A kind of superfine modified fly ash production method

A production method and technology for fly ash, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., which can solve the problems of slow hydration rate and reduced early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the present embodiment carries out as follows:

[0014] During production, first weigh 5.0kg of power plant fly ash raw powder, then add it to a drum mill with a diameter of 500mm, then add 1.5g of liquid activator to the drum mill, and grind for one hour to obtain Superfine modified fly ash, containing triethanolamine, ethylene glycol, sodium silicate, sodium sulfite, glycerol, stearic acid, sodium hexametaphosphate in the described activator, triethanolamine, The mass ratio of ethylene glycol, sodium silicate, sodium sulfite, glycerin, stearic acid and sodium hexametaphosphate is 6:5:2:1:1:1:0.5.

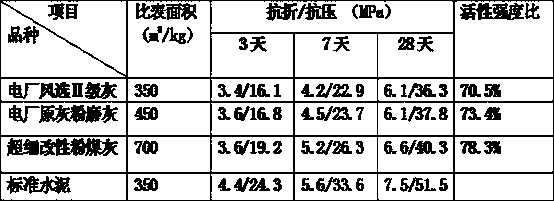

[0015] After testing, weigh 135g of ultra-fine modified fly ash, 315g of cement, 1350g of standard sand, and 225ml of water, put them into the mixing pot, and after the automatic mixing by the cement mortar mixer, add them to the triple trial grinding for molding, and maintain for 24 hours After demoulding, put it in water for curing for 3 days, 7 days, and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com