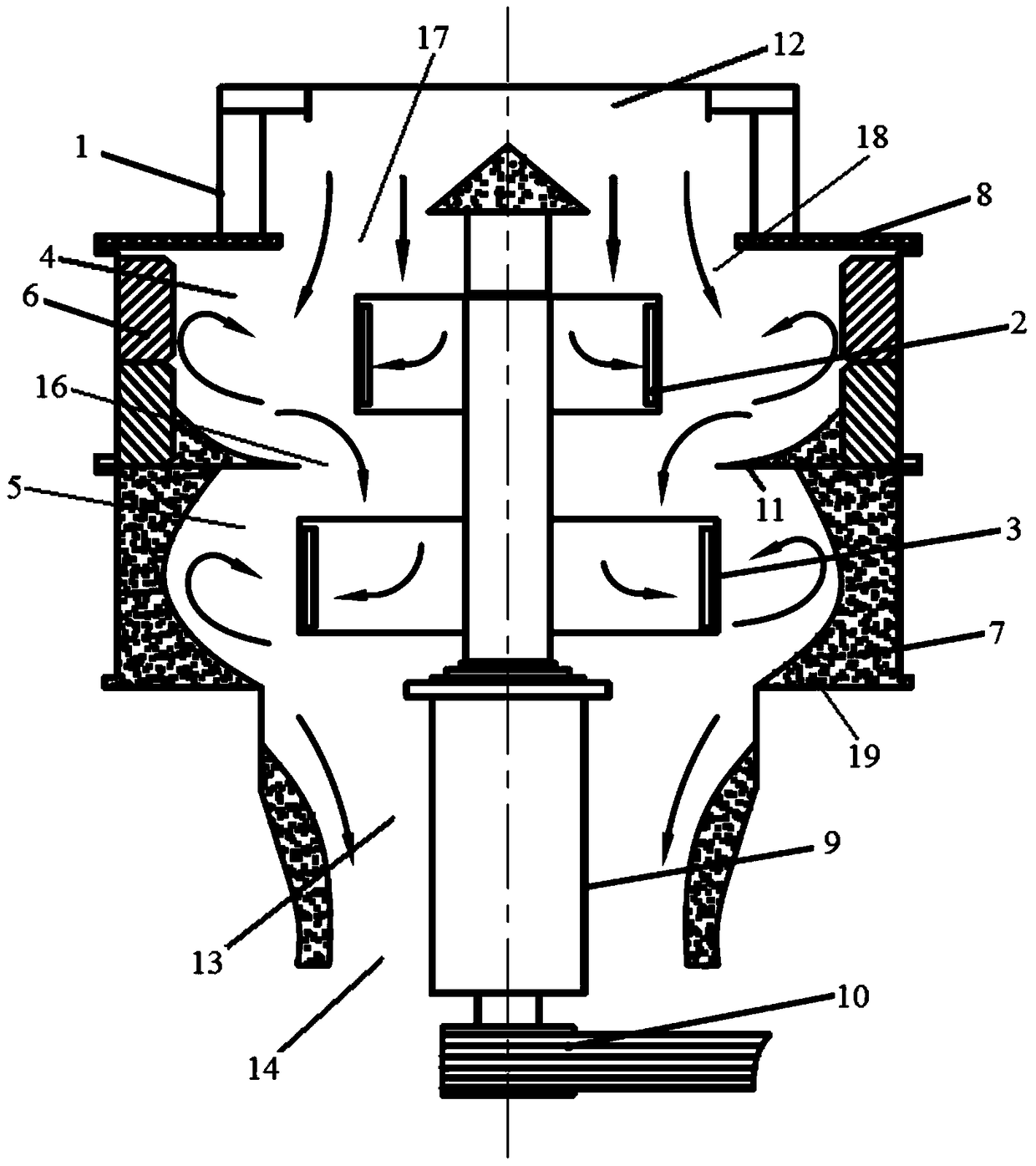

Crusher, mineral production line and material crushing method

ActiveCN106269133AOptimize particle size distributionImprove crushing efficiencyGrain treatmentsProduction lineCrusher

The invention discloses a crusher, a mineral production line and a material crushing method. The crusher comprises a first crushing cavity (4) and a second crushing cavity (5); the first crushing cavity is internally provided with a first material accelerating device and a material impacting part (6), the second crushing cavity (5) is internally provided with a second material accelerating device and a material liner forming part (19) used for forming a material liner layer (7), and a diversion channel structure is arranged between the first crushing cavity (4) and the second crushing cavity (5), so that materials subjected to preliminary crushing in the first crushing cavity (4) can be guided into the second crushing cavity (5) to be crushed and shaped through the diversion channel structure in the working process of the crusher. According to the crusher, the mineral production line and the material crushing method, by means of a creative sequential impacting mode, the crushing mode that the materials and anvils are mixed to be crushed is actually achieved, the crushing efficiency is high, the crushed grain shapes are good, and the void fraction of the crushed materials is significantly increased compared with an existing crusher.

Owner:ZOOMLION HEAVY IND CO LTD

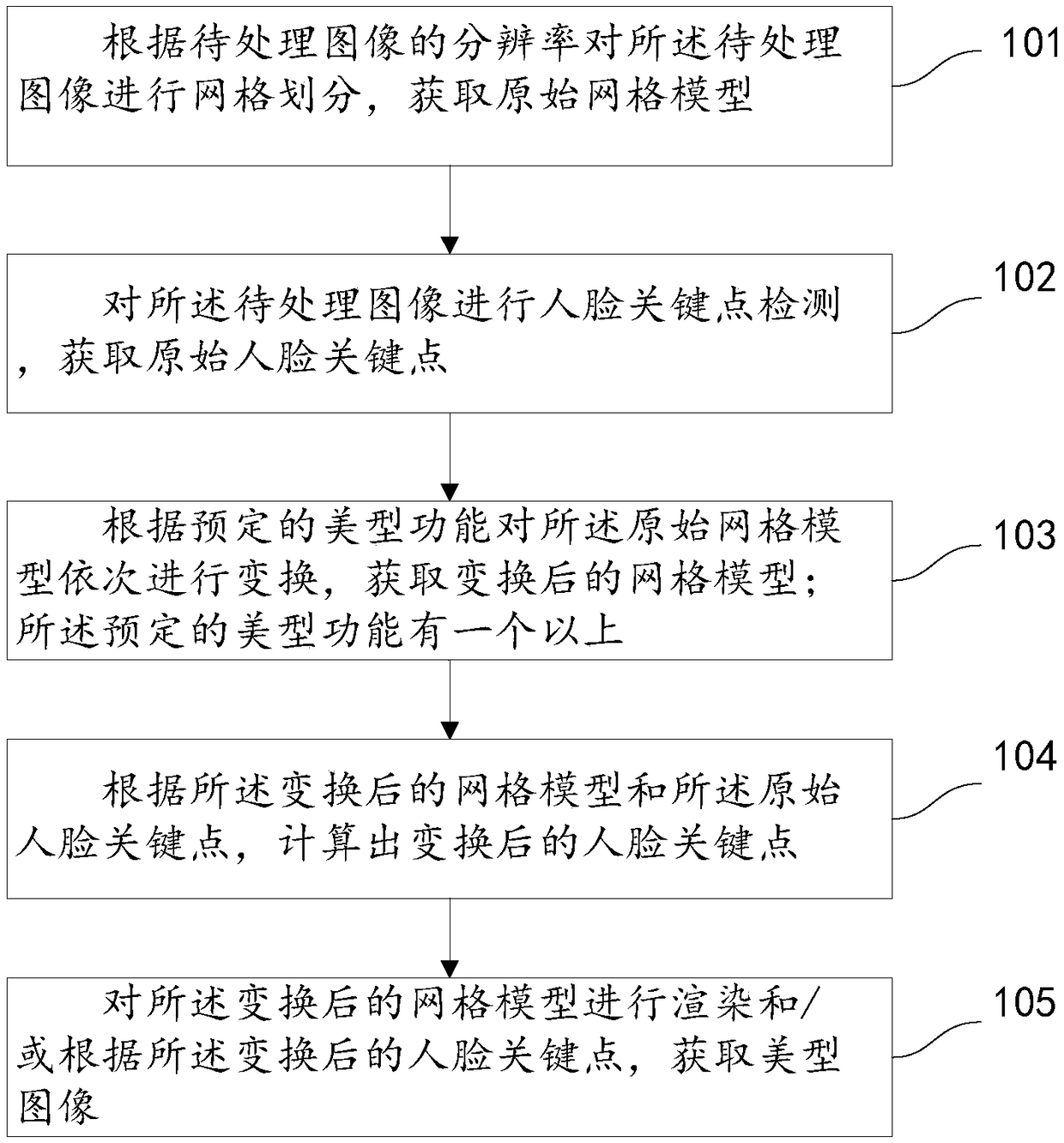

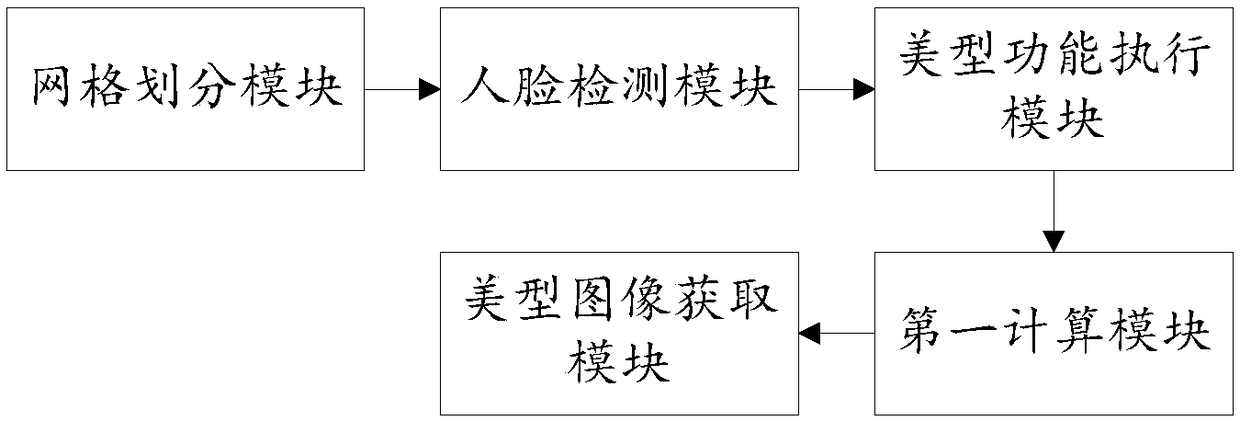

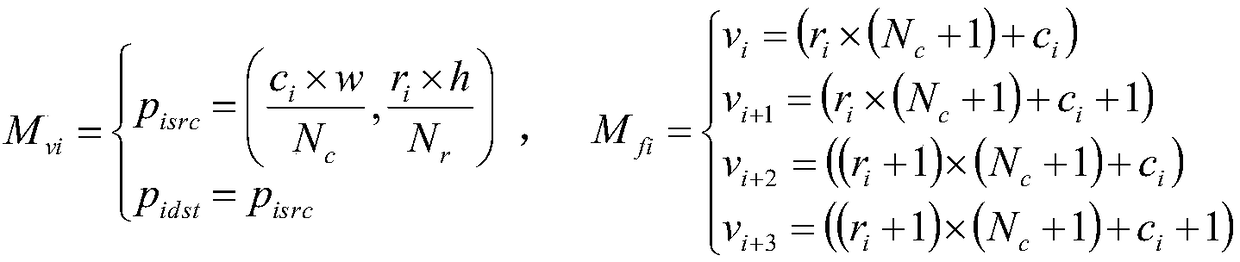

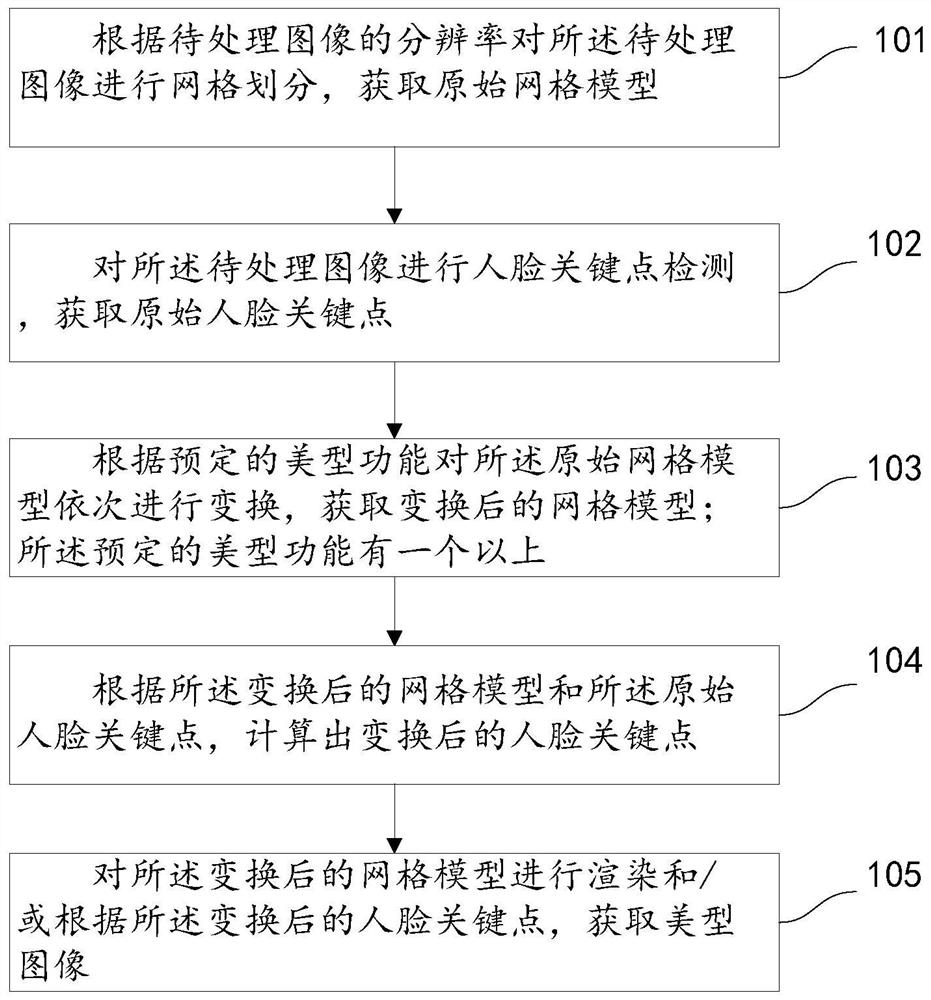

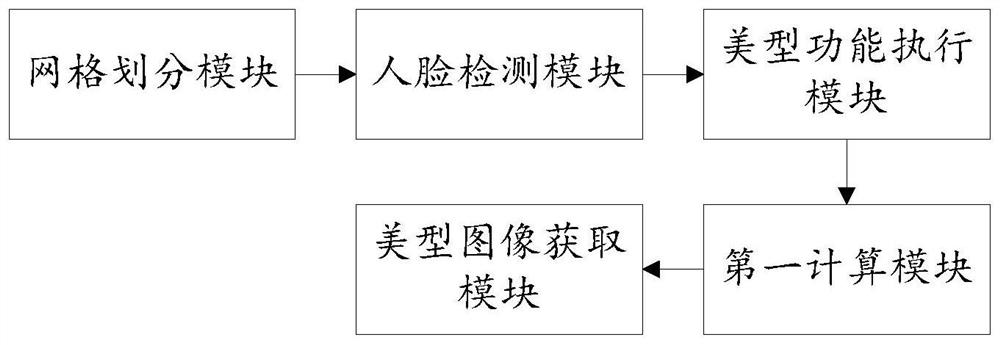

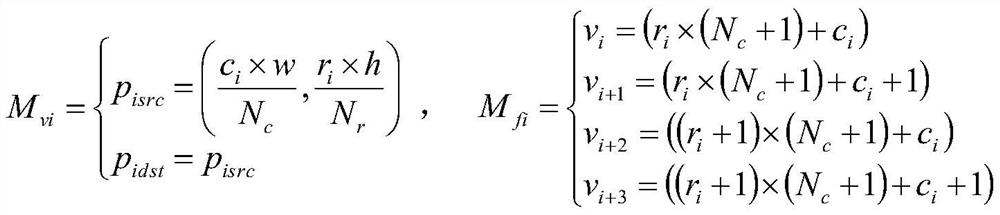

A method and system for portrait beauty

ActiveCN109146808AAvoid occupyingAvoid time consumingImage enhancementImage analysisImage resolutionMesh model

The invention discloses a portrait beauty type method and a system, comprising the following steps: meshing the image to be processed according to the resolution of the image to be processed to obtainan original mesh model; detecting the key points of the face of the image to be processed, and obtaining the key points of the original face; the original mesh model being sequentially transformed according to a predetermined beauty function to obtain a transformed mesh model, wherein the predetermined beauty function has more than one; calculating the transformed face key points according to thetransformed mesh model and the original face key points; the transformed mesh model being rendered and / or an American image being obtained according to the transformed face key points. The technicalproposal provided by the invention can smoothly perform real-time rendering on the mobile terminal, and has good aesthetic effect.

Owner:CHENDU PINGUO TECH CO LTD

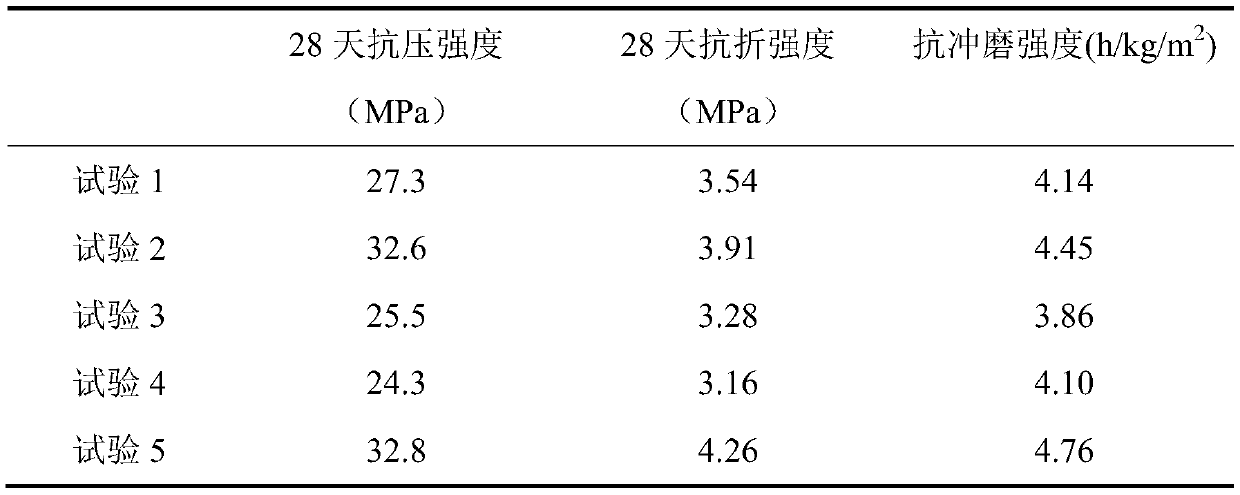

Pervious concrete

The invention discloses pervious concrete which is characterized in that the pervious concrete is prepared from the following components in parts by mass: 1500-1600 parts of coarse aggregate, 320-420parts of a cementing material, 105-114 parts of water and 4.5-5.9 parts of a water reducing agent. An anti-corrosion material in the formula has remarkable plasticizing effect, micro-aggregate effect,morphological effect and temperature peak reduction effect, and the mechanical property, abrasion resistance and denudation resistance of the pervious concrete can be improved through the excellent characteristics of the anti-corrosion material itself and the improvement of the continuous grading of the microstructure of the cementing material, so that the durability of the pervious concrete is improved, and the service lifetime of the pervious concrete is prolonged.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Heat treatment distortion control method for leaf spring parts

InactiveCN107058708AFit tightlyEven by forceFurnace typesHeat treatment process controlHardnessMaterials science

The invention discloses a heat treatment deformation control method for spring sheet parts, which belongs to the field of heat treatment deformation control. The method is as follows: ①Quenching the parts after cold forming; ②Put the spring piece into the shape-correcting fixture, fix it with appropriate pre-tightening bolts, and temper them together at the specified temperature; ③Tighten the bolts fully after half the tempering time, Put it into the furnace again and heat until the tempering process is over. The invention has the advantages that the method of fixture shape maintenance and heat correction can effectively correct the distortion and deformation of the spring sheet after quenching, ensure the corresponding structure and hardness requirements, and achieve the purpose of heat treatment shape control.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

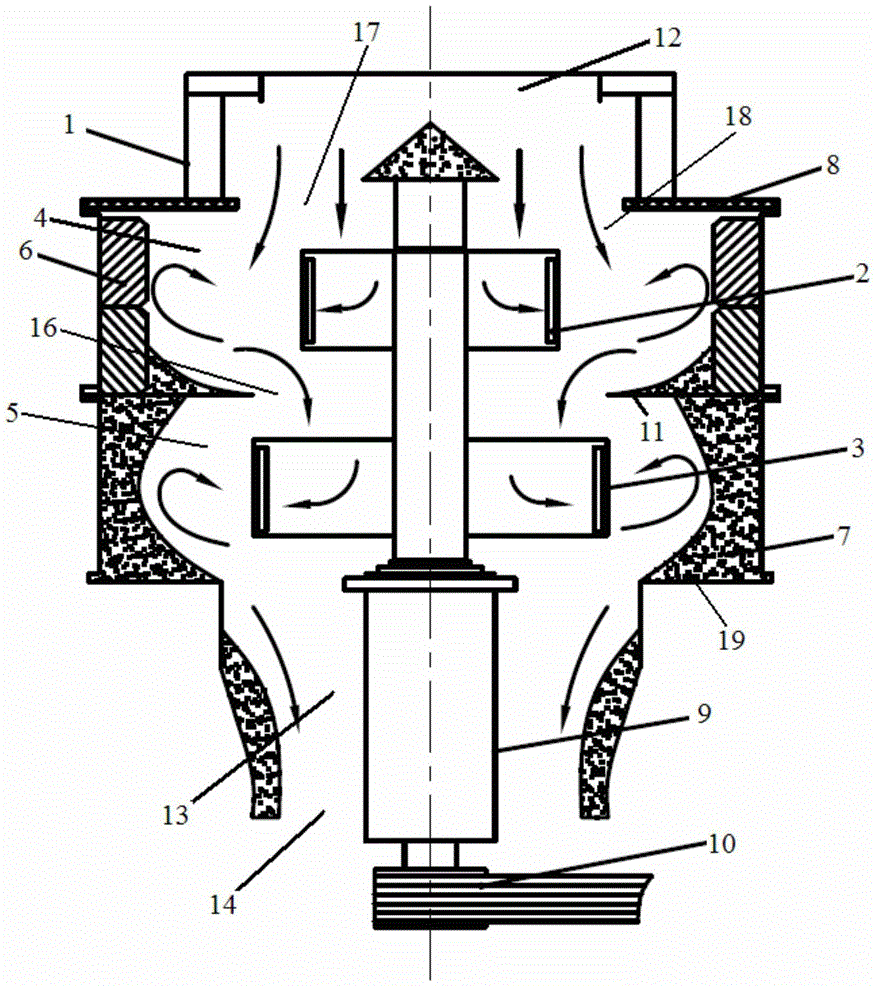

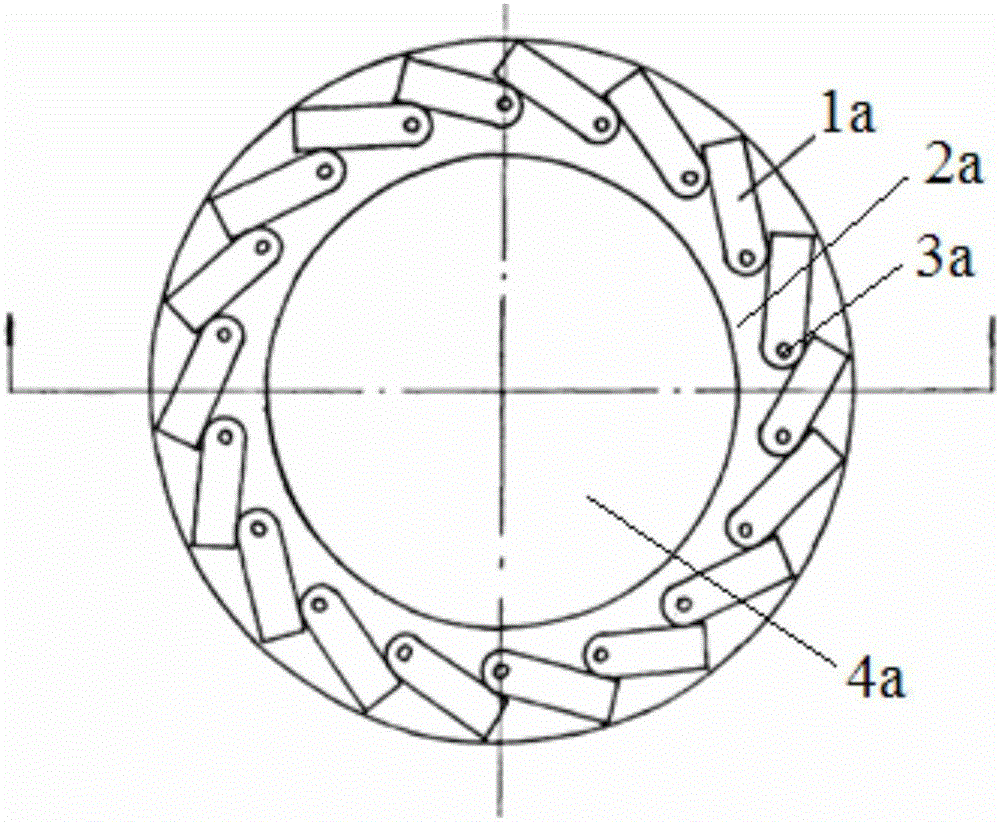

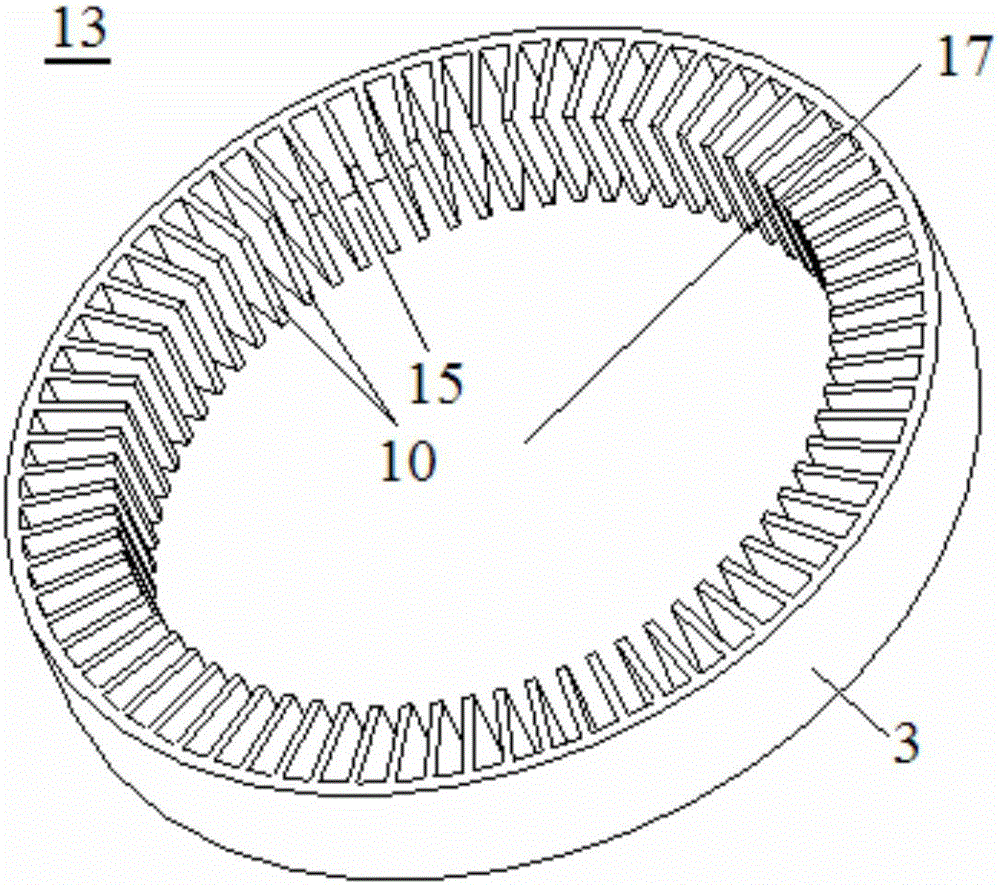

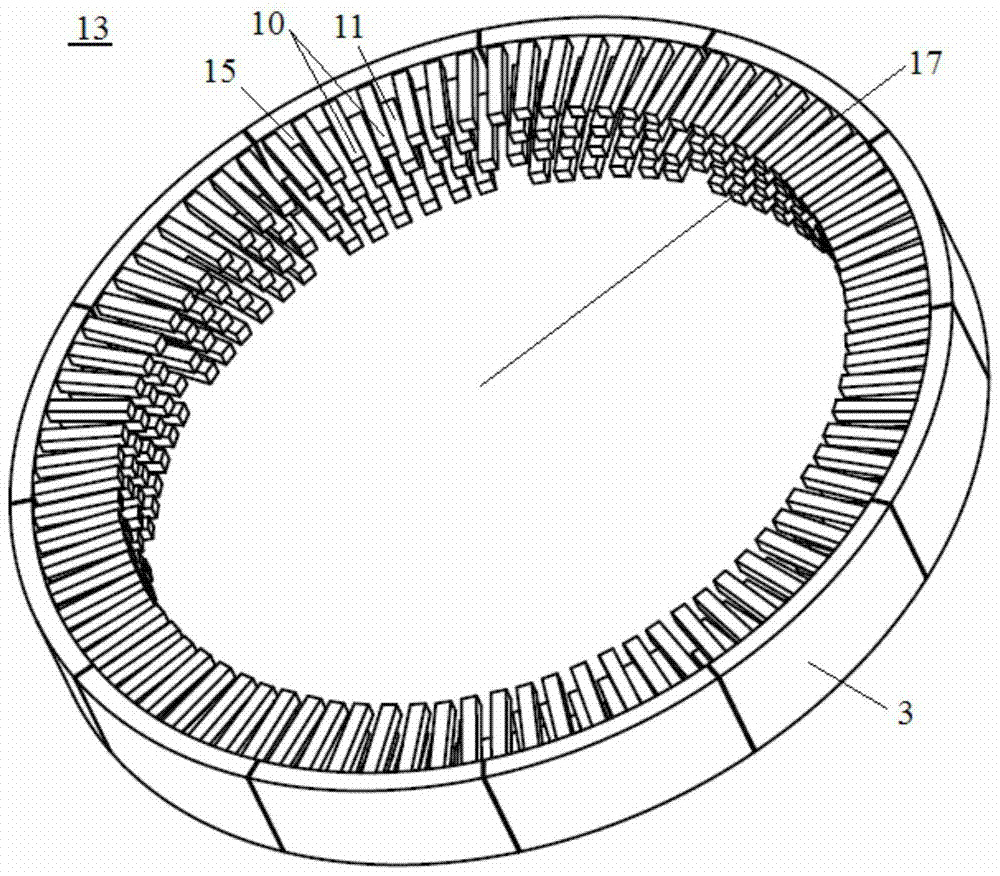

Crusher, anvil device, anvil piece, mineral production line and material crushing method

ActiveCN106269132AImprove crushing efficiencyGood broken shapeGrain treatmentsProduction linePorosity

The invention discloses a crusher, an anvil device, an anvil piece of the anvil device, and a mineral production line, and further discloses a material crushing method. The crusher comprises a crushing and shaping structure with material impacting parts (10) and material liner forming parts (11); and the relative position relationship between each material impacting part (10) and at least one material liner forming part (11) is that a material impacted by the material impacting part (10) can be at least partially turned and impacted to a material liner layer (4) of the corresponding material liner forming part (11), so that sequential impact of the material to the material impacting parts (10) and the material liner layers (4) is realized continuously. Due to the ingenious sequential impact manner, not only is the 'material and anvil mixed beating' crushing mode realized in deed, but also the crushing efficiency is high, the shape of crushed particles is good, and the porosity of the crushed material is significantly higher than that of a material crushed with the conventional crusher.

Owner:ZOOMLION HEAVY IND CO LTD

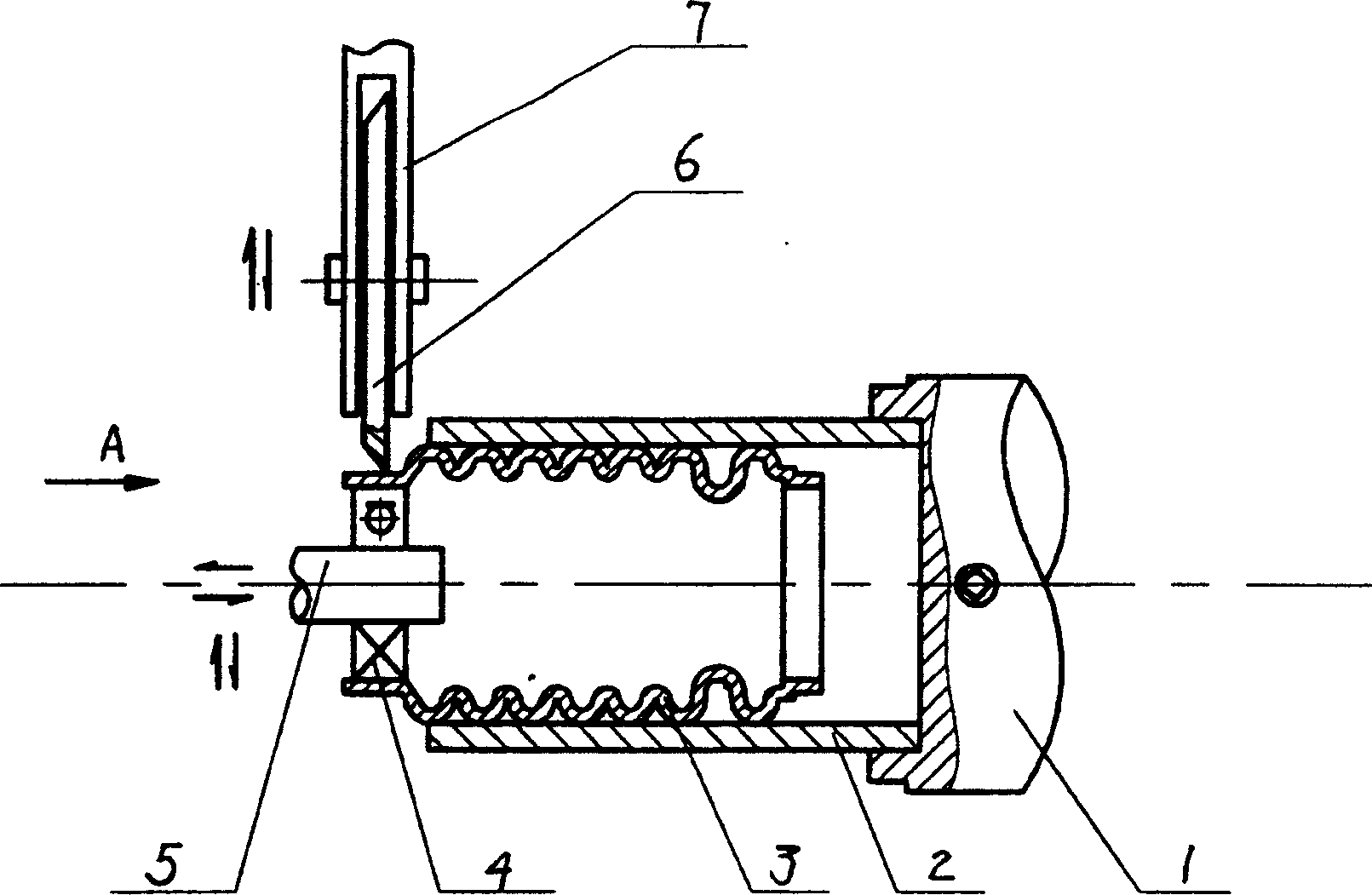

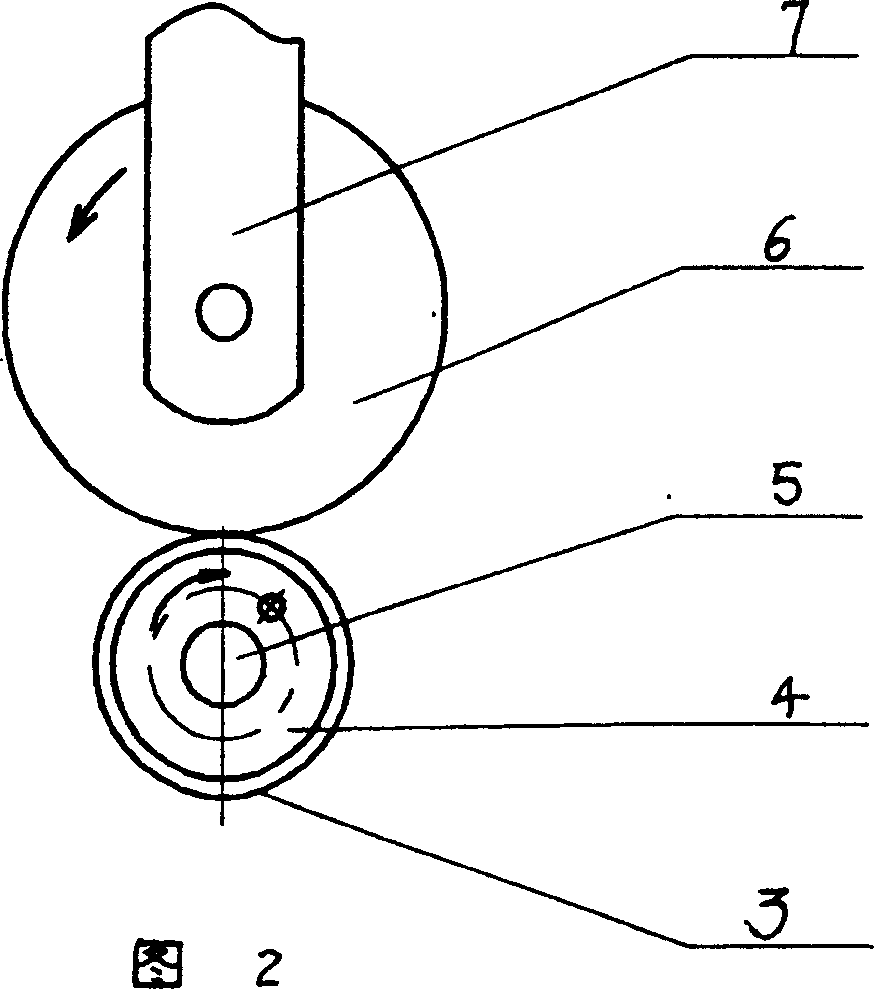

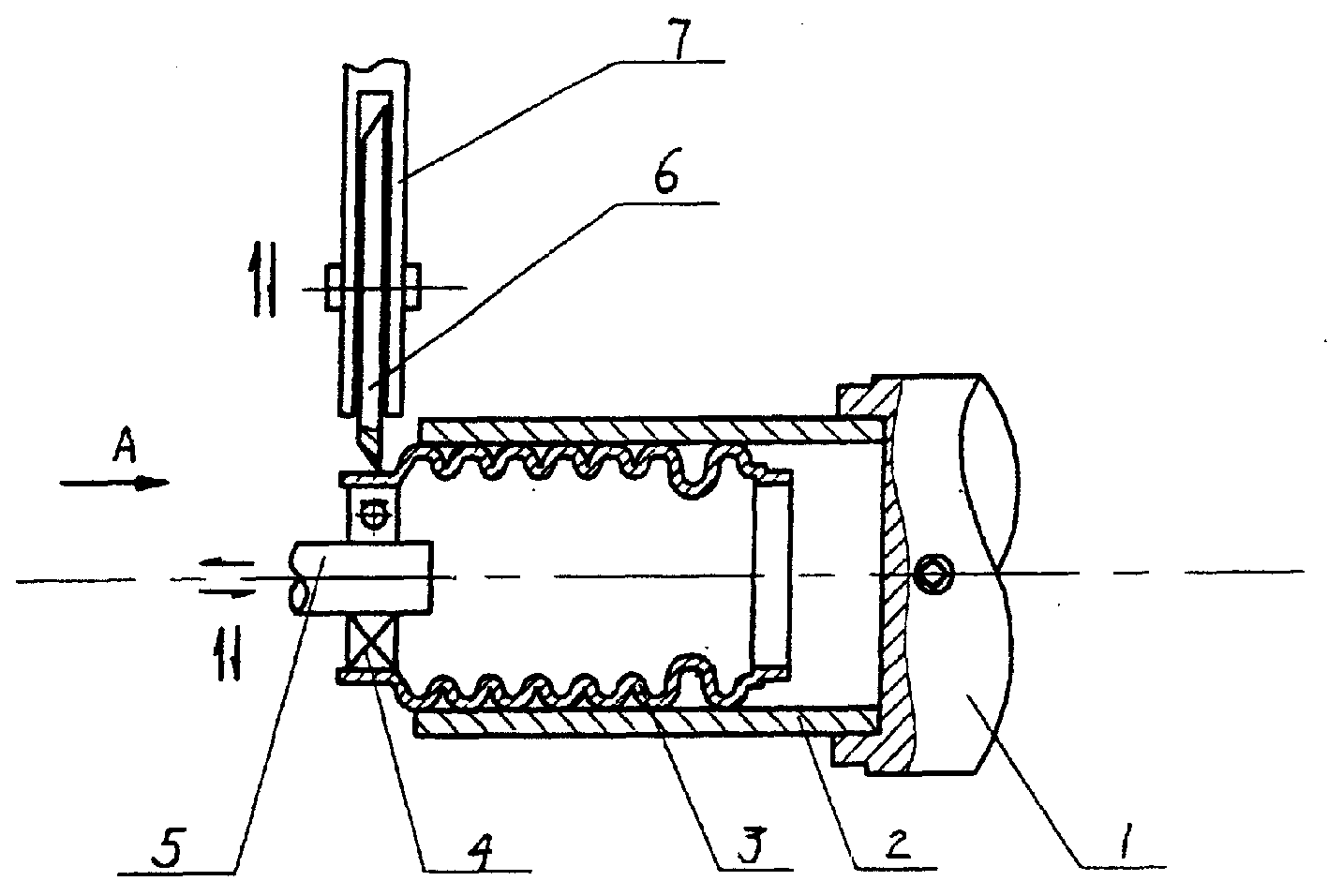

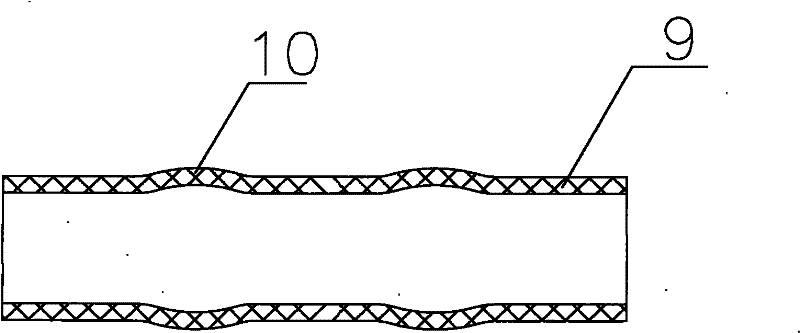

Mfg. method of metal ripple tubes

A technology for making metallic bellows includes providing annealed cold-rolling bright stainless steel band, rolling to become pipe shape, welding, cutting, shaping, cutting edge, surface treating in a treating liquid prepared from nitric acid and water, flushing with water and dewatering with alcohol. Its advantages are high productivity and quality.

Owner:锦州经济技术开发区天华波纹管有限公司

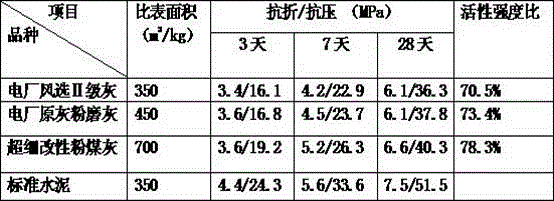

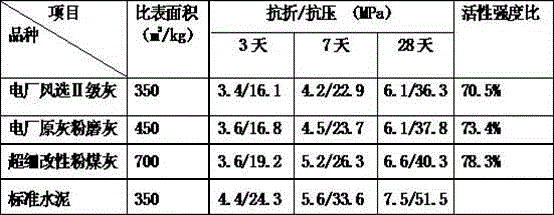

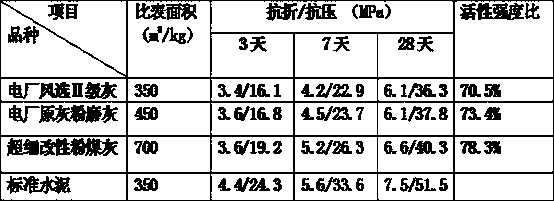

Production method of superfine modified coal ash

The invention discloses a production method of superfine modified coal ash.The production method includes: weighing a certain amount of power plant coal ash raw powder, and adding the power plant coal ash raw powder into a drum mill of 500 mm in diameter; adding an activating agent, wherein a mass ratio of the activating agent to the power plant coal ash raw powder is 3:10000, and the activating agent contains triethanolamine, ethylene glycol, sodium silicate, sodium sulfite, glycerol, stearic acid and sodium hexametaphosphate according to a mass ratio of 6:5:2:1:1:1:0.5; grinding for one hour to obtain the superfine modified coal ash.The superfine modified coal ash produced by the method has regular particles and is mostly spherical, smooth in surface, large in specific surface area and higher than common coal ash in activity.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

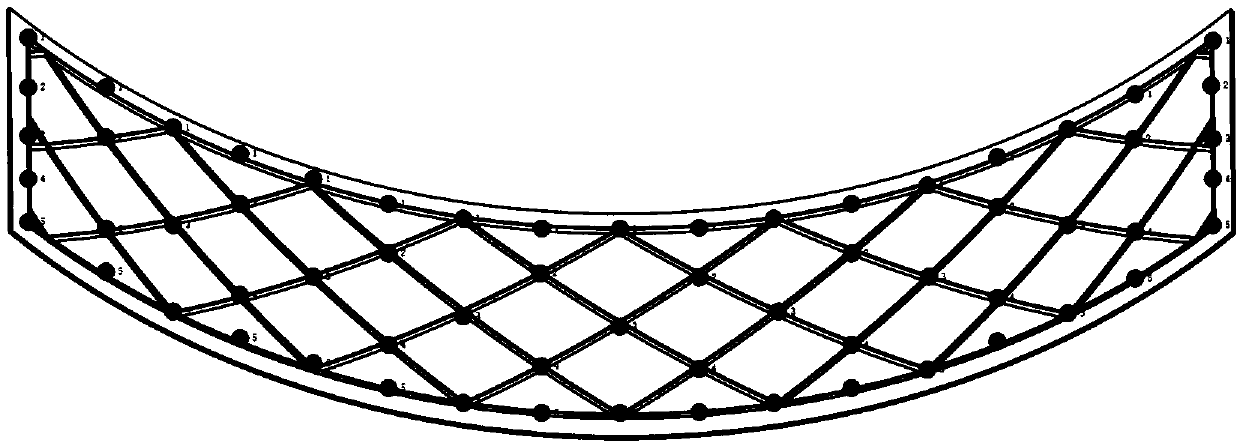

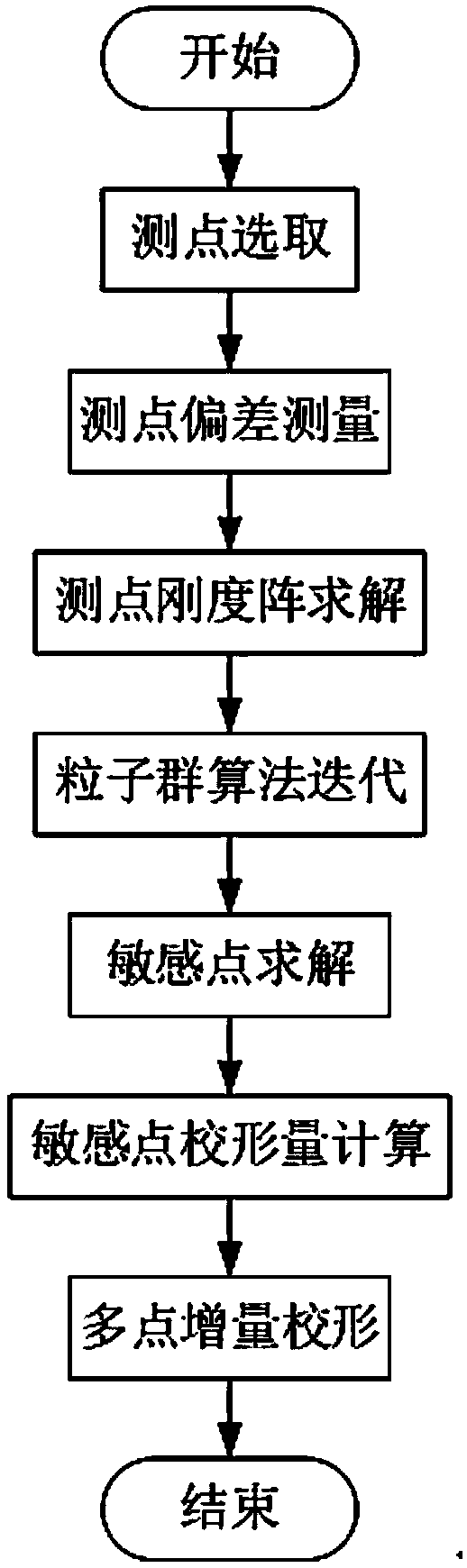

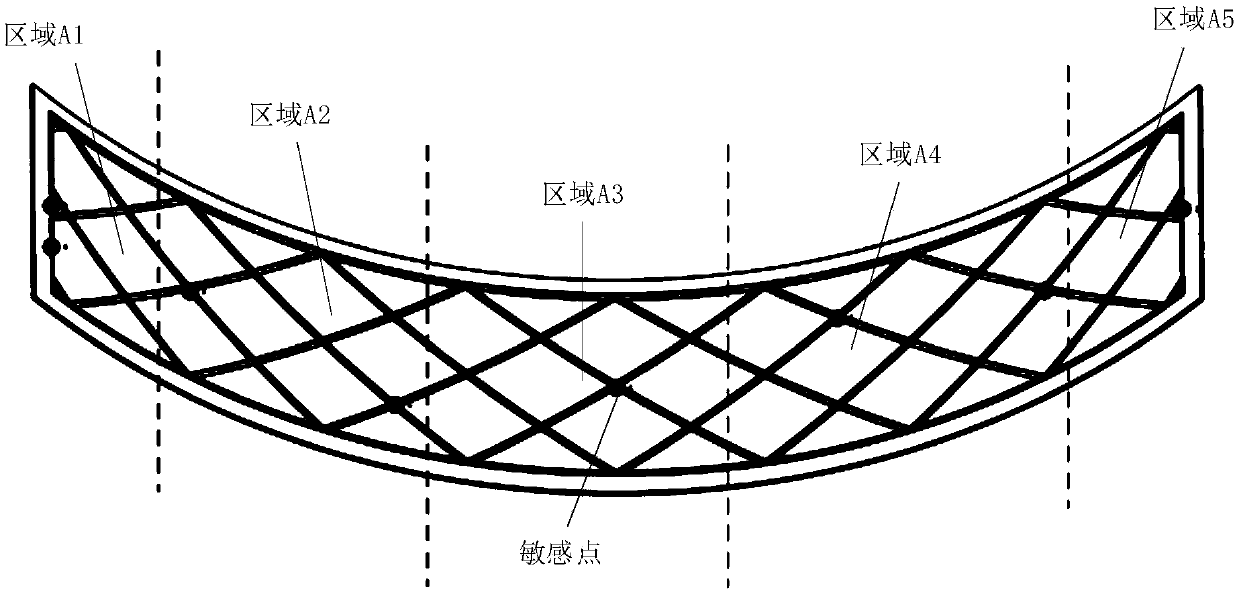

A large thin-wall stiffened plate shape correction method based on sensitive point multi-point incremental forming

ActiveCN109670271ANo performance impactGood shape effectGeometric CADSustainable transportationParticle swarm algorithmCorrection method

The invention relates to a large thin-wall stiffened plate shape correction method based on sensitive point multipoint incremental forming, which comprises the following steps of acquiring the deformation deviation on a measuring point, and iteratively solving the measuring point with the maximum contribution degree to the overall shape correction of a wallboard as a sensitive point through a particle swarm optimization by combining with a deformation coordination equation of the wallboard; then, through shape correction amount simulation calculation, obtaining the shape correction amount required for enabling the wall plate mold attaching degree to meet the requirement; and finally, applying a shape correction amount to the sensitive point, and loading, releasing and rebounding to realizethe shape correction effect. According to the present invention, by selecting a measuring point to measure the deformation deviation of the shape correction wallboard; obtaining a sensitive point with the maximum influence on the shape correction effect based on sensitive point analysis; performing simulation calculation to obtain a shape correction amount of the sensitive point; and based on a multi-point incremental forming method, applying the shape correction amount to the sensitive points, the effect of large-scale wallboard shape correction is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Impervious marble powder compound admixture and application thereof

ActiveCN110041007AReduce agglomeration effectImprove mechanical propertiesNetwork structureFour component

The invention provides an impervious marble powder compound admixture and an application thereof. The impervious marble powder compound admixture is prepared from following components in parts by weight: 75-90 parts of modified marble powder, 10-25 parts of modified metakaolin, 2-6 parts of rubber powder and 0.5-1.5 parts of basalt fiber. According to the impervious marble powder compound admixture, the marble powder and metakaolin are modified and then compounded with the rubber powder and the basalt fiber, the admixture for concrete is prepared, reaction activity of the impervious marble powder compound admixture and cement is greatly improved under the synergistic effect of the four components, an organic-inorganic three-dimensional interpenetration network structure which is stacked and staggered can be formed in the concrete when the admixture is applied to preparation of the concrete, so that pore structure distribution of the concrete is greatly improved, compactibility of the concrete is improved, and the prepared concrete has higher mechanical property and durability.

Owner:WUHAN UNIV OF TECH

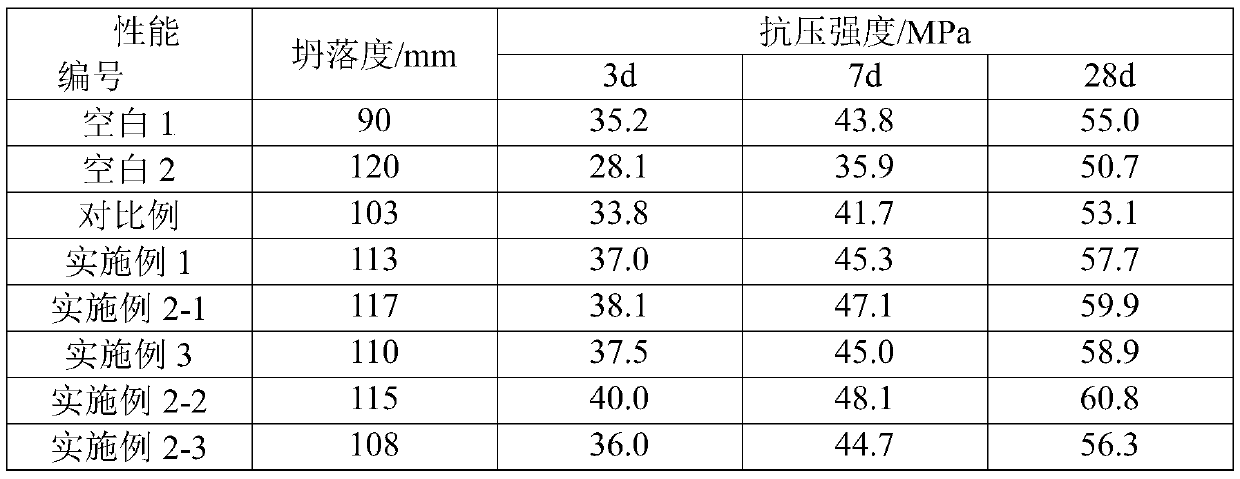

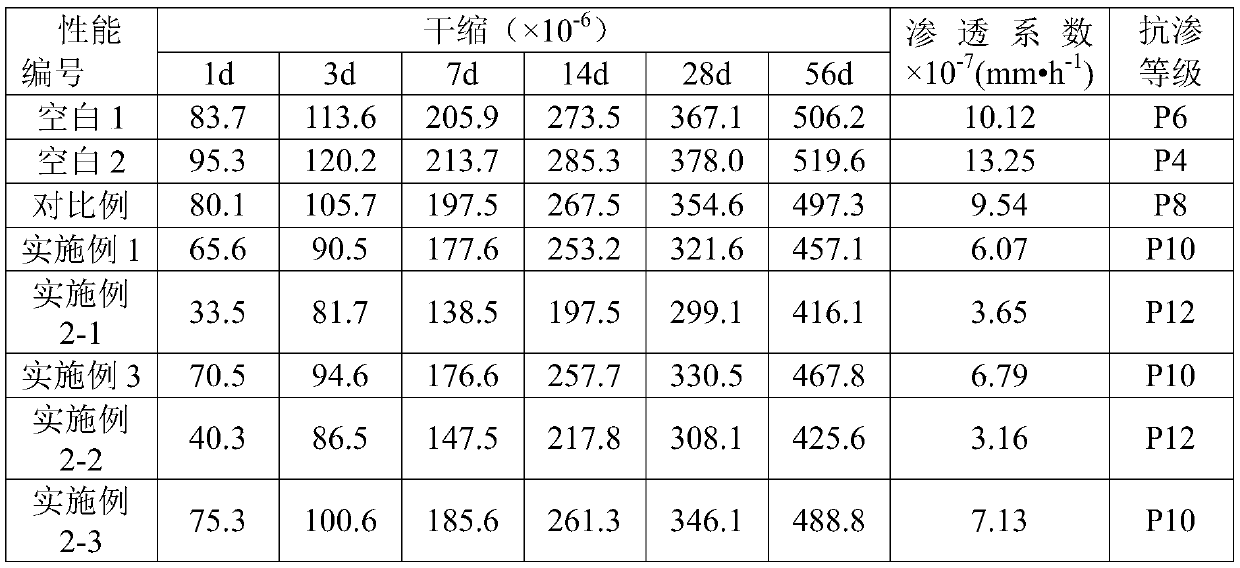

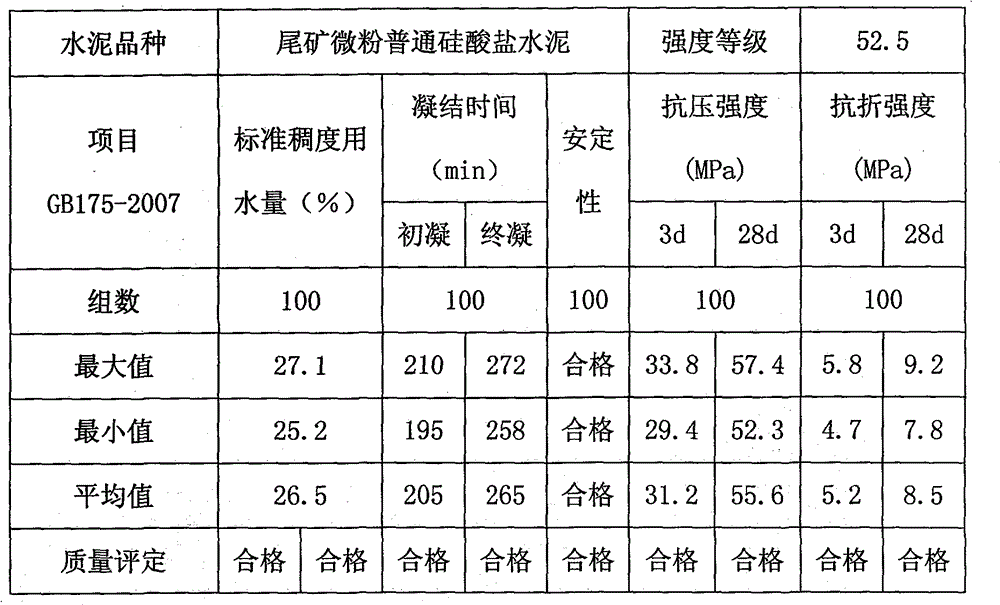

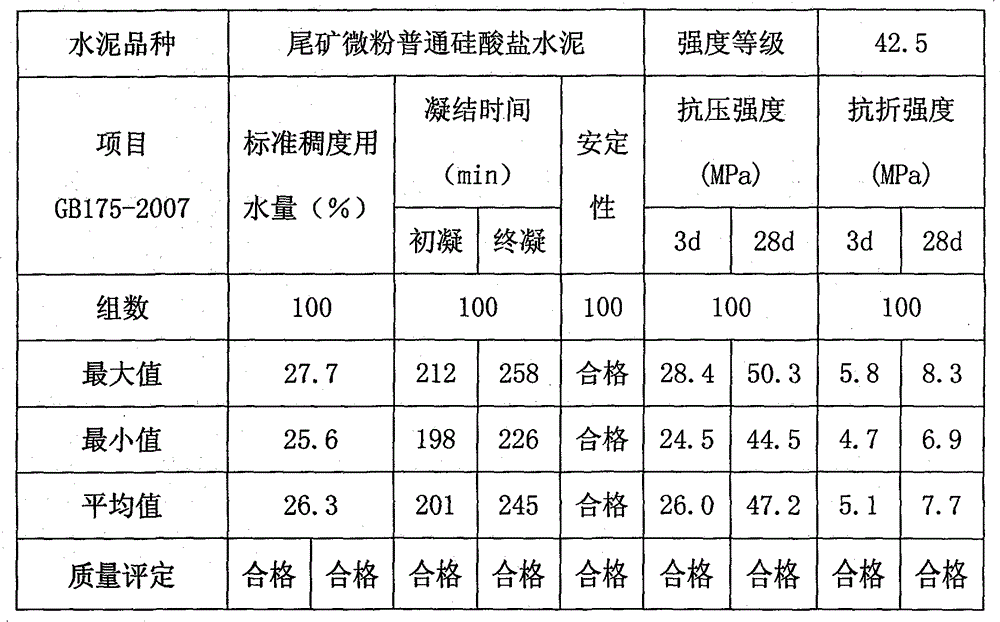

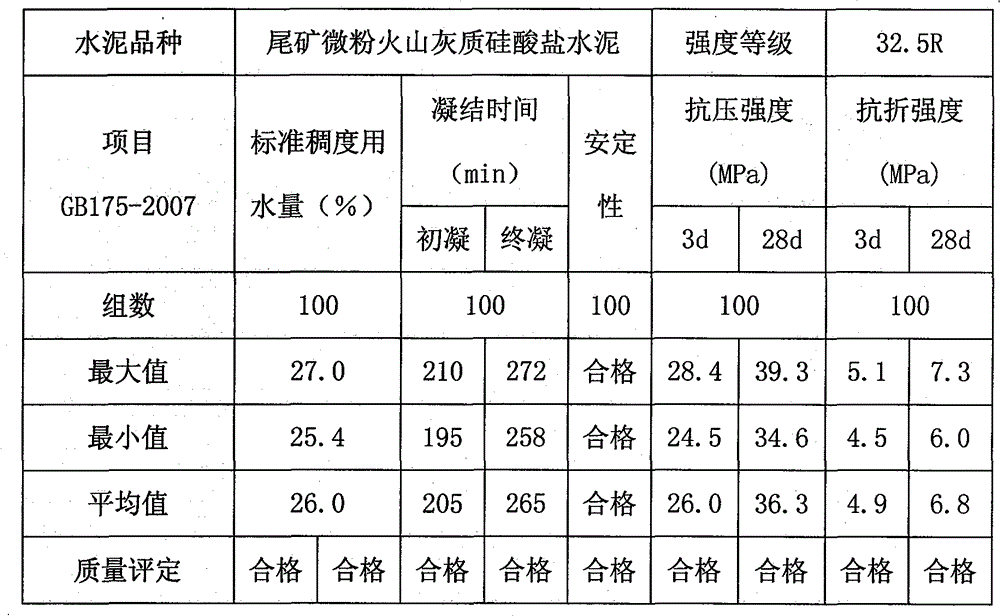

Preparation method of tailing micropowder portland cement

A preparation method of tailing micropowder portland cement comprises the following steps of: (1) crude material crushing; (2) raw material preparation; (3) clinker sintering; (4) powder grinding; (5) packaging; wherein the step (4) of powder grinding comprises the following substeps: 1. grinding 95-97% of the clinker and 3-5% of gypsum together with an added cement grinding aid to obtain a clinker micropowder intermediate; 2. adding 0.2-0.5 per thousand kg of polycarboxylic acid-alcohol amine high polymer and 0-5% kg of gypsum into 1 kg of metal tailing slag, mixing, drying and grinding to obtain a tailing micropowder intermediate; 3. mixing and grinding 95-80% of the clinker micropowder intermediate and 5-20% of the tailing micropowder intermediate, or 60-80% of the clinker micropowder intermediate and 20-40% of the tailing micropowder intermediate, or 50-80% of the clinker micropowder intermediate, 15-45% of the tailing micropowder intermediate and 5% of slag powder to obtain various tailing micropowder portland cement. Through individual grinding and then mixing grinding, high fineness and high activity are realized; the potential activity of the tailing is aroused; and the rheological property of the cement is improved.

Owner:福建省新创化建科技有限公司

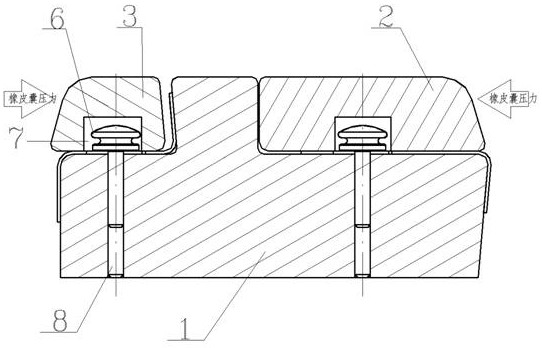

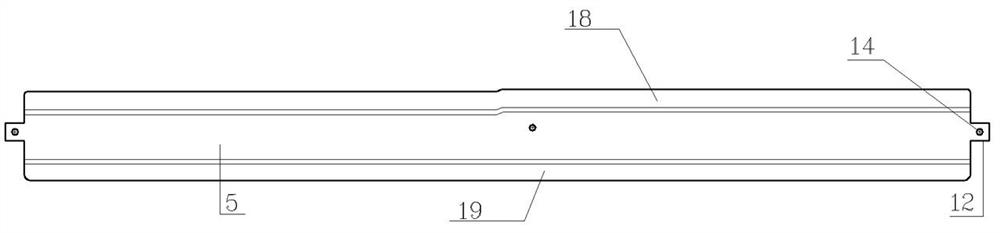

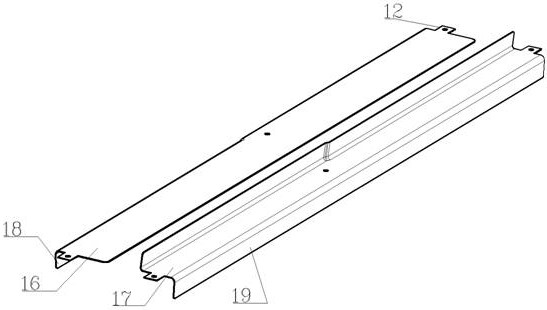

Slender Z-shaped part composite forming device and forming method

ActiveCN113441577AImprove forming efficiencyReduce in quantityVehicle componentsStructural engineeringInverted-T shape

The invention relates to the technical field of airplane sheet metal part manufacturing, in particular to a slender Z-shaped part composite forming device and forming method. The forming device comprises a die body I, a cover plate and a die body II; the die body I is in an inverted T shape and forms working faces used for the procedure A and the procedure B respectively; the width of the working face of the procedure B is matched with that of the web face of the Z-shaped part, and the shape of the inner side of the working face of the procedure B is matched with that of the outer side of the working face of the procedure A; steps are arranged on the working surfaces; the cover plate and the die body II are all molded surfaces, positioning pin avoiding grooves and die matching pin holes are formed in the cover plate and the die body II, and the die matching pin holes in the die body II are oblong holes; and the forming method comprises the steps that under the action of a rubber bag forming machine, the die body II is pressed towards the die body I, and the bent edge A is formed while the bent edge B is formed. By means of the forming device and the forming method, the problems that the forming efficiency is low, and particularly after the side face of the part is sunken and formed, the part is large in springback, the part is not prone to being attached to a die, and the correction workload is large can be effectively solved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

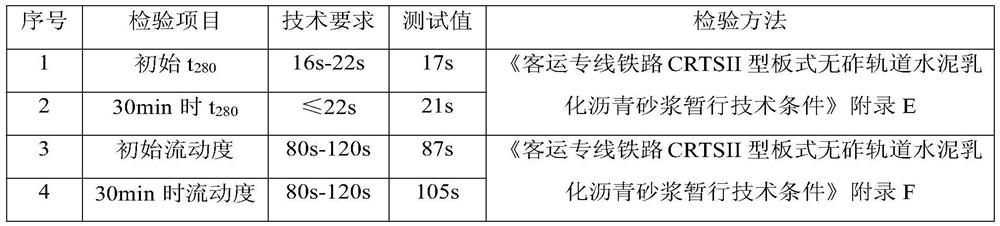

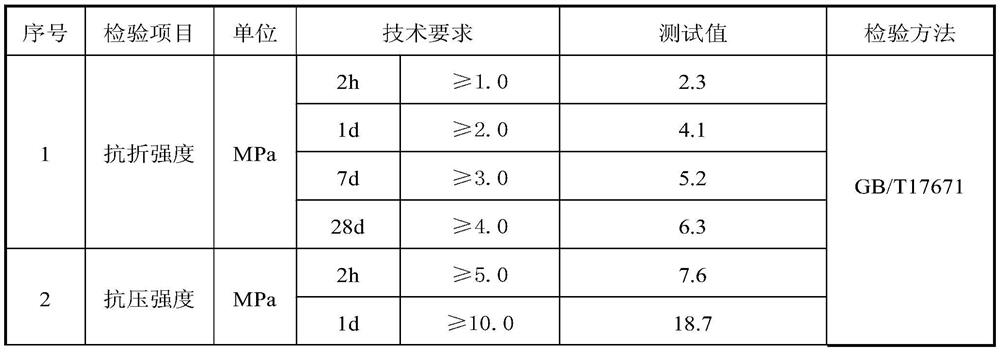

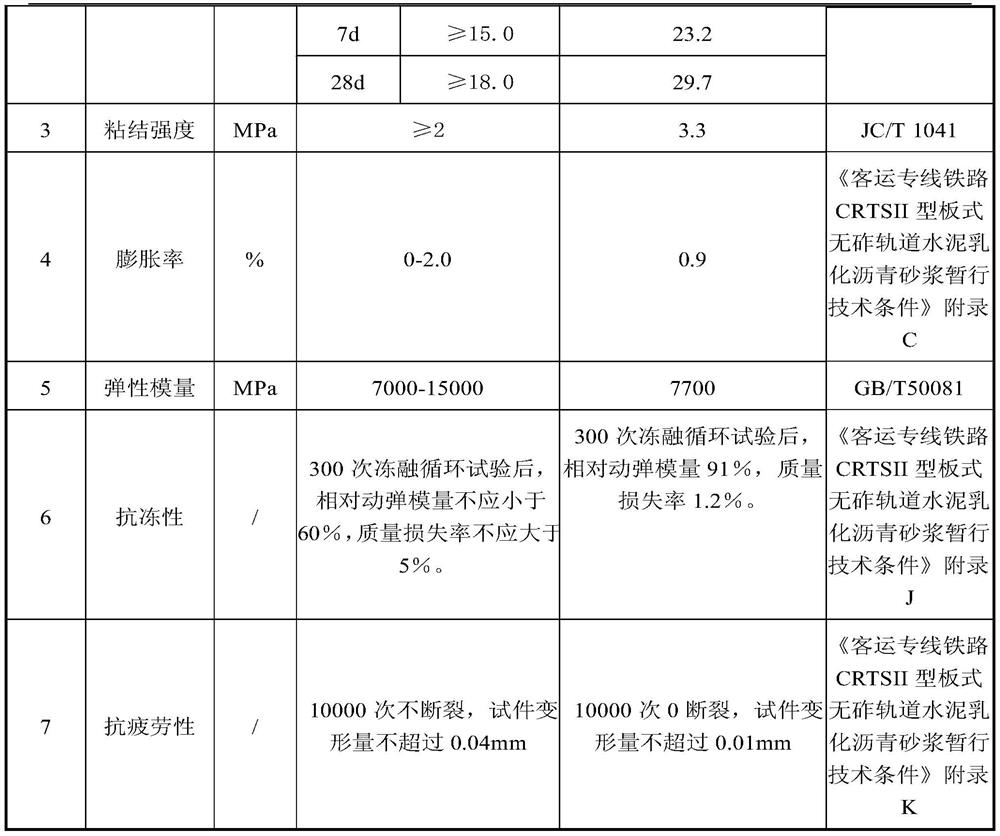

Polymer mortar and preparation method thereof

The invention provides polymer mortar and a preparation method thereof. The polymer mortar comprises the following raw material components in parts by weight: 90-100 parts of rapid hardening sulphoaluminate cement, 35-45 parts of a polymer emulsion, 2-3 parts of superfine powder, 5-10 parts of gypsum powder, 5-10 parts of an expanding agent, 190-210 parts of sand, 30-40 parts of water, 0.5-1.0 part of a powder water reducing agent, 0.5-1.0 part of polymer fiber, 0-0.05 part of a hardening accelerator, 0-0.05 part of a retarder and 0.3-0.8 part of a defoaming agent. The method comprises the following steps: preparing a dry powder material, preparing a pre-dispersed emulsion, adding the dry powder material, the pre-dispersed emulsion, the water and the defoaming agent into a stirrer, and mixing and stirring for 1-3 minutes to a uniform state, thereby obtaining the polymer mortar. The polymer mortar can meet the construction requirements of the filling layer of a CRTS II type slab ballastless track.

Owner:NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR +1

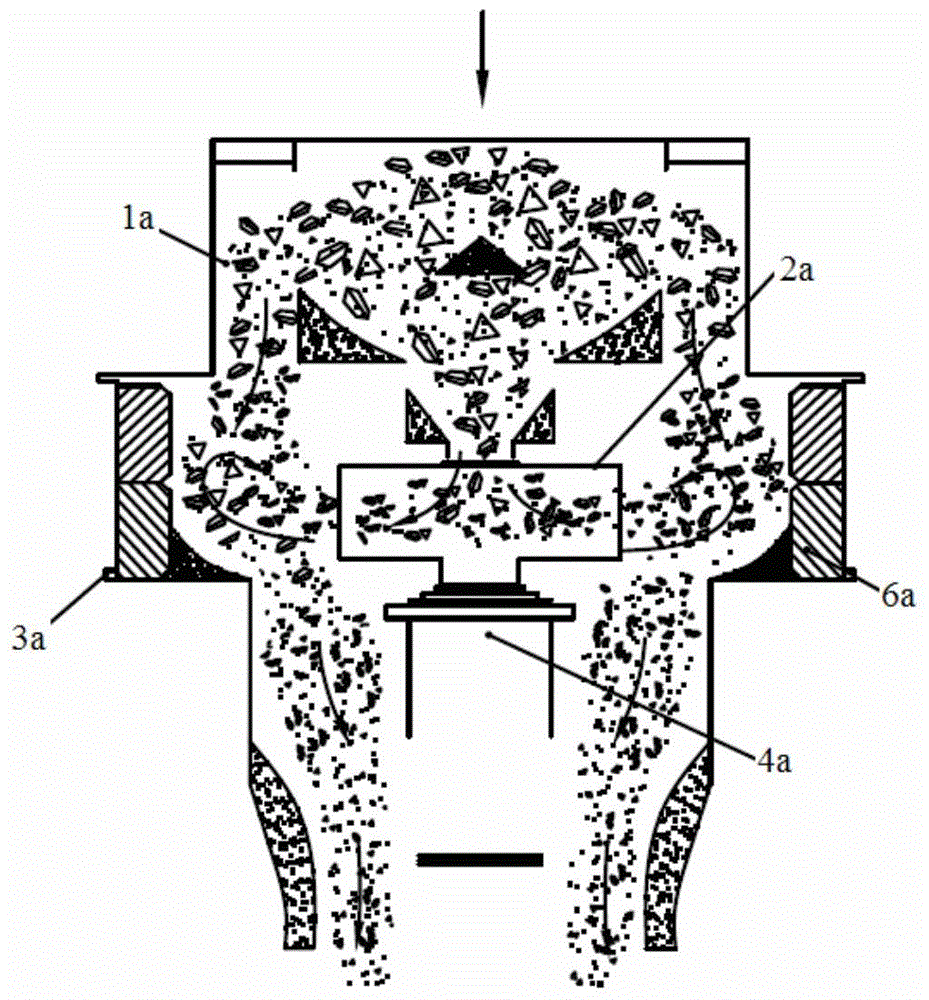

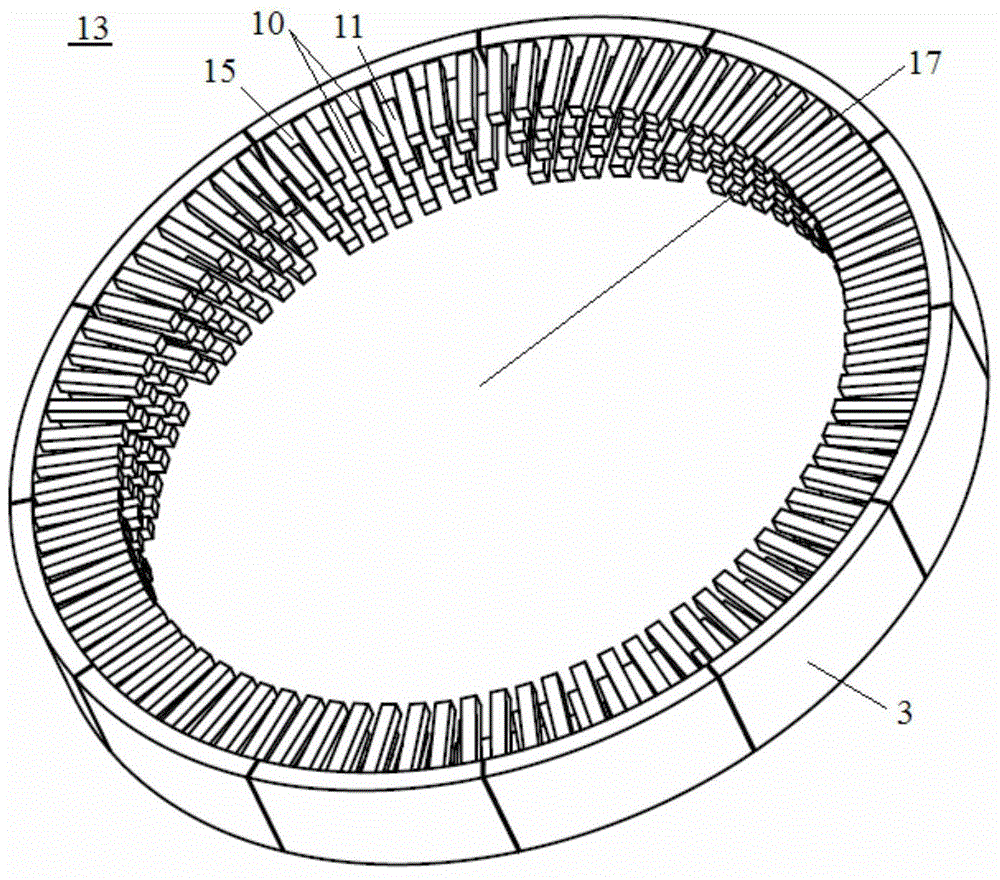

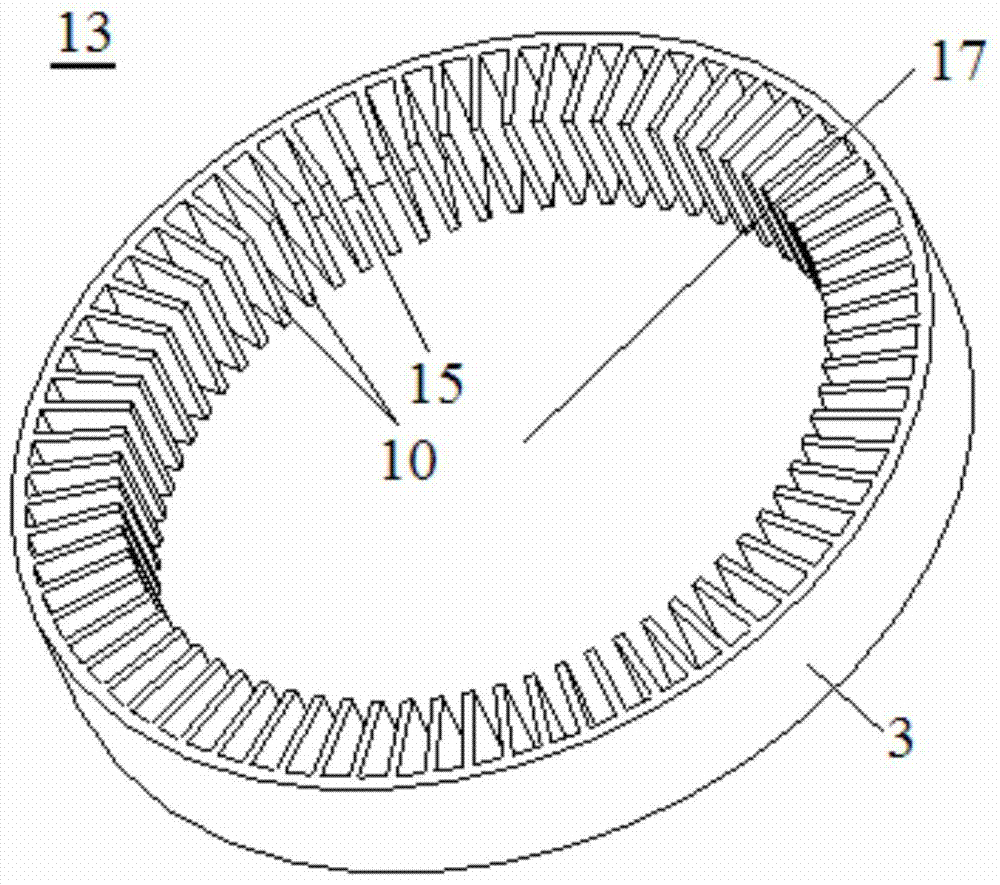

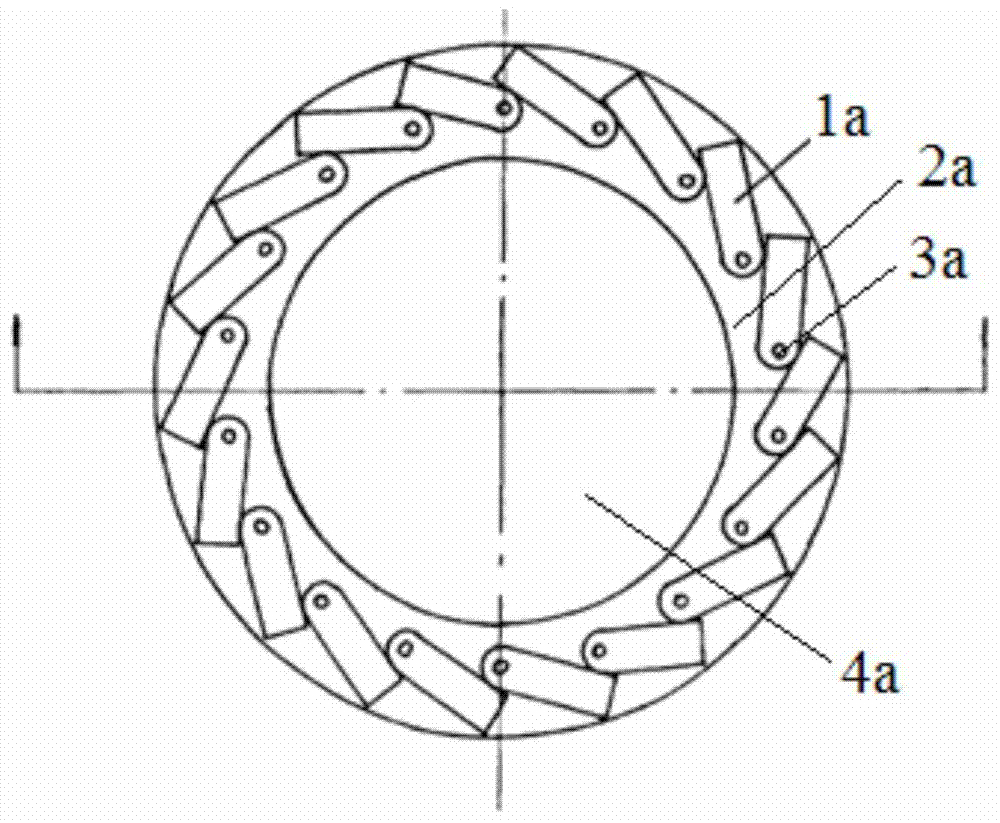

Crusher, anvil device, anvil piece and mineral production line

ActiveCN106311398AIngenious structural designImprove crushing efficiencyGrain treatmentsGrain shapeImpeller

The invention discloses a crusher, an anvil device, an anvil piece of the anvil device and a mineral production line. A crushing cavity (2) of the crusher is internally provided with at least two material impact part layers arranged in the up-down direction. Each material impact part layer comprises a plurality of columnar material impact parts (10) arranged around an impeller device (6) at intervals. In the adjacent material impact part layers in the up-down direction, the material impact parts at the lower layer are arranged to be capable of being stacked into material lining layers (4) to be doubled as material lining forming parts (11) relative to the corresponding material impact parts at the upper layer, and the inner ends of the material impact parts at the lower layer do not exceed the inner ends of the corresponding material impact parts (10) at the upper layer. According to the crusher, the anvil device, the anvil piece of the anvil device and the mineral production line, a crushing pattern that materials and anvils are subjected to mixed striking is truly achieved through an original sequential impact mode; and in addition, the crushing efficiency is high, the crushed grain shape is good, and the voidage of the crushed materials is significantly increased compared with the voidage of materials crushed by existing crushers.

Owner:ZOOMLION HEAVY IND CO LTD

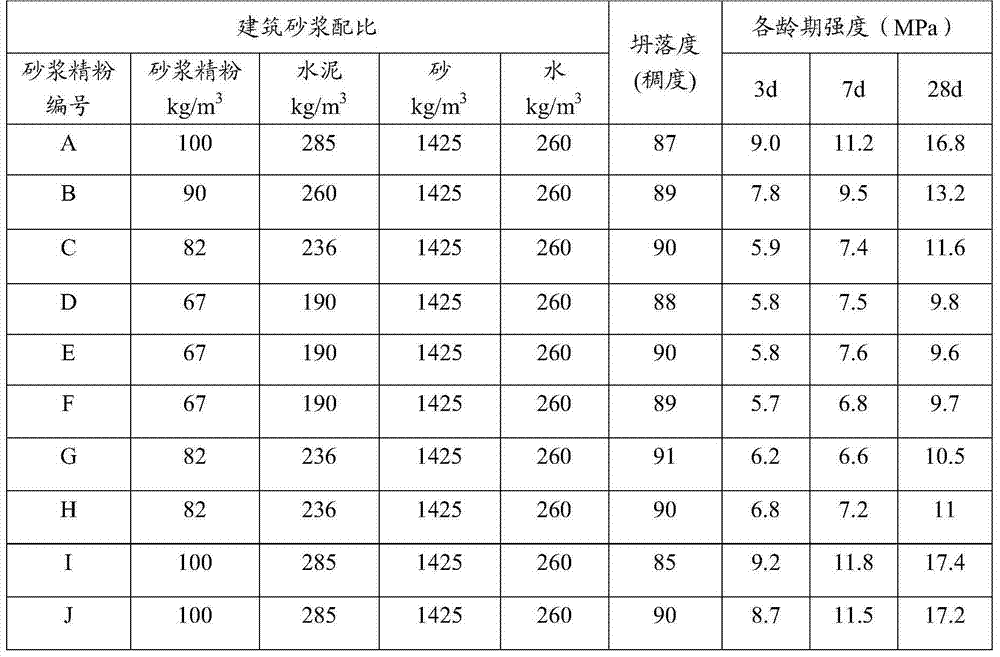

Mortar fine powder and preparation method thereof

The invention provides a mortar fine powder and a preparation method thereof, and belongs to the field of building materials. The mortar fine powder comprises the following compositions in parts by weight: 97-99.9 parts of limestone powder, 0.03-1 part of a water repellent, 0.03-1 part of cellulose, 0.0-0.5 part of polyacrylamide and 0.02-0.5 part of an air entraining agent. When the mortar fine powder is used as building mortar, the building mortar not only has the advantages of good workability, but also is improved in compressive strength and reduced in cracking resistance. Performance tests show that the building mortar modified by the mortar fine powder is improved in 28-day compressive strength by 5%, improved in caking ability by 20% and reduced in shrinking percentage by 30%.

Owner:湖南瑞吉达科技有限公司

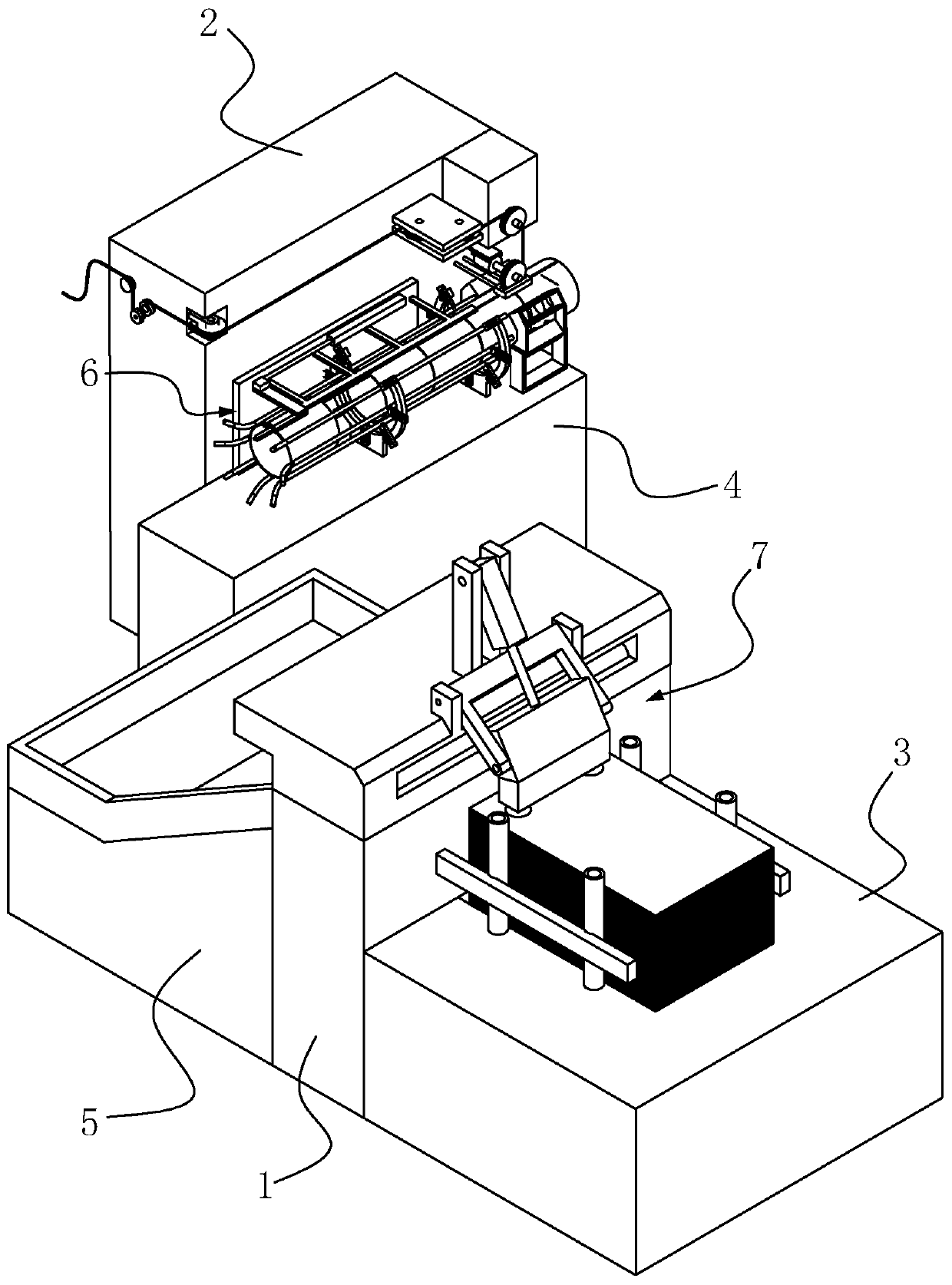

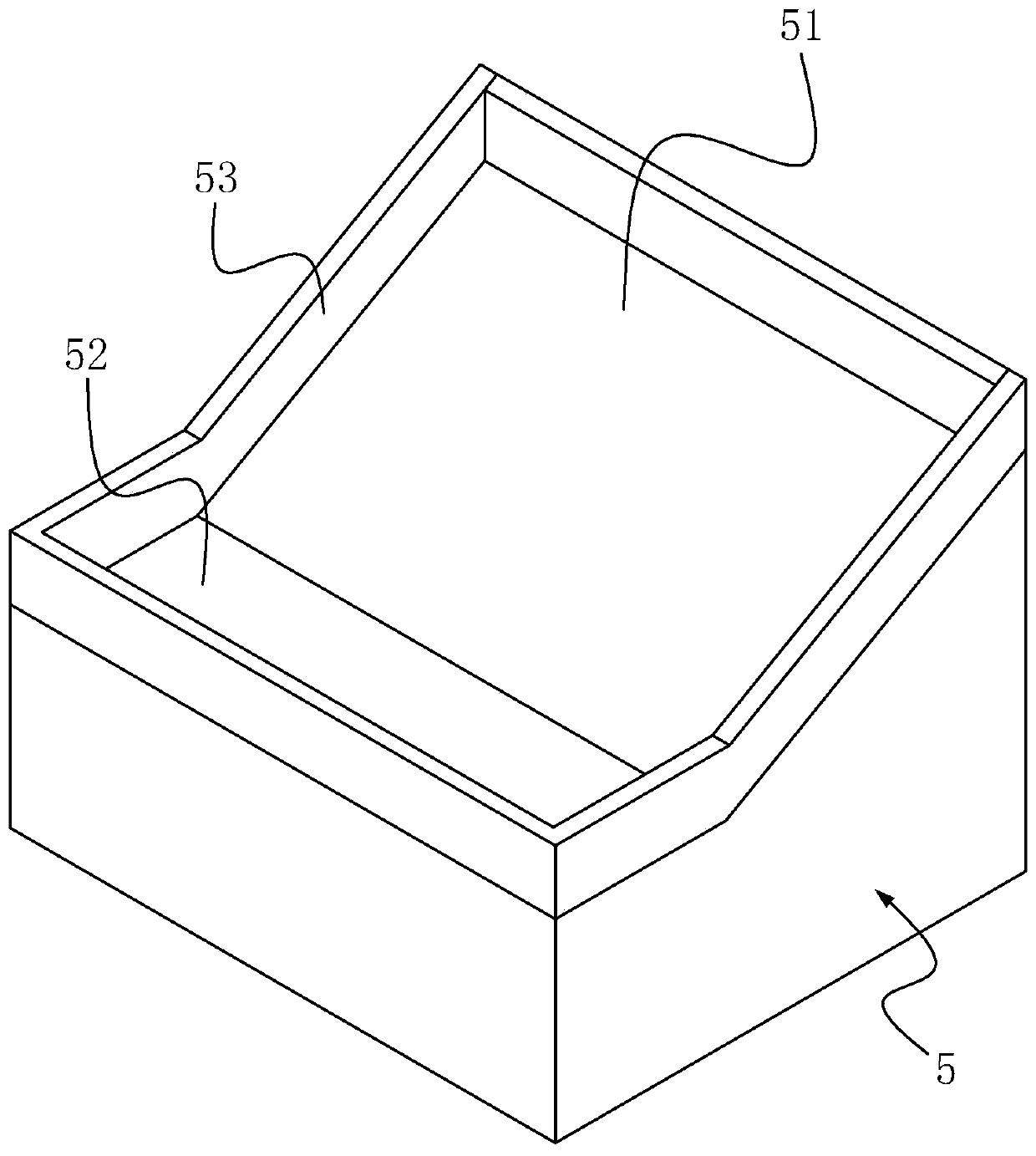

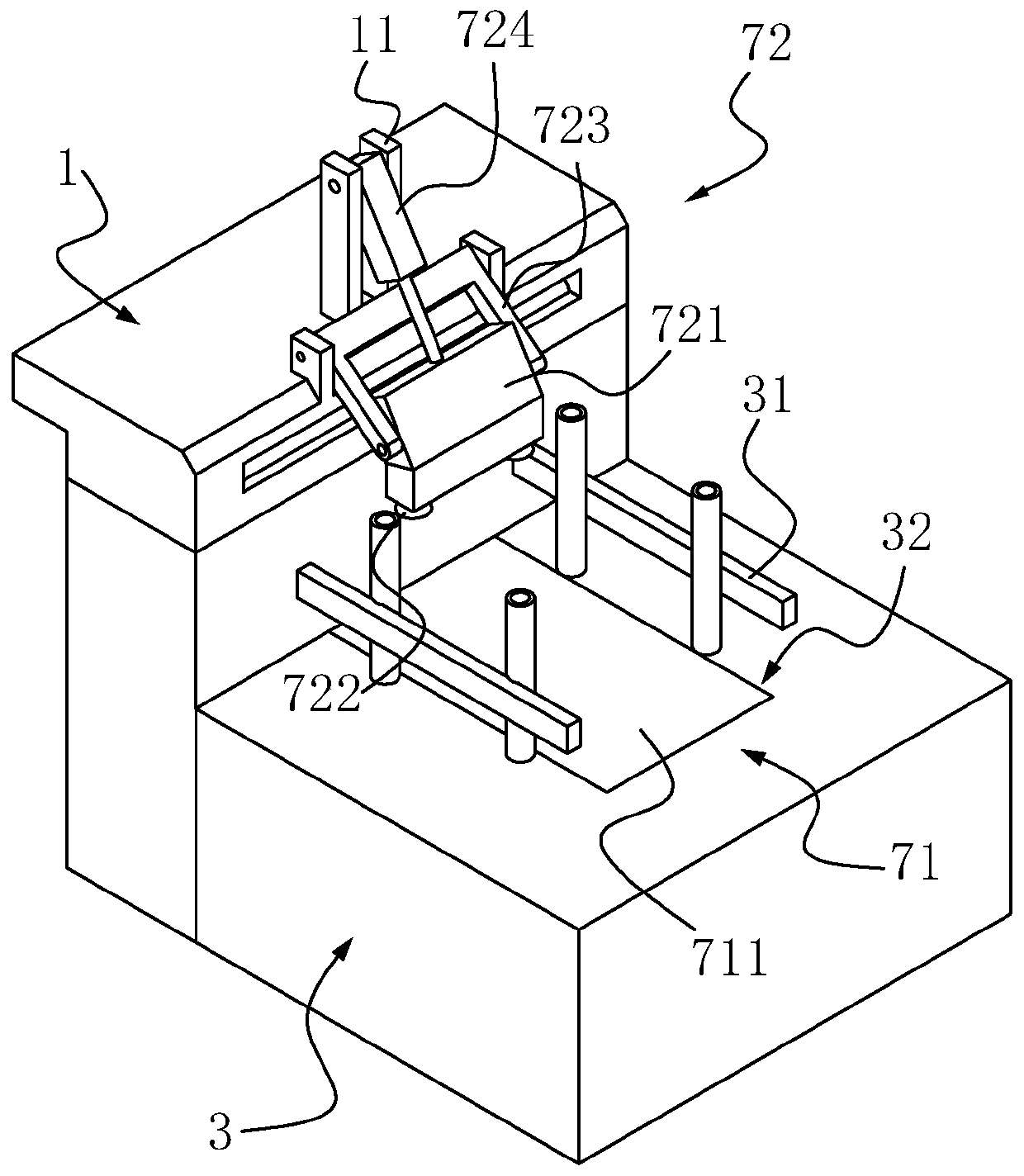

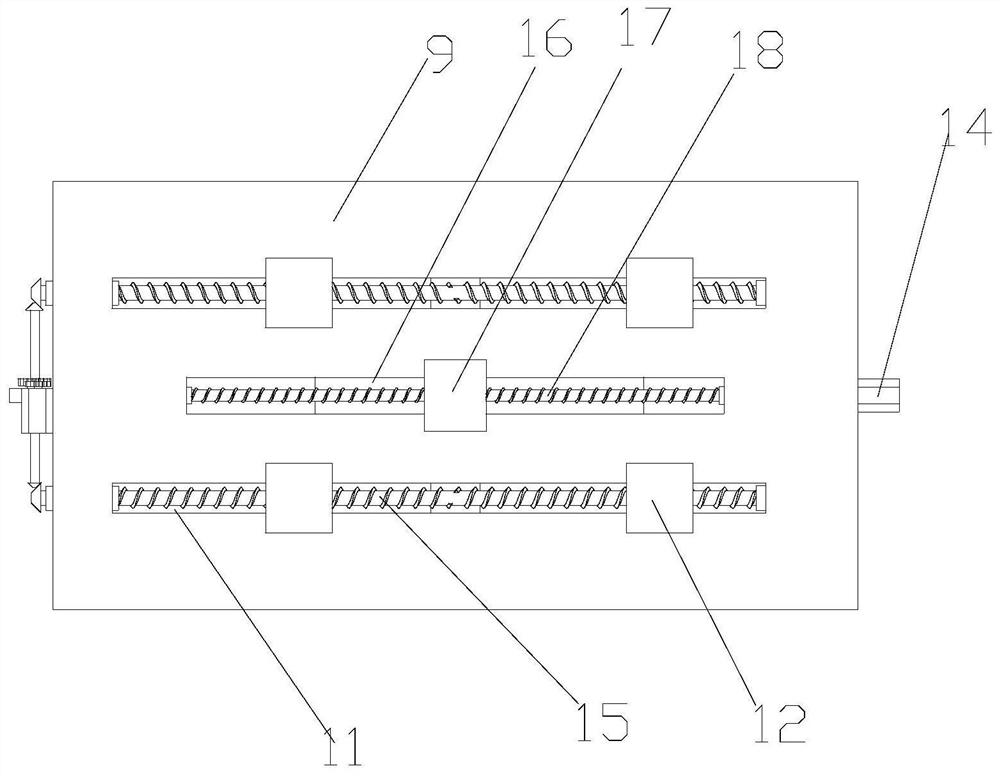

Iron sheet bucket body machining production line

InactiveCN111215899AReduce distortionGood shape effectArc welding apparatusOther manufacturing equipments/toolsSubmerged arc weldingManufacturing engineering

The invention relates to an iron sheet bucket body machining production line, and belongs to the technical field of iron sheet bucket machining equipment. According to the technical scheme, the iron sheet bucket body machining production line is characterized in that a plate reeling machine, a feeding platform, a welding platform, a transfer platform and an automatic arc-submerging welding machinelocated on one side of the welding platform are included; the material conveying direction of the plate reeling machine is perpendicular to the length direction of the welding platform, and the feeding end of the welding platform is located on one side of the discharging end of the plate reeling machine; the feeding platform is located at the feeding end of the plate reeling machine, and a feeding device is arranged at the position of the welding feeding platform; the transfer platform is located at the discharging end of the welding platform, the length direction of the transfer platform isarranged in the discharging direction of the plate reeling machine, and the transfer platform comprises a transmission slope and a horizontally-arranged transfer plane located at the lower end of thetransmission plane; and a conveying device driving a bucket body to move towards the discharging end from the feeding end of the welding platform is arranged on the welding platform. By means of the iron sheet bucket body machining production line, iron sheet bucket bodies can be efficiently and conveniently machined and produced.

Owner:杭州吴杭包装材料有限公司

Superfine modified fly ash

Provided is superfine modified fly ash. The superfine modified fly ash is formed by mixing and grinding fly ash raw powder and an activating agent, and the mass ratio of the fly ash raw powder to the activating agent is 10,000:3; the activating agent contains triethanolamine, ethanediol, sodium silicate, sodium sulfite, glycerin, stearic acid and sodium hexametaphosphate, and the mass ratio of triethanolamine to ethanediol to sodium silicate to sodium sulfite to glycerin to stearic acid to sodium hexametaphosphate contained in the activating agent is 6:5:2:1:1:1:0.5. The superfine modified fly ash is regular in particle, is mostly spherical, and is smooth in surface and large in specific surface area, and the activity of the superfine modified fly ash is higher than that of common fly ash.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

Crusher, anvil device, anvil piece, mineral production line and material crushing method

ActiveCN106269132BImprove crushing efficiencyGood broken shapeGrain treatmentsProduction linePorosity

The invention discloses a crusher, an anvil device, an anvil piece of the anvil device, and a mineral production line, and further discloses a material crushing method. The crusher comprises a crushing and shaping structure with material impacting parts (10) and material liner forming parts (11); and the relative position relationship between each material impacting part (10) and at least one material liner forming part (11) is that a material impacted by the material impacting part (10) can be at least partially turned and impacted to a material liner layer (4) of the corresponding material liner forming part (11), so that sequential impact of the material to the material impacting parts (10) and the material liner layers (4) is realized continuously. Due to the ingenious sequential impact manner, not only is the 'material and anvil mixed beating' crushing mode realized in deed, but also the crushing efficiency is high, the shape of crushed particles is good, and the porosity of the crushed material is significantly higher than that of a material crushed with the conventional crusher.

Owner:ZOOMLION HEAVY IND CO LTD

A method and system for beautifying portraits

ActiveCN109146808BAvoid occupyingAvoid time consumingImage enhancementImage analysisComputer graphics (images)Algorithm

The invention discloses a method and system for beautifying portraits, comprising: performing grid division on the image to be processed according to the resolution of the image to be processed to obtain an original grid model; performing face key point detection on the image to be processed , to obtain the key points of the original face; according to the predetermined beauty function, the original grid model is sequentially transformed to obtain the transformed grid model; there are more than one predetermined beauty functions; according to the transformed The mesh model and the original face key points are used to calculate the transformed face key points; the transformed mesh model is rendered and / or according to the transformed face key points, the beauty model is obtained image. The technical solution provided by the invention can perform smooth real-time rendering on the mobile terminal, and has good aesthetic effect.

Owner:CHENDU PINGUO TECH CO LTD

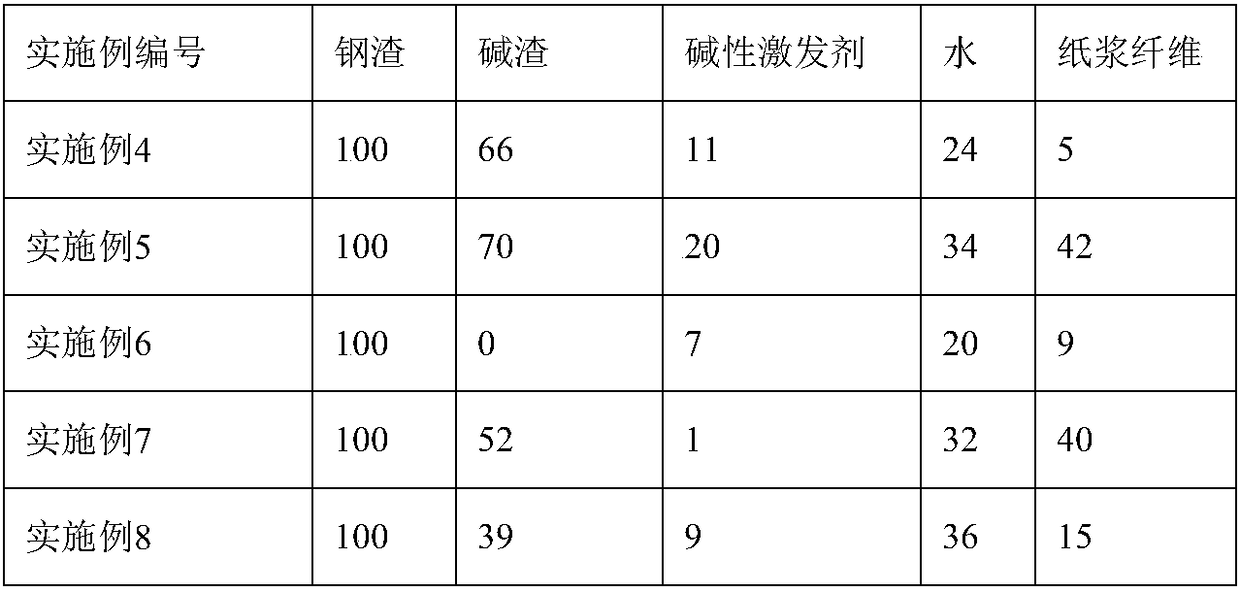

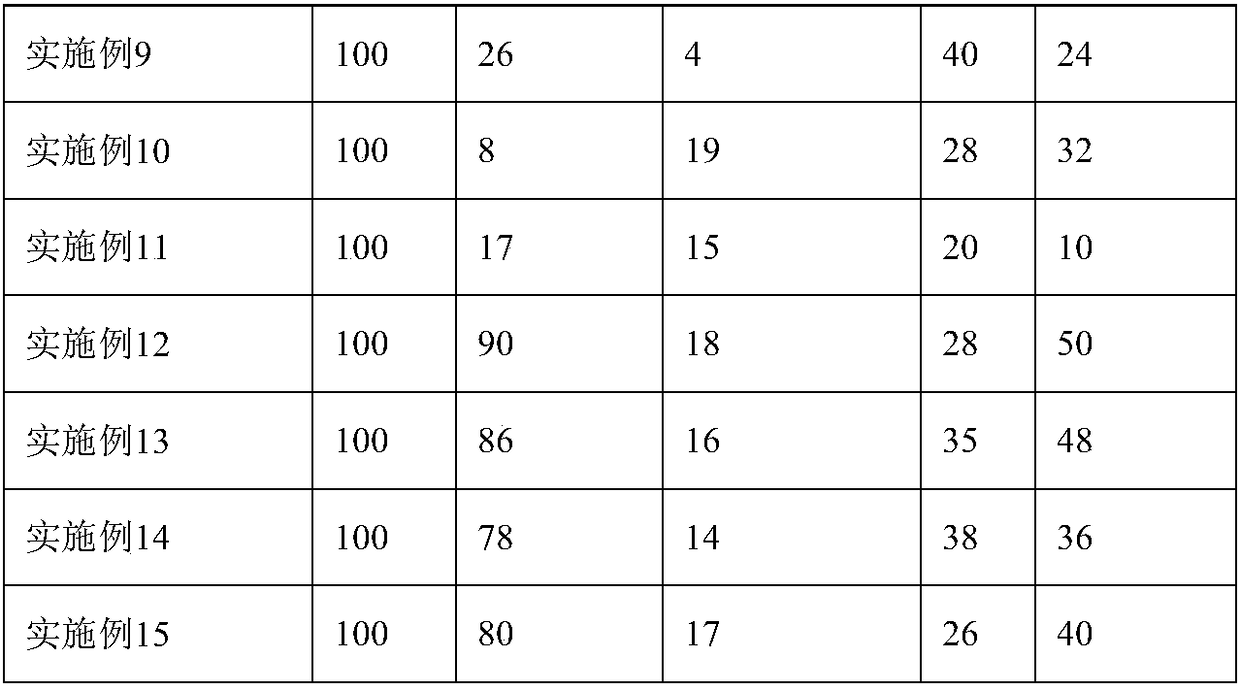

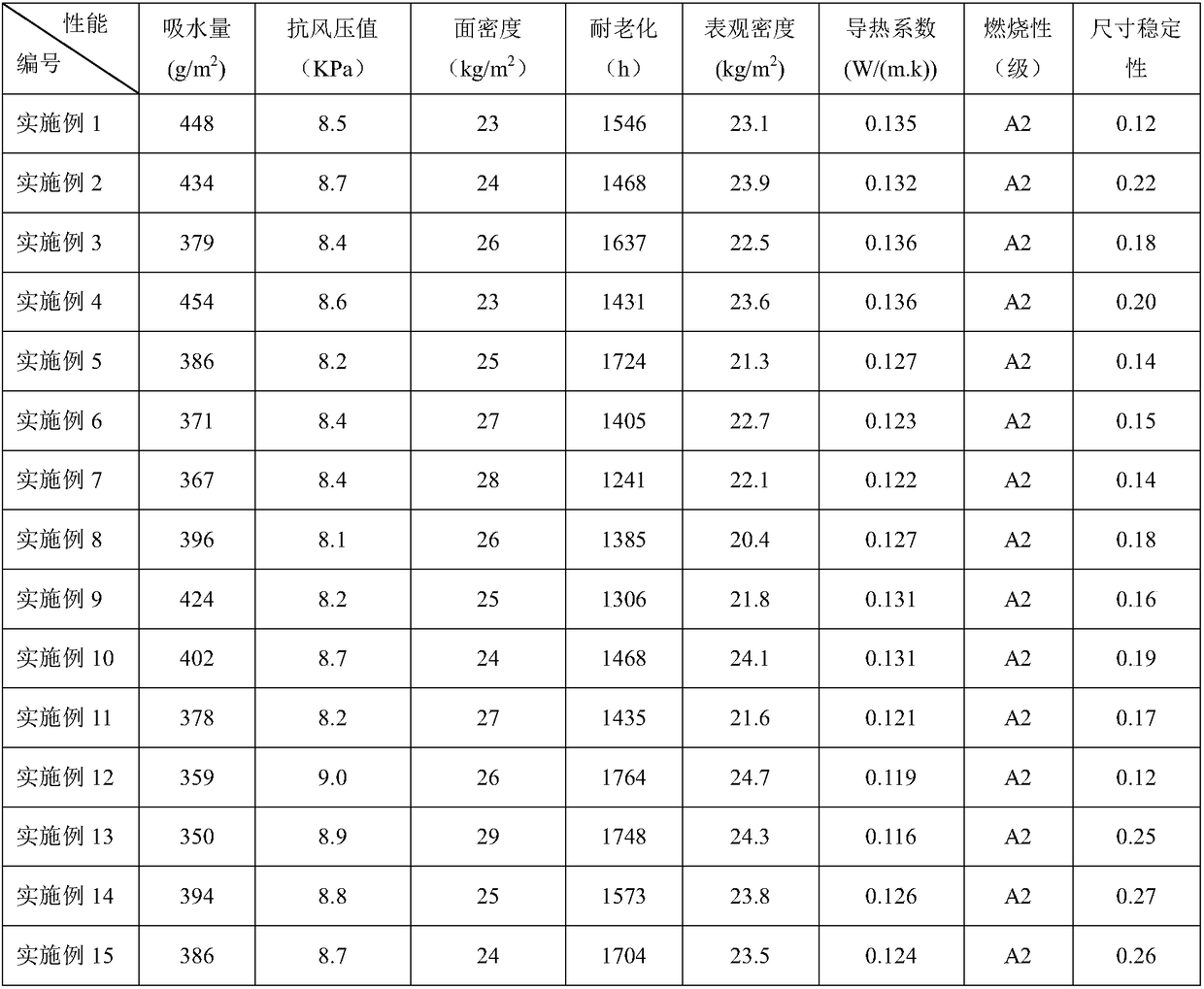

Extrusion-molded alkali-activated steel slag-alkaline residue exterior wall decorative board

InactiveCN109206065AEasy to shapeThe molding method is easy to use extrusion moldingCovering/liningsSolid waste managementSurface layerAdditive ingredient

The invention provides an extrusion-molded alkali-activated steel slag-alkaline residue exterior wall decorative board. The exterior wall decorative board is formed by laminating a decorative surfacelayer and a middle material layer. The decorative surface layer is externally sprayed with a decorative surface layer material, and the middle material layer is prepared from an extrusion-molded middle layer material. The decorative surface layer material is prepared from the following ingredients (by weight): 100 parts of steel slag, 30 parts of alkaline residue, 21 parts of an alkaline activator, 42 parts of water, 19 parts of pulp fiber, 5 parts of a pigment, and 1.1 part of polypropylene fiber. The middle layer material is prepared from the following ingredients (by weight): 100 parts of steel slag, 40 parts of alkaline residue, 15 parts of an alkaline activator, 36 parts of water, and 40 parts of pulp fiber. By the technical scheme of the invention, potential hydraulicity of steel slag-alkaline residue is fully utilized, a high-strength product which achieves various performance indexes of the exterior wall decorative board is generated at a high hydration speed, the blank qualityof the board is guaranteed, and mass production can be realized.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

A kind of superfine modified fly ash production method

The invention discloses a production method of superfine modified coal ash.The production method includes: weighing a certain amount of power plant coal ash raw powder, and adding the power plant coal ash raw powder into a drum mill of 500 mm in diameter; adding an activating agent, wherein a mass ratio of the activating agent to the power plant coal ash raw powder is 3:10000, and the activating agent contains triethanolamine, ethylene glycol, sodium silicate, sodium sulfite, glycerol, stearic acid and sodium hexametaphosphate according to a mass ratio of 6:5:2:1:1:1:0.5; grinding for one hour to obtain the superfine modified coal ash.The superfine modified coal ash produced by the method has regular particles and is mostly spherical, smooth in surface, large in specific surface area and higher than common coal ash in activity.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

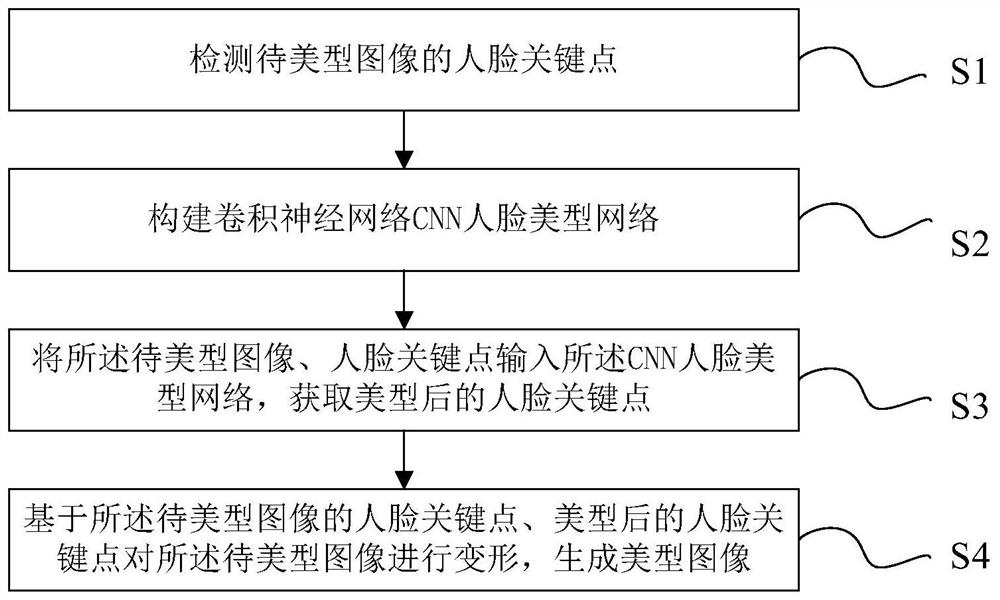

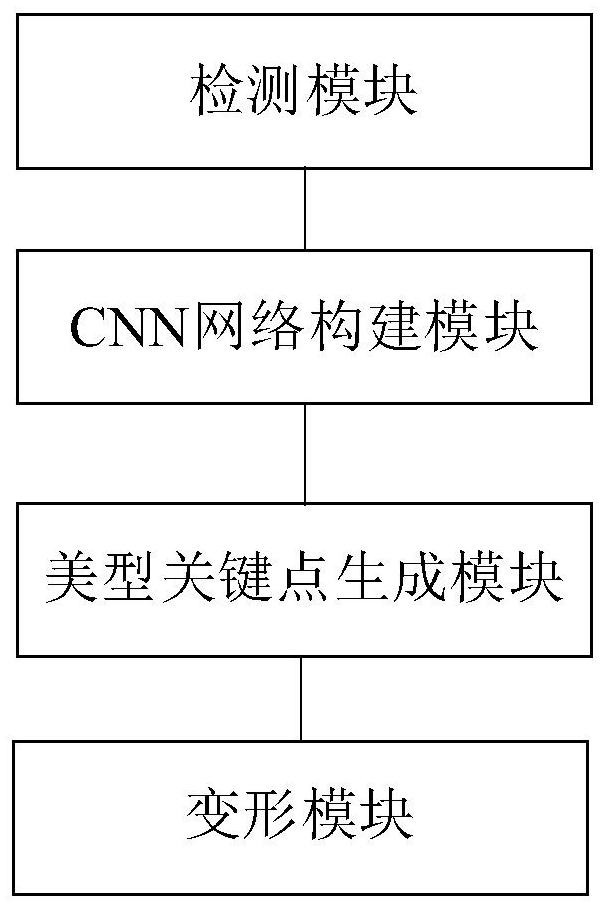

A method and system for intelligent beauty based on convolutional neural network

ActiveCN110782408BAvoid stereotypesStrong targetingImage enhancementImage analysisNeural network nnConvolution

The invention discloses an intelligent beautification method and system based on a convolutional neural network. The intelligent beautification method includes steps: S1, detecting the key points of the human face of the image to be beautified; S2, constructing a convolutional neural network (CNN) for face beautification Type network; S3, input the described CNN face beauty network with the image to be beautiful and key points of human face, and obtain the key points of human face after beauty; S4, based on the key points of the human face of the image to be beautiful The key points of the human face after point and beautification are deformed to generate the beautification image. The present invention adopts a deep learning algorithm to extract facial feature ratio feature information from a large amount of beautiful faces, deeply understand the relationship between the details of the beauty and the face from the massive data, and realize the intelligent face beauty.

Owner:HANGZHOU QUWEI SCI & TECH

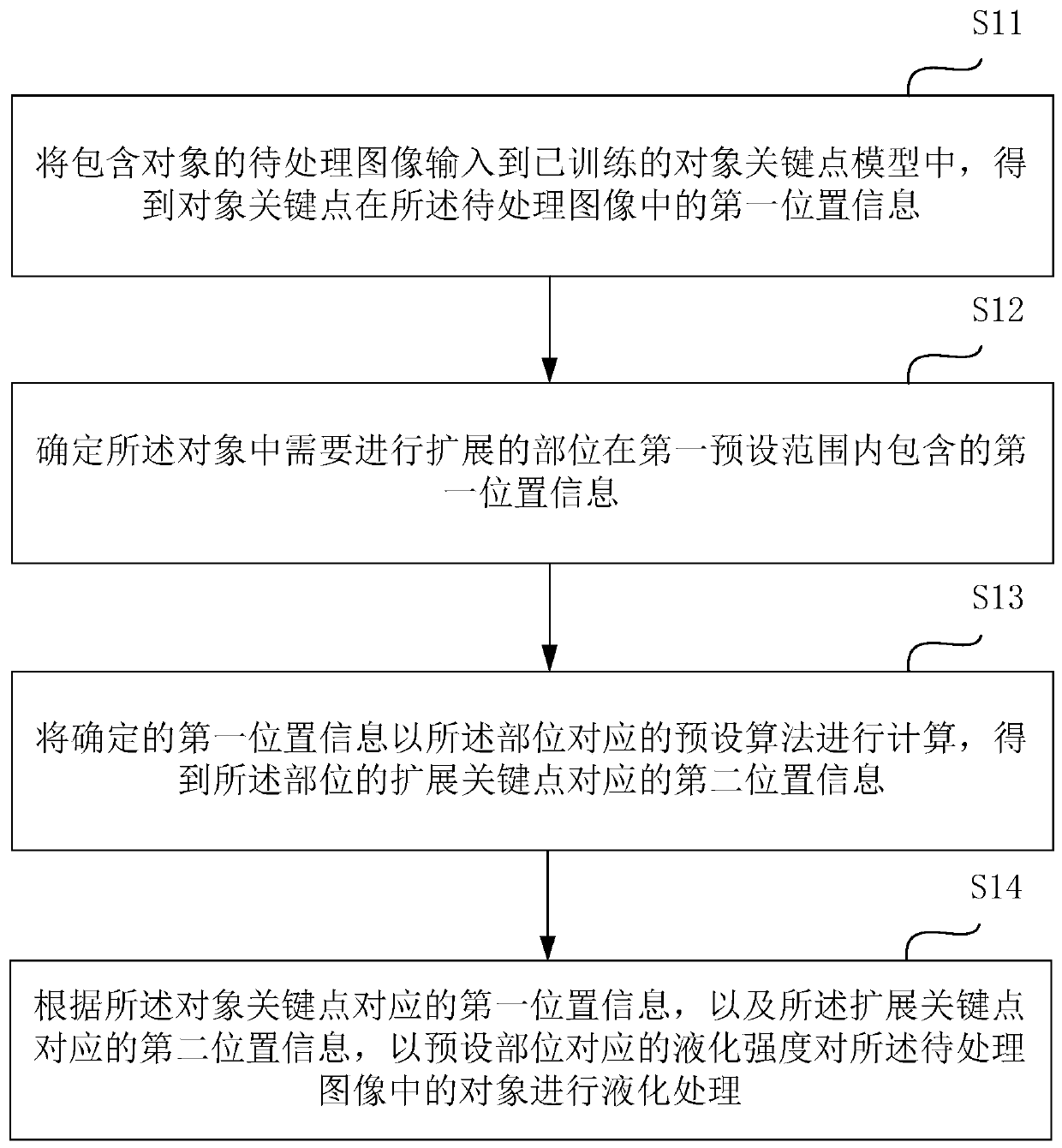

Image processing method and device and storage medium

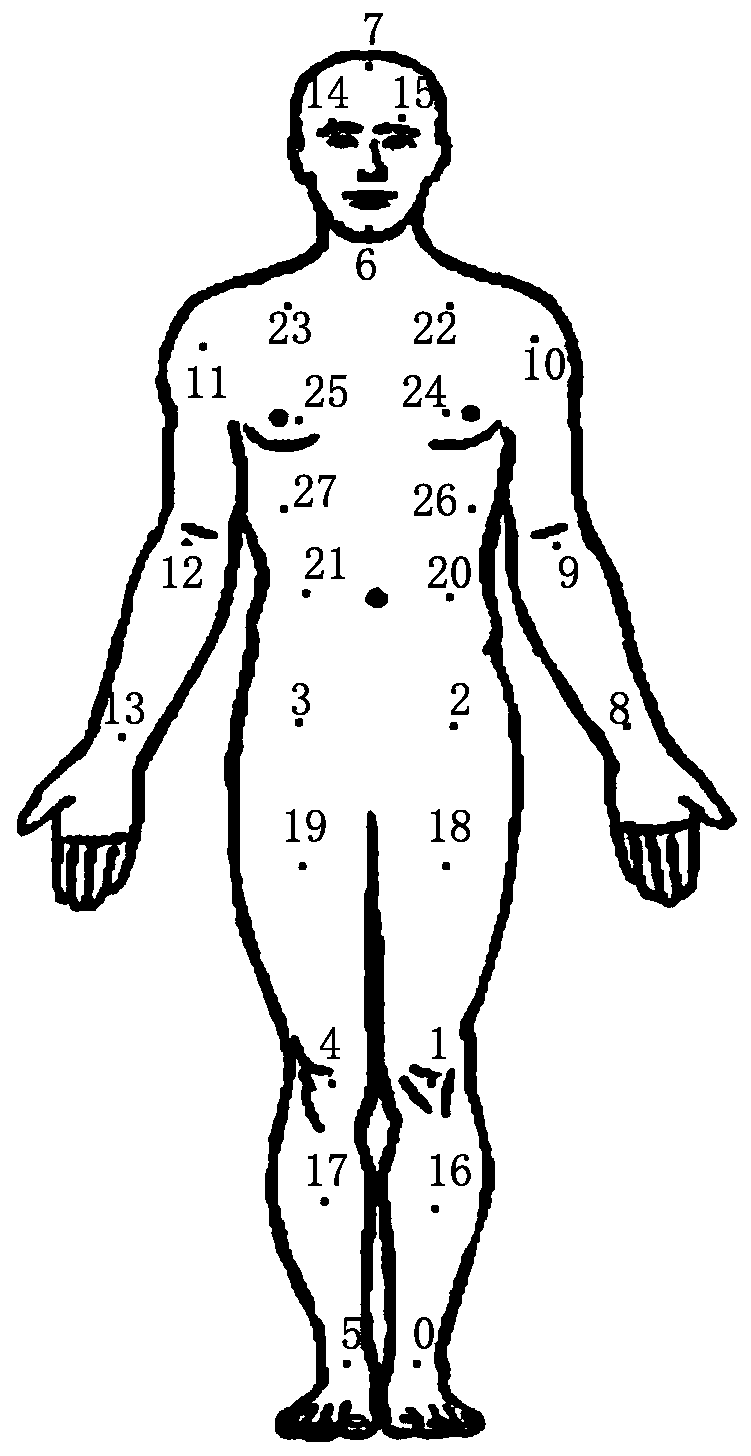

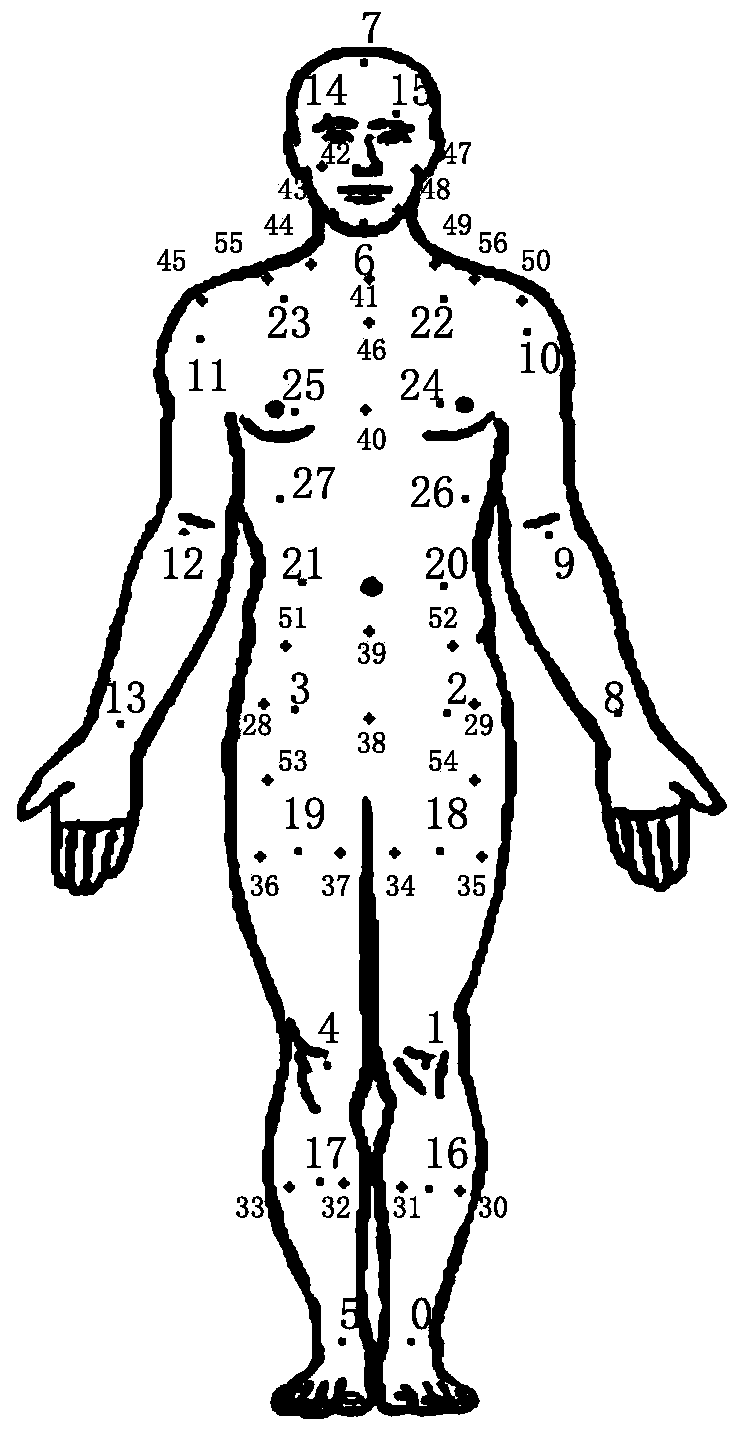

The invention discloses an image processing method and device and a storage medium, relates to the technical field of image processing, and aims to at least solve the problem of poor presentation effect caused by incapability of completely beautifying each part of a body in related technologies. The acquired position information of the key points of a human body is calculated by a preset algorithmto obtain the position information corresponding to the extended key points of the part needing to be extended, and liquefaction processing is performed according to the position information of the key points of the human body and the extended key points to obtain a processed image. Thus, the human body is beautified according to the position information of the human body key points and the extension points, the beautifying effect can cover all parts of the whole body, and the presented beautifying effect is better.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Mfg. method of metal ripple tubes

InactiveCN1248799CFlat surfaceUniform wall thicknessHollow articlesMolding machineSS - Stainless steel

A technology for making metallic bellows includes providing annealed cold-rolling bright stainless steel band, rolling to become pipe shape, welding, cutting, shaping, cutting edge, surface treating in a treating liquid prepared from nitric acid and water, flushing with water and dewatering with alcohol. Its advantages are high productivity and quality.

Owner:锦州经济技术开发区天华波纹管有限公司

Crusher, anvil device, anvil parts and mineral production line

ActiveCN106311398BIngenious structural designImprove crushing efficiencyGrain treatmentsProduction lineMining engineering

The invention discloses a crusher, an anvil device, an anvil piece of the anvil device and a mineral production line. A crushing cavity (2) of the crusher is internally provided with at least two material impact part layers arranged in the up-down direction. Each material impact part layer comprises a plurality of columnar material impact parts (10) arranged around an impeller device (6) at intervals. In the adjacent material impact part layers in the up-down direction, the material impact parts at the lower layer are arranged to be capable of being stacked into material lining layers (4) to be doubled as material lining forming parts (11) relative to the corresponding material impact parts at the upper layer, and the inner ends of the material impact parts at the lower layer do not exceed the inner ends of the corresponding material impact parts (10) at the upper layer. According to the crusher, the anvil device, the anvil piece of the anvil device and the mineral production line, a crushing pattern that materials and anvils are subjected to mixed striking is truly achieved through an original sequential impact mode; and in addition, the crushing efficiency is high, the crushed grain shape is good, and the voidage of the crushed materials is significantly increased compared with the voidage of materials crushed by existing crushers.

Owner:ZOOMLION HEAVY IND CO LTD

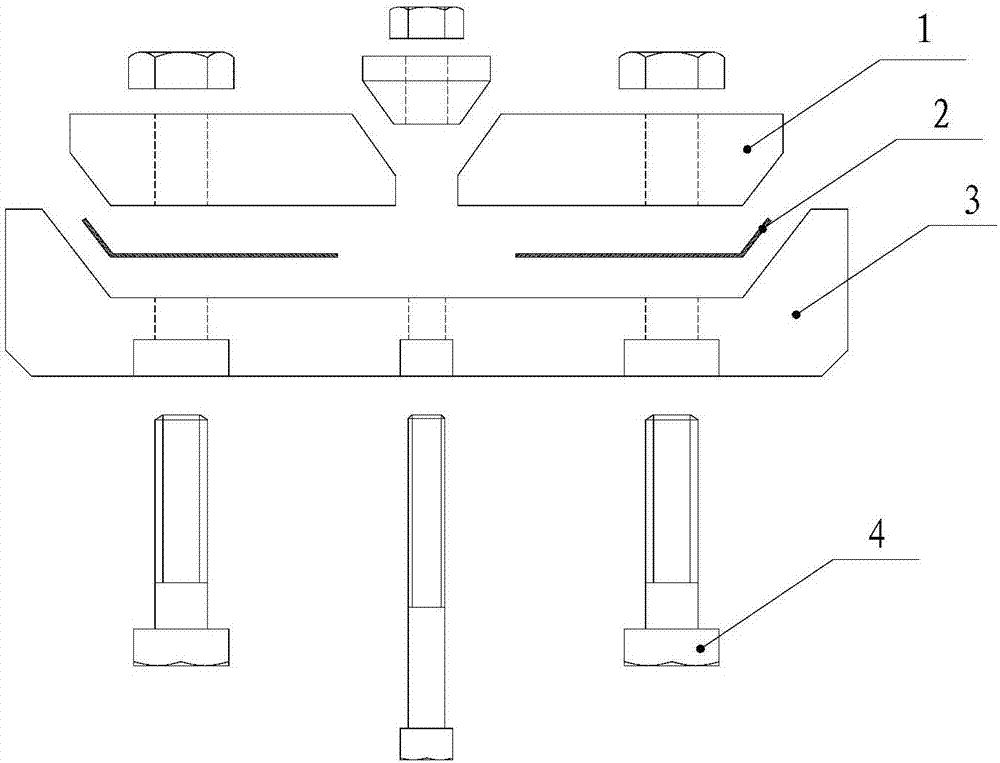

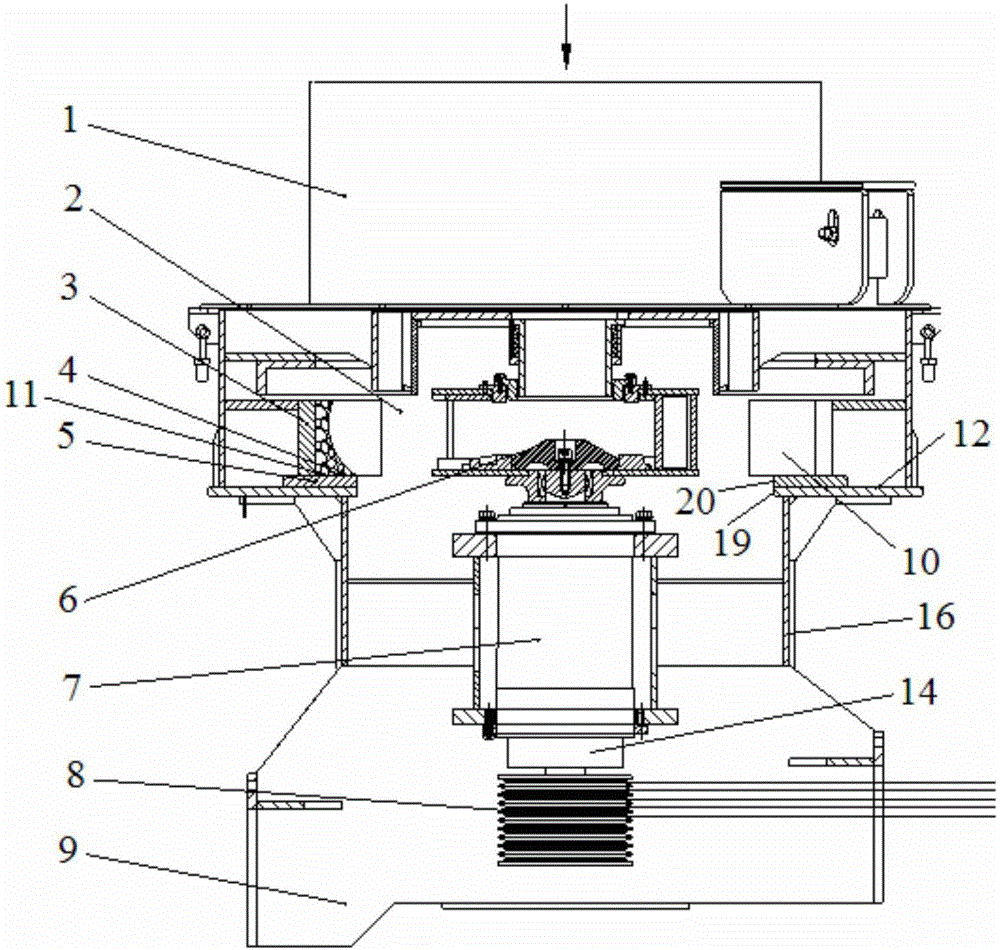

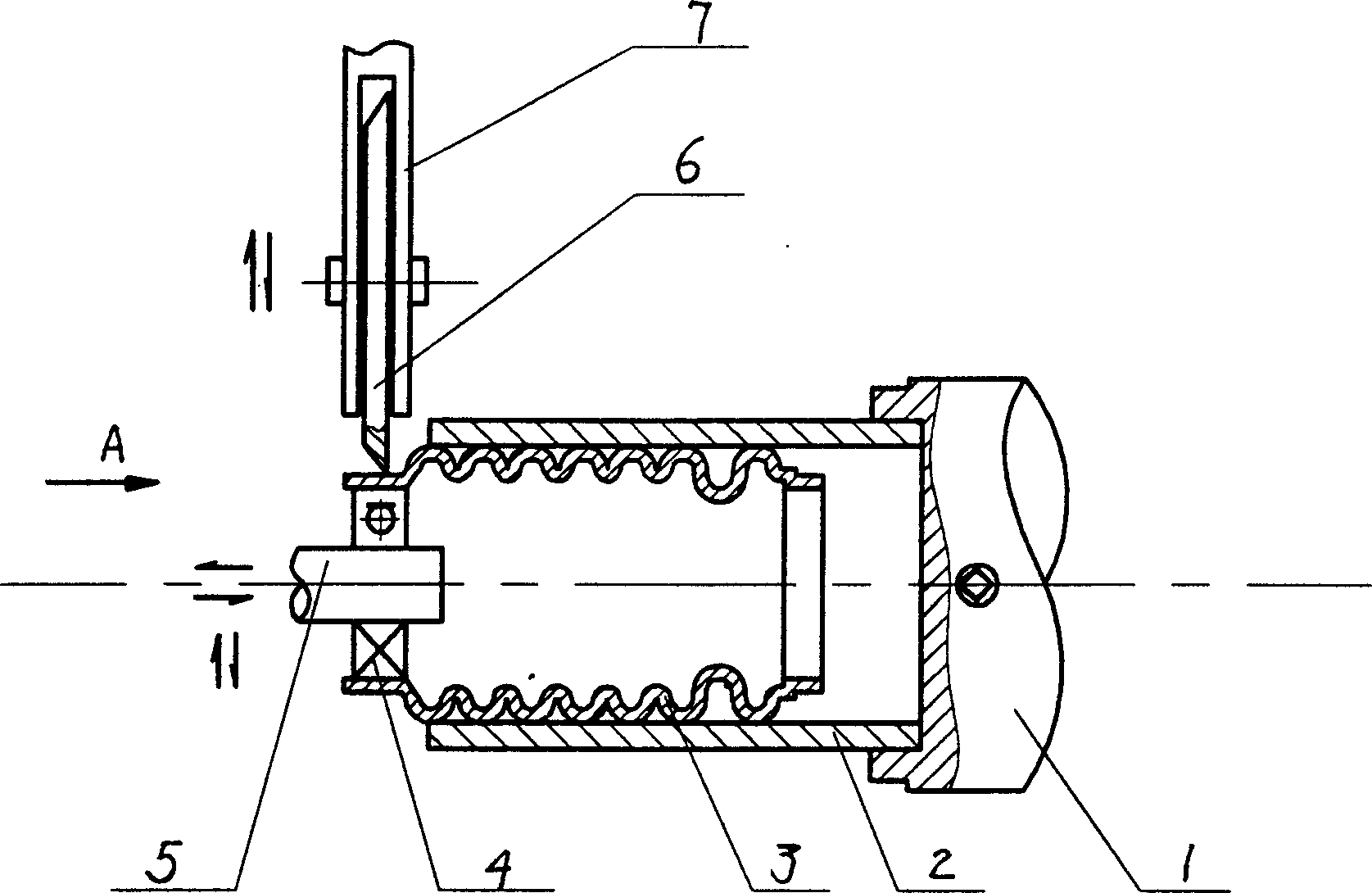

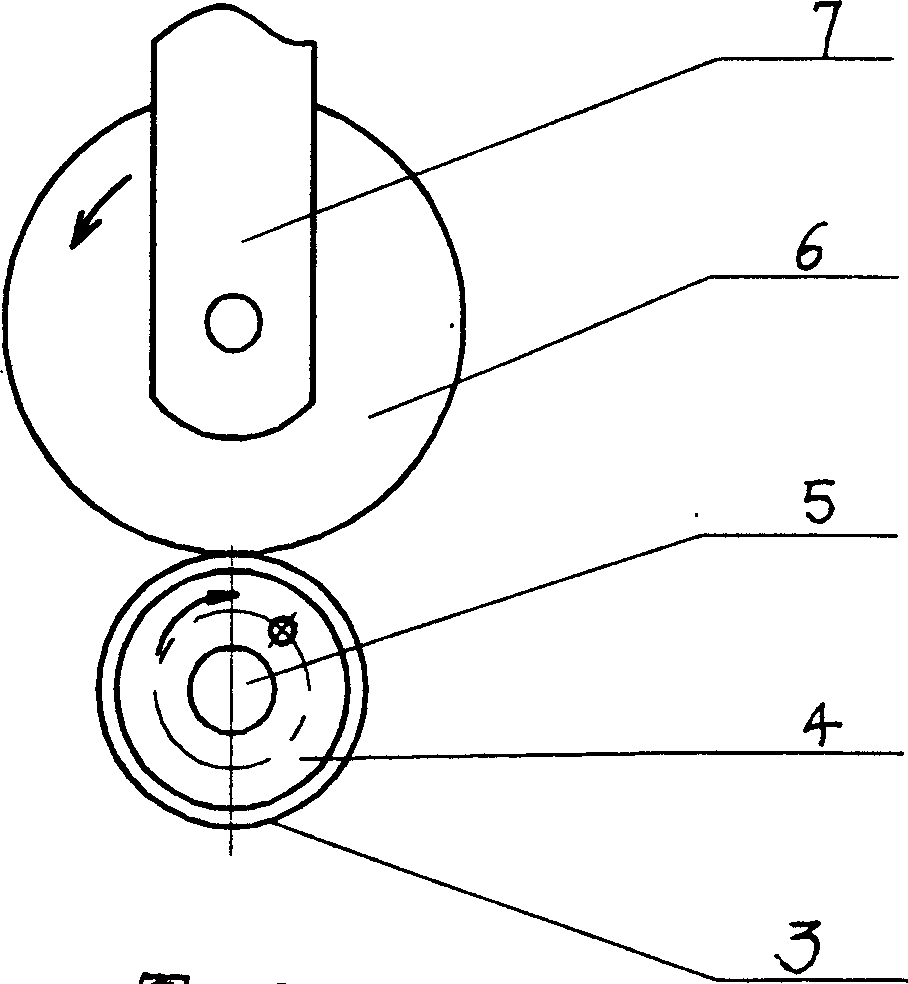

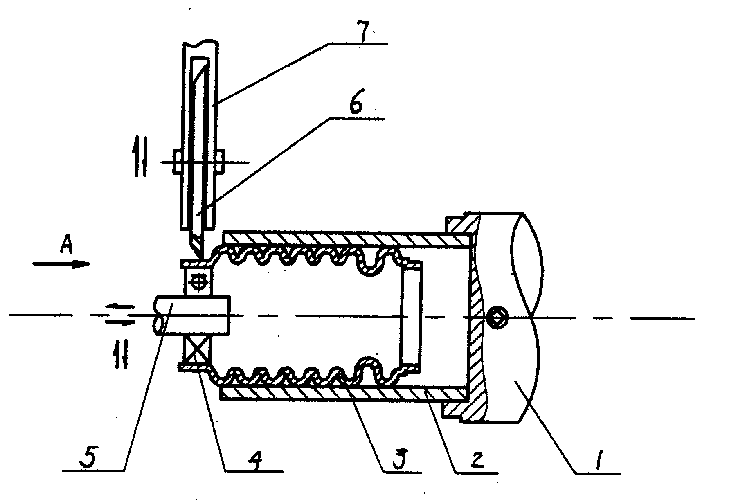

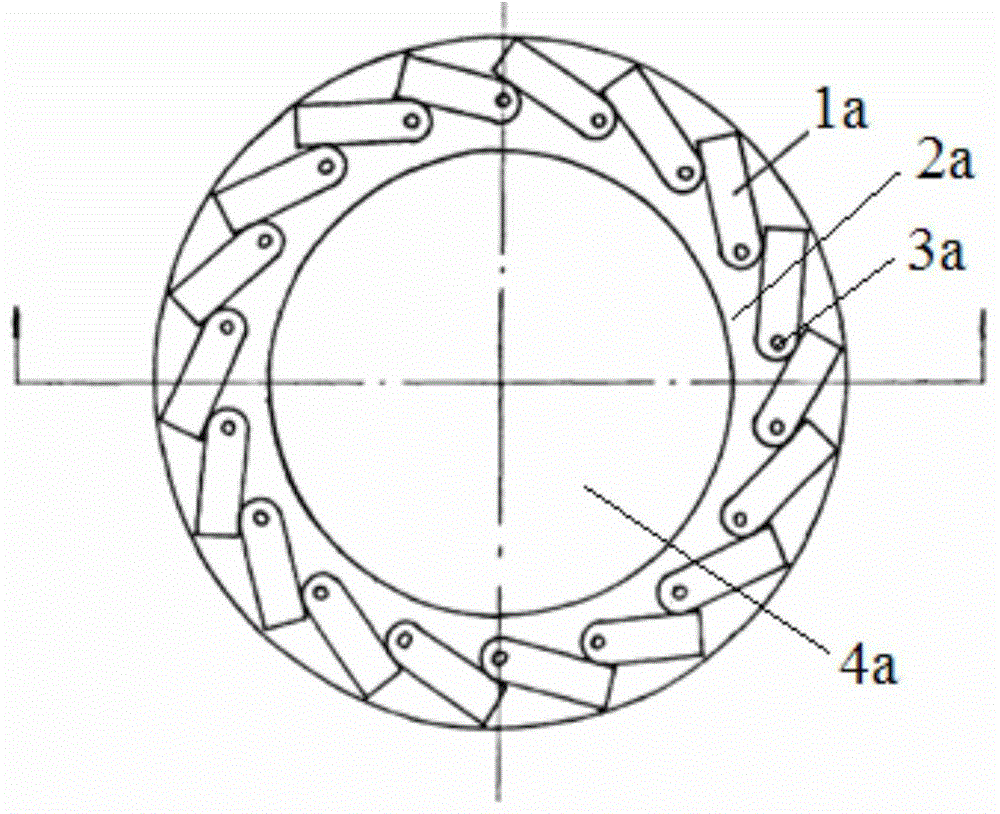

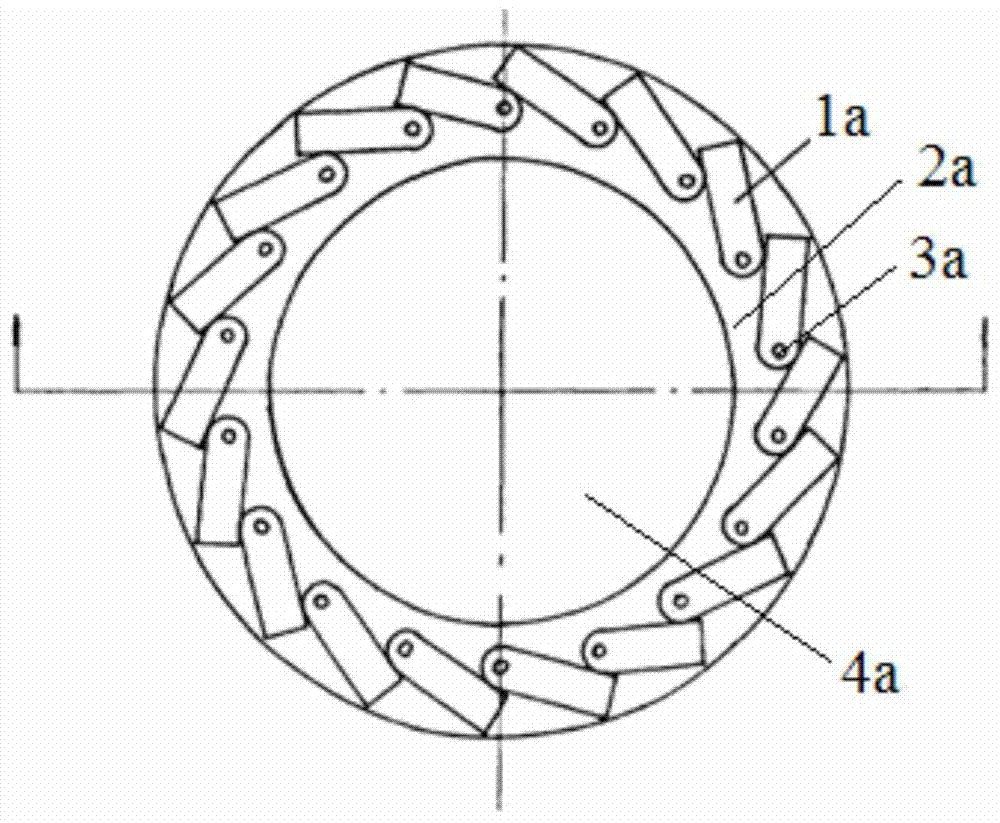

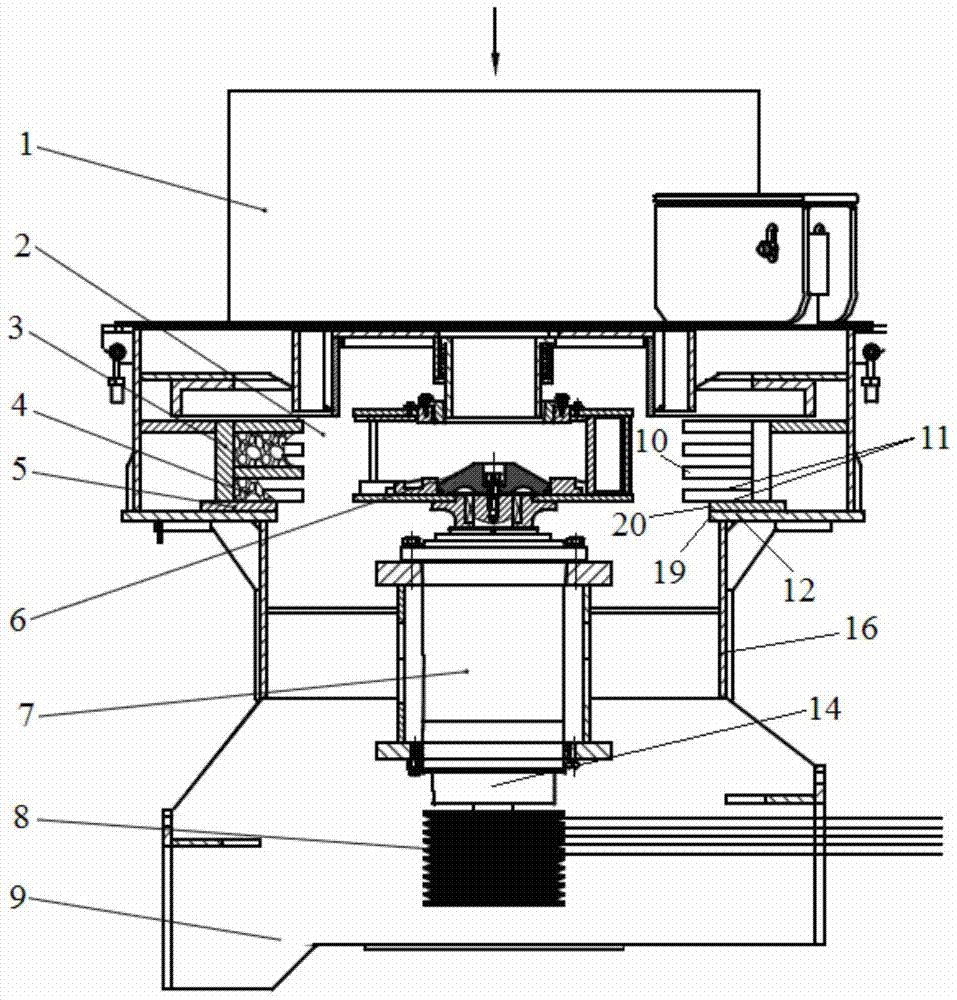

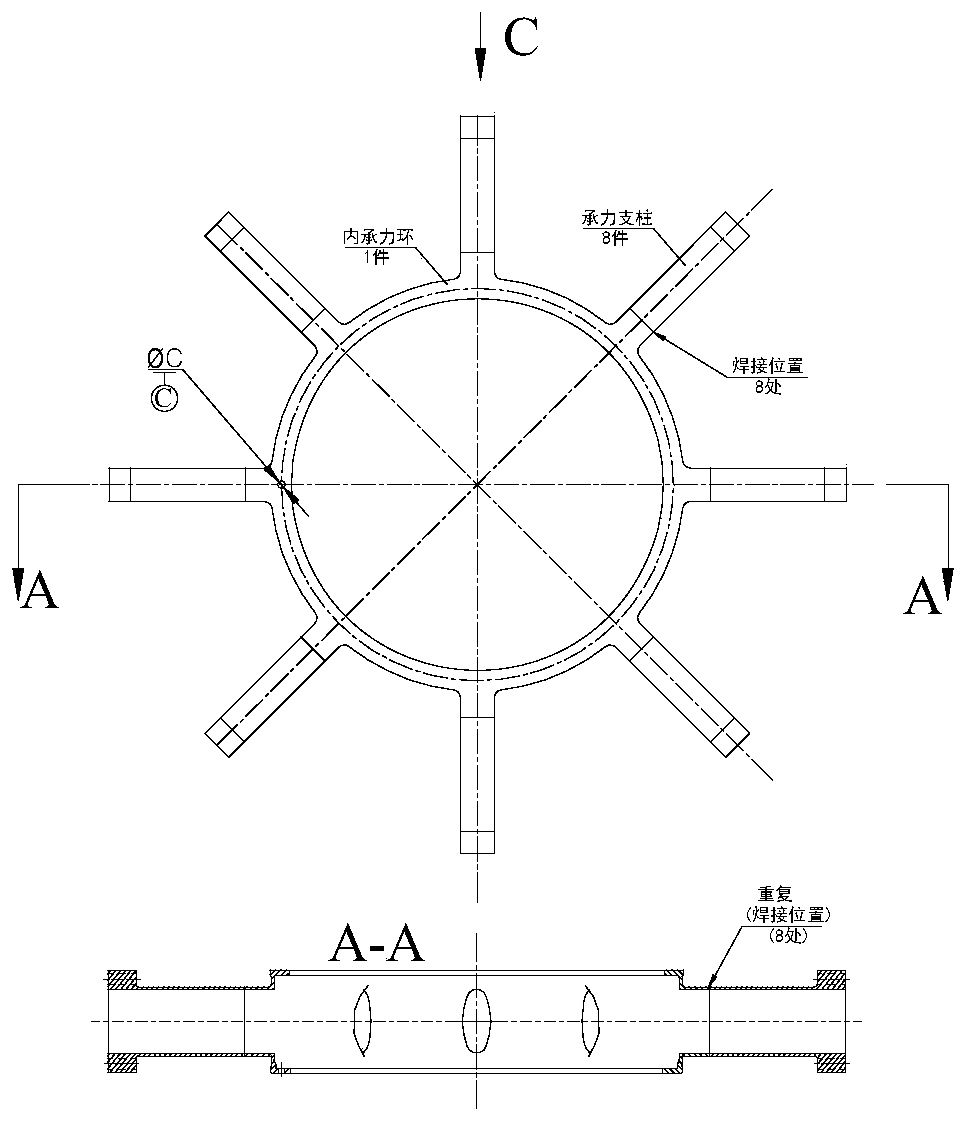

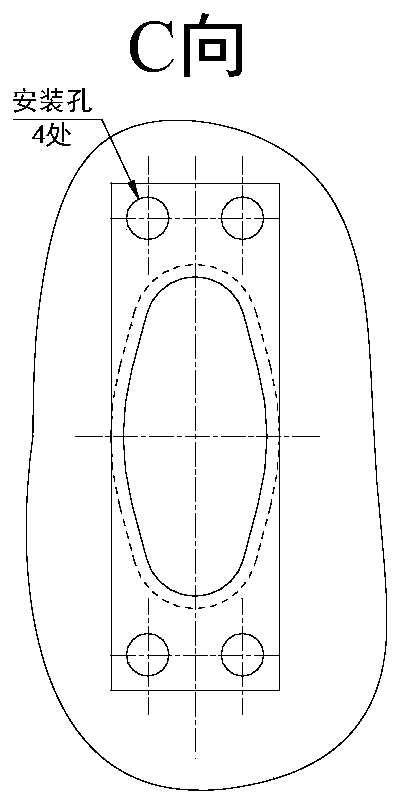

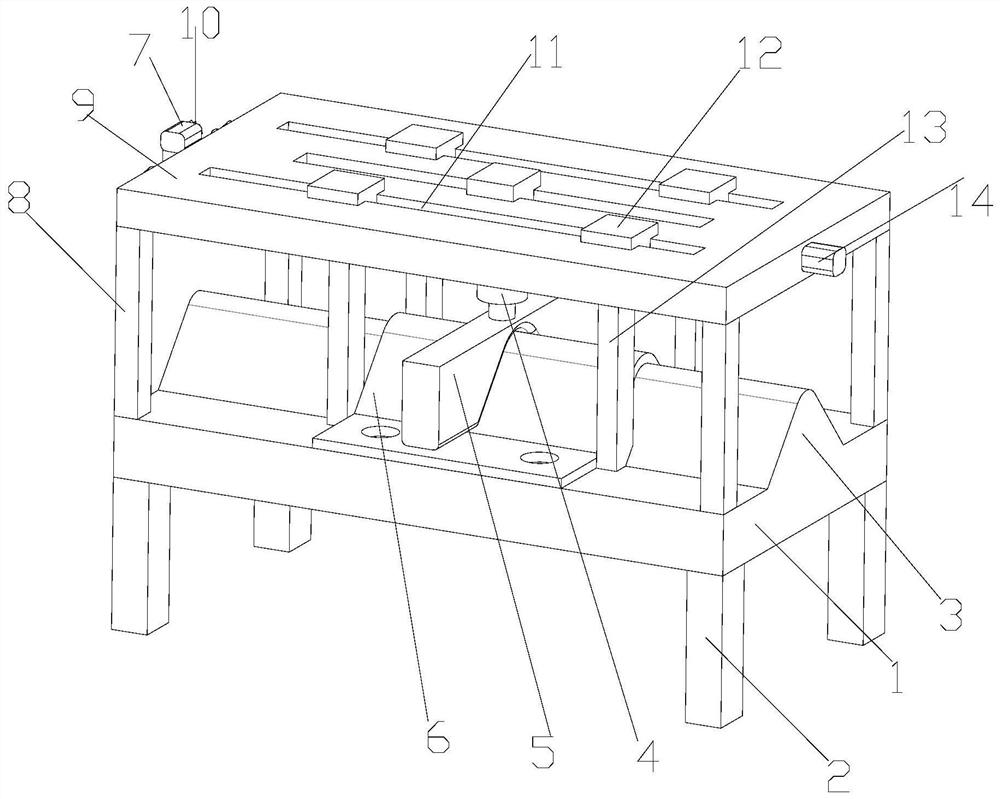

A tool for correcting the shape of engine load-bearing struts matched with heat treatment

ActiveCN108015134BGood shape effectReduce scrap rateFurnace typesProcess efficiency improvementCircular discEngineering

The invention discloses a shape correcting tool for force bearing supporting columns of an engine matched with heat treatment. The shape correcting tool is composed of a base, correcting assemblies, pressing plate assemblies and a positioning angle pin; a disc with a boss is arranged in the middle part of the base, and an axial step through hole is formed in the middle part of the boss; the correcting assemblies are matched with the force bearing supporting columns, the number of the correcting assemblies is at least four, and the correcting assemblies are uniformly distributed and fixedly connected to the surface of the disc around the boss of the base; the pressure plate assemblies is also matched with the force bearing supporting columns, the number of the pressure plate assemblies is at least four, and the pressure plate assemblies are uniformly and fixedly connected to the step of the through hole of the boss of the base; and after the welded force bearing supporting columns are assembled on the shape correcting tool according to the design requirements, the heat treatment is carried out, and then cooling is carried out. The shape correcting tool has the advantages of being simple in structure, easy to manufacture and very good in correcting effect, and the deformation of the force bearing supporting columns can be reduced to 0.3mm or less from 3 mm before shape correcting, so that welding parts meet the design and use requirements, the rejection rate is reduced, production cost is reduced, meanwhile, the blank of the shape correcting tool of the force bearing supporting columns is filled.

Owner:AECC AERO SCI & TECH CO LTD

Crusher, mineral production line and material crushing method

ActiveCN106269133BOptimize particle size distributionImprove crushing efficiencyGrain treatmentsProduction lineMining engineering

The invention discloses a crusher, a mineral production line and a material crushing method. The crusher comprises a first crushing cavity (4) and a second crushing cavity (5); the first crushing cavity is internally provided with a first material accelerating device and a material impacting part (6), the second crushing cavity (5) is internally provided with a second material accelerating device and a material liner forming part (19) used for forming a material liner layer (7), and a diversion channel structure is arranged between the first crushing cavity (4) and the second crushing cavity (5), so that materials subjected to preliminary crushing in the first crushing cavity (4) can be guided into the second crushing cavity (5) to be crushed and shaped through the diversion channel structure in the working process of the crusher. According to the crusher, the mineral production line and the material crushing method, by means of a creative sequential impacting mode, the crushing mode that the materials and anvils are mixed to be crushed is actually achieved, the crushing efficiency is high, the crushed grain shapes are good, and the void fraction of the crushed materials is significantly increased compared with an existing crusher.

Owner:ZOOMLION HEAVY IND CO LTD

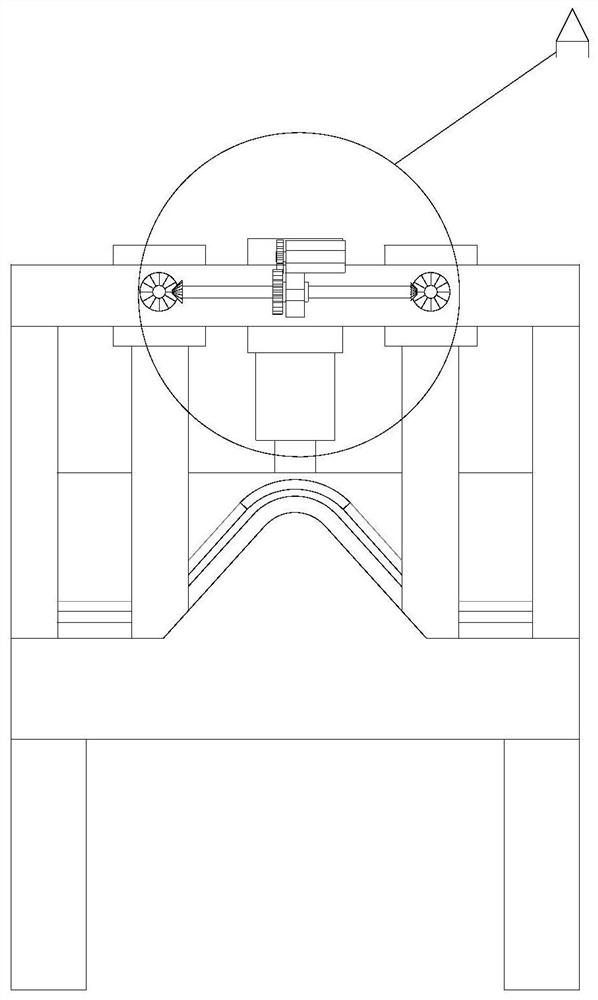

Shape correcting device for hardware stamping part

PendingCN112387812APrevent movementEasy to useMetal-working feeding devicesPositioning devicesHydraulic cylinderElectric machinery

The invention discloses a shape correcting device for a hardware stamping part. The shape correcting device for the hardware stamping part comprises a base, an arc-shaped block is horizontally and fixedly mounted at the upper end of the base, a stamping part is placed at the upper end of the arc-shaped block, and the stamping part and the arc-shaped block are arranged in a mutually matched mode; asupporting plate is arranged at the upper end of the base, a supporting frame is fixedly mounted at the lower end of the supporting plate, and the lower end of the supporting frame is fixedly connected with the upper end of the base; and a first sliding groove is formed in the upper end of the supporting plate, the first sliding groove penetrates through the supporting plate, two first I-shaped blocks are arranged in the first sliding groove in a clamped mode, the two first I-shaped blocks are symmetrically arranged, and the two first I-shaped blocks and the first sliding groove are arrangedin a sliding mode. According to the shape correcting device for the hardware stamping part, stamping parts with different lengths can be clamped, and the shape correcting device is convenient to use;and secondly, a second motor drives a second I-shaped block to move, so that a hydraulic cylinder at the lower end can move, a pressing block at the lower end of the hydraulic cylinder can move whilepressing the stamping part, and the shape correcting effect is better.

Owner:CHANGSHU SHUNLI ELECTRONIC EQUIP FACTORY

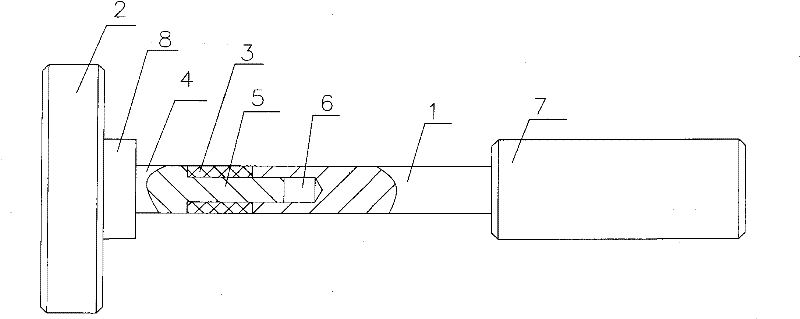

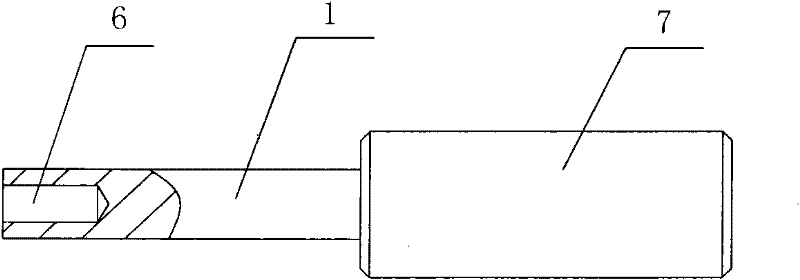

Insulating sleeve bulging tool

ActiveCN101950640BNot easy to moveImprove performanceInsulating bodiesWaveguide type devicesRadarEngineering

Owner:WUHAN FINGU ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com