Extrusion-molded alkali-activated steel slag-alkaline residue exterior wall decorative board

A technology of extrusion molding and decorative panels, applied in the field of decorative panels, can solve problems such as wall crack resistance, poor weather resistance and durability protection, glass curtain wall ceramic hanging panels, external wall bricks, self-heavy, safety hazards, and environmental protection hazards. , to achieve the effect of strong anti-carbonization ability, good plate shape effect and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

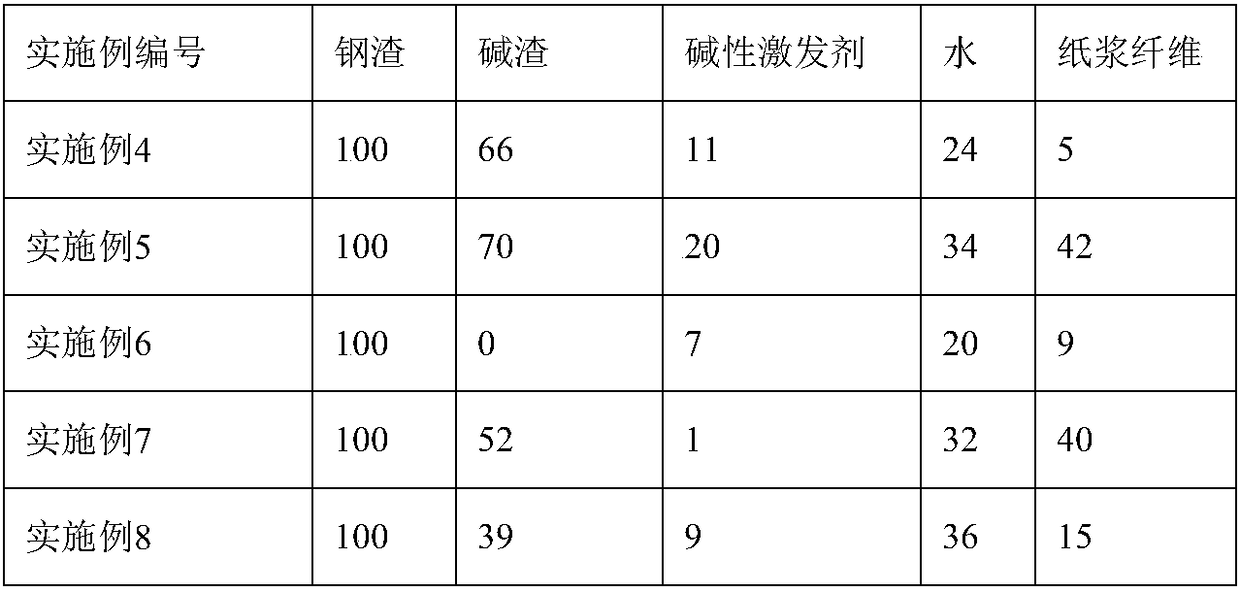

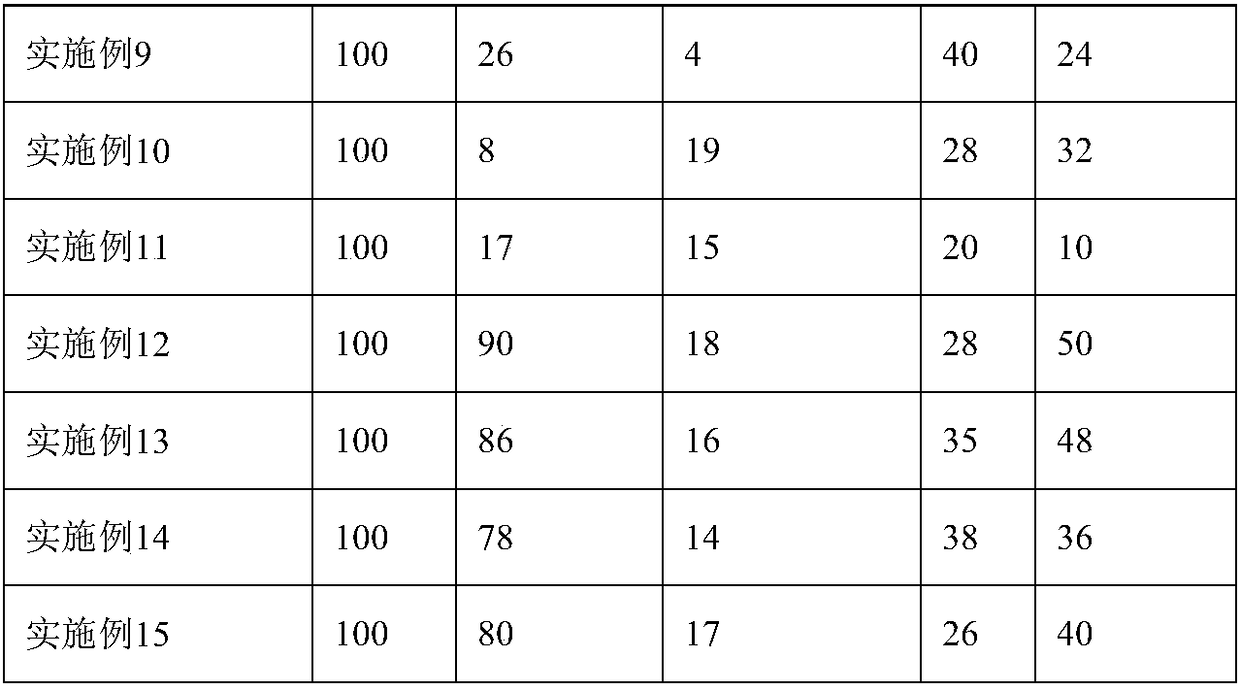

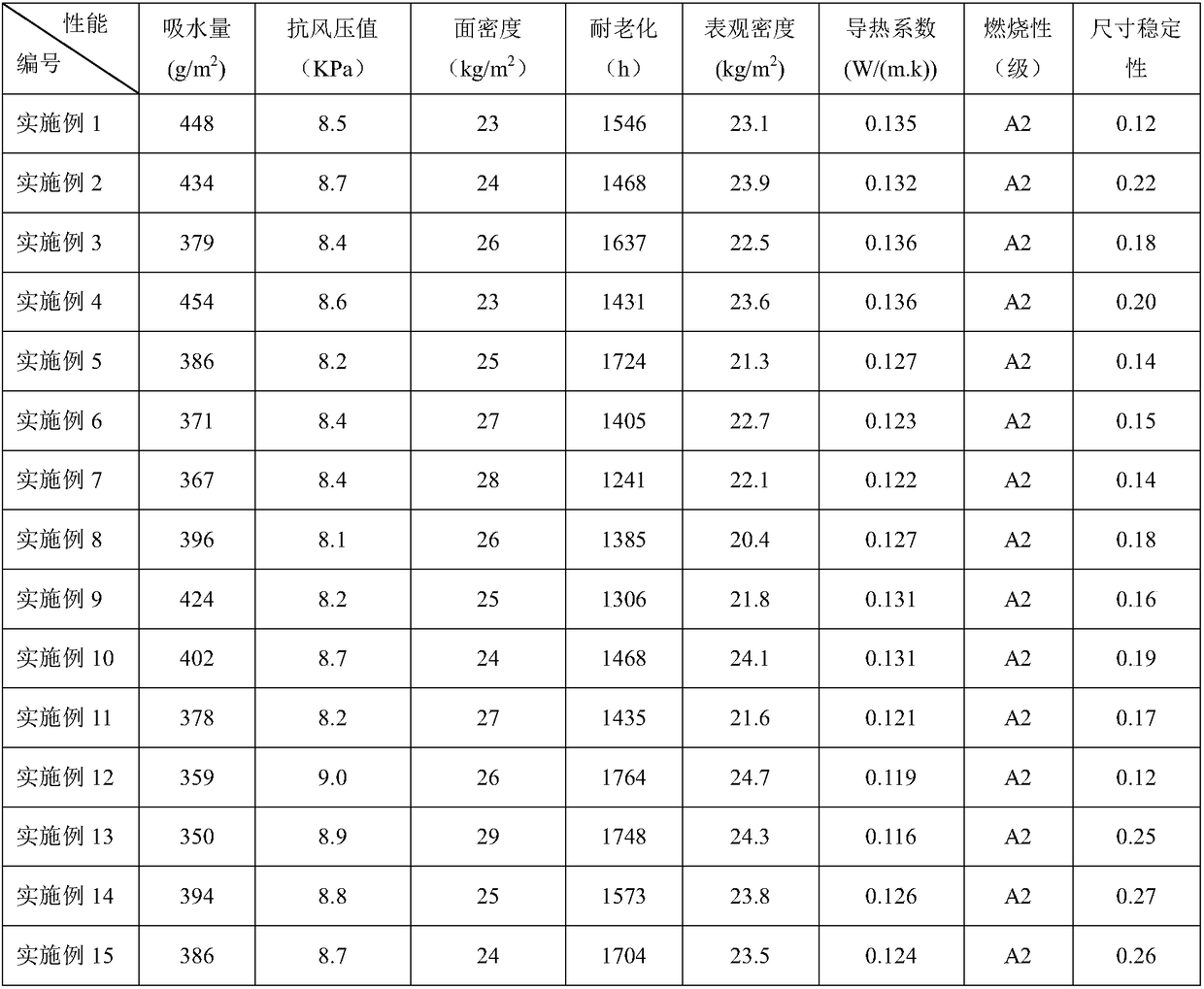

Examples

Embodiment 1

[0045] Preparation of extruded alkali-activated steel slag-alkali slag exterior wall decorative board

[0046] 1. Preparation of alkaline activator:

[0047] By weight, caustic soda: sodium water glass is 2:5.

[0048] 2. Preparation of decorative surface materials:

[0049] In parts by weight, 100 parts of steel slag, 30 parts of alkali slag, 21 parts of alkaline activator, 42 parts of water, 19 parts of pulp fiber, 5 parts of pigment and 1.1 part of polypropylene fiber.

[0050] 3. Preparation of middle material layer materials:

[0051] In parts by weight, 100 parts of steel slag, 40 parts of alkali slag, 15 parts of alkaline activator, 36 parts of water and 40 parts of pulp fiber.

[0052] The composition of steel slag in the above-mentioned components is: mass percent SiO 2 14.67%, TiO 20.84﹪, Al 2 o 3 4.06%, MgO 7.62, CaO 47.22%, Na 2 O 0.16﹪, K 2 O 0.075﹪, SO 3 0.57﹪, TFe14.30﹪, P 2 o 5 1.04%, loss on ignition 2.58%;

[0053] The composition of alkali sl...

Embodiment 2

[0063] Preparation of extruded alkali-activated steel slag-alkali slag exterior wall decorative board

[0064] 1. Preparation of alkaline activator:

[0065] By weight, caustic soda: lime is 5:3.

[0066] 2. Preparation of decorative surface materials:

[0067] In parts by weight, 100 parts of steel slag, 50 parts of alkali slag, 20 parts of alkaline activator, 40 parts of water, 18 parts of pulp fiber, 10 parts of pigment and 0.5 part of polypropylene fiber.

[0068] 3. Preparation of middle material layer materials:

[0069] In parts by weight, there are 100 parts of steel slag, 42 parts of alkali slag, 16 parts of alkaline activator, 35 parts of water and 43 parts of pulp fiber.

[0070] 4. Preparation of exterior wall decorative panels:

[0071] 1) Add the decorative surface layer material and the middle material layer material into the mixer in the order of solution, powder and pulp fiber and stir for 10 minutes;

[0072] 2) Spray the decorative surface material on t...

Embodiment 3

[0079] Preparation of extruded alkali-activated steel slag-alkali slag exterior wall decorative board

[0080] 1. Alkaline activator: caustic soda

[0081] 2. Preparation of decorative surface materials:

[0082] In parts by weight, 100 parts of steel slag, 20 parts of alkali slag, 28 parts of alkaline activator, 45 parts of water, 11 parts of pulp fiber, 8 parts of pigment and 0.8 part of polypropylene fiber.

[0083] 3. Preparation of middle material layer materials:

[0084] In parts by weight, there are 100 parts of steel slag, 10 parts of alkali slag, 13 parts of alkaline activator, 31 parts of water and 46 parts of pulp fiber.

[0085] 4. Preparation of exterior wall decorative panels:

[0086] 1) Add the decorative surface layer material and the middle material layer material into the mixer in the order of solution, powder and pulp fiber and stir for 10 minutes;

[0087] 2) Spray the decorative surface material on the template with special texture coated with releas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com