Iron sheet bucket body machining production line

A technology of iron barrels and production lines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and inconvenient operation, and achieve the effect of small deformation and good shape correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

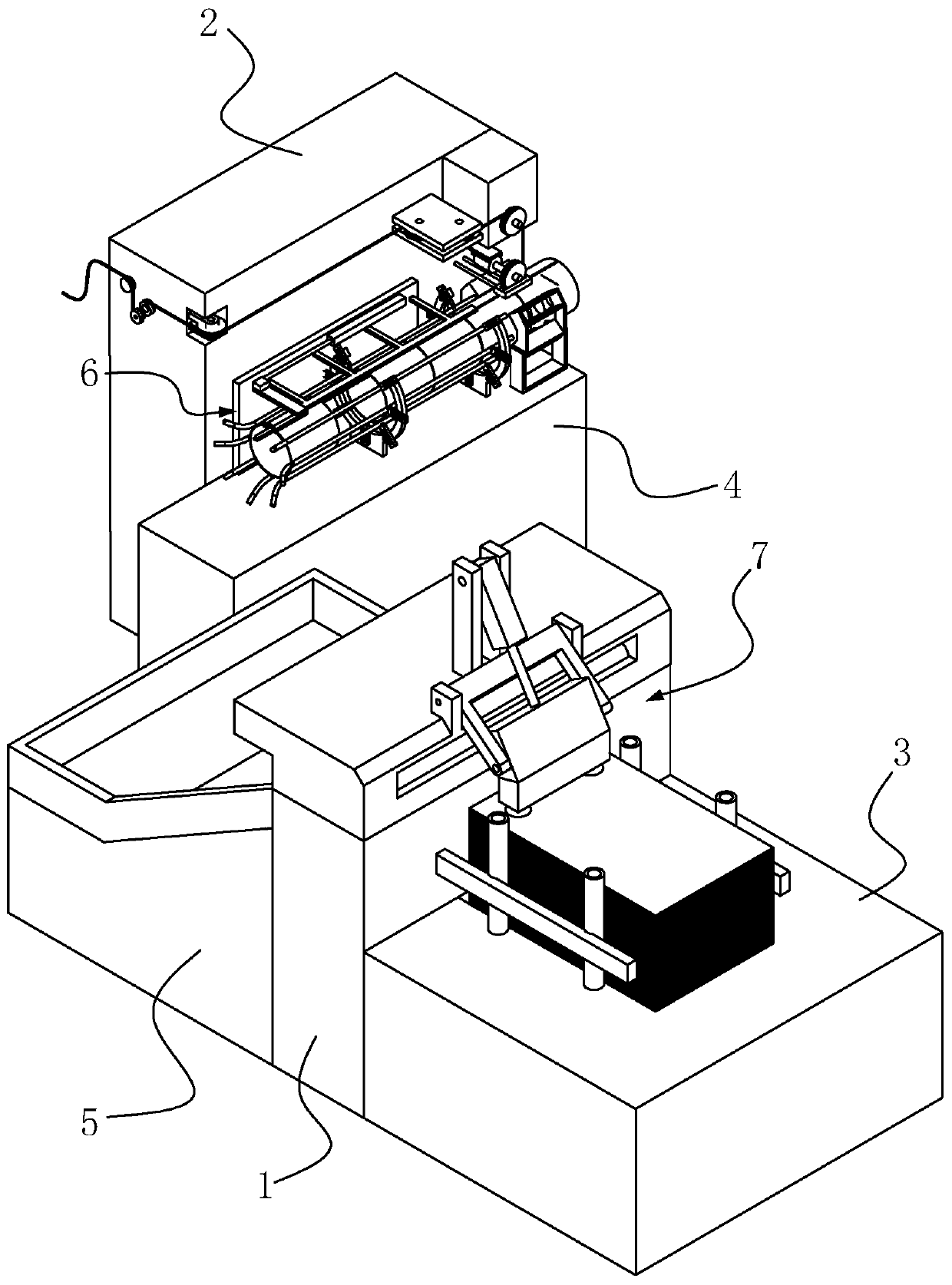

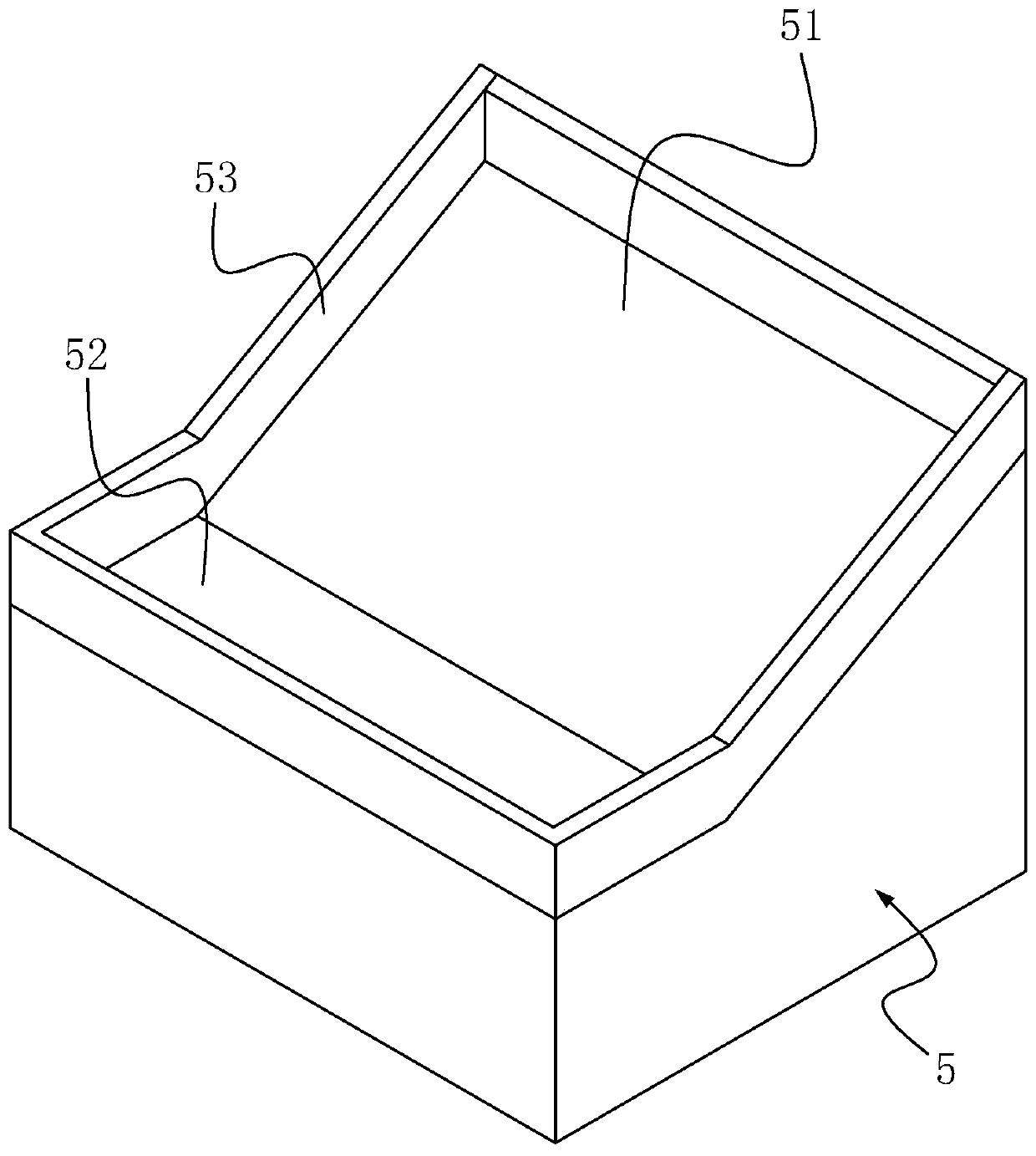

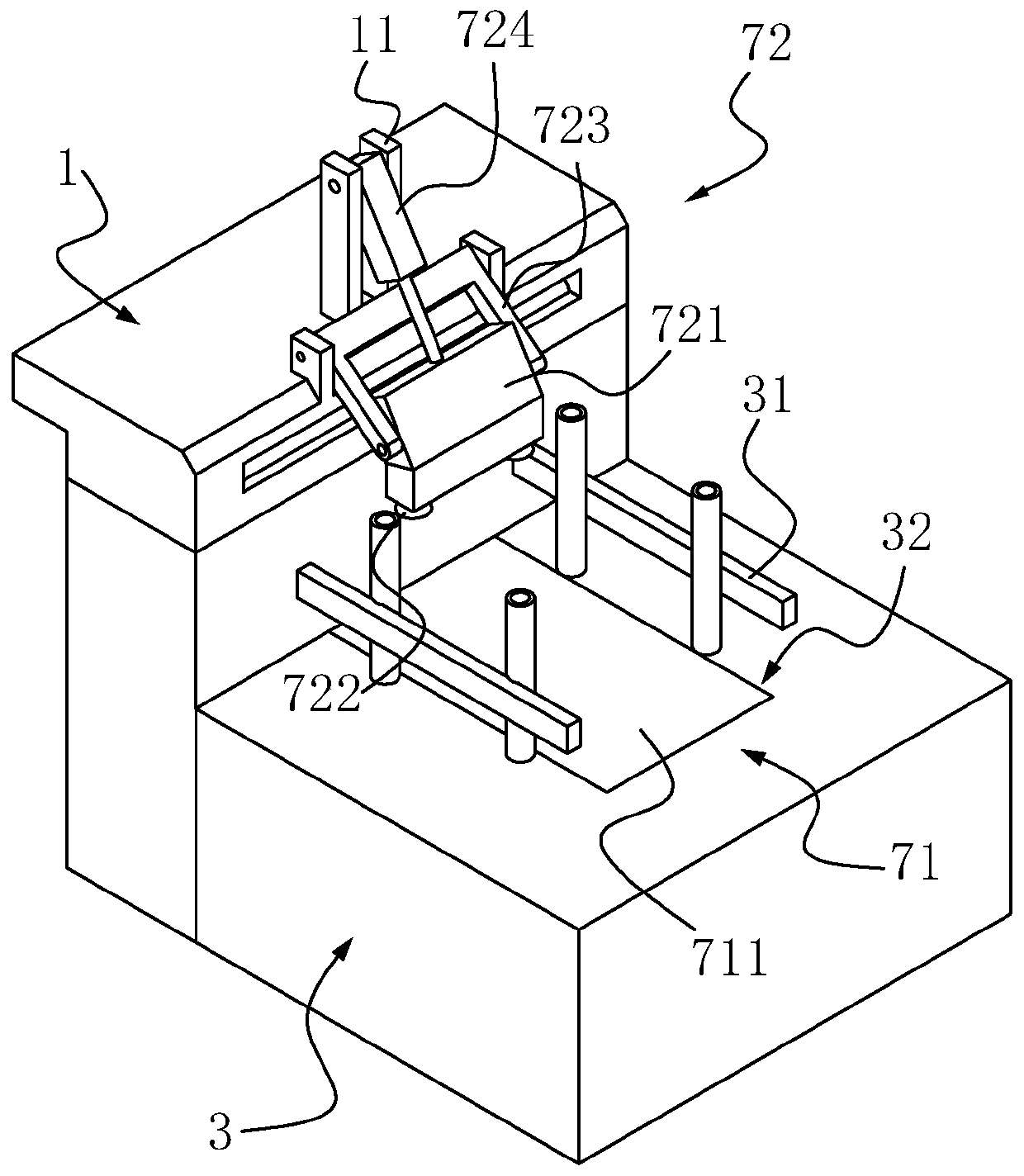

[0040] A kind of production line for processing the barrel body of iron barrels, referring to figure 1 with figure 2 , including plate rolling machine 1 and automatic submerged arc welding machine 2. The material transmission direction of the plate bending machine 1 is set perpendicular to the length direction of the welding platform 4 , and the feeding end of the welding platform 4 is located on the side of the discharging end of the plate rolling machine 1 . The feeding end of the plate rolling machine 1 is provided with a feeding platform 3 for placing thin iron plates for making barrels. The feeding platform 3 is provided with a feeding device 72 for grabbing the iron plate placed on the feeding platform 3 to the feeding end of the plate bending machine 1 . A transfer platform 5 is also arranged between the feeding platform 3 and the welding platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com